240Z Turbo

Members-

Posts

1081 -

Joined

-

Last visited

-

Days Won

1

240Z Turbo last won the day on February 3 2022

240Z Turbo had the most liked content!

Contact Methods

-

Website URL

http://www.eng.fsu.edu/~jthagard

-

Yahoo

turbo240z@yahoo.com

Profile Information

-

Gender

Not Telling

-

Location

Charlotte, North Carolina

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

240Z Turbo's Achievements

-

I don't post much build stuff on FacePlant and tend to stick to the forums because it is easier for people to find the information. It's good that you are documenting your build and hopefully it will inspire others.

-

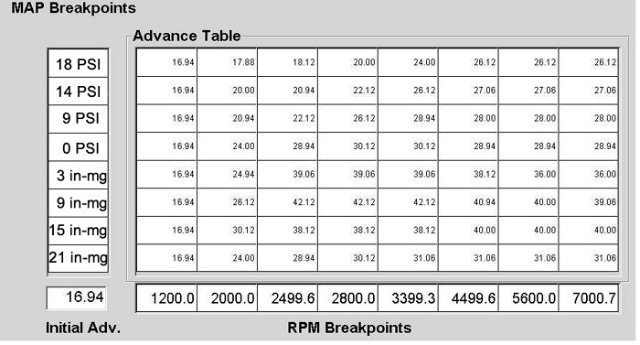

From memory I could run about 18-19psi on 93pump and on race gas (110L) I would simply add the 125shot on top of that or I would not run the nitrous and up the boost to ~28psi (from memory). Felt about the same powerwise either way on race gas, but the nitrous made the boost hit instantaneous. Because I was running a Powerglide trans I pretty much had to hit the nitrous off the line to get it going, but with lower boost (maybe 12psi). After the shift I would hit the boost controller button and go to high boost. I located what appear to by my pump gas tune from right before the car was sold and I had TimZ open the files yesterday with his software. However, the timing values seem abnormally high so I don't want to reference them. I asked TimZ if he could provide some general timing advice to this thread since he probably has the highest HP L6 in the USA. I've just been out of the L stuff for so long I simply don't remember.

-

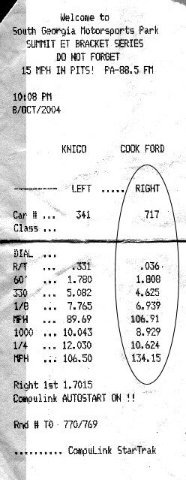

This was from 2001, but should give you a feel for what the motor would take on 93 pump and I think I was making peak torque at ~4200rpm. Didn't know as much back then so probably could have jacked in more timing at Redline, but I'll see if I can find my last tune file. Important though is that I used the knock sensor religiously to tune.

-

I just downloaded the old Wintec2 software so I need to locate my old tune files to see what type of timing I used to run on my 3.1L twinturbo w/125 shot nitrous. However, I'm thinking it was around 18-20deg peak torque. 30-32 deg seems like a lot of timing for 93 pump even at redline so be careful. The two tools you need are a wideband, which I believe you have, and a good knock setup that allows you to discern between real knock and engine noise. I can't stress enough the importance of a good knock sensor setup because your motor will live and die by engine knock on a turbo motor. You've probably seen my old setup from 20 years ago, but it ran 10.6@134 and to my knowledge that motor is still alive and running to this day.

-

On a turbo car you want to add timing as you approach redline as opposed to pull timing as you approach redline. I looked at the 123 Ignition and it appears you have two 2D tables, RPM vs TIMING & MAP vs TIMING, which is less ideal vs a single 3D map where TIMING is a function of both RPM and MAP. When you hit the throttle the MAP goes to atmospheric pressure, where you can typically set a static advance number as the car starts to build boost, which on the GTR is about 14deg. The lower that advance (retarding timing) the more exhaust energy will be created and the faster the turbo spool. The downside is that if you live in a hilly area then you are more often under slight load and the high EGT's will put your header through the test. As the motor builds boost you will then start to retard timing and at peak torque is where you will have the highest cylinder pressures so the lowest amount of timing is used. After you pass peak torque the cylinder pressures are reduced and you can then start to add back timing. As a rule of thumb you can typically add at least 5deg of timing from peak torque (where it starts to drop) until redline on 93 pump. Here is what the ignition timing curve looks like on the GTR for 93 pump 749hp@wheels. Disregard the actual numbers because that is a function of the engine and just look at how timing is managed. 7deg at peak torque ramped to 18deg at redline. You'll notice that it sits around 8deg until 5400RPM because the torque curve remains flat. Below is the same thing, but for the EVO IX on 93pump 663hp@wheels. Again, don't focus on the actual numbers, but how the timing is handled. Timing is 2deg at peak torque ramped up to 11deg at redline.

-

I'd recommend 10G from relay to pump if pulling more than 20amps and/or run is over 10ft, but 12G would be fine if you know you're not pulling more than 20amps and/or the run is less than 10ft. On the GTR I ran ~10ft of 4g from battery to the fuse block (through a 50amp breaker) and then 12G Tefzel from fuse block to two 330lph fuel pumps. I get my Tefzel wire from here, but for the low gauge wire I like sourcing from the local welding supply. https://www.corsa-technic.com/

-

The factory fuel pump wire can be used to trigger the relay, but wasn't sure if you are actually driving the pump from that wire and that caused the fire. Also, how are you retarding timing under boost?

-

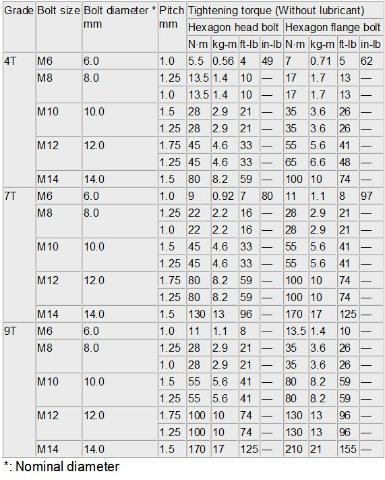

I've never experienced the issues you stated and other than my GTR, I simply tighten by feel and don't use torque specs on the downpipe or turbo inlet. BTW, the M8x1.25 can torque to 26ft-lbs per the table assuming the highest grade of "9T." I have 160K+ miles on the EVO and more than 100K of those miles was an aftermarket turbo and never had hardware failure just using out of the bin bolts from Lowes. I've also used the inconel shields on various projects (TT ZR1 & EVO) over the years and again, didn't have hardware issues. I hope you problem is solved!

-

My sincerest apologies as it looks like I gave you inaccurate information. I pulled one of my old downpipe studs from a box to measure the turbine side threads and they were M10x1.5 so I struggled to understand how I thought the studs were M8. Turns out the tap I used to measure the nut side threads was an M8x1.25 tap, but I didn't see that is was one of my heli-coil taps. To make it worse, I was reading the Nm column instead of ft-lbs for the torque spec, but luckily that was the correct spec in ft-lbs for M8 assuming you have the highest grade stud. The correct information is as follows for M10 GTR down pipe studs Turbine side is M10x1.5 torqued to 19ft-lbs Nut side is M10x1.25 torqued to 36ft-lbs Attached is Nissan's torque table for various size bolts depending on Grade.

-

That gasket looks good so you should be fine assuming the down pipe flange is flat. You can always run it on a belt sander and you will quickly discover if the surface has high spots. Now that you have the inconel hardware just get some good prevailing torque nuts and tighten to 25.5 ft-lbs and you're golden. If your threads on the nut side are M8x1.25 then the prevailing torque nuts from Nissan for the GTR downpipes are an option. If you're going to do a manifold from scratch then I would highly recommend that you go twinscroll as opposed to open scroll and vband. Also, I never have issues with the 4 bolt flange leaking on any of the iterations of turbo's I've run on the EVO. TwinScroll will give you significantly better spool and allow you to run a larger turbine, which reduces drive pressure. The lower driver pressure makes the car way less knock prone on 93 pump allowing you to run more timing or more boost or both. You'll want to keep the runners small using 1.25" schedule 10 pipe, which is good for applications up to about ~1100hp. The smaller runners will keep the port velocity higher and allow for quicker response and will not affect hp vs a 1.5" schedule 10 pipe. I'm a big fan of the S362 SXE (6268) and based on my testing in comparison to the Gen1 GTX3582r (6262), I lost no spool and picked up 50hp@wheels (~600whp vs ~550whp) on 93 pump.

-

FYI, VR38 downpipe studs are M8x1.25 on nut side and torque spec is 25.5ft-lbs so don't over think it. If you're having issues sealing then it is likely due to the mating surfaces not being completely flat and that gasket, which appears to be just a flat piece of metal with no raised sealing area. VR38 gaskets are thicker with a raised edge around the sealing surface to create the seal. If you have future issues you might consider the remflex carbon gasket (18-005) as they conform the surface due to their ability to be compressed.

-

Why not just use prevailing torque nuts? That is what my GTR uses from the factory and they don't loosen. The pic below was from my GTX3071r turbo swap, but you can see the factory stover nuts and they don't budge.

-

Love the thread! What size rims and offset do you run in the rear with those 245's?

-

Twins should spool well if properly matched with the right turbo. Keep the runners small using Schedule 10 1.25" Pipe (1.44" ID) for anything below 1000hp and this will keep exhaust velocity up to improve response. I wouldn't go bigger than G25-550 and you'll need to play around with the A/R. Knowing what I know now I would probably opt for a single turbo in a twinscroll configuration with something like a S362 SXE. You'll have to find someone to build the manifold and it needs to be paired correctly with two independent wastegates. My two twinturbo setups....