-

Posts

856 -

Joined

-

Last visited

-

Days Won

17

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Zetsaz

-

A musician's therapist (The $300 Z)

Zetsaz replied to Zetsaz's topic in S30 Series - 240z, 260z, 280z

I may take you up on that. Underneath the car, the fuel lines are one of my biggest frustrations. They work fine, but I just flared them for EFI rubber hose for now. Trying to get my cousin to help me 3D print some mounts to run along the frame rail, right now they're just sort of hanging with only a couple of clamps in the back and front and zip tied to the brake lines which are more properly mounted. Stock rubber mounts don't work since I upgraded to 3/8" stainless line. it's not too bad since I only have very short sections of rubber, especially at the front. The rail is deadheaded and the FPR is running "returnless" style. I've heard that's not ideal with boost, but I figure if the "Medusa" Z is running that way with much more power than I'll ever have and Z Car Garage didn't bother to change it when they did a lot of work for him, then I'm probably fine. -

The radiator is physically taller in a 280z. I'm sure a 280z hose would work fine on a modified radiator with a straight outlet, especially closer to 240z dimensions since you don't need to lengthen the hose. At the very worst, you'd be trimming an inch or two off the end if the new bend from having the radiator outlet a bit higher somehow created a kink in the hose. I trimmed my 280z hose to fit a Mishimoto radiator which only comes in the 240z style with the lower outlet upturned. Z Car Depot has aftermarket 280z upper and lower radiator hoses as well as OEM units, the Mishimoto hoses are only made for the 240z upturn but seem excessively expensive.

-

A musician's therapist (The $300 Z)

Zetsaz replied to Zetsaz's topic in S30 Series - 240z, 260z, 280z

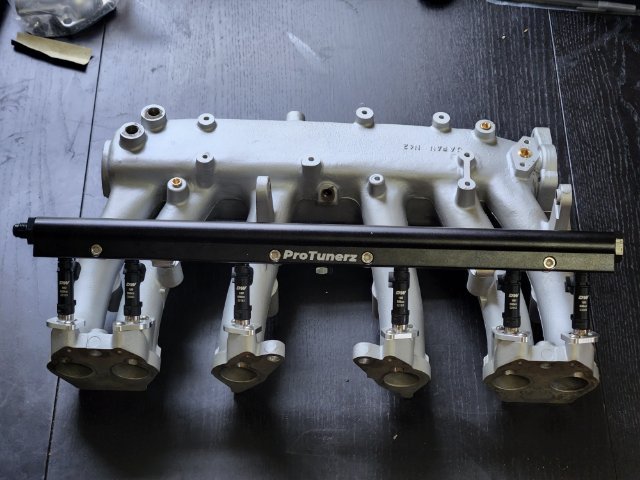

Thermostat housing is on and turbo is split apart for a sec while i wait on a couple of AN adapter fittings for the coolant lines which should arrive tomorrow. Occupied myself installing new door dome light switches and touching up the paint around the old busted ones. Finally managed to pull the old turbo studs put for the new longer ones to use with the spacer. Even welding nuts on the end didn't work. The stud extractor tool was worth every penny Had to relocate the PCV to clear my wastegate actuator and ground down the mount for the original one as well. While i was at it I baked the intake and exhaust manifolds in VHT flameproof paint. It's not quite ceramic coating, and I've heard of some people having issues with it flaking off, but realistically I'll eventually replace the intake at the very least with a nicer and better flowing Protunerz manifold. In the meantime, I'm satisfied with how i plugged some of the open holes and cleaned things up. Will probably run wiring under the fuel rail to keep things tidy. -

Looking goooooood. Not sure why you had to kick down at the trans mount though. But your 73 is a bit different than my 75. Just saw your post on Facebook and started following so I could see other's ideas haha.

-

A musician's therapist (The $300 Z)

Zetsaz replied to Zetsaz's topic in S30 Series - 240z, 260z, 280z

Spacer, new fuel rail and injectors and thermostat housing. Started getting the exhaust manifold fitted up and figuring out the correct angle on the compressor housing to clear everything. Super happy with the quality on the thermostat housing, but notice they accidentally sent me another outlet instead of the water neck haha. ProTunerz has excellent service though and already said they ship the neck on monday along with a return label to send back the extra outlet. -

Yours is looking much nicer than mine, i must say! Granted you have a much nicer workspace than what I have available to me

-

A musician's therapist (The $300 Z)

Zetsaz replied to Zetsaz's topic in S30 Series - 240z, 260z, 280z

My very much not Chinese made spooly boy has arrived. Thermostat housing and injectors should be shipping out sometime this week according to protunerz SO close to a new "first" startup. Will just need to sort water lines and the intercooler piping once it's bolted up, but it's super close. -

A musician's therapist (The $300 Z)

Zetsaz replied to Zetsaz's topic in S30 Series - 240z, 260z, 280z

Since I'm running the very conservative stock compression with dished pistons I figured the "newer" ball bearing turbos would get me better response on the low end, even though the GT series is starting to get a bit dated. The GTX for this size is apparently only a marginal improvement, and the G series is just too expensive for me right now. I got the whole assembly (housing, outlet, and water neck) for $194+shipping. Looking at other options which are just stock replacements that does seem like a good deal now that you mention it. Andrew (Milkfab) is also running a clutch fan and has now problems, but he has 3" intercooler piping which caused some fitment issues going under the engine. Mine is all 2.5" which fits great so far as long as I'm able to aim the compressor outlet just right to clear the steering column without having the couple hit anything. -

@JMortensen Those charts are barely legible even if you zoom in. It's one of my big frustrations with the forums after the major update some years back. Images uploaded directly to it all get compressed and you lose detail on some of this stuff. I have personally experienced the lift that you're referring to and the front definitely makes the most difference. A lot of people don't realize how much of a parachute effect the front hood has to create lift. My coilovers were adjusted poorly before adding more of the interior and carrying some things in the rear deck which caused the back end to lower enough to cause problems. Before the front splitter was added, the lift on the front end was enough to make the back rub since it was already close. Over about 55 or 60mph the lightest blip of the throttle would cause one side to rub. Over 65 or 70 mph the front end lift was dramatic enough to cause constant rubbing.

-

Ahh, somehow I missed the post by calZ. I had intended to post the pics from my phone after doing the typing from my desktop only to realize they were taken around the time my old phone got bricked a few weeks ago and weren't part of a back up haha. I'll take a few tomorrow.

-

Hmmm.... Looks like I'll have to redo my heater hoses to set them up like yours. Can you link to the thread? I don't have the T like you, I just set them up like my old NA engine, but I do still have the T from the turbo block's heater hoses. For the water lines, I saw PMC taking the cooler feed from the block plug in the back under the exhaust manifold, and returning to the thermostat. TonyD seems to have suggested using the turbo as a replacement to the original bypass line which I don't have right now. Posting a photo from my phone of the clearance. Your clearance between the frame rails and trans crossmember should be a non-issue. My low spot is under the diff, but unless you hit something that's going between your tires or get a LOT of suspension travel over a bump, I just don't see how it would hit anything, For the most part that entire area is gets more clearance as the tires move over things.

-

Looking might similar to mine so far Your engine bay is going to be MUCH prettier than mine... I forgot to ask earlier, how is your water cooling for the turbo routed? Are you taking the feed from the block and exiting to the thermostat housing?

-

A musician's therapist (The $300 Z)

Zetsaz replied to Zetsaz's topic in S30 Series - 240z, 260z, 280z

Recent orders that are hurting my wallet but should get this thing going. -Garrett GT3076R that I mentioned, with a 5 bolt ford style exhaust housing to bolt in that ultimate internal wastegate setup. Should keep things simple. -Tial 10psi actuator to keep things more reliable than whatever questionable chinese actuator was on there before. -650cc injectors and adapters for the 14mm O rings. Should be more than I'll ever use, but they were the same price as the 550s that were recommended to me to keep up with my turbo and psi goals. Will give me plenty of overhead, and better tuning since they're new and will actually come with a data sheet. -The new thermostat housing and waterneck from protunerz that I preordered ages ago should be here in time to install the water lines for the turbo. Was shocked at what they're asking for them now. I'm expecting them to be really great pieces, but I'm glad I preordered. Will give me more ports in more common modern threads while also allowing me to move away from the pitted oem pieces I have that developed a hairline crack on one of the sensors. They've been impossible to seal as a result and always blow some coolant steam onto the bottom of my hood and onto my header. Electric fans are still up for debate. I know that I can route the intercooler piping in front of the oil pan right now (have test fit my piping) and my clutch fan is working beautifully. Might avoid the extra expense and work for now just to get myself going. Don't want to have too much all at once on the to do list. If I purchase electric fans and the wiring it might wait until next month when I'm finally reimbursed for a conference I was at in February. -

@Sanchez Looking forward to that video. Would be helpful if you link it here. My steering rack is... usable haha. I'm at a very awkwards spot where tightening the big screw even by a few degrees too much creates a light sticking point just outside the center of travel either way. So I have to keep it more loose than I'd prefer.

-

A musician's therapist (The $300 Z)

Zetsaz replied to Zetsaz's topic in S30 Series - 240z, 260z, 280z

The new G series lineup seems so tempting but too rich for my blood... Nearly 1k over the popular 3076 L series guys seem to like! If I get a new Garrett I think I'm leaning towards the GT3076R with a .63 a/r -

A musician's therapist (The $300 Z)

Zetsaz replied to Zetsaz's topic in S30 Series - 240z, 260z, 280z

A few shots here. First shows where we put the hangers. I'm glad we could keep them as simple as we did. They're mountin to the stock muffler area mounts on the car. Had to cut and weld some random hangers I ordered from amazon. Those were only mild steel though, so I cleaned them up and painted them with a few coats of rustoleum just to make sure nothing was rusting under the car. Third pic shows it mounted. It looks like it's pointing slightly to the passenger side, but that's the distortion from my phone's wide angle. It's about as centered as you can make it considering how we built the exhaust, and it comes out pretty parallel with the ground! Currently debating ponying up the money for a GT3076 and just finishing up the car PROPERLY before I got to mexico or just running the new ebay turbo I was given with the engine block. Going to Utah for spring break to meet my new nephew so I fortunately have a week to think it over. -

A musician's therapist (The $300 Z)

Zetsaz replied to Zetsaz's topic in S30 Series - 240z, 260z, 280z

Will post pictures here when i get home later. Right now it only has the two hangers near the stock locations for the muffler. One about 6" from the muffler casing, and one towards the back close to the rear valence. I'll probably try to figure something out for the midpipe or just before the differential crossmember down the road, but we made the clearances pretty good and it's pretty tucked up just from tightening the V band clamps. The issue with another hanger in the middle is I don't have the stock shield over the transmission tunnel that the 280z had, nor do I have the mounting points for it because the floors were replaced by the previous owner. Yeah, the V bands were definitely the nicest, but even the butt welds are really good, they're just not internet "weld porn" pretty haha. we didn't clean them up at all either, so it looks much nicer in person than on the dimly lit stuff I've posted so far. We tig welded all of it (well... my friend who's charging me the "homie discount" did). Don't have the things to back purge, but we used solar flux to make sure the back of the welds were clean. Essentially becomes glass on the back of the weld and shields it from oxygen so you don't get the oxidizing and "sugaring" that can happen when the other side isn't shielded. None of the welds are ground down. They're pretty smooth as is. I'm probably just gonna wipe them clean and let them be whatever color they're going to be after heat cycling when it's running again. -

I mean, realistically if you're doing things the most overkill way possible you would run something like this from the attached pdf. The stock turbo system has the block going through PCV to the intake and it's relatively well designed. arrington_ccv_bible (1).pdf

-

Not my method, this is a direct quote from Matt Armstrong in Vancouver who builds a lot of these He goes stock block vent to stock pcv valve on the intake, then valve cover breather to catch can to intake on the turbo So two small systems Block Vent --> PCV Valve --> Intake Valve cover --> Catch can -->> Turbo intake

-

A musician's therapist (The $300 Z)

Zetsaz replied to Zetsaz's topic in S30 Series - 240z, 260z, 280z

15 hours of work later... The video is a bit better despite poor lighting. Some of the welds are great, particularly in the V band flanges, some of them slightly less so because we weren't as careful as necessary about heat like the short pie cut just before the muffler that gets the angle right where we wanted it. That said, even the worst welds are better than the weld on the rear pipe off the HKS muffler. It's a nicer exhaust than I ever thought I'd have on the car, and I still have loads of room on the straight for a resonator or a second muffler if I decide it's too loud. Finishing the hangers tomorrow and it'll be done -

A musician's therapist (The $300 Z)

Zetsaz replied to Zetsaz's topic in S30 Series - 240z, 260z, 280z

Have spent maybe another 10 hours mocking up and test fitting back from the downpipe since my last post. O2 bung is welded in but might have to be relocated. It ended up being angled just a biiiiiit close to the transmission. Perfectly workable for now and no clearance issues getting it in or out. Mid pipe is done and welded. Back end is tacked up. Doing a quick realignment of the muffler today then we'll be able to fully weld the back end and get the hangers done. Super close! This will be a nicer exhaust than I ever imagined having. Pics to come as soon as we finish it up -

A musician's therapist (The $300 Z)

Zetsaz replied to Zetsaz's topic in S30 Series - 240z, 260z, 280z

Downpipe made. Need one more weld on it tomorrow plus the O2 bung then we'll hopefully finish up the mid pipe -

Hey everyone, I feel like it's the first time in a while I've made a new thread about anything but I'm curious if anyone here has experience. I'm running an RT Diff mount with the GM top mount. I know of at least one person (can't find the thread anywhere) who cut his stock crossmember to improve space for exhaust routing. Instead of being a crossmember for the diff, it's now just brackets to hold up the front of the control arms. Z Car Depot now offers billet pieces that do the same thing as pictured. The big question is whether or not this would worsen lateral rigidity. I can't imagine the RT diff mount adds nothing but it's not exactly the same as the crossmember adding a brace straight across. Would love to hear people's opinions/thoughts.

-

You can get some new GSP Axles from Rock Auto for about $50 ea. Not really worth trying to find them used unless you get a better deal than that

-

A musician's therapist (The $300 Z)

Zetsaz replied to Zetsaz's topic in S30 Series - 240z, 260z, 280z

New parts tease. Friend of a friend who's welding all the stainless for me is hoping we can get it all done the end of next week. Should give me enough time to make or order some intercooler brackets and finish up the cold side piping