-

Posts

62 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by supershanesta

-

-

I purchased the MS3 for my car and soldered it by hand. I have soldered in the past and thought I would save some money. I would actually advise against it personally. It look hours and I had to recheck my work multiple times because it was not working properly by using their ms testing unit https://www.diyautotune.com/product/jimstim-v1-5-megasquirt-stimulator-w-wheel-unassembled/. I would get the testing unit unassembled to have fun soldering.

In terms of wiring it up, there is so much documentation here to help. I also paid someone on this forum to tune the care after I got it running. Lots of some things you will have to think about.

Was a long process but boy did it feel great to have it running. -

I was just pulling my 240z out of the driveway and it died. I originally thought I might be low on gas but it turns out I am not getting spark. I connected my computer and it senses rpm. I can test the injectors and even hear the clicking in the cabin when doing a spark test but it's not creating a spark on the distributor.Do you have steps I could follow with a multimeter to figure out the exact issue?MS2 3.0 L28et. Single coil to stock distributor setup.Thanks,Shane

-

On 7/9/2019 at 10:03 AM, LS130 said:

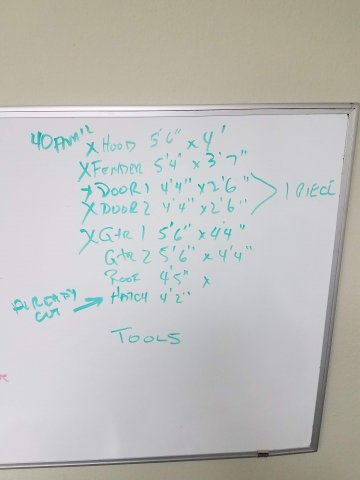

This may have sealed the deal for me wrapping mine. Just curious, what tools did you use for sanding? I will probably end up buying whatever you used.

I used harbor freight Sanders and a hand block kit. Very very important. Used the electric stuff to get the over Bondo off than used hand to finish it up

-

-

3 hours ago, toolman said:

If you interested in repair the hatch repair, go to V8 Z forum-GenIV-Heavy Duty Frame section, there are photos of the hatch repair. Hope to finish

it by this weekend. Hope this helps you.

Thanks I will definitely take a look!

-

2 hours ago, rturbo 930 said:

Dude, that's a terrible goal. Do the job properly, or don't bother. If you can't afford to do it properly now, wire wheel the rust, and treat it with naval jelly to stop it. That will at least buy you some time.

Shit but effective means that the welds dont look pretty but it effectively shields from water and rust. It is non structural and hidden. If the weld is solid, grinded flat, and painted you would never tell the difference. It can be done properly with patience. Which I have. I will post pictures after.

Thanks,

Shane

-

On 5/26/2018 at 3:26 PM, grannyknot said:

Don't buy a HF welder, you will regret it, they are garbage. Learning to Mig is pretty easy on a good machine. If you can find a used Miller or Lincoln that would be ideal and after the car is repaired if you find you are not using it you will get every cent back when you sell it on Craigs.

This is the part you need, https://tabcoparts.com/1234-42395.html

Drill out the spot welds, clean up the rust underneath, weld in your new sill.

Oh, just re read your first post, so you already have the sill, get a spot weld drill and you're ready to go. I can send you some detailed pics of the procedure if you are interested.

Well I hate to be the bearer of bad news, but I bought the cheapest welder that HF has to offer! lol. I have seen others use this on a datsun and weld in panels without too much issue. I know it burns hot, I know it uses flux but I plan to do small beads and move around to get it done right. I am practicing with sheet metal now.

If you think this is a very bad idea let me know, but after doing testing I think it can be done. Might not be the cleanest, but It can be done.

My dad always tells me "SBE" Shitty but Effective. That's my goal.

-

6 hours ago, Neverdone said:

Go to your local community college and take a class in welding if you're really worried and want more than getting your degree the University of Youtube.

That being said, there's a lot of guys out there who put a lot of great information on this on Youtube. Picking up some random pieces of sheet metal, cutting them and welding them back together is great practice. Plus when you're done you have a welder and have learned a new skill!

Your right. At the end of the day it will be worth it for me to learn. I can use it on other parts of the car later down the road.

3 hours ago, socorob said:Since thats not really a structural piece, I used body panel glue will a few spot welds all around.

Also a good point as it is not visible and structural. If it doesn't look great who cares.

I really appreciate your guy's responses. I think I will be going the diy route and buying welder. It will come in handy for sure! I will be posting my progress here later in the weekend and hopefully get it done in the next couple weeks after I feel comfortable welding.

Thanks,

Shane

-

Well I got a quote.... $600. This is from Craigslist.

At that price I feel like I should just buy a Vulcan 140 welder from Harbor Freight for $400 and make this a DIY. Practice for a week and go for it.

Anyone here weld? Do you think it would be too ambitious of me to try to do it myself with little to no experience?

-

18 minutes ago, ZHoob2004 said:

Craigslist can be a decent source for semi-pro welders. I just dropped my z off at a guy I found that way and I can't imagine he'd want more than a few hundred for that repair.

Interesting. Did he do the same repair or something else?

-

20 hours ago, supershanesta said:

(fag and welding)

lol

I need to find a buddy to weld.

Well I guess I will start looking into it. Better sooner than later.

-

21 minutes ago, Neverdone said:

That would drive me insane looking at it every time I opened the hatch.

The rest of your car is looking pretty good right now. Are you going to be ok with that rather large cancerous section that's constantly getting worse?

To me, it just depends on how much worse. If its not going to change much in 3 years then i would rather wait. But it does suck to stare at it.

-

Hey Guys,

I just finished doing vinyl work on my car and forgot about a major rust area at the back hatch sill. My question is.. can I wait? I plan to get the car sandblasted, rust corrected and painted in 3 to 4 years and would like to hold off but I can tell its bad.

I bought a replacement top sill but I know damage is done underneath. If I paid someone to do the bottom piece (fab and welding) would it be expensive? Say over $500. I am not comfortable welding.

I am in California and owned the car for 2 years and never touched the rust knowing I need to asap before the rear tail light area gets worse.

Would the rust get much worst in that time or would it be similar and I should just wait.

Thanks for your help,

Shane

-

Here is a video of the process that I did. Just a quick edit if you want to check it out.

-

33 minutes ago, JeffB said:

How do you get the vinyl under the windshield molding? Do you pull it back with a plastic tool and tuck the vinyl in? If I need to sand this area out because of damaged paint, do I need to prime and paint the area under the rubber molding? I'm assuming that the molding cannot be removed without also removing the windshield.

Yes. You tuck it under with the vinyl wrapping tool and I used like a tint square or interior trim tool. I used vinyl wrapping knifeless tape to cut it very close to the rubber and just tuck maybe an 1/8 to a 1/4 MAX of an inch under the rubber. I practiced before and I would used knifeless tape. I did the rear hatch by hand and messed up although you can't notice unless up close.

The spots with damaged paint... I sanded. primed and painted. and sanded 1000 grit wet. It needs to be smooth like original paint to stick properly. I would do a good job painting because I had issue with paint peeling when I lifted the vinyl to pull, which ruined vinyl and finish. My first post talks about that. I would sand with 400 or 320 then prime, then sand, then paint, then sand. It needs to be hardened and stick well to the original paint. It needs to fully cure before applying vinyl. I would wait a couple days before applying as the gas from paint curing can ruin the vinyl.

I had issue around the rear hatch with 1. Bad paint and 2. Bad gasket. So I paid to have the glass removed and reinstalled with new gasket. As he was working on the new gasket I sanded the area and applied paint.

It would be really hard to wrap around dry, crusty rubber. If its in half decent shape and the paint just has chipping just sand it smooth and your good to go.

The only time you need to apply new paint is if you sand through to metal. Normally you can fix chips with just light sanding.

-

25 minutes ago, AlbatrossCafe said:

That is a very good price. $1500 is totally worth it to me.

I was hoping that you had a front air-dam on there so I could see what you did. I have a urethane one now (haven't put it on yet) but I'm thinking vinyl will not stick to it. Might sell it and go with fiberglass if I am gonna wrap.

Hmm idk. You could ask a vinyl guy. Might need paint over it first.

-

Thanks for the responses guys. I appreciate it! My car did look like shit for sure, but turned out okay. Wrapping the z is doable with patience's.

10 hours ago, AlbatrossCafe said:Thanks for the review! I've been thinking about Vinyl for my car. It seems like a much simpler option than going through all the paint prep and it looks just as good or BETTER! Yours went from "scrapyard look" (no offense haha) to a Z that looks damn near perfect!

Plus it seems cheaper. Although, I am not as brave as you and don't think I would do it myself haha. Glad to know it seems reasonable though.

If you paint it in good shape this is a good option for sure. I actually was just speaking with a guy who finished a 240z and he only charged 1500 which included the vinyl. I was thinking next time I would have them do it. It turned out great.

Anyways here the final results!!!

The hard part was taking off all the locks, windows, door handles, and finding the same bolts to put it back together.

-

-

Hey guys,

I got this car and never cared to look although I knew that I needed to add bump stops. The prior owner mentioned that he added lowering springs and that he forgot to add the bump stops. I really need to put those back in because going over any hair thin crack in the road causes my whole car shake.

While I am at it changing those. Do these springs look overloaded? They have almost no play and look nearly bottomed out. Is this normal under load without bump stops?

Thanks in advance,

Shane

-

-

I took the guts out of a 280z tach on eBay for 40 dollars and put it in the 240z housing, with 240z gauge plate and needle. Works perfect with my ms2 and cant see a difference. There is a guide out there for this. Like softtopz said might be other ways but its pretty darn simple.

Shane

-

Funny you say that. I built an MS2 from scratch for l28et, with stock dizzy and single coil and have the save issue with my leds. My board works. Car runs great. Everything works just no leds. In my opinion, if it works... it works. I worried about it for a while, but now I haven't thought about it until right now!

BUT i did have all leds working on my megastim. Again if you see input in TunerStudio then your good in my experience. RPM will not be right unless you switch it to the correct setting for the megastim.

Shane

-

On 5/4/2018 at 3:59 PM, JeffB said:

How much vinyl should I order to do a wrap?

I ordered 50 feet but did not wrap the cowl or the front lower valiance. I still need to wrap the buckets and turn signals and am hopping I have enough. I would recommend 55 or more to be safe. I have almost no vinyl to spare. Also for testing purposes or if you make a mistake it would be good to have.

On 5/3/2018 at 12:26 PM, Austenp405 said:Good Job SS! I've seen a couple pro installers and there is definitely an art form to it. It may be a 20 footer but looks way better than what you started with.

Thanks Austenp! Exactly the goal not perfect, but enough to look pretty good!

-

Thanks Dennis! I am hoping it holds up!

Looking to get into Megasquirt Diy kit

in MegaSquirt

Posted

Writing your own EMS code would be pretty sick but insanely difficult. I program for a living and seeing what the MS3 software can do makes me so happy I don't have to think about it lol! I bet their are basic packages that exist to get you started if you really wanted.

Here is speeduino, written in C++ which is lower level but faster than python generally: https://github.com/noisymime/speeduino