djwarner

Members-

Posts

111 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by djwarner

-

Planning on a 2012 Chevy LFX engine transplant-need help

djwarner replied to djwarner's topic in Other Engines

Hi Dennis, The OEM BCM anti theft system is horrendous cannot be defeated without the GM hardware. I found a third party BCM replacement because the firmware in the TCM only recognized the Paddle Inputs that came through the GMLAN. I had also hoped to get the GM cruise control working but the design of the BCM was originally designed for LS engines. It does have the charging control you are looking for. http://oecontrols.com/ Bob Valentine there can give you the details. As for the AC Compressor, I mounted a small Sanden compressor where the OEM PS pump was located. I had room to mount the PS pump below it. Had to design a bracket that mounted on the front of the crankcase. I got away with the smaller compressor because the cabin of the Miata was so small. I made samples out of hardwood before having a local machine shop cutting one out of 1" aluminum plate. Of course I ran into problems clearing the steering rack with the first attempt and had them make version 2.0. The problem with using a local machine shop is that one off pieces have zero priority and long delays for production work extended my build time. If I were to do it again, I would use two pieces of 1/2" aluminum plate. I did have to get a slightly longer drive belt to adjust for the changed locations. The Helmholtz exhaust system was designed to fit on a 350Z. At lower rpms it is fairly quite. At 2000 RPM and above, it pretty much sounds like a straight pipe. I would caution to keep the X pipe or H pipe in the exhaust. -

Planning on a 2012 Chevy LFX engine transplant-need help

djwarner replied to djwarner's topic in Other Engines

Nice Work 67LS1, You must have some unique experience and knowledge. As for my project, after not finding a suitable roller Zcar and considering the modern design features of a Miata such as airbags and antilock brakes, etc, I decided to swap the LFX/6L50 into a 2011 NC Miata Touring edition. While others had swapped in LFXs with 6sp MT for racing, I decided I wanted a true daily driver with functioning AC, antilock brakes, power steering and a full functioning instrument panel. My swap was the first 6L50 swap into a Miata. As such, the project took 13 months to get back on the road. Another 12 months to refine the project - get the paddle shifters to work and tuning the engine and transmission. I've put some 6000+ miles on the car since the swap, driving it daily. The 2 major issues in the swap was relocating the AC compressor and power steering pump with a custom bracket, and learning enough of the wiring harness and GMLAN system to integrate into the Mazda electrics and CANBUS. Very little body work was required. Back then there were no 3rd party wiring harnesses or other kits to support the swap. I named my car GRIFFIN, a chimera, half lion and half eagle. With larger intakes and exhausts and tuning, I am putting something over 300 hp at the wheels. Torque scheduling at low rpms has proved to be something of a problem as anything approaching available torque below 2800 rpm results in unintended burnouts. Fortunately, the LFX engine management system is based on a virtual torque model (actually a 6 dimensional table predicting available torque at various operating regimes). Manipulating this table tells the ECU at low rpms, that actual torque available is lower than what the engine can actually produce. Once the virtual torque value is achieved, the drive by wire throttle closes somewhat to maintain what the model says. As the rpm climbs or a higher gear is selected, higher torque limits allow for full throttle operation. Someone asked me about gas mileage and I honestly had to admit I can't stay off the gas long enough to get a good estimate. Even with thrashing it, I do get 25MPG on premium. Smiles per mile has yet to be determined. 0-60 times are sub 5 seconds. I haven't taken it to the drag strip yet. -

Haven't seen this posted but worth a look.

-

These moldings are still available from CustomAutoTrim.com But they are expensive.

-

Saturn Electric Power Steering In A Datsun 280Z

djwarner replied to socorob's topic in Fabrication / Welding

I have a Saturn electric power steering unit and the electronic interface available for anyone who would like to do this conversion. I was going to use this on a Miata engine swap, but decided to engineer a new engine bracket and retain the hydraulic PS system. PM if interested. -

Silver is a non-color, and the original Datsun blue/green being darker is almost a negative color. Some of the prettiest engines I've seen on this forum are lipstick red accented with the natural aluminum color on the raised letters and ribs on the valve cover.

-

The oil pressure sensors available today are designed to work with gauges and/or idiot lights. When the oil pressure is above 8 psi or so, the sensor connects a potentiometer and reads a resistance. This resistor is in series with the meter in the gauge. As the resistor varies, the meter varies. When pressure is below 8 psi, the sensor disconnects the potentiometer leaving an open circuit. For idiot lights this forces all the electric current to flow through the bulb, lighting it. For gauges an open circuit causes zero current flow and the spring in the meter forces the needle to the left extreme position, just as it does when the ignition is turned off. The oil in our early Z engines gets thin when the engine is hot as when driving at highway speeds. Idling after pulling up to a stop sign after a highway speed drive will often have oil pressure below the 8 psi limit. The pressure will increase once the revs go above idle. I was told by an old timer not to worry about it. Its a gauging problem, not an engine problem.

-

Cursive Handwriting - What name is this?

djwarner replied to ~KnuckleDuster~'s topic in Non Tech Board

Not a final answer, but interesting: http://www.moonzstuff.com/articles/oldhandwriting.html My vote is for "Lieut". Name spellings and abbreviations were far less standardized back then. -

BTW the link you posted tried to hijack my browser. Don't click on the link.

-

There is a minimum warm coolant temperature you should strive for - 185 degrees F. Due to radiational cooling overnight, water vapor can condense in the interior walls of the engine. And despite common knowledge, oil and water can mix to a slight degree. Oil can absorb up 1% water by volume. This water can drastically reduce oil lubricating ability and must be removed. Raising the temperature to 185 degrees is high enough to drive off the water.

-

I use Grundy after Hagerty said I drove the car too much. Been happy with Grundy and also use them to cover my daily drivers at a very competitive rate. I saw an TV ad recently where Hagerty says they no longer restrict mileage. This maybe why your rates jumped so much this renewal. One difference with Grundy is that they write stated value policies for many cars when they identify them as future collectibles. My wife bought a 2 year old Camaro Convertible a couple of years ago. They came up with a stated value higher than what she paid for it. When it got totaled 6 weeks later (not at fault), Grundy ( through AIG) sent us a check no questions asked. Said they would go after the at fault driver's insurance.

-

CAN BUS question for the Gurus out there

djwarner replied to djwarner's topic in Gen III & IV Chevy V8Z Tech Board

Fitting for as simple a vehicle as a Miata, the CAN BUS is a fairly simple single high speed bus. Since my transplant vehicle does not have Dynamic Stability Control or Advanced Key Locks, The only control modules are: the Engine Control, Transmission Control, Instrument Cluster, ABS Brake Control and Hard Top Control. The Instrument Cluster receives Vehicle Speed, RPM, Engine Coolant Temp, Odometer, Fuel Injection Amount from the ECU. It Receives Transmssion Gear Selection info from the TCU. It also receives indicator status for MIL, Generator Warning, Cruise Control Status, Brake System Warning, ABS Warning, Power Retractable Hard Top Warning, AT Malfunction Warning, It outputs Fuel Level to the ECU. It exchanges Immobilizer signals with the ECU. -

CAN BUS question for the Gurus out there

djwarner replied to djwarner's topic in Gen III & IV Chevy V8Z Tech Board

The only physical connections required are a CAN BUS High, CAN BUS Low, CAN BUS Ground. The voltages on the CAN BUS are all standardized. -

For those familiar with the J1979 standard. I am transplanting a 2012 Chevy LFX engine into a 2011 Miata. (could find a reasonable Z transplant candidate). Since I have a post 2008 CAN BUS devices, I am wondering if I could connect the ECU CAN BUS signals into the Mazda CAN BUS to drive the instrument cluster? From what I know about CAN BUS the basic performance parameters are polled using a standard prefix and a standard bus protocol. Other manufacturer specific data points would not be polled, but they shouldn't be needed to run the instrument cluster gauges. There would be several advantages in using the Mazda Cluster rather than replacing it with Speed Hut CAN BUS gauges. Besides limited space available in the Miata, there are some 12 indicator lights for non engine functions that would have to be replaced with the Speed Hut Gauge package. The Camaro gauges can't be used because the Body Control Module converts the high speed bus from the ECU into a medium speed bus that feeds the Instrument Clusters. The Miata however, drives the instrument cluster directly from the CAN BUS. How feasible is this?

-

It looks like some bezel rings are in your future. Good job otherwise. I found an unusual source for 2 1/16" bezel rings. Holley Carbs now sells instruments for their EFI setups and includes a variety of black and Chrome rings. My hub ring option is cheaper though.

-

Planning on a 2012 Chevy LFX engine transplant-need help

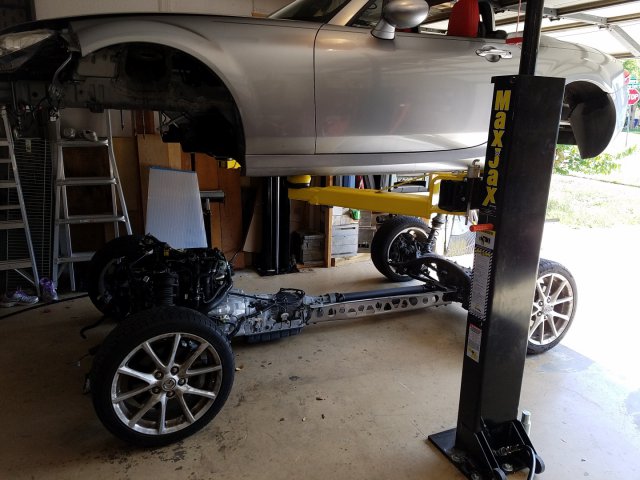

djwarner replied to djwarner's topic in Other Engines

I've gotten the Z up on a lift to check mounting options for the LFX/6L50 combo. Doing this to help others who might want to go this route as well as keeping my options open. The tranny mount points look strong and would be a good starting point to lay out an installation. Because the LFX is shorter and has a different mount position than the L24, using the tranny mount points would put the LFX engine mounts about 5 3/4 inches aft of the center on the Datsun engine mount towers. This suggests using a cradle mounted across the front rails. It would require removing the Datsun towers to provide clearance for the alternator and AC compressor, but otherwise everything else fits quite nicely. Does anyone see a problem mounting the cradle across the top of the rails rather than underneath like the front cross member? Would you need to re-enforce the rails because you are now loading and extra 150 lbs per side? Comments welcome. -

Planning on a 2012 Chevy LFX engine transplant-need help

djwarner replied to djwarner's topic in Other Engines

I've been frustrated looking for a candidate Z to receive my LFX/6L50 with the added technical problem of devising an engine mount. Just about any local candidate is extremely rough and/or missing tons of serviceable interior components. This doesn't even mention the price being asked for rolling shells. Considering what hybrid Z's are going for these days, it's getting hard to make any economic sense. While looking for mounts I've found a company that makes one to fit the LFX into the Miata who might be willing to design/fabricate one for the Z. Frustrated in finding a serviceable Z, I've begun looking at a Miata candidate. Being readily available, I find they are also have similar weight and wheel track to the Z. Also they offer antilock brakes, air bags, etc. So before taking to the dark side, I'm putting out the call for anyone with a serviceable Z that they would like to see living a happier, longer life. Obviously, price would be dependent on completeness and condition. I'm not a sheet metal worker. Engine and transmission condition is obviously not important as they will be replaced . Please PM with candidates, otherwise your comments on the Miata would be welcome in this thread. -

Where would you mount the knock sensor on an L24?

-

Planning on a 2012 Chevy LFX engine transplant-need help

djwarner replied to djwarner's topic in Other Engines

Xnke, Thanks for the heads up. I will have to take a serious look at it once we get it on a lift to remove the engine. My wife was a actually doing at least 35 MPH and coasting when she was hit. the passenger rear tire was moved 4 inches forward compared to the driver's side, so the possibility is there. Doing some rough measurements before pulling the engine, it looks like the engine/tranny combo may be too short to put the Camaro mounts on the front cross brace and have the tranny mount reach the fire wall. The block of the LFX is only 17 inches compared to the 28" on the L24. Distance from the LFX engine mount to the tranny output shaft is 20 inches while the mount to the firewall is almost 21 inches. -

Planning on a 2012 Chevy LFX engine transplant-need help

djwarner replied to djwarner's topic in Other Engines

Thanks for the link NewZed. I am a little limited in the accuracy of my measurements because I haven't pulled the engine yet. But the block appears to be about 16 inches compared to the 28 inches of the L24. In fact, interpolating from the photos, the transmission appears rather short, measuring some 20 inches from the engine mount to the output flange. On the Z this compares to approximately 21 inches from the center of the engine mount to the fire wall. This surprised me until I realized the Datsun AT has a long tail cone added to it. It looks like I might have to position the engine further aft of the engine mounts to secure the transmission mount plate. I will know more once I get the engine/tranny pulled. -

A year ago my wife's 2012 Camaro with 21K miles was totaled in a rear end collision by a box truck. While rear was severely damaged, the engine compartment remained intact. Earlier this month, the car came up for salvage auction and knowing the engine condition, I bid and won the auction. The stock LFX engine produces 323 HP and only weighs the same as my L24. the 6 speed AT weighs about a 100 lbs more than a Datsun AT but is located near the center of mass so it shouldn't make much difference. Interestingly, the engine has exhaust manifolds cast into the heads and makes a neat 21" wide package. I have a source for modifying the engine wire harness, and plan on using Speed Hut CAN Bus gauges. But I have a couple technical questions to answer, namely engine and transmission mounts and drive shaft. The engine mounts on the LFX is cast aluminum and sits on thick rubber pucks. The pucks are oriented vertically. I imagine the aluminum castings can be removed and replaced with fabricated mounts mating to the existing cross member mounts. But I've been wondering if any LS mounts might be a good candidate? I know the crank shaft on my L24 tilts down some 3 degrees at the rear of the engine and this aligns the drive shaft with the differential. The MYB AT from the Camaro uses a rubber flex plate to couple to a 2 piece drive shaft, Since the Datsun AT has a spline joint to accommodate any length variation as the rear suspension is exercised, what is the appropriate drive shaft design for this transmission. Third question is about the power steering pump. Since it is an integral part of the serpentine belt, I was anticipating leaving it there and running a hose from the outlet back to the inlet. Any other suggestions?

-

No idea what this knob does...Anyone?

djwarner replied to M.Bonanni's topic in S30 Series - 240z, 260z, 280z

Definitely a thermostat. -

Mack is correct. The area of the opening when the valve is depressed in the shape of a cylinder. The area is equal to the lift times pi times the diameter. The increase in cylindrical area would be equal to 44/42 or 104.7%. The smaller valve can easily be compensated for by a slightly higher lift.

-

Great point Bob. I happen to have two sets sitting on my desk. They were installed in the map light and overhead light until I replaced them with COB lights.

- 4 replies

-

- LED

- LED Glove Compartment

-

(and 2 more)

Tagged with:

-

Does it stumble during the rev up or when you let your foot off the accelerator? Earlier you mentioned the vacuum advance was kaput. Its prime function is to advance the timing when you let off the accelerator with the engine still reving and high vacuum created when you close the throttle.

- 10 replies