Firepower

Members-

Posts

11 -

Joined

-

Last visited

Profile Information

-

Location

Fresno, CA

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Firepower's Achievements

-

I’m just using a butt dyno and going on feel of how the car accelerates and cruises on the freeway. Any comments appreciated.

-

For anyone interested… I have a ‘73 240Z but with a 260Z engine. Rebuilt E88 Head, new valves etc…. I got dome top SUs rebuilt by ZTherapy. They supplied SMs as part of the deal. After messing around a lot, I went back to N57s - closer to stock 240Z needles. After doing sone research & looking into it, today I just ordered a pair of BC needles. I could post specs and differences if anyone has an opinion on this move. I think this car had twin HS6 SUs: AUSTIN HEALEY 3000 BJ7 ORIGINAL SU METERING NEEDLES: 'BC' -Richard

-

My .02 I run Tokico Illuminas & Tokico springs on a 240Z body, sounds to me that swapping the suspension between your 2 cars could help. The Tokico setting of 1 or 2 (soft) is fine for me on the street. just don't put urethane everywhere. Lasts longer, rides like... a dog. i added ST suspension beefy swaybars and it made little difference- well the rear didn’t have a swaybar so maybe it helped a little bit. I don’t track the car, but do some spirited canyon driving in CA. Finally- If you changed wheels from stock to 15”+ you may need to add billet ‘bump steer” spacers to get the geometry right. They cost <$100 and make a huge difference. Best suspension item I added, and except for rubber track rod bushings was the cheapest. Alignment guy told me it ‘squared up’ better after adding bump steer spacers. Another Richard

-

Hi - I know this is an old thread, but for anyone interested I too added the comp cams 84-119-6 to a stock 260z engine with dome top SUs, rebuilt E88 head. The grind number is 252s: Better Torque than OEM (esp ~4K+) but still fairly decent idle. I’m running SM needles, but a dyno would probably say these are not providing enough fuel and would need tapering. Or just go with DC04 45 carbs. Couple of other things come to mind: 1. This cam lets you set both Intake and Exhaust valve lash to .010” which makes it slightly easier. 2. Adding an electronic ignition, and “hotter coil” and removing the ballast resistor from ignition helped as well.

-

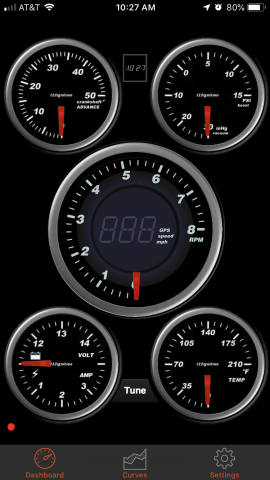

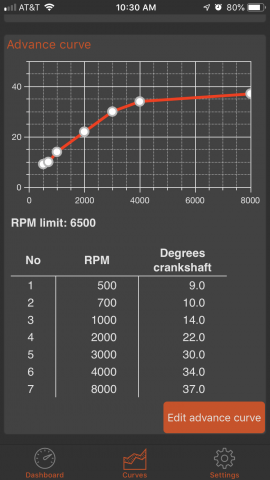

You can buy a Bluetooth dizzy from 123ignition and run an app called 123/Tune+ that lets you set advance curves and vacuum advance. You can tune advance +/- “on the fly” and also has gauges on your phone showing: accurate rpm, advance, vacuum map, voltage, gps based mph and dizzy (so engine compartment ) temp. You can set a max rpm, which is random spark cyl suppress enforced. It can also do an ‘immobilize’ with pin code. I previously used a ‘kill switch’ with my stock dizzy for this A nice bit of kit for the L6 engine. My 240z (2.6L, N42 rebuilt head, SUs, header, NA) runs better than it used to.

-

+1 SM Needles didnt work well for me on a 260z L26 engine with rebuilt dome top carbs. Far too rich at idle, and if you lean down to get that right- the top end beyond 2600 RPM suffers. I’m happier with the N57 needles and the carbys synched with a meter and fuel/mixture set by the lift piston methods, and then a colour-tune. Wants to get up and go now, fuel economy is better tham with SMs. Plus - my eyes dont water from a fat fuel/air mixture.

-

I went looking for this article today, and found it here: http://www.zparts.com/zp_html/zptech/articles/mal_land/ml_sucarb2/images4/SUcarb_111601b.htm

-

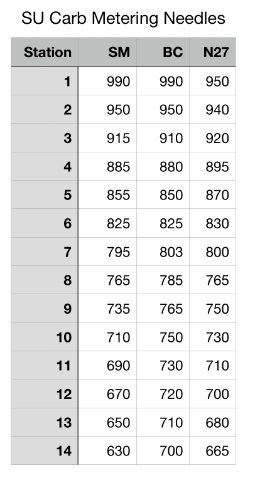

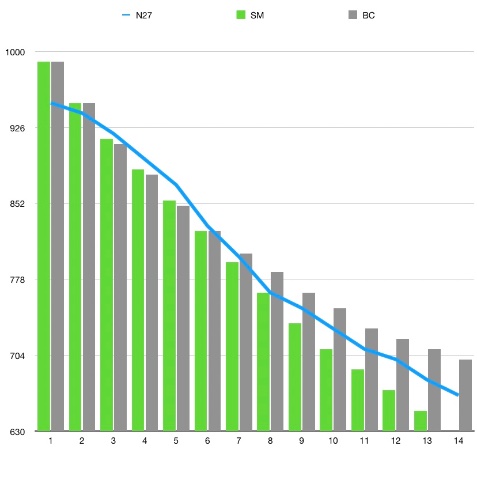

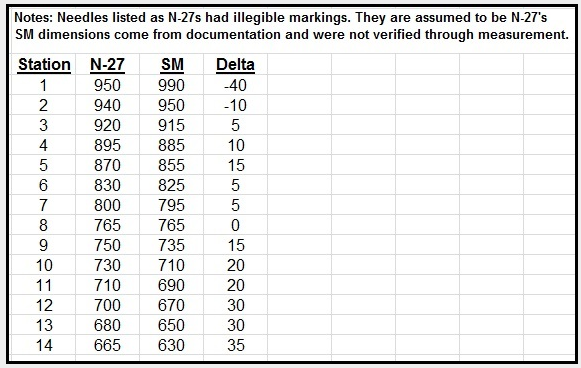

First off what I run: I have a 240z body, L26 engine, rebuilt E88 head, with the dome top carbs, 5-speed tranny, R200 3.90 diff and 6-into-1 header. So - after I rebuilt the dome top carbs, I replaced the stock (N27) Needles in my carbs with SM needles, as these were recommended to me. My experience is my L26 ran worse. Way too rich at idle, to the point where you had to go to 10+ degrees advance and it still idled lumpy. So I tuned it over several tries, balanced the carbs etc, and then have to lean down the mixture at idle, but then the top end pull suffers (for me) at 3-5K RPM. So I swapped out for N54 - which I think are original 240z needles. And these let me tune idle a lot better and still get more response from the engine in the ‘normal driving’ acceleration ranges. Much better for the driving I do. I don’t have a needle profile for the N54 - if someone has these numbers It would help me understand why they work in my case. I suspect they will be close to the N27 or maybe the SU BC needles (part is AUD1063). From what I can find out, the BC were what Hitachi used when adapting over the HS6 SU over to the 240z. BCE is considered a ‘240z needle’ but after idle will run richer even than the SM. Maybe an L28 stroker would need that much fuel. See: http://www.teglerizer.com/cgi-bin/needle100db.cgi?Needlecode=BC For a list of all the BC needle profiles. What I’ve learned is that you can go to a needle with a leaner idle profile (Stations 1 & 2) and then the rest of the needle can give a RICHER mixture than the profile suggests. That’s because of where you have to position the jet when getting the correct idle air/fuel mixture. Conversely, when selecting a needle with a richer profile for idle, it can give a slightly LEANER mixture than the profile suggests. SM needles can work, provided the carbs are ‘as new’ with no jet wear, and your ignition and timing are all good. (Good vacuum advance, no vacuum leaks). I now consider the SM to be “Race Needles” and if you order some, they are SU part AUD1328. The ‘stations’ of a needle profile are measured in 1/8” intervals Station 1 is immediately below the shoulder of the needle, Station 2 is 1/8” below that, etc. For the HS6 (and thus the Dome top carb): Stations 1 and 2 are idle, 3 to 7 are cruising and acceleration (with about 35mph around Station 4, 50-55 mph around Station 6) and 8 to 13 are closer to the top end rev range of the engine. You can ignore the Stations beyond that for a 1 3/4” carb. This is what I have for the SM profile: .0990 .0950 .0915 .0885 .0855 .0825 .0795 .0765 .0735 .0710 .0690 .0670 .0650 .0630 Again, anyone that has numbers for the “stock” N27 or N54 needles can you please provide them. I don’t think the attached which I found online can be correct for the N27. Thanks, Richard

-

Fuel Pump problems.....again

Firepower replied to datsun_dom's topic in S30 Series - 240z, 260z, 280z

First off I’m assuming it’s a 240z- as you don’t say. If so, i think you could have clogged mesh fuel filters in the float bowls -they sit in a banjo bolt that’s holding the inlet tube to the float bowl. You remove the lock washer thing, and then crank a 17mm wrench or socket to get them out. Also your float levels could be wrong. Going uphill you aren’t filling the bowls up because the float(s) valves are stopping flow. When the bowls empty the engine dies. Some pumps break if you have them on & then block fuel flow. So you need to run the return lines, if that’s the case. I had an electric pump on mine for a while, it’s no better than mechanical imho. I stopped at a light smelled gas, and I had blown a hole in a brand new hose between fuel rail and float bowl. The electric fuel pump kept running at 4psi because the engine was still running float bowls stayed full at that point. I was lucky not to have a fire. Do NOT defeat the Datsun electronics in your fuel pump harness. It reads the oil pressure and won’t run the electric fuel pump if the engine isn’t running. Having to carry a can of starting spray to get things going is a small price to pay to avoid death. -

I have a 240z with rebuilt E88 head, rebuilt dome top su carbs and I just went from stock manifold with 2.5” exhaust pipe and cherry bomb muffler to a header. I kept the pipe and muffler as the weren’t stock anyway, I just added a flexible connection from the collector to the existing exhaust pipe. Actually now I wish I didn’t do this modification. It’s really noisy and I’m not sure that moving away from the OEM cast iron exhaust manifold was a good idea. It seemed to do the job... any comment on the performance improvements or lack there of? One other point - within 6 months I had a fuel leak right over the header pipes even with all new fuel lines. It totally cooked the new fuel lines from the float bowls to the jets. They were cracking and perished. Dangerous. I have since replaced the SU carb fuel lines with correct parts, and modified the heat shield with an additional aluminum plate which sits under the fuel hoses/jets. I also added some heat wrapping to the fuel lines. Makes tuning more of a chore, but gives me peace of mind. Anyone have a solution to the header noise issue? Add a resonator? Change the muffler to a better one? I can tig/mig weld so would buy parts online and do the install myself. I’m not a boy racer (nearly 60) and it sounds like an F1 car now when I put my foot down. Yeah, I know- some of you would think that was a ‘bonus’. Richard

-

Starter going "click" even with new battery

Firepower replied to rskdsk's topic in S30 Series - 240z, 260z, 280z

I know that this is an old thread. But I had the same problem and knew it wasn’t the starter or solenoid as I had replaced them recently and the old one tested good Cleaned up the ground wire connection to the fender wall opposite the starter solenoid. This was rusty on my car- I cleaned the ring terminal, the lock-washer (do any other washer) and the bolt threads with a wire brush. Then I cleaned the spade terminals to the solenoid and replaced the brass T-connector that hooks both female connections to the male terminal on the solenoid. Re-terminate them if they are loose or beyond hope. Problem is gone for a $2 part. Doorman 85412. Use the part pictured or the one that matches what’s on you solenoid. If it isn’t your starter and isn’t your solenoid, then do this first. I was chasing around looking for other wiring problems and should have checked these connections. I suspect adding the direct ‘relay’ is sometimes just cleaning up this connection, when other loom problems from the ignition key switch aren’t to blame.