Leaderboard

Popular Content

Showing content with the highest reputation since 04/20/23 in all areas

-

Don't tell my wife Like I tell other people. some like to fish, some like to bowl, I like to make.5 points

-

He's saying although we are launching a DOHC head in 2024 we readily admit it will be pale in comparison the mighty KN20 from Datsunworks. At least that's what I'm hearing.4 points

-

4 points

-

**UPDATE Went to court yesterday and basically played dumb. Told the judge that "I went to the state ref and he told me since the car is so old that he couldn't do anything to certify it. So how do I go about taking car of this ticket. The vehicle is a pre smog vehicle so I've never had to SMOG it" The judge said "Ok so what Im going to do here is dismiss the case cuz it seems like your car doesn't qualify for an inspection. Sorry about the inconvenience Mr. Soto" I tried to play it cool but I was so happy. After reading all the horror stories from other people about having to revert to stock and all that I was lucky I guess Hope this thread helps someone going through something similar4 points

-

Greetings Everyone, Due to the increase in spammers HybridZ, registration has changed from being automatic to manual. That means one of the Admins will need to approve any new registrants. If you ask or tell someone about HybridZ (please do) let them know registration isn't automatic anymore. We'll do our best to stay on top of any additions and hopefully you all will see a lot less spam. Thanks, The HybridZ moderation team4 points

-

Unfortunately, it is too late. Maybe for round 6 in a couple of years Got the shirts in and will start breaking things down and shipping things out next week. This week is busy with work travel, so appreciate your patience while I get a few out each day on my lunch breaks.3 points

-

They received all of the shirts without backorders and are starting on printing this afternoon!3 points

-

I really wish things would swing back towards the forums. I can't tell you how many times I know the answer to or could add to a post on FB but I don't since it really has no longevity. I always felt like I was adding to the overall knowledge base when I posted here. I can go on and on but I really hate it.3 points

-

First start up since starting the restoration. Kind of shocked she started right up on the first go. Was expecting something on the MegaJolt to need fixing, but it worked great. Went with Magnacor wires, but they made a mistake and did not fit them up with the right coil boots. Being remade and shipped, so I am using 05’ ford explorer NGK wires for now. Went with a “7” heat NGK plug on account of the 10:1 CR. It’s raining this weekend, but just need to dial-in some crude alignment and she will be road worthy IMG_2339.mov3 points

-

Just wanted to say again a HUGE "Thank You" to @cockerstar for doing this (a FIFTH time)!!!! Really appreciate all his time and effort to make this happen. You da' man, Ryan!!! 👍👍3 points

-

3 points

-

It's not the votage drop that matters it's what the voltage drop indicates. No spark will be created if the current through the coil is not stopped. You could also disconnect the coil negative at the coil and check the wire for continuity to ground, key off. Disconnect the wire, put one meter probe on the end and the other probe on a good bare piece of metal or the engine block. You should get OL or infinite/huge ohms on your meter.2 points

-

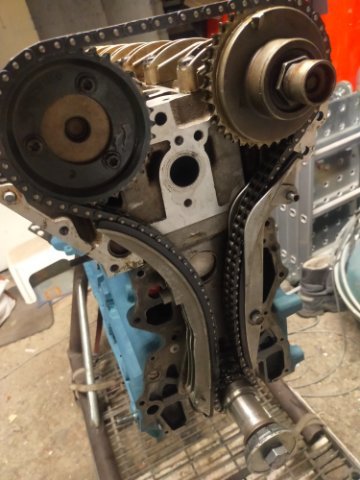

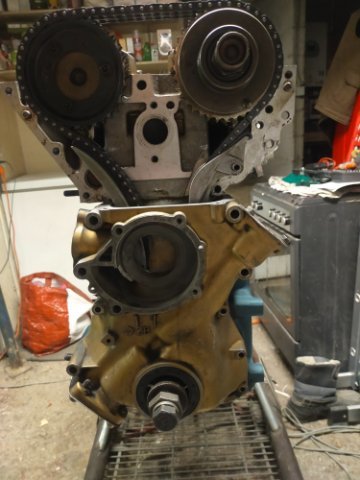

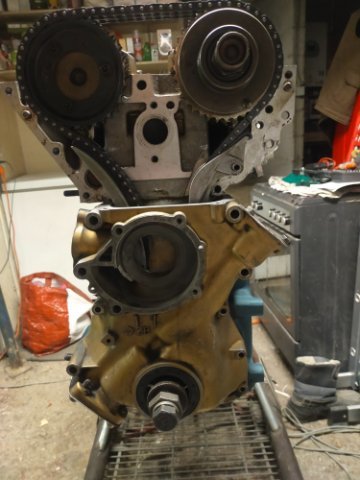

well yes , stock guides , just to make lower axes in the block, and the stock cover is modified to make some space, electric water pump ( davis Craig ) , and tensioner on the right side, in place of the water inlet ( spring and lock without oil pressure ) no need for oil pump drive or distributor for i put dry sump pump system and megasquirt ignition and injection EFI with yamaha bike itb's So simple and cheap , just a little of brain storming ! oh ! and a little joke for the head cover !! Lol !2 points

-

There is no swap hardware to put the Z transmission behind a V8. It wouldn't handle the torque anyway. The 260Z engine is about 158 cubic inches, compared to 350 for a SBC. The old Z transmission bearings are typically ready to fall apart besides that, not uncommon even with the stock engines. It would probably last about one pull. I haven't done it myself, but I wouldn't even try it just based on what I've learned.2 points

-

You have packed a lot into your intro. There's some good advice below to consider in the posts to your question. But I have to ask you what is it about the 280 you love? I don't mean that coyly or as some flippant remark. What is it you really like? I'll give you why I like the Zs. I grew up around them when they were new, my uncle was a general manager of a Datsun dealership so we got to try out the new cars. We raced with my uncle at autocross and hillclimbs (I was a kid so I just went along). Back then the Z cars were fast and sounded awesome (I have the hearing loss to prove it), and were amazing at cutting through the corners both stock and modified. Our local racing club had about 10 people driving stock to all-out racing versions. 50 years pass and a lot of that coolness has mostly worn off except for the look of a lowered S30 with an airdam and rear spoiler. I have to admit the sound of a modified Z makes me happy when I hear it. But this site exists to help people get the most out of them. And the reality of that is as cool as the L28 engine is you're looking at spending a lot of money and you'll have an engine that makes 200 to 250 HP. Sure you can get more but then all the other parts that connect to that engine are starting to get pushed past their limits given the age. While I don't disagree with any of the posts below you should still read about a lot of the mods and why they were done. You'll find that in many cases they were driven by it costing too much, parts NLA, etcetera. A bit of advice from me. Never by an engine, transmission, or rear end unless you plan to use it within a few months. Even if you plan to use it that's not the same as ready to bolt in. If you want a street car with a certain coolness and triple Weber carbs, then build it. But when you spend 10K on an engine and find it's somewhat finicky to drive but cool all the same. But for less, you could have 350 HP V6 in the DI Chevy LV3. It won't sound the same as the L-motor but it's lighter, a lot newer, and will get excellent mileage, It will start anywhere if it's hot or cold by the sea or at altitude. This site has a ton of info on how to do the same for the suspension and how to get a cheaper rear diff, especially if you want an LSD. I could write a lot more but this is probably too long as it is. Welcome to Z ownership. Cary2 points

-

Yes, with the carbs you can get rid of the ECU and EFI parts. The complete EFI harness can be removed. The guys that know on the site (from the past) say that the exhaust system is restrictive and opening it up helps a lot (see John C posts from the past) , and that if you decide to use a performance cam go big (see JMortensen posts from the past). The typical "Stage" 1 or 2 cams don't add much, apparently. So, the simple and effective way to add some power is with a better exhaust system and a big cam. Cams are more expensive than they seem because you need to buy lash pads and rocker arms along with the cam. The collection of parts costs can add up. But it's a pretty simple operation to get it done. Many people like the lighter flywheel. It takes more finesse on the clutch pedal but they say it's worth it. Fidanza is a good choice. For street driving an LSD doesn't add much. You might wait on it and see if you have traction problems. There is a ton on the site from the old-timers, around the 2000 to 2015 time range. Things have slowed a lot on the site as people have moved on. But their contributions are still here. Many of the guys were racers and/or engineers/mechanics/machinists and spent a lot of time and money on their projects. Today's car hobbyists really only know turbos and EFI since that's what they were raised on. Good luck.2 points

-

2 points

-

Even if 100 people commited to purchase, its still tiny small numbers vs an OEM production. Its got to be done out of passion and at least not to lose money. This is why this is such a huge acomplisment for someone like Derek, We are fortunate the passion runs deep. I cant imagine the hours of "un-billed" time2 points

-

Life has been kicking my ass lately! Between my job changing significantly, being super sick, and some significant medical issues with my daughter I haven’t made the progress on shipping orders that I have wanted to. Post here if you’re really itching to get yours and I’ll move it to the top of my list. Otherwise I’m moving along as ordered. I’d like to get these wrapped up so I can transfer the remaining funds over to Dan.2 points

-

We’re going on track this Sunday at Willow springs Will set-up the car tomorrow at a friends shop since they have a flat-level garage floor (which I do not). Also in the middle of adapting the front brakes to 280zx rotor and caliper per EP spec-line. Caliper mounting on the strut assembly will require some welding and drilling, so it will have to wait till after this weekend. Greg Ira was nice enough to ship me some race pads he has that fit the OEM calipers.2 points

-

2 points

-

Hi everyone! I have the shirts and should be able to start getting some out today. I was primarily working from home at least 80% of the time, but my job just got pushed to 60-80% travel so I haven't had breaks at home like I used to.2 points

-

Well, after more testing, it seems to be a user error. Was able to drive for a good hour today without and bucking/shudders. I think it's a combination of a new clutch and upgraded transmission/rear end that I have to get used to. The car seems to like higher rpms when starting from a stop, and a different clutch engagement that what it was before. Car is much more fun with the new parts. Not a fast car, but a fun one.2 points

-

No, you just pull the bearings off of the front of their shafts. The countershaft bearing is pretty tight to the gear and takes some trickery. The mainshaft bearing needs a puller with long arms. You can push the rods back to get more room. The transmission will have multiple gears engaged but it won't matter. When you reinstall the front case put it in a single gear (one rod moved) to avoid locking up the transmission by accident. Here's a decent video about the countershaft bearing, different tranmsision but same concepts. He did the same thing I did, clamping a two jaw puller in to the gap, otherwise the jaws pop off. The mainshaft is a more normal operation but the length of the shaft has to be managed. It takes some work. If you have friends that have pulled bearings or gears it might be worhtwhile to get some more ideas and tools on-hand. Notice the odd combination. Go to 4:00 if it doesn't start there.2 points

-

4th gear doesn't use the countershaft, it's direct drive. That's a good clue. Sounds more like the countershaft bearing. Looks like you'll need to split the cases, so you might as well do the mainshaft/input shaft bearing also. It's not a super-finesse job. Just needs some ingenuity. It's fun. Part of Z ownership. Here's a good illustration of the parts you'll be looking at. I'm sure that there are "how-to" videos out there somewhere. You can get a factory service manual on the internet that shows how to take it apart. Good luck. https://www.zhome.com/ZCMnL/tech/240SX5spd/Transmission2.htm2 points

-

"Grinding" is not very specific. Can you add details? Have you driven it? Is it the same in every gear? 71B's are known for destroying the adapter plate bearings. Did you find any metal on the drain plug magnet? If you've been driving it you might drain the fluid and see how it looks. Might also be worthwhile to lift the car and get underneath with the engine running to see if you can locate the noise. Replacing the main and countershaft bearings is not very difficult. You only have to split the cases and pull the bearings off of the ends of the shafts. The adapter plate bearings are more difficult.2 points

-

Order is with the screen printer and will keep you guys posted when I get an ETA on delivery.2 points

-

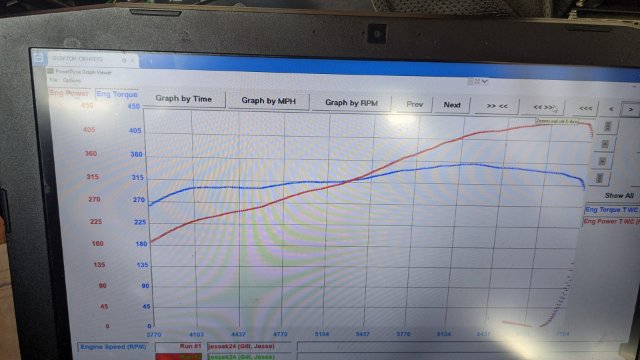

Finally got this thing tuned right, kept fighting an issue where the car would break up on quick throttle changes and in boost. Engine had NGK b6es-11 plugs, I went to a NGK bpr7es and all my problems disappeared. Engine is leaking oil pretty bad though from what looks like where the timing cover and cylinder head meet, l am genuinely amazed at how much oil can come out of there. The stock head gasket was torn there, and I RTVed it up a lot after the fact. Maybe my PCV valve is faulty and pressurizing that area under boost? Once I get this oil leak handled Ill take it to the dyno.2 points

-

2 points

-

@calZ, I spoke with John yesterday and I'm going to do another round. 36 item minimum from my print shop, but I think we can hit that!2 points

-

I am still around, I don't check regularly. I still have my Z. I joined here when I was 15, I am about to turn 38.2 points

-

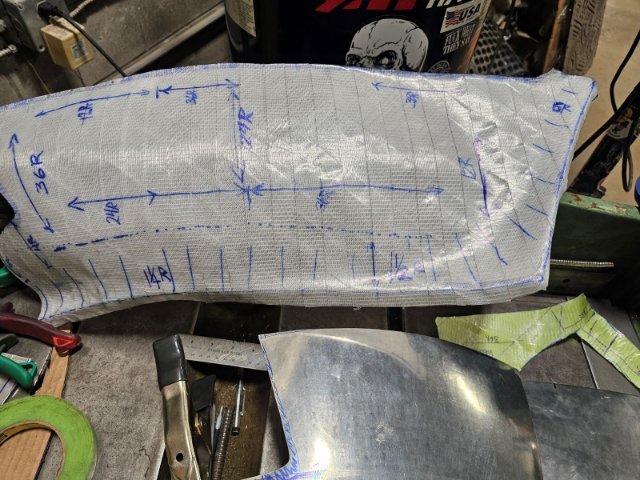

I dont want any filler, so I fit each part perfectly with a butt joint, dolly it out where possible, then grind it flat and smooth for an original fit. before any welding I prime all parts on the back side and pinch points with weld-thru primer the arc and inner rocker are new in this picture then the rear of the rocker, putting back the spot welds in the OEM position Some more primer to look super clean and blend in tot he original rocker which was perfect everywhere else Finally fit the outer skin and tig it in small steps so no warping Some more smoothing of the welds and original spotweld locations used Just a small skim coat of filler on the upper weld seem, but making sure to leave all the factory spot welds to show through the paint. Other side is the same, so on to the front fender next1 point

-

my hood mold is made for racing only, no inner reinforcement and no stock mounting hinge supports, design for hood pins mount only.1 point

-

1 point

-

You’ll lose nothing in my opinion, Fuel injection has a tunable acceleration feature just like a pump on the Webbers. I ditched mine for fuel injection and it was way better everywhere and no hundreds of dollars to make a jetting change, just a few click on the keyboard to make changes and tune it. I would never go back.1 point

-

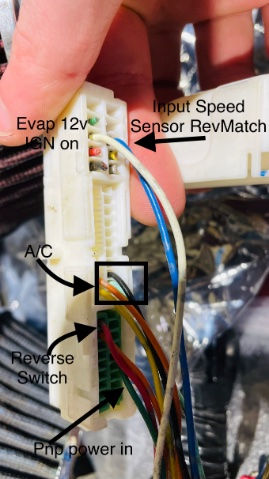

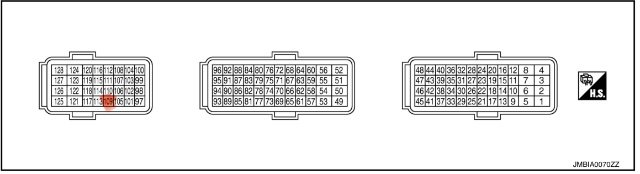

@Gumiho3 If you are referencing this picture then yes that is a green wire that supplies power for the PNP. In my case Hexa Garage never hooked up the wire running from my PNP to the ECU so I was powering that green wire at the plug but it never told to ECU to trigger a start signal and I had to borrow a snap-on diagnostic tool with Nissan protocols to see that, so you may want to bypass your PNP switch entirely and just run a signal directly to that pin on the ECU plug. I’ll check my FSM quickly and get that pinout for you. It is pin #109 (marked it on the image). Remember this pin out is from the harness side so it is as if you are looking through the connector when the wire side is facing you.1 point

-

Those are the new emulsion tubes he created. He also made new idle jets for weak vacuum(normal with a hotter cam) my 2.75L engine produces 275bhp with 45dcoes and 37mm venturies and runs close to a injected engine except the difference in hot/cold and high/low altitude. You can subscribe, give him your engine and dcoe specs, tell him your problem and he will help with a lot of patience and knowledge until it works.1 point

-

1 point

-

Or go a complete new way of tuning with Keith Frank at https://vintagetechnologygarage.groups.io/g/sidedraft/topic/100219752#4322 He has a big knowledge of the DCOE carbs and helps to the end of tuning. I went his route and find them way better and easier to tune compared to the original weber. He has his new kind of jets at this store. https://www.webstore.com/user,pgr,82598,ac,82598,owner_id,other_items1 point

-

A friend built an endurance car (Chumpcar/Lucky Dog) and was going to use a new Nissan gasket. I talked him into gluing the windshield and was amazed at the results. The difference between this and a normal gasket was the same having a strut bar or not. This car has been used hard, ridden some large curbs, and never cracked a windshield. I'm not saying it can't happen on the street but I'll be gluing in my street car's windshield when we get to that point. Cary1 point

-

1 point

-

Just a photo dump update. Car is on the road. Just need a few loose ends and I’ll be off to a test & tune track day. - added too much rear track in my rear. Too much for the Datsun restomod STI CV shafts. Had a spacer made by send-cut-send w/ a centering pilot. Works great so far. Will eventually get longer length CV inner shaft made. - fuel cell bladder was giving off way too much fumes to be normal. Replaced the bladder…. Gosh they are expensive! - got a set of used Longacre scales for a great deal! - rigged up a way for the valve cover breather and block breather to dump into a single catch can. Can is ventilated back through the air cleaner of my forward SU. Floats are also vented to the air cleaner. - polycarb windshield is on. Works great, and almost looks like glass. I need some tips on keeping it scratch-free. - new fire bottle on the way (mine expired years ago). SFI cert 5-pt harness is in. Still need some time to adapt Greg Ira’s race seat into the car, but for now the cheap used corbeau seats are working. - IMG_2376.mov1 point

-

Thanks, man! I appreciate the suggestion. I've subscribed.1 point

-

Greeting all. Great news, after a year and a half of design and testing I have finally finished my latest project. I now have for sale replacement distributor magnets for all matchbox Datsun distributors. This is the magnet that most people find broken when they do a distributor repair. The original magnets become brittle and stick to the stator and usually break in multiple pieces when you pull the stator off. The magnet has become NLA (no longer available) from Nissan. I purchased about 30 of them a couple of years ago and sold them and tried to order more and they were all gone. I thought that finding the material to make a reproduction magnet would be pretty EZ.....not! The issue is that most flexible magnet material is not magnetized correctly and has very poor magnetism retention and the material is not suitable for hi temperatures. The material will loose its magnetism and the material will degrade when exposed to temperatures over 150°. After contacting all of the big magnet experts I was running out of hope and that is when Captain Obvious from over at Classic Z Car contacted me and we talked about what I was attempting to accomplish and he suggested a place I had not contacted. After contacting this company, I was able to purchase a material that is the same thickness and has a temperature rating of 250° and has the correct polarity needed to generate the induced voltage to trigger the ICM. The sample that was sent to me was cut out and tested in all 3 of my Z cars and I then sent it to Captain Obvious, from Classic Z Car, for some in depth bench testing for signal strength and quality. The results of the bench testing were great. This replacement material actually generates a higher signal strength at both idle and hi RPM ranges. Peak voltage at idle for an OEM magnet was 1.28v. Peak voltage with my reproduction is 1.68v, that is a 31% increase in induced voltage signal strength going to the ICM to trigger the coil. Peak voltages at 2500 rpm for an OEM magnet was 2.96v. Peak voltage with my reproduction magnet is 4.00v. That is a 35% increase in signal strength. With the higher signal strength, extremely hi temperature rating and an exact copy of the design my reproduction magnet is a great option when rebuilding your distributor. Couple this with my improved breaker plate bearing retainer and you will have many years of reliability from your distributor. Here is a couple of pictures of an NOS Nissan magnet next to my reproduction magnet. I challenge you to tell me which is which. I had to mark them to tell the difference. The parts I sell are in Mandan North Dakota. I can be contacted either thru a private message or you can email me at chaug@bis.midco.net or text me at seven zero one -471- fifteen thirtyfour. I sell the magnet for 35.00 and the breaker plate bearing retainer kit for 30.00. If you want both I can cut you a deal for $60.00. Shipping to the lower 48 USA is included in the prices. I do ship international. I have sent Breaker Plate Repair Kits to Europe, New Zealand and Australia. Shipping for international has been in the $18.00 - 20.00 range1 point

-

@NewZed if one were to avoid using a surge tank in the engine bay, I agree. You would have to solve your slosh/starvation issues at the tank. Even a momentary vapor bubble pulled into your fuel line will cause a problem with EFI, if the ~40psi doesn’t cause it to collapse. SU’s, you would be OK to a point, since the fuel dumps into an atmospheric reservoir anyways (float chamber). I am a big fan of the quart surge tank though. S30 has a ton of space up front to choose from, but it would be a struggle to fit Z31+. That’s a heck of a lot of fuel to run-through, and the shape means you will use it all before you pull Vapor into your EFI pump. To be specific, this is my experience with the L28et street Z I have (@16psi). Have not raced yet… I’m just an Engineer that comes-off as a know-it-all, and humbly accept criticism as a result. I don’t mean to be condescending, but I recognize i can be. John and Ben are real racers though cars almost running! Should be hitting the track by Feb (thanks to my California mortgage payment). good luck to the OP! PS: same problem to consider with oil starvation, but it would take significantly more lateral G’s than what it takes to suck Vapor in your tank when <1/3 tank.1 point

-

+1 on the stock halfshafts as John mentioned. These things are shockingly resilient. Greg IRA won two national road racing championships with 100% OEM half-shafts. I still don’t quite understand how these U-joints last so long without being serviceable or an obvious means to keep them lubed. in theory, CV’s will gain you back ~2% drivetrain parasitic loss thanks to the “constant velocity” component (why else are they called CV’s), but I’m not aware of anyone who has done a side-by-side dyno test specifically in a Z. Too bad about Fritz getting out of the game. I don’t blame him. It is really, really hard to turn a profit with these low-volume manufactured parts. There really isn’t an inexpensive way to make them in low volume and still have decent quality. T3 and Apex are all the rage thanks to good marketing, but their parts are fairly inexpensive to make. I can find many of their components on McMaster-carr, and the rest is just fabrication, CNC, water jet, etc. not knocking them, just pointing out why it’s so hard to make reasonably priced rotating equipment.1 point

-

Almost ready for the drive back to Utah tomorrow. Car has been running quite well since swapping the ignition coil. I'm currently in "square" GM truck coils, and next year plan on fully swapping all of them out for reliability so I'm not having the issues I had this summer. Christmas visit I think will finally be time to run the AC lines. Over 1000 miles on it just since Thursday, and probably another 1000 between short rides here and the drive back to Utah before I head off to Mexico again. Got to do some nice rides out here on the islands as well as up to Vancouver. Despite the repeated frustrations, and various rattles and small noises I'm not expecting becoming extra obvious with so many miles in it, it really is a joy to drive and I'm happy with how insanely different this thing is from even a few years ago. I was telling my brother in law that it's weird looking back at old folders of pictures I had of other cars for motivation because my car is better than most of them in most ways now haha1 point

-

1 point

-

I don't know if will help but check out post #36 https://ls1tech.com/forums/conversions-hybrids/1345592-78-datsun-280z-5-3-build-2.html1 point

-

Thanks Davy. I had it out yesterday for the first time in a long time. The dang thing has turned into a garge queen. For a fairly stock '91 305 tpi with a WCT5 on 3.54 rear gears turning a pair of 305/50/15's it still gets rubber in the first three gears. Bags of fun! The last two years, '91 & '92, for the 305 in the f-body cars were the most powerful. Nearly as strong as the 350 of that day. And it's such a cool looking motor. Good fun on a budget.1 point

.jpg.31c23f188b91cbfddb2de872e10f840a.jpg)