-

Posts

658 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by AkumaNoZeta

-

Time Delay Wiper: Need Module Ideas

AkumaNoZeta replied to AkumaNoZeta's topic in S30 Series - 240z, 260z, 280z

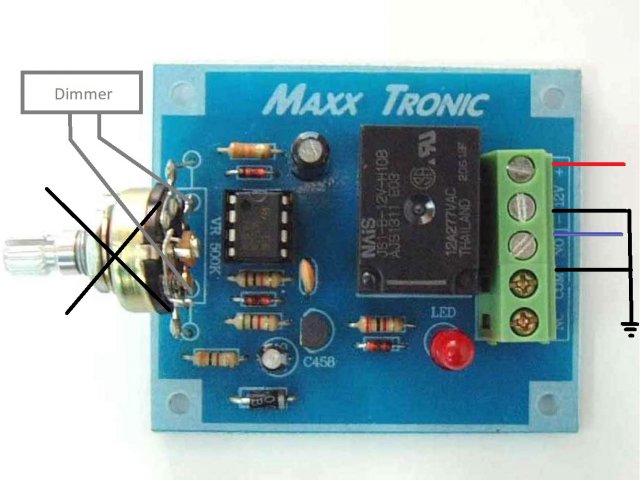

There's this one from Amazon https://www.amazon.com/12VDC-Windshield-Wiper-seconds-Assembled/dp/B07R4G5Q3P/ref=asc_df_B07R4G5Q3P/?tag=hyprod-20&linkCode=df0&hvadid=459552016478&hvpos=&hvnetw=g&hvrand=16009245967525828046&hvpone=&hvptwo=&hvqmt=&hvdev=c&hvdvcmdl=&hvlocint=&hvlocphy=9026036&hvtargid=pla-943048975422&psc=1 Would this modification of desoldering the potentiometer and attaching two wires work? Or my idea of how the wires should attach to the pins? -

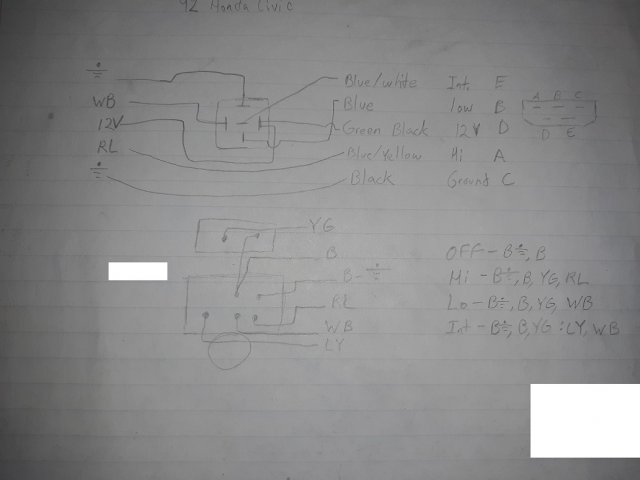

Ok, it's been ages since I posted anything and my car has been torn down for over a decade now, but last weekend I got a bug up my butt and spent the last week drawing out wiring diagrams for the chassis wiring of the entire car. I got everything done besides the wiper diagram and I have an idea, but having trouble finding ways to make it work. A little background on the car first. It's a 74' with factory intermittent wipers. I did the Honda motor swap back when I was driving it, but just as Lo/Hi because I was stupid and threw the wiper delay relay/module in the trash thinking "I don't need no stinking computer in this car." But I also messed up the wiring install, and being my only vehicle at the time I just quickly installed a push/pull headlight switch. Now when I go back together, I want to use the factory switch again. After ohming the switch in the different positions, I found making the Lo/Hi circuits would be easy. But I also felt I would be annoyed by having an empty "click" where the intermittent is supposed to be so I've been thinking about making it functional again. I have my results of the ohming in the attached diagram (wire colors are from the switch side of harness, if I remember correctly the harness side differed). Also, I never liked dimming my dash lights so I would also like to reuse the factory rheostat as the delay settings, which makes it harder for me to find a suitable aftermarket module/relay. I have played with the Honda motor and found that just ground the blue wire will make Lo work, and ground the blue/yellow for Hi, but I also tried something the blue/white but it got hot and I lost the park function when I tried through the 5 pin relay again, so I don't know if any further testing with the current motor is valid. Now, looking at how the switch ohmed out, it connects the blue/yellow and white/black circuits together in Int., but not through the ground circuit like the other settings. With the white/black being the one that's grounded in the switch for the Lo setting, I'm thinking that I need a module that will connect to the blue/yellow and time delay it to ground, which will essentially just periodically ground the Lo circuit. As mentioned earlier, I would like to be able to control the length of the time delay with the factory dash dimmer rheostat, which I believe is just 2 wires (the dash is stored in the attic so I haven't been able to confirm.) If this sounds right, does anybody know of any aftermarket module able to accomplish this? None of the ones I've seen fit my bill. I'm not afraid of attempting to solder up my own mother/daughterboard type thing either if someone can figure that part out. I'm not worried about having the washer motor on that circuit as having wipers that come on automatically while hitting the washer button has always annoyed me.

-

I like how that looks Litman. Almost makes me want to do twin tail pipes.

-

Drag racing suspension

AkumaNoZeta replied to walkerbk's topic in Brakes, Wheels, Suspension and Chassis

Here's a photo I found of the torque arm on a Miata. I can't attest to the effectiveness of it. The way I see it, no matter what the diff's behavior is going directly into the chassis itself so I can't see it doing much, not like with a live axle where the diff is a part of the suspension instead of the chassis. I would just use a RT mount to keep the nose of the diff stable. My car has been modified to use a Ford 8.8 and it's still a few years away from being able to test drive or anything, so I have nothing to back up my claims, just keep that in mind. haha. -

Drag racing suspension

AkumaNoZeta replied to walkerbk's topic in Brakes, Wheels, Suspension and Chassis

Don't the older Miatas do something like that? I want to say I've seen it when we had one on the hoist one time, but it may be a false memory. Here's my thinking on it though, when you have a torque arm on a live axle, the force goes directly to the tires. While on a IRS, the tires aren't ultimately bolted to the differential so it won't have same effect. Also, a shorter torque arm is supposed to give more anti-squat since it's closer to the neutral line so if that the case, and it did happen to work for IRS too, than a short nose diff would be more effective then adding a arm. I'm not really a drag racing fan myself, so I don't really know what you need to make IRS launch harder since you can really take advantage of the pinion climbing the ring gear. The only thing I can think of is keeping it stiff enough to limit squatting, and finding the proper camber angle to make sure the tires are flat to the ground when you apply power. Wheels and tires are a big part of it, everyone these days are running giant wheels with rubber bands. A smaller wheel with more sidewall gives a better contact patch and also a smoother ride. I used to have 17X9s with 275 cheap performance tires and I got sick of them so I traded for 16X8s with 245 mid-grade all season tires and the car performed better, spun the tires less, rode better, and didn't rub anymore. Like I said, I'm not a drag racer so somebody with more experience will hopefully chime in. -

I haven't done it myself or anything, but given that the car was produced in the days of larger margins of error, as well as gone through around 40 years of abuse, I wouldn't have expected it to be exactly "symmetrical". I would suggest just drawing it out on the panel, step back a few feet and see how it looks. Just keep re-drawing til it looks how you want. I feel when it comes to aesthetics, what your eyes see is more important than what the tape measure sees.

-

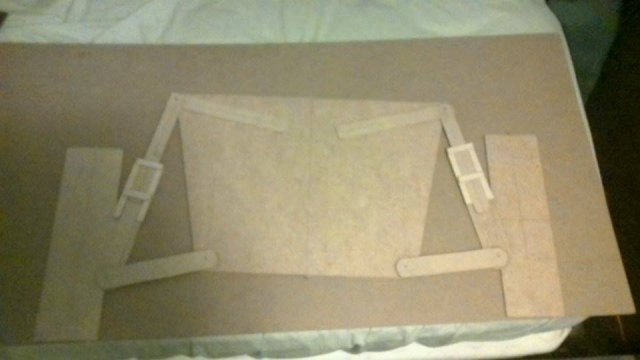

Thanks to 74_5.0L_Z's measurements I was able to get the pieces cut out. I took a couple photos of what I have so far. I'm going to do up the base piece with reference marks and use some white and black paint to get more contrast for photos. This was very fun to make and it's a joy to be able to move things by hand.

-

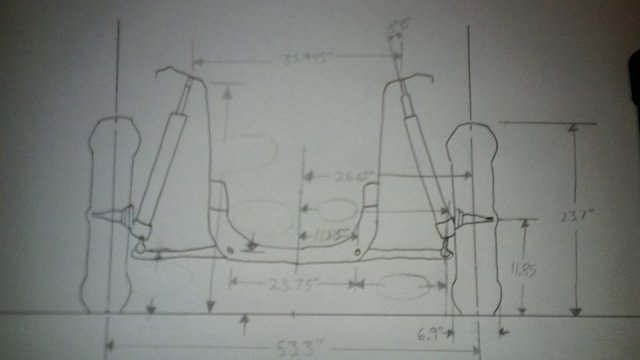

I'm in the process of making a 1/2 scale model of the front suspension of a stock S30. I got most of the measurements I need from the chassis diagrams that are still floating around the internet, luckily, but there's still quite a few I need. I have a crude drawing, I don't have a scanner so I used my computer's camera and flashlight to get the sharpest image I could. You can see what I have and don't have (I hope), based on a 175/70/14 tire. My car was so far gone in the beginning that I couldn't take measurements if I needed too, now there's nothing left of the factory set-up...so I hoping you all can help. I can still get the length of the lower control arm so don't worry about that one, I still have my arms lying around. So if you have a bone stock 240Z, with the 175/70/14 tires, unaltered ride height, and the time, will, and means to get me a couple numbers, it would be greatly appreciated. I'm going to design my own later on, but I want to have a factory model to compare it to and see how it behaves in bump, rebound, and roll. Of course when it's done I will post photos and everything here so everybody can learn from it.

-

Coolant overflow tank for 1972 240z

AkumaNoZeta replied to princejqman's topic in S30 Series - 240z, 260z, 280z

For my 5.0 Mustang I went to Oreilly's and got one of these https://oreillyauto.com/detail/dorman-help--4422/cooling---heating-16773/coolant-recovery-tank---universal-17482/coolant-recovery-kit/54002/4528645/1976/ford/mustang-ii It worked great with a triple pass radiator which I highly don't recommend. When I was driving my Z I simply used a Sobe bottle, back when they were glass. I put two holes in the cap, one with a rubber hose going almost to the bottom, and the other I left open as a vent. Never had a problem with it either. -

Getting back to it. Working on the Z again.

AkumaNoZeta replied to AkumaNoZeta's topic in Fabrication / Welding

Well, driver's side is almost done. Ran out of MIG wire so had to stop, coincidently I also ran out of cut-off wheels, needed some bigger drill bits, and also got me a pack of new tips for the welder. -

Thank you for sharing. I don't get on Youtube anymore and this is very entertaining and informative.

-

All of the vibration issues I've encountered were fixed with either u-joints or tires. Anything is possible. Shouldn't be hard to pop the back cover off and give it a visual. Just put a jack under it, take the mustache bar, and cover off. It's been a LONG time since I've seen an unmodified set-up so I can't remember if there's anything else in the way.

-

Clean car, but the title threw me off. I was expecting some 32' hot rods or someone found a picture of a Z on 32" rims. Haha

-

Like RonA, I'd be afraid that the oil pan will be scraping the ground while the valve cover is flush with the roof. The Z has a long nose and I don't think length would be as big of an issue. I remember someone was putting a GM Vortec 6 cylinder (forget what it's called now) into a S30 and if I remember right it stuck way above the hood and the oil pan was below the crossmember.

-

I'm a big Toyota fan so I'm voting for the 4Runner. I don't have first hand experience like JHM, but when I worked for a shop we would never see any Toyotas or Nissans come in except for oil changes, brakes, and belt replacements. Had to do wheel bearings once, and it had 300,000 miles on it. That's why I broke down and bought myself a 15' Tacoma. I was driving a 1990 Mustang/1986 Capri hybrid before hand, and I just worked on so many Fords that I couldn't bare looking at them anymore. As for the low torque, there oughta be supercharger options out there, they make those kits for everything these days. On a side note, I love Toyota enough to throw a 7M-GE in my Z.

-

Performance/Modern cooling system in old cars

AkumaNoZeta replied to corey_49's topic in Cooling Systems

I'm a big fan of electric fans, mainly because I don't like how mechanical fans make the car sound like a giant vacuum cleaner. I've never met anyone brave enough to use an electric fan on anything that racks up a lot of street miles, except for I believe GM used them on some LT1s from the factory. My biggest concern is parts availability. I like the peace of mind that if the car is broken down a few hundred miles from home, I can get parts at any parts store, though I may have to spend a night there (been there, done that.) I also prefer 2-row, cross-flow radiators with the extra wide core tubing. And like Seattlejester said, electrical loads play a load. It's been a while since I've used a stock alternator, it's only like 40 Amps isn't it? -

True, but if your S30 is like mine, it has stainless steel drip rails that just clip onto the end of the mild steel roof. And on my car, that was pretty much the only spots not rusted out, haha. I think it would be fine if it the area is painted, and I would use some RTV between the surfaces to seal them from moisture better.

-

It appears that the cheaper one only comes in stainless steel, I would only bolt that one in since it's not proper to weld mild steel to stainless steel. The more expensive one can be bought in mild steel so it can actually be welded in easily. Those won't fix the rust hole in the sheet metal underneath it though.

-

I know what you mean. I like the gunmetal gray idea but I've known people to paint them white to make leaks easier to spot and I've always played with the idea of gold so I can tell people "She's got a heart of gold." I've seen metallic blue engines that really pop as well. Black is just...'eh'...

-

Getting back to it. Working on the Z again.

AkumaNoZeta replied to AkumaNoZeta's topic in Fabrication / Welding

Probably the same thing my old co-worker did when he couldn't get the clutch fan off a Dodge pick-up that was left hand thread, mess with it for an hour and then ask me for help. I tried to show him that you can tell which way to go by looking at what side of the belt the pulley is laying on, not sure if it stuck with him though. -

Getting back to it. Working on the Z again.

AkumaNoZeta replied to AkumaNoZeta's topic in Fabrication / Welding

I used to sit in the car and act like I'm driving all the time, but it makes it hard to do when there's no seats, steering wheel, or pedals left in it, not to mention the fact that it's essentially standing on it's side. I absolutely agree with the Idiocracy thing. I won't be surprised if I hear people start watering their gardens with Gatorade and wonder why nothing is growing. And the way cars are going, I don't think mechanics will be getting doctor wages, but instead the mechanics will probably be replaced by electrical engineers and computer geeks. No one is going to know "lefty loosey, righty tighty" anymore and they'll have to use power ratchets with two buttons, one labeled "In" for tightening and the other labeled "Out" for loosening. -

Getting back to it. Working on the Z again.

AkumaNoZeta replied to AkumaNoZeta's topic in Fabrication / Welding

Got some more done. When I had the idea to make these strips to reinforce and beautify the floor joints, I didn't realize it would be this much work and take so much time. I love how it looks even though it may be nothing more then excess weight. I'm going to do inch long beads spaced out to finish welding it up, then it's off to the driver's side which should be a LOT easier since it doesn't have the exhaust clearance made into it. When that's done, I'm going to start focusing on the front suspension. -

Even if all aftermarket parts were perfect, after 40 years of use and abuse, and rust, every car is going to be different too. I agree, do what needs to be done to get the angle of the dangle. Unwanted vibrations suck to have.

-

Front brakes keep glazing and make noise

AkumaNoZeta replied to JTCN's topic in Brakes, Wheels, Suspension and Chassis

We had the same exact noise problem when we installed new pads on the 10/74' 260Z. When we removed them and looked at them, they had some shiny silver spots in it. Rotors were freshly turned so I think some steel or something might have been accidently poured into the pad material. We replaced them with another set of new ones, same brand and everything, but this time they didn't have the silver spots and were noise free. I should add that the shop I used to work for always used the cheapest parts available, including pads, so that didn't help. One of the reasons why I quit. -

Idea for front knuckles.

AkumaNoZeta replied to AkumaNoZeta's topic in Brakes, Wheels, Suspension and Chassis

Here's a crude drawing I did. The scale is as accurate as what 20 minutes of eyeballing can be, but it gets the idea across. It's only a thinking exercise at the moment so no need to take actual measurements yet. The idea is with a S30 knuckle with a welded on pedestal for a 3/4" stud to use a 3" Johnny Joint and then another extension welded on the top for bolt-on struts. Of course it throws the spindle out more, but should allow more backspacing. Theoretically, the top extension can be made to put the KIA wherever you want, bottom one too I guess but you don't want to make the control arm shorter than necessary. Scrub radius will depend on tire height, KIA, and wheel offset. Moving the ball joint inwards like that I think would give you more room to play with Ackerman, and separating it from the ball joint makes it easier.