-

Posts

1382 -

Joined

-

Last visited

-

Days Won

12

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by rossman

-

I finally welded on the top panel😁. Got a little too aggressive with the grinder on the spot welds... nothing a little filler can't take care of.

-

What you mean by stumbling? Does it idle smoothly?

-

I love both my Miller 140 MIG and Everlast 200DV TIG/Stick. I bought the Everlast on recommendation from our Weld Engineer at my work, who is a welder by trade. He stated that if you're not a professional welder then some of the cheaper brands will be just as good as the more expensive American blue and red machines.

-

A musician's therapist (The $300 Z)

rossman replied to Zetsaz's topic in S30 Series - 240z, 260z, 280z

Sounds good Zetsaz! I'm excited to see some progress when you get back to her. I will say though, that the .63 A/R GT35 combination on my 3 liter chokes the exhaust and power starts to off earlier than it should, around 4.5 - 5k. I'm sure that the GT35 being tool much compressor for the engine doesn't help either. I'll be "upgrading" to a more modern small frame turbo some day... It's totally ok and normal to loose interest from time to time. I know I do sometimes...but she's always there ready when I am. -

The factory didn't hard pipe the drain for a reason - there will be movement from thermal expansion.

-

Now that I think about it again, I used TWO 45 degree swivel fittings. One of the fittings is a standard AN nut to hose adapter swivel seal, the other is a hose adapter to NPT swivel seal. Using a swivel seal fitting with a NPT built into it saves just enough space for it to work. The hose adapters end up pointing each other at 45 degrees with a short piece of hose in between. I also had to rotate the turbo center section and fitting swivels slightly to get the hose adapters to line up properly.

-

I may just be thinking about aluminum. Seems like I remember that some chemical strippers don't play nice with aluminum. The emblem appears to be some sort of electroplated metal...maybe nickel plated steel? Anyway, I'm moving on now. Currently restoring the original 240z steering wheel in parallel with the hatch panel. Hopefully I can finish up the hatch panel this weekend.

-

Well, I answered my own question. I tested the stripper out on the back side of the badge and the metal appears undamaged.

-

A -10 45 degree swivel with Pro-Lite 350 hose was the only combination that I could get to work for my turbo drain hose. You can get the hose with an internal reinforcement to minimize collapsing too but it wasn't needed since in my case since the hose portion is essentially straight.

-

This is going way OT but since you brought it up....black also absorbs radiated heat really well. This would cause the reverse effect when rolling over sun soaked super hot back-top and when the black undercoating is near your exhaust.

-

Leave it black so repairs are easy later on if/when you do get a chip thru the coating.

-

Anybody know if this steering wheel badge can be stripped with paint stripper without damaging the metal? It's some sort of nonmagnetic metal, like brass or nickel alloy. Its too heavy to be aluminum.

-

Duplicate

-

I used 3M seam sealer on my floor pans that I picked up on Amazon. Seemed to work well. It reminded me of thick caulk.

-

If you come up empty...you can also simply tap the hole with a 1" NPT tap and screw in a 1" NPT to hose barb fitting. Just stuff a rag in the cavity to prevent chips from falling in the block or pull the pan and vacuum out the chips.

-

I just checked out the POR-15 website. They are recommending that you apply the stuff over rust holes. It's shit marketing like that tends to steer me clear of them. The PO of my car painted over floor pan rust with POR "Rust Encapsulator." Guess what I found under the paint? More rust and pitting slowly eating away the floor pans... Anyway, I digress 🤪

-

So far I've had pretty good luck with the Upol zinc weld-thru primer. It seems to work better than the 3M stuff. I only use the stuff when I have lap joints. Originally planned to seam weld this panel without the lap joints but decided to make it look factory instead, so lap joints it is! Thanks for the heads up regarding the zinc fumes. I definitely will be wearing my respirator. What makes the POR-15 seam sealer so great? I'm very happy with the quality of the Klassic Fab panel. They are now my go-to source for panels. I saw on IG that they are working on full 240z quarter panels. They will be the ONLY supplier of full quarter panels besides NOS Nissan stuff which is impossible to find and extremely expensive when you do.

-

That's exactly what I plan to do! I actually pulled out my DMM today to verify that the weld thru primer is what it says it is - conducive primer. While I was at it I tested the Ospho. As I suspected, it's not conductive, but very thin - if you poke it with the tip of the probe, you get no resistance. The primer is conductive as advertised.

-

During my lunch break today I sanded off most of the hard coating Ospho left behind (since it's not conductive) Then prepped the surface with tack cloth and wax & grease remover, masked it, then finally painted it with Upol zinc weld through primer.

-

-

A musician's therapist (The $300 Z)

rossman replied to Zetsaz's topic in S30 Series - 240z, 260z, 280z

I purchased the bracket and compressor together, nothing else. -

A musician's therapist (The $300 Z)

rossman replied to Zetsaz's topic in S30 Series - 240z, 260z, 280z

That was Nostalgic AC not Vintage Air.😁 -

A musician's therapist (The $300 Z)

rossman replied to Zetsaz's topic in S30 Series - 240z, 260z, 280z

I didn't realize the VA made brackets for the mighty L6. Good to know though! Given your constraints seems it would make sense to just swap your turbo long block into your current NA setup. It's almost inevitable that something unforeseen will pop up when converting to turbo. -

Heavy Duty frame rails and connectors

rossman replied to toolman's topic in Gen III & IV Chevy V8Z Tech Board

Lookin' good! Those "stock" units never really worked well, especially by today's standards. The condenser relies on a drop in pressure between the fan and the condenser to pull air across it. As such, it won't work well if there are ANY air leaks (gaps, cracks, etc.) between the fan and condenser. Additionally the coil is an old school inefficient design AND parts are difficult if not impossible to find. Because of all that, I installed a Vintage Air Gen II Mini system and couldn't be happier with it. Anyway, just and FYI. I am sure Hawaii is at least as hot and humid as Houston so you will appreciate a strong air conditioner as much as I do. -

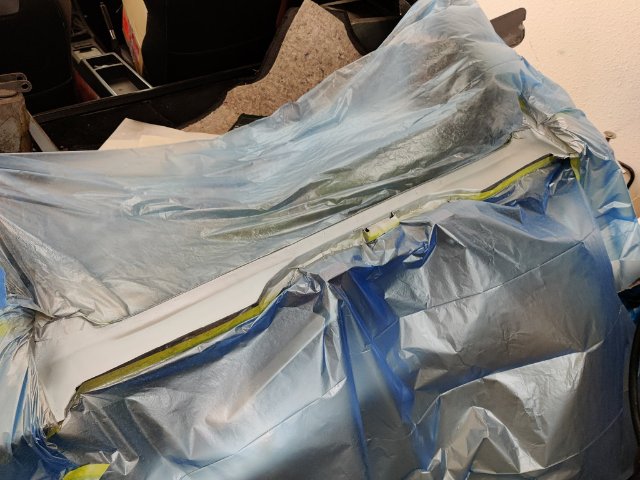

Spent a few hours working on the car today. I'm out of c25 so there was no welding today. The piece from Klassic Fab Vintage JDM arrived last week in like 3 days, shipped direct from Columbia South America. I'm honestly impressed with the quality of the panel and wouldn't hesitate to buy another panel from them. These guys are the real deal. Thanks again for the recommendation @AydinZ71! Here's a picture of the panel in place. It's pretty much a duplicate of the stock panel. The MSA panel by comparison is generally the right shape but the detail is lacking - like the two holes for the license plate light and seams that aren't quite right. I also spent some quality time laying in the hatch trying to get the seal gap correct, or at least close enough. I think I'm sweating the details of this work way too much for something that's going to be covered up - but I just can't let it go . Spent some time panel beating the weld distortion in the license plate area and grinding welds flush. Again, spending way too much time on something that will be rarely seen after I cover it all up.