Dkyle

Members-

Posts

34 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Dkyle

-

or.. did you want to send just the sketch?

-

looks good.. i see that the gray one would be much less sanding. i'll take it. how much? i trust ABS is paintable? you could play around with the sketch a bit and try making a "quarter" size inset about 2mm deep or so that an emblem of some sort could be glued in. But.. i don't have anything now.. i would be happy with what you got. Maybe later you could make a custom one that an emblem could snap in.

-

I am encountering contrasting opinions on where the vacuum advance should be connected to while wrestling with getting my 280Z NA tuned correctly. http://datsunzgarage.com/engine/index.htm states.."For the vacuum advance dashpot to work properly it needs to be connected to a "manifold vacuum" inlet as opposed to a "port vacuum" type". Others, including the shop that will put my car on the Dyno this Saturday says it should be ported vacuum. I've been running it disconnected for now, set the ignition timing at 14deg with total timing around 30deg. While it accelerates OK, I'm trying to fix the "stumbling problem that the engine has at rpms lower than 2500. So.. that problem aside.. why is their a difference of opinion on where to get the vacuum advance? What is the consensus here?

-

280Z conversion to NA - stock Fuel Pump Safety Circuit

Dkyle replied to Dkyle's topic in Ignition and Electrical

Did you employ the "inertia switch" ? That circuit would appear to have 2 safety components. Inertia switch normally closed until it receives a "whack", or there is no oil pressure. I'm confused with the "Oil Press Switch"; is it used to trigger the relay when starting or when there is oil pressure? and.. if it works for you.. there must be sufficient oil pressure to activate the switch that, in turn, activates the relay as soon as the engine starts. -

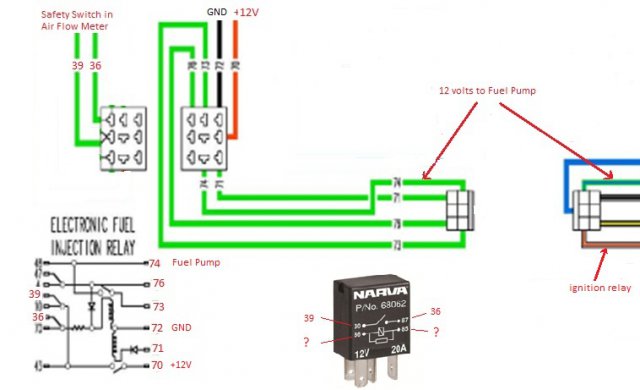

I have a 1977 280Z that the engine was replaced & converted to SU carbs. I have kept the stock Fuel Pump, and it runs to a Holley FPR & back to the Tank with a back pressure line of 4psi when it runs. I have separated out the EFI/Fuel Pump relay connectors from the EFI Harness and reconnected them back up to the relays. The picture shows the current configuration. I have a toggle switch now where the lines were to the safety switch that was in the Air Flow meter. The pump now runs when the ignition is on "Start" & when the ignition is "ON" if i connect "39" to "36". I should put in a safety circuit, but don't know how. I assume I can buy a relay like the one in the picture.. & I assume I would connect lines marked "39" & "36" (that is now on a toggle switch) to the relay's pin 30 & 87. What do i use as a signal to make the relay switch on? A +12V signal when the engine is running.. right? Either from the coil, distributor or alternator? In other words.. what do i connect to the relay's pin 86 & pin 85? ..or is there a better way to utilize what exist as a safety circuit.

-

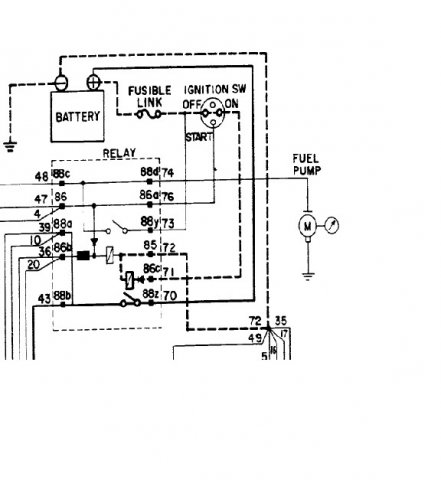

yes, I have the UniSync; I'm much more confident with the carbs. I had the engine running about 2000 rpm and it was firing at about 30 deg BTDC. I'll have to look into that also, but now the dist is mounted all the way counterclockwise. Advanced as far as it goes. I would like to use the fuel delivery i have now; stock pump and the FPR. In the picture, the line to the right feeds the carbs at 4psi. The line to the left is where the pump is feeding in, & the center line returns the fuel to the tank. My problem now is that I have to manual switch 12 volts to the pump because i removed the EFI harness. I would like to use a relay & an appropriate signal to activate it. Here is a schematic of the existing EFI relay.. I would think (with utter lack of knowledge) that I could connect the pump to #74 & +12 volts to #73. Would then a signal on #72 & #76 activate the relay causing the pump to run? And where would that come from? It doesn't have to be from the ignition switch.. right? I should replace the ignition switch, replace my button setup i used as a workaround & get back to "normal". It will still leave me with having to manually turn the pump on before starting the engine.

-

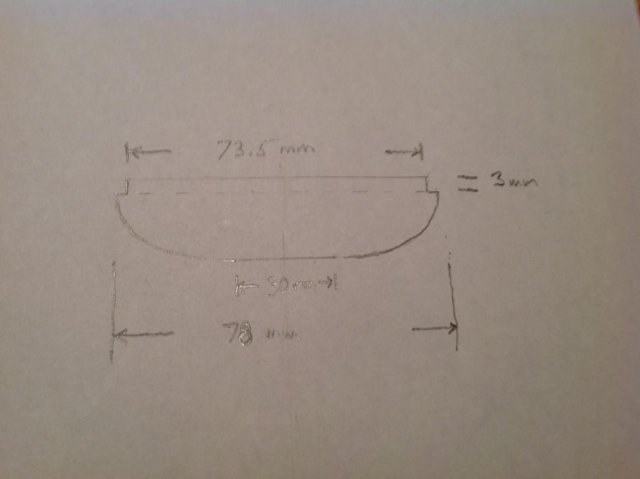

2mm thick.. ABS. Should be sufficient. The overall height (or depth, from the perspective of looking at it installed) should be 25mm. At that depth, with 2mm material thickness, the 30mm "flat spot" measured from outside, it be enough room inside to clear the nut.

-

Update: I have the oil/dist. spindle 180 deg. off. I thought I was careful about that notch, i must have missed it when i pulled it to prime the pump. So now my #1 plug wire is 180 deg. off from everybody else. The car started right up with my set of toggle switch/buttons I have to use in lieu of an ignition switch. Fuel pump does not run; with or without the EFI harness. The harness is removed completely, & the fuel pump is running directly off the battery. I have a guage on the line to the carbs; it does maintain 4psi. Back carb is sucking more air than the front one.. another issue to work one. I'll get a new ignition switch. I would like to know how others maintain the stock pump & use a regulator.. what circuit do they use? While I'm at it.. Does anybody have a schematic they use to bypass the ignition switch?

-

I don't know why I stated "5 volts", must've had Arduino on my mind. It's 12 volts at the postive lead of the coil with it disconnected, 0 volts on the negative lead. With the terminals attached, both measure 12 volts. No voltage to solenoid. My biggest fault is that I don't know what is suppose to happen, other than turn over and start when key is turned. I find it physically difficult to measure at the switch. I did bypass the switch & was able to get it turn over, it backfires a bit.. but not a lot. Gas appears to be getting into the cylinders. I am going to get a new switch. I had the EFI harness removed completely & found that the fuel pump was NOT running when cranking. When i installed the harness, battery connection, & the relays, & the white connector with all but one green wires, the fuel pump was pumping while cranking. Another issue I need to understand. I'm now concerned if the timing is way off. It seems way too advanced. I show that the gear is in the right position at TDC. But it seems the rotor is too far forward. The line on the green tape is the center of #1 plug wire. This may explain the backfiring? Is it firing too soon? Don't how I could adjust any further than it is. So, there it is.. multiple problems.. & still lack understanding of how that relay circuit of the EFI harness plays.

-

I did nothing to affect the switch. Just know that I got a "kick" from the starter bypassing it. Manual transmission. I do have +5 volts at the positive lead to the coil with the key in the "on" position. With the coil hooked up it measures +5 volts at both coil terminals. Did i miss a grounding terminal somewhere when replacing the engine? There is a short black heavy wire that is in the bundle that connects to ballast resistor; it is open ended, only about a foot in length. I assumed that it was grounding a component on the EFI. Still looking for an answer on whether the pictured EFI harness can be removed completely, or whether I need that part of the circuit that goes from the battery to the relays & connector under driver side dash. I get the +5 volts at the coil (key at "on") with that circuit both connected & disconnected.

-

This iPad allows me to attach a file. The PC at work was giving errors.. I should start again.. I removed the EFI harness (attached pic). When I tried to start the car, it would just make "click" sound coming from under the passenger side dash. I'm assuming that is the ignition relay. I then installed the harness, connecting the 2 leads to the battery (the line going down & off the picture) and the 3 connectors at top of picture; black & white ones going to the relay under the driver side dash and the other white one that seems to connect to the coil, ignition relay, starter, etc. It seems that i will have to extract that set of wires from the EFI harness. But.. It still behaves the same when I try to start it.. just a click coming from under passenger side dash. I pulled the plug from the ignition switch and connected across terminals 14, 18, 16, & 15 & the starter moved, gave a " kick". My shaky handheld jumper wires allowed only that, did not pursue it any further. That is why I am now considering a circuit to bypass the switch altogether. I don't trust the switch. I did have a problem moving the key off the "Lock" position. And the key seems quite loose inside the cylinder; seems like it could just fall out while in the "On" position. I may be able to hook up a meter up to the coil & starter to read it while turning the key before I proceed. I was also asking, in the beginning, what others have done when replacing the EFI with SU carbs. I have only read that you remove the EFI harness entirely, but it appears that the EFI harness is just part of a bigger harness. And there seems to be hardwired connections between the 2. It's not intuitive, or straightforward how one separates the 2.

-

-

think "cap that covers the front wheel bearing nut"

-

looking at the '77 wiring diagram i find at http://atlanticz.ca/zclub/techtips/electrical.htm.. I need to restore the power to the EFI relay (&/or fuel pump relay?) and the connector that connects to coil via ballast resistor, ignition relay, the fuel pump, & starter. I still have the problem; looking at bypassing the ignition switch now. Any suggestions? seems a will need a couple of toggle switchs in series, then a momentary switch across the connections to the starter and the center of the ballast resistor. A toggle switch across 14 and 16, then that connected to toggle switch across to 10. Then a momentary switch across 18 & 16 (damn! I still can't paste, or attach a pic in a post)

-

i have reconnected the power to the white connector, plugged the other 2 connectors, all under the driver side dash. that was part of the efi harness i initially removed. That appears to be the EFI Relay; though elsewhere in documentation i see it is 2 relays, inc. a fuel pump relay. i connected the other white connector that connects to the coil, fuel pump, ignition relay, fusible links, etc. Lots of green wires there. it still behaves the same.. one click in a relay under passenger side dash. ignition relay? It's confusing (not the least because of my ignorance on the whole subect of wiring a car) to read ".. remove the EFI harness entirely, don't need it", & yet that wiring that comes directly off the battery to the relays seems necessary & all wrapped up in the EFI harness. BTW.. i will look into another setup for a fuel pump. i did run the pump seperately to fill the carbs.. successfully. The carbs get fed from The FPR on a 3.5 psi back pressure side. installing a low pressure pump is another wiring job i'm not famaliar with.

-

it appears i do not know how to upload, or attach pictures.. either.

-

I have '77 280Z that was running OK until Head Gasket blew. I then removed engine and the EFI harness & installed new engine with SU carbs. I kept the fuel pump & installed a Holley FPR. With the the EFI harness removed (inc. the power connections to the relays removed) I tried to start the engine and it does not turn over. It just clicks at some relay under the passenger side dash. Starter works ok; i jumped the connection to solenoid with screwdriver with the key in "on" and it turns over ok, but no spark, and fuel pump NOT working. I connected the power leads of the EFI harness back up to the relays & connector under the driver side dash; the fusible links are good; still won't turn over, just clicks at some relay under the passenger side dash. What am I missing? Here is a picture showing the 3 connectors i hooked back up, A,B & C

-

i tried to PM Pharaohabq; I see he has offered his services, but i get an error. I'll try my hand a "Sketchup", maybe "Blender", something that is free.. but I don't have access to a printer.

-

3D printing a 240z steering wheel center cap?

Dkyle replied to Dkyle's topic in S30 Series - 240z, 260z, 280z

thanks, I did check that post out. I tried to send "Pharaohabq" a PM, but received an error that he cannot receive new messages. -

I posted a request for a 3D ABS print of center cap that would fit a 240Z steering wheel.. & then I found this post. Is that feasible? already done & available?

-

I like the 240Z steering wheel on my 280Z (a car that has parts from 1972 to 1983).. & I like the clean look of not having the Horn Pad (which I don't have, & don't want to fix the '77 version to it). However, I wish I had a center cap to cover the bolt. Does anybody have a 3D printer capable of printing an ABS "cap" that would fit snugly inside the center of the steering wheel?

-

Does anybody know if the 38mm air horns touted here.. http://datsunzgarage.com/catalog/z.htm is available anywhere? The site has no contact info & the phone listed for DatsunZgarage is "out of service". It seems like an old outdated site, though it did state "..still have several pairs in stock but I'm not selling them until I find time later in 2015."

-

i have the longer bolt. the $5 washer is 8mm thick.. thick enough.. onward & upward.. thanks

-

my advice is to call Dave Rebello, http://www.rebelloracing.com/ Give him what you have, what you want, & he'll come up with a regrind plus the right lash pads at good price.

-

i read the "Cracked Crank Pulley.." post of 2010; now I'm worried. I suspect the $11 washer is one that is "stepped", & one that I should not use. I have 25mm of crankshaft snout, measured from the end to the pump/dist. gear. The pulley measures 26 mm thick. The crank bolt seems to start bottoming out with 4.5 mm gap from the end of the crank to to the bolthead. So, it would seem that i need a washer that is at least 4 mm thick to get 110 lbs pressure applied all the way through to the chain gear. I'll include the $5 washer with my order, & compare that with the KA24 that i can find.