-

Posts

725 -

Joined

-

Last visited

-

Days Won

8

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by FricFrac

-

Sounds like a hard short to ground. Likely a wire worn through the insulation to the chassis.

-

Yes.... and your Datsun 510 or your 620 pickup or your S13 240SX, etc, etc....

-

Link not working?

-

Do yourself a favour and run aftermarket gauges..... which will require their own wiring.

-

I live in Canada - most every 280ZX I've come across has very good if not perfect dash. Just depends on how much sun the dash got. I have two from WA - one is mint and the other has some spliting on the dash. My FL car has a mint dash as well. Both US cars with mint dash lived in a garage. I keep a dash cover on my WA car as it doesn't currently live in a garage. Remeber plastic has a UV inhibitor typically from manufacturing but it tends to off gas eventually so you want to use a quality UV inhibitor/cleaner like Optimum Protectant Plus, etc (NOT Armourall).

-

Finding a used 280ZXT dizzy is getting to be a real challenge now. Some have modified the Jeep cam sensor IIRC to mate up to the old pump spindle. I thought another cleaver way would be a cam gear and hall sensor mounted on the valve cover. You can always run a crank sensor as well. I like the 280ZXT dizzy with the diyautotune trigger wheel. Gives you crank and cam outputs if you want to go sequential fuel and/or spark. It an easy bolt in solution. The 123 looks nice but its complete overkill when you will be running a stand alone. I've done a few NA MS setups - are you staying stock or thinking of boosting?

-

New to me 280ZX (1983) but not new to the Z family

FricFrac replied to SmoothZ's topic in S130 Series - 280ZX

Congrats - amazing looking 280ZX! Hard to find them in this condition but there are ones just like you describe - sitting in a garage for years. Oil in the filter. I'd take it apart and see if there is oil in the piping going back to the throttle body or if someone just left a jug of oil and it spilled on the filter housing. I would think you would have some massive oil consumption to get oil all the way to the filter which is pushing air against the source of oil from the PCV valve. Every L I've had in good working order never burnt a drop of oil. Once the rings go or the valve steam seals its a different story of course. I also had a barn find 280ZX. Had to replace so many items due to it sitting unused for so long. Fuel tank, injectors, hoses, belts, struts, etc, etc. Stiffer springs and struts are always a nice upgrade from the stock marshmallow suspension. Makes it a lot more enjoyable for some spirited driving.- 5 replies

-

- nuggetgoldmetallic

- datsun280zx

-

(and 1 more)

Tagged with:

-

Buy matched injectors. Stock injectors can be out as much as 10% from each other (tolerance is +/- 5%). People tend to glaze over this critical piece of equipment. You could be running dangerously lean on one cylinder but have a moderate AFR reading since it only averages all six cylinders.

-

Why are you running two injectors per cylinder? You might want to upgrade to a modern ECU. You'll probably have a hard time finding a Tuner that will work with that dinosaur A rear mounted intercooler is just complicating things and adding piping - you want to minimize it as much as possible....

- 25 replies

-

- turbo

- twin turbo

-

(and 2 more)

Tagged with:

-

Use the stock tranny - it's pretty decent. If/when it fails the S13/S14 is probably the simplest/cost effective/available. The Z31 turbo/Z32 is one of the toughest Nissan trannies but it's more work to adapt

-

Is it the plug for the automatic testing system module located under the dash?

-

81 is completely different - its CAS. You need a pull up resistor either inline or built into the MS unit itself

-

I use Fair enough - let me rephrase that then: I use Mil Spec wiring (if you want the part numbers I can list them). That is Teflon coated and often silver plated (depending on the Mil Spec number of course) wiring. It is heat and chemical resistant and can carry up to twice the current of lower grade wiring of the same gauge. It is excellent for engine bays because it is virtually impervious to the effects of gas and oil - it will not become brittle and break when exposed to these conditions over time as do most other types of insulation. I'm an Electronics Engineering Technologist and worked for the Military for 15 years in electronics during which time I have built and repaired countless wiring harnesses and connectors according to Mil Specs. Base on the knowledge of those systems and my training I design my harnesses for maximum noise immunity BEFORE it ever makes it to the ECU. A lot of companies are happy to let the software take care of (most of) the errors produced by noise. The engine bay is not only a harsh environment physically but also electrically. There is a lot of noise induced into sensor lines. I use Mil Spec (again numbers provided if that has any use to anyone) shielded wiring for ALL sensors and a properly designed grounding system throughout the entire harness. I'm trained in Mil Spec soldering, connectorization, metrology, noise immunity, etc. Typically when someone says their harness is Mil Spec it just refers to the use of Mil Spec wiring and/or connectors NOT the above techniques which do produce a very high quality product. My products have been around for years - ask anyone who has one about the product and/or support and I'm sure you'll find that statement to be true. Hopefully that clears up any confusion.

-

Hey guys - sorry about not being available but I am back making my high grade mil spec harnesses and plug and play systems (and I mean mil spec - not just the phrase people throw around in the automotive industry now adays ) If you have any questions feel free to ask or give me a call directly at 250-896-5930.

-

Test layout for grommets. Installed Test fit - hog rings not installed yet Grommets with inserts Cleaning the glue gun can be a pain. Work smarter - not harder! Seat bottom panels starting to go together

-

Progress on back panel

-

Now that I've got the main panel for the back of the seat done I'm going to do the seat. These are the two main panels and the majority of the work. My daughter and I decided on textured stripes to match the diamonds on the seat back. The angles are the same as the diamonds and the pleats will match up to the seat back. Test layout Precision fitment is critical here. Not sure if this is the way to do it but it looks sharp in the end. Kind of wrinkly from manhandling around the sewing machine. Some close ups to see the stitch work. Colour is washed out but more detailed shots. Rough idea of the main panels.

-

So I start watching some YouTube videos so I can try and figure out how to do this and of course I decide to go with a blind stitch because it looks cool. Problem is that it works for one row of diamonds but the material starts to bunch up if you add another set top and bottom. Layout for blind stitch Too much puckering 😕 But a chance to see what the upper panel will look like on the seat Do over on the panel. Colour is just washed out with the camera and lighting. There is a problem with the stitch on the bottom RHS diamond which I have since fixed. Added a second row of top stitching.

-

Now the fun part - time to get creative. My daughter wants to paint the car powder blue so the theme is mainly black with pink and blue for the interior. A blank slate. Vinyl on top glued to 1/2" foam then a bottom layer of fabric glued to the other side of the foam to make a vinyl/foam/fabric sandwich. Layout is done in chalk - it doesn't stain and is easily erasable. Just sharpen a stick of chalk on a piece of sandpaper to get a chisel edge to do fine lines. I haven't seen this anywhere but I thought I'd try it. Using a bamboo basket weave pattern embossed vinyl and glued diamonds onto the panel with contact cement. You need to be very precise with the cutting so a ruler and Olfa blade works very well. Before gluing down textured vinyl on base Panel sewn. You can see how the 1/2 foam sandwich makes nice pleats in the panel. Close up of the diamonds

-

Label and pictures.... if you don't need them no problem but once you're scratching you head it's too late I tried ironing the leather to make a template but a lot of them have a coating similar to vinyl and it will shrink and pucker so I use weights from my barbells to cold press them as flat as possible. Once that's done I stapled them to some heavy cardboard to make templates.

-

I won't put all the pictures I took here but I'll try and keep it as step by step as possible so you can see the process. Take lots of pictures as you take it apart. Sometimes there is something you need to go back as reference. In this picture you can see where the top stitch was done so that you replicate it when you sew it back together and it lays properly. Bottom of the seat - you can see where the hog rings attach the seat cover and hold it in place. On furniture you use staples into the frame to hold the fabric in place. On a car seat you use hog rings and wire in a pocket sewn into the cover. or a reinforcement of some sort like these plastic sew on strips I'm reusing the wires from whats left of the seat covers so I make sure they are labeled. You can make your own of course. It looks like they bend the ends back to keep it from poking through.

-

Thought this might be a helpful reference for anyone wanting to redo their seats. The process is the same for any car seat. This is my first attempt at a car seat so I did a lot of reading and watching YouTube videos (Chechaflo is excellent). I've got a little bit of experience fixing up a couple of antique chairs so I thought I'd try my hand at some automotive upholstery. I bought an industrial sewing machine so I'm kind of committed now The plan is to do the interior on the 280ZX and 510 but thought I'd practice on my daughter's 240SX interior. The seats are BEAT! I can only make them better than what they are and that's not saying much - a piece of duct tape is a vast improvement On the "to do" upholstery list The 4dr 510 and future upholstery recipient So lets start with some before pictures. Like I said I can only improve on this

-

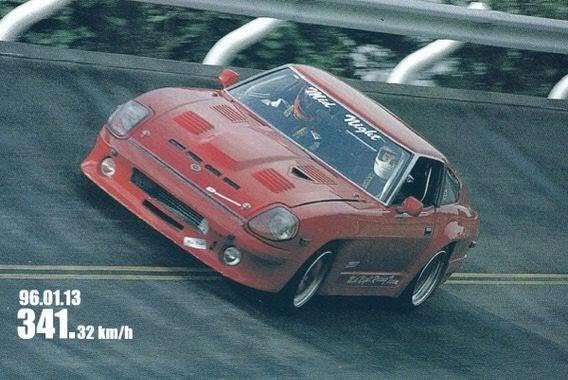

The original Devil Z - read 'em and weap S130 haters The 280ZX is a capable car and proven itself countless times. People have long hated on it and will continue to do so just like the red headed step child of the Z car lineage - the Z31. Of course few, if any, of those who hate on these models have owned a decent version of said cars. So given time and the unavailbility of an S30 and the inability of most Millenials to even tell the difference between an S30 and S130 the prices continue to rise. https://oppositelock.kinja.com/wangans-infamous-blackbird-porsche-930-turbo-1520243773

-

If you are running an NA or a mild turbo the 240SX swap is more than ample. No need to swap to a Z32 tranny unless you are putting down some serious HP