budgy

Members-

Posts

100 -

Joined

-

Last visited

-

Days Won

3

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by budgy

-

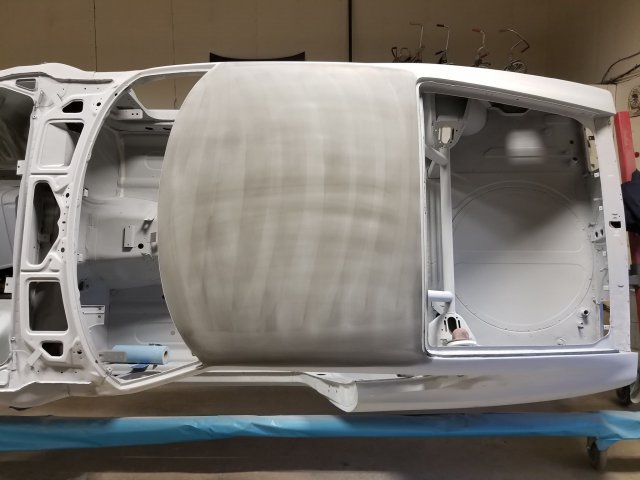

Engine bay/roll bar done in PPG GM black. Outer body is just sanded slick sand, still got some shine to her though even before primer

-

Dry ice and vapor honing. We got a great local business here who does a hell of a job with that stuff.

-

Metal work is pretty much done, bad dog frame rails are welded in as well just don't have photos of them at the moment.

-

Was about $2200. I am sure I won`t regret it all when its done, but definitely an LS also fits much better, no issues with hood latches or the cross member.

-

Progress on my insane VQ35HR 240Z project

budgy replied to markrolston@mac.com's topic in Nissan V6 Forum

Sounds crazy! Congratulations on finishing this heroic build Mark; absolutely beautiful car, hope you enjoy it for years and years to come -

Upper radiator support changed to a bolt in style for much easier engine pulls and install. Moar slick sand, part of the battery tray removed...things are rolling along Also picked up a new daily last week to replace my Mazdaspeed 3 which I am now selling. 2018 Golf R, dark violet pearl, im digging the colour, very comfy...a little too comfy...and I know everyone here knows exactly what I mean..unlike many other online car forums

-

Getting closer and closer to paint...still have to do one of the headlight buckets and fenders to match the finished side, bad dog rails, and fix that gnarly ass battery tray...but after that...shes pretty much ready to be sprayed.

-

Fenders moved up and snip snip EDIT: Added photo of the inner edge, didn't want any sharp edges that could wreck a tire or a finger in some bizarre unforeseen incident.

-

Thank you! Yeah we want this thing to be more corrector as opposed to less corrector

-

Thanks for the feedback! So realistically, lining up the lip of the flares with the fenders sounds like it makes sense.

-

Flares being fit, I think we will move these rear ones up about 1 cm, the tire is going to be out a lot more once the what looks like 6 degrees of negative camber are gone Might run a small spacer to get a bit more flush if need be, but really happy with the fitment altogether. Correcting the body line with the door, looking much more chiselled. Lots more exterior body work getting done soon, I didn't take photos but most of the holes in the engine bay are welded up now too. Simple roll bar, functional, strong, I love some of the full cages people run, they look glorious but realistically I am not going to race this car, it might see an open lapping day here and there so it can be enjoyed properly and stretch its legs.

-

I see a lot of the old images I used to link from facebook aren't visible, maybe one day I will clean that up...but I did manage to get something else cleaned up. Not the full motor as I am not rebuilding it completely. But the most visible aluminum pieces have been cleaned up using some dry ice and some sandblasting. While its apart, got a Z1 motorsports clutch/steel flywheel, heavy duty clutch slave going on. JWT C2 Exhaust Cams, ATI Crank Pulley, new oil galley gaskets. The goal is to have 400 crank horsepower but just be reliable and maximally responsive. Was not originally going to do one, but a simple roll bar that is safe for mostly street use is going in soon. The front upper radiator support is going to be modified to be bolt in/out for much easier engine install and service. Most of the exterior body work is done now. But once the metal work is done things will start moving quicker. We have the roof in slick sand and other areas will follow once the metal work is completed, then it can sit around and shrink for a good long while before being properly sanded down.

-

Yeah the metal on the front end of the donor roof was a bit janked. The old roof was perfect, so the two have been merged to prove philosophically that two wrongs can make a right

-

Lots of work happening here finally! I am looking into getting a GT-R intake manifold for this engine and I am nervous about fitment as there is basically no more room under the hood as it is. Can anyone confirm if a GT-R manifold is taller than the stock plastic intake?

-

Things have moved pretty slow on the build as a couple hang ups caused big delays. Door Hinges were sent to MSA for refurbishing and the company that does the work I guess was delayed due to come contract they scored so those are finally coming back soon so we can mount the doors and make sure the drip rails will be done properly due to my roof swap. Waited about 6 months for those if they show up now. Could not find any used ones locally or any junk yards that had them. No luck calling around either for spares. There was also huge delays to even get the motor in the car and get the project started in earnest, I ordered the mounts and headers from McKinney in August 2016, I wasn't told at the time of order that the headers were going to be all that long of a wait, hell I saw another member had some headers and they looked great, but I ended up waiting about 6 months for headers. So the car was never brought to the shop for tear down until February 2017 when we were hoping to have the car in by late October or November in 2016. After all that, the mounts from McKinney I will say are a bit disappointing, they are very strong, but the trans mount is not usable, it does not even reach close to the transmission, we got measurements for a driveshaft to Mack over a month ago but haven't heard back even after asking for updates. So the communication of it all just sucks. In his defense, I haven't even told the guy about the transmission mount not being usable because I just want the damn driveshaft first. The main engine crossmember mount is also a little bit short of making full contact with the frame rails in the engine bay so we may have to do some fabrication this way as well. All in all, a few lessons learned on my part. 1) Don't buy hardly any pre-fabricated pieces for a motor swap, just get a proper local shop to build custom ones. It will be cheaper, done better and done much faster. 2) Should have bought a donor 370z for other parts too, instead of cobbling pieces together. Although at the time I was buying up parts in August 2016 I was optimistic things would go smoothly and on time and that I would have a driveable car this summer so ponied up to get the pieces I needed quick instead of being patient and waiting for a donor to be available for a reasonable price, even though I ended up waiting around for a long time for other critical pieces I lost the entire driving season anyway. So that was a lot of money spent for absolutely zero benefit. Definitely has been a disappointing year, somewhat disenchanted with the entire aftermarket auto industry over these experiences. But still optimistic that it will be worth it in the end. I am basically just accepting the fact that there is no way ill drive it until next spring even if the build is done much before then.

-

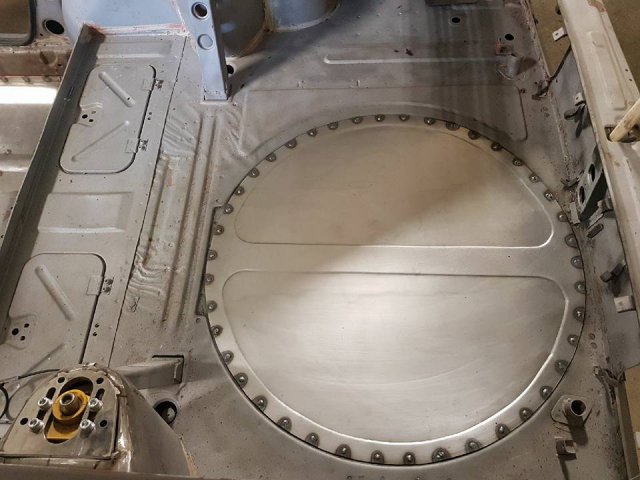

Decided to get rid of the aftermarket sunroof for the cleanest possible look. Removal of factory drip rails was poorly done. Got a fair bit of metal work to do before she goes into primer, but things are finally about to start moving forward more rapidly. Wanted to share a photo of a truck that was painted the same way my car will be. It's why I chose this small shop, guy does excellent paint and body work.

-

ZFever builds complete harnesses for these swaps Little sneak peak of what was being worked on today!

-

-

Wolfcreek is now known as Futofab and they make the CV Axles, I actually purchased mine through Techno Toy as they are a Futofab dealer and it just made things easier for me being in Canada for shipping reasons. Not entirely sure they would work with the 350Z R200, if the housings are the same I guess it would not be an issue.

-

Typical Datsun stuff, hopefully its not too bad to fix behind the battery tray that thing is a nightmare. Hoping I get mounts and headers from McKinney soon so it doesnt hold things up before body primer. Drip rails very disappointing to see what was basically just flat steel welded in before. A whole new 'C' shaped piece will have to be made and welded into place.

-

Getting sent off for water/media blasting soon!