-

Posts

75 -

Joined

-

Last visited

-

Days Won

3

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by stupid_fast

-

re-mapping and live tuning L28ET 1982/83 S130 ECCS

stupid_fast replied to stupid_fast's topic in Other EMS

J-pipe is fine its just non-intercooled so its more prone to detonation due to the higher intake temps. You should be able to run quite a bit of power as long as the timing is conservative and you keep it a bit rich. The NA ECU has no ignition control, the advance curve is mechanical like a carbureted car. I'm pretty sure there have been NA-T guys on hybridz who have run a stock dizzy without problems, you should be able to find some old topics about it. For the knock sensing its pretty simple, you can even use a mechanics stethoscope with a pipe bolted to the block, or an electric setup with a small headphone amp and a generic knock sensor. The factory sensor should probably work too but I haven't listened to it. This is what mine looks like with a generic headphone amp off amazon. -

re-mapping and live tuning L28ET 1982/83 S130 ECCS

stupid_fast replied to stupid_fast's topic in Other EMS

For drivability you really want good amount of advance in the low load areas. I never really understood why anyone would remove vacuum advance, since with the correct weights setup it runs the same at the top end anyway. The stock map has a lot of advance. remember however it had 7.4:1 compression, motors with flat tops and NA motors will take a lot less ignition timing reliably especially with the stock j-pipe. I just built some knock ears and I'm still getting light knock at around 5200rpm with only 24 degrees timing at a 12:1 AFR on the j-pipe and stock wastegate. My motor is around 7.9:1 compression. I was probably saved before by the motor running very rich mid 10:1's on boost. These motors hit mbt around 20 degrees at 3000rpm (at 6psi), and they're prone to knock in the 4400-4800 range. Really the take away from this is just make sure you have some kind of audible knock detection when you start rolling into the boost for the first time, there's no real replacement for a good ECU with proper spark control. I was collecting some more information before doing a final update and conclusion for this thread, which is most likely going to end with my car running on a dropbear ECU. It was fun to go in and verify or debunk rumors on how things worked inside the factory ECUs. -

simplicity and reliability, ZX turbo track toy

stupid_fast replied to stupid_fast's topic in S130 Series - 280ZX

I think the suspension is just too stiff, I'm going to get softer springs first then see from there. There's practically zero body roll in corners and not much compliance over curbs. Also running the big MSA sway bar kit front and rear, the rear bar might be too stiff. Unfortunately I threw away my stock sway bars. The tires are 225 front and a 245 rear, they've got most of their tread and are about 2 years old but garage kept. The rears are also a few months newer than the front tires. If they were shot I would expect another few seconds on the lap time. Grip level is about right for a 340 treadwear summer tire and I didn't get a chance to dial in the pressures, they were about 28psi hot. camber -3 front -1.8 rear toe 1/16" in front 0 rear About 3.5 degrees of castor. It used to have heavy understeer bias when it was lower a few years ago when I ran it at Thunderhill west with 205 tires. Almost the same alignment specs from back then, just different ride height. -

simplicity and reliability, ZX turbo track toy

stupid_fast replied to stupid_fast's topic in S130 Series - 280ZX

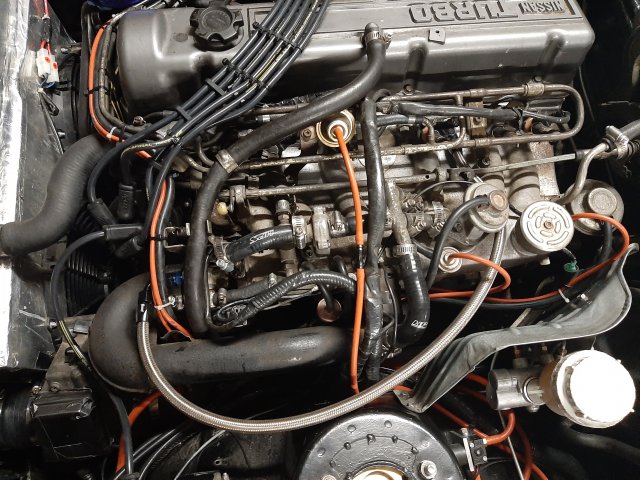

I did lots of things to the car this year, but didn't feel it was necessary to update here until I had some results. The main outstanding issue with the car after Thunderhill was the cooling system. Got a TIG welder earlier this year in February and learned how to booger weld aluminum enough to start on cooling modifications. I started with building an intercooler setup. Since I'm staying with stock EFI, I wanted to add a recirculating BPV so that required the intake boot to be replaced. The factory intake box does not fit with the intercooler, considering my options I was unhappy about just running a pod filter in front of the radiator. After a bit of angle grinder action, I found room for the intake under the headlight bucket. I bent up a piece of aluminum to box in the filter. Took one out of the lemons build guide and secured it with self tappers. Rivet nuts can be added later. Welded up the internal water pump bypass. Welded up the radiator cap, removed the restrictive shroud, and relocated the oil cooler behind the radiator. Methodology here is that the cooling stack is supposed to run from coolest to hottest. Added in a cheap ebay expansion tank and overflow bottle with a 22psi cap. I extended the fuel pump bracket to add a pre filter and upgraded to an 044 pump and changed the differential to an open unit. Built another set of axles, and tired of killing them I raised the rear ride height by 1". Also adjusted the camber back to negative since I'm not drifting. I modified the wilwood combination prop valve bracket to fit on the z32 bmc. Changed the cam to a factory 'A' cam. The extra RPM wasn't doing anything for me. I decided it was time to rebuild the rear brake calipers even though they were not leaking. After pulling them apart I found the cylinders were complete junk full of rust pitting. Got a set of reman calipers and now the rear brakes are working well again. Built a bracket for a generic ebay adjustable wastegate actuator. It seems to work better than the old worn factory units I have. The ZX engine bay looking even more crowded than it did from the factory, however its now at the best state its been in since I got it. Back to Buttonwillow for the yearly SpeedSF black Friday event. Last years event they lost the lap timing for my fastest lap, but it was somewhere in the 2:13 range. I had some issues in the morning but was able to get out for the last two sessions and managed to get down to a 2:08.582 with the same tires from last year. Positives from this event, the car is making a lot more consistent power in spite of running rich. Still on low boost around 8psi. The cooling issues are completely gone, the water temp stabilized at 185-190 and didn't move pushing it for a full 20 minute session. Oil temp stabilized at 250. Now that the car is running faster the oil pressure is dropping on almost every right hand corner. A baffled oil pan is next on the list before I can get back on track. I changed to an open M30 differential, but raising the ride height gave a huge oversteer bias on the car and now the thing is really skidding around everywhere. Going to move to softer springs and adjust the suspension geometry a bit. Going to be interesting from this point on, I feel like the car is at a stable baseline and I can start actually tuning things rather than fixing major issues. -

@AlShelby I will not be parting out the T5, but the points dizzy is available. @Villeman Sorry I gave away my extra thermostat housings already, I can't find any more.

-

Hey guys, sorry I haven't been on here in a while. @chopkins12 I have the clutch still, your profile says you're in NY.. its going to be unreasonably expensive to ship it. I don't have any spare turbo parts other than what's listed. @McKleenZ message me if you're still interested in dropping by. @ISPKI Shipping is very expensive for any bulky parts, you're probably better off getting it local but I can get a quote if you're determined.

-

simplicity and reliability, ZX turbo track toy

stupid_fast replied to stupid_fast's topic in S130 Series - 280ZX

@260det, thanks for that. I've got a few ideas going right now, going to do some prototyping and hopefully make some improvements. A few updates from recent activity. Earlier last year when I rebuilt the gearbox I replaced the factory transmission mount isolator with the 240sx unit. The only modification required was drilling two holes in the crossmember. This Megan racing mount came on one of the 240sx boxes I got, and is a bit more robust than a ZX unit. The engine mounts tore again, so I ordered some OEM Nissan mounts from japan. The OEM mounts immediately delaminated on installation, so I ordered up some silver project mounts and they work just fine on the stock ZX. They are a bit stiff at idle with the cam, but while driving I can't tell the difference. Took the opportunity while everything was apart to finally fit on my #5 bypass, should help flow at the back of the head at least a little bit. AN to BSP fitting was easy enough to source. The throttle body heater cap was also leaking, so it was a good time to re-seal that. The front sway bar was also binding due to some janky drifting stuff I did to get more clearance for the brake calipers at full lock. Steering is much more complaint now, as it should be. Went to Thunderhill East this weekend and got on track for my first lap, engine was misfiring and I get black flagged for oil smoke in only a few laps. The driveshaft munched up the transmission output shaft seal, and it sprayed fluid all over the exhaust causing the smoke. I suspect it was due to the old failed engine mounts, but I'll find out for sure if it fails again. The parts shop in town had the required seal, I also got a coil and spark plugs to combat the misfire. I missed a few sessions, but I got it back on track with no leaks and running better than it has in a while. Set a 2:16.030, at least at a similar pace as the rest of the run group. The water temps get too hot after just 4 laps flat out, as mentioned previously in the thread I'll have to start doing something about this. A while ago I had adjusted the water temp enrichment table in the ECU to go very rich when the CHTS detects 240 degrees, and it worked great. At just about 230 on the gauge and it goes rich so I'm not tempted to keep pushing it. -

simplicity and reliability, ZX turbo track toy

stupid_fast replied to stupid_fast's topic in S130 Series - 280ZX

260DET, thanks for the comment. I'm still running a locked center, and really can't justify the expense to upgrading to an LSD for this car since I'm not doing any level of competition. A huge contributor to the high speed instability is the alignment settings, my last alignment was optimized for drifting and was almost ideal for that purpose. An LSD has been on the list for a long time, but with how beat up this chassis has gotten over the years I'm starting to only do the maintenance required to get as much seat time as possible rather than upgrades. I'd like to also start messing with some front air dam and basic budget aero as experience to apply to my lemons team car. Nothing crazy like a big wing, probably just front air dam, under body panels, and a simple diffuser to keep the end back down. Cooling is still an issue, typically Its creeping up to 220* water temps after a hot lap session. I'm currently working on a few more maintenance bits and optimizations, going to be on thunderhill 3 mile in a couple weeks with SpeedSF. -

simplicity and reliability, ZX turbo track toy

stupid_fast replied to stupid_fast's topic in S130 Series - 280ZX

I lost a bunch of pictures from recent work when my phone died, but here's a brief update. When I slapped in my cam in a few months ago before the Buttonwillow event I also installed a new Powerbond crank damper PN# PB1212N. Last weekend I went to check the timing after my dizzy cap screw backed out and couldn't find the crank mark. Pulled everything apart and re-checked the balancer against a degree wheel, the outer ring has rotated by about 35 degrees. I bought the new part because I was afraid of the 40 year old factory unit slipping! During disassembly I found that my new aftermarket engine mounts are also starting to fail again. Going to just order up some OEM nissan units, the original factory parts never had issues. Annoying to still struggle with reliability at this point, but at least there's less things to fix at this point. After ignition issues at Buttonwillow I realized I simply hadn't changed my dizzy cap & rotor for several years! Finally took the time to finally install these Accel 8.8 plug wires that have been sitting on the shelf for over a year. Really can't tell if they've helped anything, but they look good. As it sits today, waiting for the decision on what crank balancer to go with. From Buttonwillow a few months ago. -

AFM / air flow meter for 1982/1983 280ZX TURBO

stupid_fast replied to stupid_fast's topic in Parts Wanted

Hey there, I already got some spares to test from another Hybridz member and confirmed mine were still OK. Thanks though! -

simplicity and reliability, ZX turbo track toy

stupid_fast replied to stupid_fast's topic in S130 Series - 280ZX

Having trouble uploading the video, but if it worked here's a lap from my recent visit to buttonwillow. Had some running issues, but overall felt great to get out on track. edit; re uploaded w/ youtube. Fasted lap was 2:21.374. https://youtu.be/xv4rmxQ1vH8 -

After taking a closer look at the part, it seems i made a mistake with the mustache bar. Its in fact an R180 mustache bar. Sorry about that!

-

Parts located in Sacramento Delta area, California a few miles off hwy 12. Reasonable offers accepted. I no longer have the desire to horde z parts due to other goals, I would prefer these parts be used again by those who need them and not get scrapped. There are also random ZX parts I still need to sort through, all the chassis controller boxes for an 83 such as the dash diagnostic control unit and cruise control unit. L28e dish pistons with rods $40 L series 6 cylinder points distributor $20 L28 F54, bored out too far, needs to be sleeved. have sonic test numbers. $80 obo 280zx turbo oil cooler core $40 L series 'white bunny' clutch setup, 240mm flywheel. $40 280ZX turbo R200 long nose 3.54 with welded center $80 R200 long nose 3.9 with welded center $80 good shape 1982 turbo ZX T5 box, needs reassembly and some parts, message for details. Will not part out. MANIFOLDS: 2x L28e EFI intake manifolds $75 each 2x L28e EFI exhaust manifolds $75 each 1x L28 smog exhaust manifold welded up $75 L16 exhaust manifold 1972(?) $50 WHEELS PAIR of 15x7 +22 Road line 4x114.3 no tires $100 PAIR of 16x8 +20 XXR 4x114.3/4x100 with new Archilles ATR 2 225/50r16 tires $200

-

Other than a bit of a mishap installing the rear main seal, Gollum's new loaner motor ready to go. I dropped it off earlier today. Came out of a 240z in running condition that my buddies doing a v8 swap on. Had a pair of SU's and a points dizzy on it! To my surprise it was a P90/F54. Put front & rear seals and replaced the valve stem seals, installed an A cam and a newer OSK timing sprocket from my engine while I was at it. Looks like a clean original turbo motor, but there is evidence the timing chain has been changed at some point. Should be a good runner for Gollum to get some seat time while he collects parts for his swap.

-

simplicity and reliability, ZX turbo track toy

stupid_fast replied to stupid_fast's topic in S130 Series - 280ZX

I'm usually driving to the track in my blue Geo Metro. I'll keep an eye out for your car as well! Won't be out at Sonoma for a while unfortunately. -

simplicity and reliability, ZX turbo track toy

stupid_fast replied to stupid_fast's topic in S130 Series - 280ZX

Leon, My first time in lemons was at the last Sonoma event in the rain, the E36 was fantastic to drive! Its a monster in the wet. I'm in the unicorns aint U's car #201. It'll be a couple months before I'm ready to go to the track with the z, after moving and all. Also waiting on funds for a new wheel & tire setup. I'll definitely let you know, it should be either sonoma or thunderhill. Probably will be with SpeedSF to start out as I've already gone to several of their events before. I'd be interested in some other track events as well, as long as they aren't super novice oriented. Open passing and plenty of run time makes me happy. -

simplicity and reliability, ZX turbo track toy

stupid_fast replied to stupid_fast's topic in S130 Series - 280ZX

Thanks Rossman, drifting is fun but the scene here is annoying me. There are a few Z's drifting out here as well, but they're not great cars for it. Here's a bit more details on the gearbox I blew up. The annoying part of all this is that I replaced the T5 since it was known to strip out gears! The S13 box was rebuilt before I installed it in 2016. It received fresh bearings, synchros and clearances checked to FSM spec. I also blocked off the oil passages in the sandwich plate (jb weld held fine for this) , and relocated the rear bearing oil scraper to 5th instead of on 1st to reduce oil transfer to the back of the box. Note, there were also two main shafts available. The top one has a larger diameter, and longer splines on the output shaft. I threw away the larger one, the output splines were twisted so I decided it was unsafe to use. Another topic from mid 2017, The turbo CV ends I had were worn out and making very loud horrible noises. They never completely failed, but the noise was unbearable for driving the car any significant distance. As the axles were over $700 each from Nissan, and rare to find used I needed to find a better solution. These were toast! My other pair were just as loud, even though they still had plenty of grease in them. So what's the solution? Most nissan CV axles used the same spline through the 80s and 90s. The 300zx CV joints aren't an option anymore, as they're either expensive from nissan or not available in the aftermarket. I looked at the Infiniti M30 based on a single comment I found here on hybridz. It has an R200 long nose with the same differential spline, and suspension similar in design to the z31. Its also a newer model, and it only came with an NA VG30e and automatic transmissions. Junk yard axles are likely to be in good condition. The stub axles are required to run M30 outer CV joints. They're similar to Z31, use bigger bearings and significantly larger spline. M30 on left, S130 on right. The M30 stubs kick out the track an extra 5mm, and the brake caliper requires a spacer to function properly. The next issue to deal with is the axle lengths, the M30, Z31, and pretty much all newer nissan axles are too long. The two shorter axles are S130, the longer ones are M30. The S130 turbo axle shafts are pretty much identical including the spline. The only difference is that the tripod bearings are pressed onto the s130 axles, vs c-clip fit for the M30. Another benefit, the CV boots are now readily available for $15 aftermarket or $40 from Nissan. The end caps are a pain to get off and on the first time, slap them against the tripod bearing a few times they'll pop off. They're press fit need to be clamped and sealed when replaced. I used sleeve retainer 640. haven't had an issue yet. The M30 factory axle bolts come with some sort of thread locker, so I always put more on when I replace them. $75 replacements are much better than paying over $1500 for a custom axle solution. S13 inner tripod CV joints are functionally identical to M30 outer CV joints. New aftermarket S13 inners are available for $40/each from febest. I've found that usually the outer CV joint wears out before the inner. Since I stripped out my gearbox before having an issue with one of these axles, I'd say they're strong enough for most use cases. The M30 long nose 3.91 also fits with minimal modification, just need to swap over the input flange & grind a bit off the casing. -

simplicity and reliability, ZX turbo track toy

stupid_fast replied to stupid_fast's topic in S130 Series - 280ZX

Leon, Thanks! Its nice to know someone finds my ramblings entertaining. I'll do my best to keep this updated as things progress with the car. Although I have all the parts, I'm taking my time rebuilding the gearbox for now as there's several tech discussions I need to go back and read. On another topic, i just ran another lemons race in my friends E36 on the Thunderhill 5 mile. I really want to get my z on that track and make it set some respectable lap times. -

simplicity and reliability, ZX turbo track toy

stupid_fast replied to stupid_fast's topic in S130 Series - 280ZX

The steering rack issue ended up just being a small installation oversight due to the way I put the center seal in, I had pushed it over the gear and it cut the seal. I assembled the rack from the other side of the main shaft and was able to get everything to seal up no problem. After a proper alignment on a nice dug-in rack and a new set of tires, I was ready to head to my next event at jackson county sports park in Medford Oregon. Dropped the cars off at the track, and went back to town to spend the night. We arrived at the track in the morning, attended the drivers meeting and I ended up being the first one on track, drove for a few laps and started getting comfortable and BAM! Stripped out 3rd gear on the initiation into the first corner. This is was a late KA / SR larger gearset. (there are two gearsets for the KA with the same ratios) I pulled the gearbox at the track, cleaned up the bits and resealed it and dropped it back in to drive home. A waste of a track day, but at least I got home without a tow. Luckily I have a spare gear set on the shelf, so all will be fixed soon. The blown gearbox being pulled apart. Here's my spare big gearset vs another early KA box I got. The big gearset is about 2mm bigger on each gear. The state of my new garage is bad as well, so lots of things need to be addressed before this thing will be back out. -

280ZX ECU/ECM REPAIR SCHEMATIC & PARTS LIST

stupid_fast replied to FRANK_ZEE's topic in Nissan L6 Forum

The all caps post is really annoying to read. Please structure your future posts better. There are no schematics available online for proprietary ECUs. The transistors are hitachi. From left to right D970, D970, B791, B566A You can figure out the resistor values by reading the color bands. The white resistor thing is marked 'ARW 0.5 ohmK JRM NK' The big one is marked 'RS3B 0.1 3 RIKEN Z' Your ECU may or may not work if the burned components are replaced, but its worth a try if you have the ability to do it. -

re-mapping and live tuning L28ET 1982/83 S130 ECCS

stupid_fast replied to stupid_fast's topic in Other EMS

I was referring to Gollum's megasquirt logs. I've just updated the rom data translation spreadsheet with my more recent findings. https://github.com/eccs-reengineering/280ZX-Turbo-ECCS/blob/master/Rom Data Translation/S130T_ROM_Address_Translation.xlsx You're welcome to look, and if you have any questions about a specific table I can test the results of changing it. I've modified and tested almost every bit of used data while the engine is running to find out what it does. I've verified which maps are in fact used, and which are not by checking which tables are referenced and loaded by the assembly code. The next step is to verify if in fact the AFM is hitting its limit. If so, the real solution would be finding a way for the ECU to measure flow past the AFMs max flow capability. Edit, found what appears to be the injector constant (Generally referred to as the K constant in the Nissan world) it is a DWORD at 1F44 on the stock rom. Adjusting this dword changes fueling characteristics across the whole range. -

re-mapping and live tuning L28ET 1982/83 S130 ECCS

stupid_fast replied to stupid_fast's topic in Other EMS

I made a mistake by saying 'air flow would be consistent'. I'm trying to figure out the explanation as to why there's a severe drop in AFR after a certain RPM, but the fueling would remain constant with a flat AFR target above that value. -

re-mapping and live tuning L28ET 1982/83 S130 ECCS

stupid_fast replied to stupid_fast's topic in Other EMS

Ah every time I think I understand something I learn some new information. I've uploaded a video example of how the AFR targets react over the RPM range. This may illustrate what I've been trying to explain on the lean out above 4000rpm. Also the video is slightly offset from the innovate & address tracing, but it gives you a general picture of what the afrs are at a given target. 2019-03-15 13-20-35_Trim.mp4 -

re-mapping and live tuning L28ET 1982/83 S130 ECCS

stupid_fast replied to stupid_fast's topic in Other EMS

Good stuff, based on the megasquirt logs I've found the VE on this motor is somewhat flat from 4000 to 6000 so makes sense that airflow would be consistent. A minor detail to include for sake of information sharing; The S130 AFM uses an inverted signal, approximately 4.78v is the maximum with the flapper closed, and fully open is 84.2mv. I've verified these settings as correct within OEM specs across about 5 AFMs, including one that was factory sealed and the PCB traces in very good shape. There's a +8V reference from the ECCS unit, its also grounded directly to the ECCS unit not the chassis. I just need to find a passenger, I live far from most of my friends. I like the idea of logging for future modifications though. I'll check out the 944 data from tunerpro. If its a 3" bosch AFM, its quite possible it could be an identical unit mechanically, however I don't think any other cars in the era used the JECS inverted output resistor board. Although that detail is more prevalent to comparing code, and not so much the tuning side of things. -

re-mapping and live tuning L28ET 1982/83 S130 ECCS

stupid_fast replied to stupid_fast's topic in Other EMS

@bradyzq I see, if the TP drop is normal then I may be maxing out the AFM's flow capability. L28ET torque curve on a stock turbo is from 3000 to 4000 rpm with the peak somewhere around 3600rpm, so it backs up what you're saying. My Multimeter doesn't have any logging unfortunately, its kind of difficult to check a voltage meter while driving. A logging oscilloscope also works, but I don't have one that interfaces with a computer. The best approach I thought of would be to log not only the AFM 0-5v output, but also RPM. That would give the most useful data. At least I can correct the top end fueling using the data, and don't have to get a rising rate FPR. Re:quattro, I think I understand now, the fueling tables make a lot more sense if continuous injection is factored in. So the ECU fuel control is more for closed loop correction and enrichment in boost using the map sensor. I was wondering why it was missing any kind of VE table.

.jpg.031c9bf5828b75571904ddcea2894304.jpg)

.jpg.77c876b7a97f3531d69dc65c419082b5.jpg)

.jpg.229e3573aa8968bffc1f1af0963e5f5f.jpg)

.jpg.654a0344c450b582848268ccfef4d0c7.jpg)

.jpg.6644416f029fd144f4c23869d283702d.jpg)

.jpg.edb8531c5c5cd29264ffb7113f58ed18.jpg)

.jpg.760b597e3ce4aea97b96766dc7cbca32.jpg)

.jpg.19e2c987ee2c1f8e4c13fb39e9e5d4f5.jpg)

.jpg.b89ea5443f904e04ed7a64f295320cd9.jpg)

.jpg.6a60e6dec39c06ee6c163a3a07f0fd94.jpg)

.jpg.7f2c41629c9019de5ee3f1c0e371ea96.jpg)

.jpg.20a37ede00085ba15d200d3e977d9971.jpg)

.jpg.d841281d451b7b1d52db6037b4460b51.jpg)

.jpg.0be029c28d3aed42a5174d669b6475f3.jpg)

.jpg.90ee573e2b4cdbb43a04ffe97a96fe28.jpg)

.jpg.e4b8e4d404efa44a1d47ac32cea20bbc.jpg)

.jpg.4e8c11cc2f69c1ac363be89a038d76d3.jpg)