-

Posts

536 -

Joined

-

Last visited

-

Days Won

8

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by zredbaron

-

NA 3.1L=>head & camshaft questions. No shortcuts, max

zredbaron replied to zredbaron's topic in Nissan L6 Forum

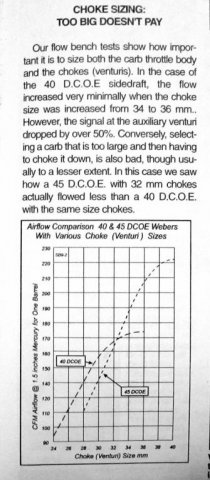

Nope. The image came from the internet, but I own the book as well and can confirm that's all we get. There's one other potentially useful graph, which bases venturi selection on cylinder displacement and peak horsepower RPM. The numbers on the chart are lower than what road race engines use, so it too is more interesting than useful for our purposes. I feel the book(s) could provide a LOT more charts, to include distinction between "street" charts and "maximum performance" charts. In my experience those that tinker on carbs do not value books very much past initial familiarization, because, well, that's all they're useful for. (EDIT: In practice, what matters is what works, not why. "Why" fosters improvement; knowing what works fosters repetition.) Perhaps this is part of why the carburetor books "lack" tangible, scientific data relative to other industries in the information age? (EDIT: Yes, fuel injection, I know. Carbs are still purchased new!) Carburetor "theory" without solid carburetor "data" decades after the theory was written? Hard to improve if we never circle back with upgraded, modern perspectives. Doesn't seem like the industry is interested in such a thing, either. Sounds like our government! I digress... -

NA 3.1L=>head & camshaft questions. No shortcuts, max

zredbaron replied to zredbaron's topic in Nissan L6 Forum

Anytime! Regarding the 40-41mm venturi, I don't expect much difference either. I still reference this Weber chart, particularly the note about aux. venturi performance. (EDIT -- comment about carb body's exit removed, as I was mixing up the numbers with the 40mm carb body.) I have no idea how accurate my "209 cfm per cylinder" flowbench measurement from yesteryear is. A 5-10% variance between that and the chart would translate to a + 2mm venturi size accuracy. That's a blind guess, so it renders this chart conceptual. It's still nice to know that, in theory, around 39mm you're starting to get all that you can out of the 45mm carb body. Road testing will quickly determine which > 39mm venturi offers the most mid-range drivability, no doubt. -

Wow, I just dedicated a post in his honor today in a different thread! Couldn't agree more, Rebekah. Tremendous contributions, John. We thank you eternally...

-

Wow, I just dedicated a post in his honor today as well! Tremendous contributions...

-

NA 3.1L=>head & camshaft questions. No shortcuts, max

zredbaron replied to zredbaron's topic in Nissan L6 Forum

Gathering the final details. Need to order a best-guess DCOE venturi (choke) for my upcoming engine dyno pulls. Engine Dyno approach: Phase 1 - 40 mm DCOE, 36mm venturis (already installed) Phase 2 - 45 mm DCOE, 36mm venturis (came with the new 45mm carb bodies) Phase 3 - 45 mm DCOE, ?? best-guess venturis Joe's experience with road-race DCOE engines lent him toward 41-42mm chokes. I asked the question about torque band, about how drivable these road-race DCOE engines are in lower-RPM ranges and varying throttle positions. His natural instinct is that this won't be an issue, as this motor will not lack for torque. True, but I still want to be confident in selection. Since drivability is more important than peak hp, I posed the question: Is it better to start big and see what the engine likes or wants? Or better to start conservatively (~38mm?) and open up the venturis as needed? Now that I've slept on it, the cost of venturis is, well, less than the cost of having a dyno crew and engine builder on the clock. Then I think about why I waited so long and why I'm being so thorough with the engine dyno phase to begin with. To do it right. To share, and contribute. I'm here for the experience, after all... I didn't know it until just now, but it turns out I want the experience of open R&D. If it isn't too lofty of a dyno-pull list, I now intend to add a couple of choke sizes. Any thought and experience here is appreciated! Wouldn't that be some nice data to watch 36mm, 38mm, 40mm and 41mm? It's not like I can't sell the almost-new parts afterwards. In honor of John Coffey. His R&D is in my E31 head, after all. This is how our community "lives." -

NA 3.1L=>head & camshaft questions. No shortcuts, max

zredbaron replied to zredbaron's topic in Nissan L6 Forum

Kameari cam gear. Far more affordable than most of their products! http://www.zccjdm.com/catalog.php/azcarbum/dt43033/pd858307/KAMEARI_L6__L4_FULLY_ADJUSTABLE_CAM_GEAR_#IMAGES http://www.rhdjapan.com/kameari-full-adjustable-cam-pulley-sprocket-gear-l18-l20-l26-l28.html -

NA 3.1L=>head & camshaft questions. No shortcuts, max

zredbaron replied to zredbaron's topic in Nissan L6 Forum

If only 1 in 6 can handle the 3.1L overbore, why don't we hear warnings from the unhappy owners of the other 5 of 6? Interesting claim, but I'm with Steve -- I don't buy it either. I don't think our community would be silent on that kind of a failure rate. Gettin' close and looking good! Head and valve train assembly complete, only minor assembly remains. No idea when the engine dyno will be scheduled... -

NA 3.1L=>head & camshaft questions. No shortcuts, max

zredbaron replied to zredbaron's topic in Nissan L6 Forum

More challenges and a bit more progress. Rockers. According to my builder, the CNC Rockers from ZCCJDM aren't a viable OEM replacement rocker at this time. Something about the ratio not being correct. Probably contributed to the last engine failure, but that doesn't excuse the previous builder from ensuring proper clearances. Joe is working with Brian to help him update his design. Back to OEM rockers for this guy! Springs. Short version is that valve springs that have been ordered and reordered multiple times yet still do not produce the expected seat pressures from the cam spec sheet. Joe presented me with the springs he uses in his L4 motor, and we are proceeding with those. More pressure than the cam spec sheet calls for, but less pressure than other options. Still retains an outer-valve only design. Might raise the RPM limit slightly. (Not sure how one would test that safely?) I still do not have a dyno date set yet, but very little assembly remains. "Six minutes, Turkish." -

Weber jets??All who live for their triples please read this

zredbaron replied to datfreak's topic in Nissan L6 Forum

For me, this kind of issue was always due to carb linkage either sticking or slipping on the common throttle bar, that is, a link from one of the carbs is not travelling wide open or won't fully shut with the other two. Sometimes it slips hitting WOT, sometimes it slips when closed shut. How smooth or hard on your pedal you are also is a factor: loose linkage vs. tight but not tight enough. My instances were more typically pronounced, but not always. Regardless if where/how/why... my instinct is carb sync / linkage friction / spring tension. You might be able to find some play, limited travel or some sticking while the engine is off. Are your synchrometer numbers still the same? If so, try doubling the return spring tension on the carb linkage, to ensure a fully closed throttle across all 3 carbs. (Or try letting the return spring close them and them close them further with your hand while the engine idles. It shouldn't change.) This may stall your engine, which would identify your issue. -

Weber jets??All who live for their triples please read this

zredbaron replied to datfreak's topic in Nissan L6 Forum

By "reason for concern?" are you stating this is a concern and asking why? Or are you asking if this is something to be concerned about? Either way... mathematically/theoretically it would distribute the load and volumetric efficiency more evenly if you are able to reduce the throw of the carb linkage to adjust the variation as follows: 1 - 7.0 to 6.0 (5.25 + .75) 2 - 5.5 to 4.5 (5.25 - .75) 3 - 6.0 to 5.5 (5.25 + .25) 4 - 5.5 to 5.0 (5.25 - .25) 5 - 5.0 to 5.0 (5.25 - .25) 6 - 5.5 to 5.5 (5.25 + .25) I understand this is difficult to achieve, but I always shoot for the moon when tuning. Actually, I just always shoot for the moon... -

NA 3.1L=>head & camshaft questions. No shortcuts, max

zredbaron replied to zredbaron's topic in Nissan L6 Forum

I found two for $900. One ended up being a dead end, and the other left me with the opposite of a warm fuzzy (I wanted it magnafluxed; he wanted a cash deal.). I ended up going with one from SoCal from a fellow racer who had been hanging on to it and was Johnny-on-the spot with communication and prompt pics of it being magnafluxed, video of it turning in a block, etc. I paid $1,300 primarily because I had wasted too many hours on it and wanted to have a chance to get one autocross event before the end of the season. With the cost of custom pistons and new rods.... a full kit that's already balanced and is truly an upgrade is definitely the way to go in my opinion. That said, there's no question this is a custom motor. Is it worth the cost just to be custom? Probably not. Helps me be less frustrated, though. Driving would help, too. -

NA 3.1L=>head & camshaft questions. No shortcuts, max

zredbaron replied to zredbaron's topic in Nissan L6 Forum

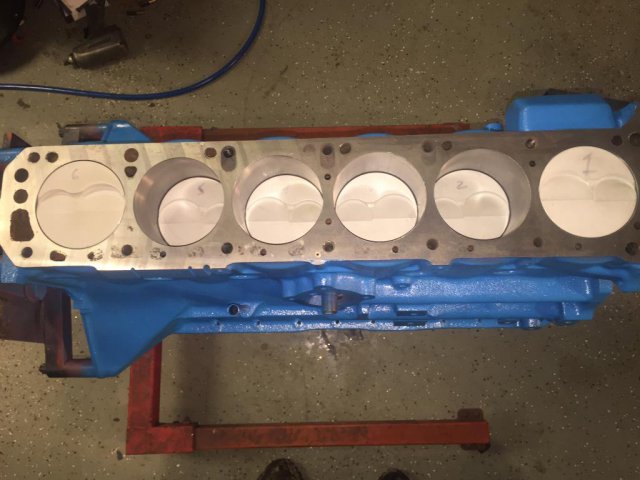

Getting closer. Block is assembled. Pics of coated pistons and new L24 rods below (Eagle). I don't know the weight difference yet. Also included are pics of the coated E31 head. Combustion chamber, valve faces and exhaust port all received a TBC (thermal barrier coating, SwainTech). Not yet assembled. Sounds like coordinating a window to use the engine dyno is proving difficult. Best case another delay, worst case chassis dyno only. Not sure what to expect. At this point, it's been so long (again) I'd just assume wait until the engine dyno can be utilized. "August?" I think I've busted my budget by about 300% or so, too. Couldn't have afforded all this without the year of waiting to pay for it, wow! -

NA 3.1L=>head & camshaft questions. No shortcuts, max

zredbaron replied to zredbaron's topic in Nissan L6 Forum

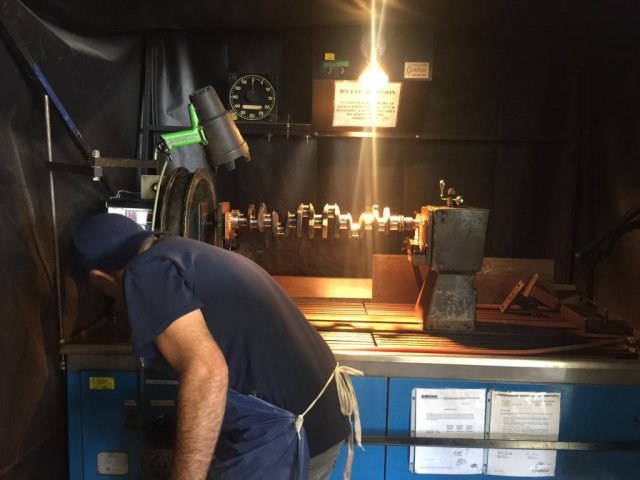

Well, as unpleasant and uncomfortable as it was and still is, I paid an exborbitant price for a used LD28, and the ball is once again rolling. The new-used LD28 passed its magnaflux test and will be balanced / polished this week. Main bearings are being sent off for coating now that the journal sizes are finalized, too. So... barring any unforeseen challenges, final assembly and dyno tuning are all that remains. I don't have a date set yet, but it looks like there's a decent chance that "July 2016" might be the month I officially get to try again! -

NA 3.1L=>head & camshaft questions. No shortcuts, max

zredbaron replied to zredbaron's topic in Nissan L6 Forum

As far as I know, it's an exact LD28 replica. Definitely give Thomas a call, he was very personable on the phone and seems very interested in making advances for our L6 community. -

NA 3.1L=>head & camshaft questions. No shortcuts, max

zredbaron replied to zredbaron's topic in Nissan L6 Forum

Slow but steady progress: billet crank is out, stock LD28 it is! The prospective billet crank finally arrived at Rebello. Dave's assessment: "It's a nice crank. It's not one of ours... but it's nice." It's made of solid 4340 and arrived knife-edged. All parties were surprised that the crank weighs in at 51 lbs, with stock cranks coming in around 52-54 lbs. The vendor for the crank: Thomas Thorman of Sugar Hill Speedshop (GA), (678) 546-6055, https://www.facebook.com/Sugar-Hill-Speed-Shop-1001732356563108. I spoke to Thomas; this is a new part for him and he is still getting the details (mods?) up to speed. I'm not sure what his plans are, but the price I was quoted in its current, raw form was $2,575, "pre-balanced within a gram." For me, this is too much cash for too little performance upgrade at this time. I want more strength, less mass (or improved CG) and more stroke for that kind of money, but that's me. Below is a picture. On the left is the new crank in question, and on the right is a Rebello crank for his 3.2 kits. Really makes a case for Dave's bottom ends! Maybe one day, okay very probably, but not this year... That said, I still rely on experts, and oversights continue to cost me a lot of time and money. Had I known my crank was shot six months ago, I wouldn't have ordered custom pistons and would almost certainly have purchased a 3.0 or 3.2 bottom end from Dave knowing what I know now. I sincerely hope my experience is helpful to someone in the future. -

NA 3.1L=>head & camshaft questions. No shortcuts, max

zredbaron replied to zredbaron's topic in Nissan L6 Forum

No word since last week. Dave hasn't received the prospective billet crank yet, and doesn't know when he will. No luck in used LD28s, either. I've thought a lot about 3.0 vs. 3.1 vs. 3.2, and I've landed on... who cares? Very surprised that I landed on that, given how important each detail / choice has been, given some of my statements and sentiments above. Why the shift? I don't have a single, simple answer. It's big-picture... and when I zoom out and assume that I'll have the car another 18 years, then it doesn't really matter what configurations it passes through along the way. I then saw the block the same way I saw the intake: it's been not-ideal for years, and I kept it why? Because I enjoyed the iterative changes and how different each dyno plot is when go-fast parts are swapped out. I enjoyed the control of comparison against the last engine. So... "who cares" more accurately translates to no changes for now. This iterative changes philosophy is no doubt very odd from a competitive or financial perspective. This is neither. This is the journey, the experience. "Enjoy the ride." (Not the finish line!) My heart wants to finish building the 3.1L that I set out to build so many years ago. Yes, I want to be competitive, but neither the suspension nor driver are dialed-in with each other yet, so at this point in my experience, class entry is moot. I'm racing the clock. I know that "one day" I will probably move to ITBs. That may not be until I want to be more competitive, so maybe a 3.0L would make more sense at that point in time. Bottom line, I simply woke up one day and wanted to keep things the same. For now, anyway... -

NA 3.1L=>head & camshaft questions. No shortcuts, max

zredbaron replied to zredbaron's topic in Nissan L6 Forum

I might have a line on a used LD28 in OR for $900 (vendor is trying to locate it in his inventory). I thought it was high at the time... but didn't yet know that $750 is about the going rate at the moment. He's definitely the patient vendor type, so $900 is in the ballpark it would seem. As for the possibility of tossing my new pistons and going with a full kit from scratch... Ouch! On so many levels. Cost, time, patience, sentimentality (fleeting)... Mostly cost and patience and the enjoyment of custom HybridZs. Kits are less personal, and this car is an expression of me. I'm an only child, never married, no kids. I've had this VIN longer than I've been an adult, and have carried it to the east coast and back. This car is my creation in the world. We all can probably relate to our steed being, well... honorary, inanimate family of sorts. For some reason, the idea of a kit strikes this particular chord. (Which is odd perhaps, because I bought a 3.1L "kit" back in the day... in my mind custom pistons makes it no longer a kit.) Steve, you just might be right about the sound -- I do believe it's *mostly* a result of the head/cam/exhaust, but I'm not sure about rod/stroke. I do suspect that it would change the sound a bit, but in what way and by how much? Maybe I'm being stubborn, possibly a twinge of ego? Maybe it's fear of guessing wrong, spending all this time, emotion and money (3x!), and not achieving or surpassing what I drove "that one time" in Arkansas? Sigh. Now that we're honing in on the detail, part of my engine intoxication is the "raw anger" that is physically felt in my chest in its presence... the aspect of the engine that shakes the camera when it starts up and during throttle blips. Open exhaust to what degree, I wonder? Maybe VP109 fuel is a factor, too (oxygenated). It made a HUGE difference to my ear (and chest) back in 2008, which still used MSA headers, fully muffled with air box and hood, etc. No way to truly know, and only so much can be gained by wondering. As an enthusiast and not an expert, I wonder that maybe the less-than-ideal rod/stroke is why it sounds more rough, and therefore why Rebello engines sounds more smooth. I prefer the rough. This particular steed fills a void in the heart of a Naval Aviator that hung up his flight suit, after all. Details always matter. Thoughts to ponder. (I'm still all ears, of course!) We'll see what Dave R comes back with when he gets a chance to evaluate the potential billet crank. I'll likely inquire about a kit, and fully consider my options. Good feedback, gentlemen! Always appreciated. -

Where was the official BHJ response posted? I searched and looked at Chris@BHJ's content but did not find a post more recent than the post above.

-

NA 3.1L=>head & camshaft questions. No shortcuts, max

zredbaron replied to zredbaron's topic in Nissan L6 Forum

Holy.... What!? A used crankshaft for $2k? (I paid $1,800 for the full 3.1L kit directly from Nissan Competition.) They aren't made of unobtanium just yet! For that price, one might as well go with a new, billet crank, if available. Heck, even a brand-new Kameari crank is "just" an additional $900, but it at least fancies itself an upgrade, not a used mystery source. -

NA 3.1L=>head & camshaft questions. No shortcuts, max

zredbaron replied to zredbaron's topic in Nissan L6 Forum

Interesting timing. Just got off the phone with Dave... evidently he is expecting a billet LD28 crank to arrive in a couple of days. It's a new part for him, so he hasn't seen the quality and doesn't have the price yet either. He suggested I inquire again later this week. As for the 3.0/3.2 liter setups... Dave doesn't use the L24 rods in those kits, so his pistons have a different compression height. (It wasn't "harmonics" as I stated earlier.) My new pistons certainly have me "locked in" to my current configuration. Proceeding with the LD28 crank, no question. For some reason I thought he was using more than one crank... Must've been something I saw online somewhere? -

NA 3.1L=>head & camshaft questions. No shortcuts, max

zredbaron replied to zredbaron's topic in Nissan L6 Forum

madkaw - was planning on calling Dave today... I'm ill-prepared for a discussion about the possibility of a non-LD28 crankshaft. From what I understand, Dave doesn't like the harmonics of the Nissan Competition 3.1L (stroke and rod length combination) and recommends either the 3.0 or 3.2. As far as my "painful and expensive journey" with my 3.1L is concerned.... I'm not sold on the 3.0 or 3.2 at this time. For me, I'm very attached to "my" unique 3.1L build... I've never heard another L6 sound quite like it, and I'm more interested in my intoxication by the engine than having a competitive FP car (3.0L limitation). I truly have come to enjoy the incremental improvements and noting the dyno graphs' evolution -- changing the bottom end was never a part of my experimentation at this stage... I always put that part off for "one day" when performance has plateaued both as a car and a driver. Still going to call Dave! LanceVance -- PM sent! -

NA 3.1L=>head & camshaft questions. No shortcuts, max

zredbaron replied to zredbaron's topic in Nissan L6 Forum

So... the fat lady coughed up a hairball: my LD28 crank is cracked. Obviously, several humans had several opportunities to catch this before now, but luckily, it was caught before it was put in my engine. The short version is that the crank was magnafluxed late-stage (should have been performed prior to any welding and balancing, no doubt) after it was found to *still* be out of round... and a crack was discovered. So... my June 10 target just got a little tighter. Let the scramble for an LD28 begin... Anyone have one or know of one? Thoughts and recommendations welcome. I'm starting to get that while-I'm-at-it nervous tick.... -

NA 3.1L=>head & camshaft questions. No shortcuts, max

zredbaron replied to zredbaron's topic in Nissan L6 Forum

Steve -- Engine build details start at post #277 of this thread. Leon -- Huge balance tube between the runners, I'm not particularly a fan of it either. I'll probably purchase a different manifold down the road, but keep this one for now. Incremental changes. My primary reason is the 40mm/45mm dyno comparison is arguably moot if the manifolds aren't apples to apples aside from the port sizes. Plus the Cannon more or less came bundled with a new set of 45 DCOEs. I've more than busted my budget this year, too. Am I to understand you prefer shorter runners? Better peak hp at the cost of driveability, is that about right? Or are you primarily looking at the balance tubes? Jon -- Yep, the Cannon only comes crudely matched for 40mm DCOEs, 45mm cuts out quite a bit of material indeed... -

NA 3.1L=>head & camshaft questions. No shortcuts, max

zredbaron replied to zredbaron's topic in Nissan L6 Forum

Updates are slow this year... JE pistons received. Pics below. Mock assembly went well. Rocker arms received. DP oil pan received. Pics below. (Wow!) Coated: head (CC and exhaust port), piston skirts and domes, valve faces, crank bearings Valve spring retainers from Kameari won't work. Joe ordered custom dimensions from Isky, I don't have the numbers at this time. (I think the Kameari dimensions didn't work because I'm using outer springs only.) Outer valve springs received 3x45mm DCOEs with Cannon Intake received Waiting for confirmation: Crank repair and rebalance Block bore/hone to match coated pistons ("new" block) Intake manifold port match (45mm) It's been a long year. Targeted engine dyno date is June 10. -

Weber jets??All who live for their triples please read this

zredbaron replied to datfreak's topic in Nissan L6 Forum

Nice! Well, not nice.... but nice to know! I was never very impressed with changing E tubes. Thought I was missing something. Probably still am. Hard to believe, I remember we used to get 20 emails a week on this thread. I have two updates, well, maybe they're sort of the same update: I will be engine-dynoing my new, rebuilt, new-rebuilt race motor (third time's a charm!) this spring / summer. I will be comparing 40 DCOEs (36mm venturis) to 45 DCOEs (36mm venturis) on the same motor, same day (two Cannon manifolds port-matched respectively). I don't know of such a comparison on the internet or in a book for any application. The comparison isn't fair to the 40 DCOEs, as my head outflows what the carbs can deliver. This is the whole point of the unfair experiment... to compare the dyno plots of a restricted intake (past the Weber flowcharts) to a more appropriate intake (within the charts). Appropriate being relative, of course, because 45 DCOEs are still a top-end compromise for a full race motor, and this is a deliberate compromise to maintain low-RPM torque and throttle response (autocross). This experiment is partly a result of painting myself into a corner in a discussion that came up on my engine thread, and partly out of my own curiosity and enjoyment of our mutual hobby. Weber debate begins here, which ultimately trails off with me citing a Weber chart and then saying I'll let the dyno settle the debate once and for all. My theory is that the draw of the pistons at a given RPM creates a given vacuum signal regardless of intake, drawing metered amounts of fuel set by the carburetor / jet combo. If under-carbureted, inadequate air matches fuel metered for adequate air, producing a rich condition. (The carburetor "feels" more airflow than is actually present.) This cannot be patched at high RPMs with air correctors, because what the engine needs is a more open intake, period. The thread has been pretty silent, not sure if I was too aggressive with my argument? Regardless, should be a fun experiment. We all expect HP and torque to rise... but what about the A/F graphs? What will those look like? And no, I'm not trying to send the debate to this thread. I've already typed too much on the subject as it is! Just completing the circle and replying to Steve. He's right, it's been a long time coming.