dpuma8

Members-

Posts

246 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by dpuma8

-

A lot of what I read is getting the maps to be fairly smooth so I have been autotuning to get near AFR goals but then I will manually smooth cells out. The problem I am having is my AFRs will vary 1 AFR when cruising. Obviously, the goal is to give the car what the car wants but what is more important when tuning is pretty close? Smoothing the tables and ignoring AFR swings as long as the engine will not be harmed? Or is hitting AFRs goals the best way to go? CurrentTune.msq 2019-11-13_07.48.07.msl

-

Get a running car with no rust. As mentioned above, upgrade everything else and do the engine last. My first Z sat for 4 years in the garage because I tried to upgrade everything at the same time including the engine

-

Possible spark blow out. How small of a gap can I run

dpuma8 replied to dpuma8's topic in Turbo / Supercharger

My 105 amp alternator is a 1 wire setup. Is there a general safe advance map for an L28et? I see some of the maps in the Megasquirt map sharing section of hybridz but I am not sure if any of them are safe or not. My voltage issues are better after rearranging things but not perfect. Now MS will read 12V at idle, increase to 14.2V while drivinjg with some moments where it drops to 12 again before raising up to 14. -

I used this diagram from 5thgenluder's 2010 build and it helped a lot. I do remember brakes being a problem and I think I just took one brake wire that came from the EZ fuse and routed it to the brake switch, took another non EZ wire and connected it to the other brake switch prong, routed it back to the brake lights. EZwiring Diagram 3.pdf

-

Possible spark blow out. How small of a gap can I run

dpuma8 replied to dpuma8's topic in Turbo / Supercharger

Not sure why my voltage is so low and I am not sure where to start looking. I have a Z Specialties 105 amp alternator that needed to be rebuilt for bad bearings after not too much use. I don't have any extra accessories like a radio or anything like that. My car is wired with EZ wiring harness. My boost flutter issue has been fixed by rearranging my vacuum lines. My MAP sensor was hooked up to the #5 intake leg so I moved it to the port between #3 and #4. I still have an issue though where it feels really flat once I get over 4500 rpms so I can't tell if this is because my P90 cam is losing steam, my ignition timing needs more advancing, or because I have spark blowout. 2019-08-07_20.57.25.msl CurrentTune.msq -

Possible spark blow out. How small of a gap can I run

dpuma8 replied to dpuma8's topic in Turbo / Supercharger

Just an update. I smoothed out the tune a lot and now I can rev it without any issues like I had before. My problem now is fluctuating boost at WOT. My logs show boost is erratic up to 12psi meaning that it rapidly goes up and down 3 psi until I get to 12 psi near 6,000 rpms. Above 4500 rpms, the car sound slouder but doesn't feel much faster. My voltage is in the 12's and will drop to high 11's at higher rpms. So possibly a spark blowout? I am using an All-Star 81230 coil, magnecor wires, Tial MVS wastegate with 10psi springs, NXS manual boost controller, Greddy BOV on the hot side. The MBC and BOV share a vacuum line connected to the intake manifold. -

I have an L28et with GT3076r turbo and Megasquirt 2 3.57 with NGK R BPR6EY plugs that were gapped at .03. With this gap, I could not rev past 3200 rpms but after gapping the plugs down to .025, I now can rev my car to 4200 rpms before it happens again. Do I need new plugs or do I keep closing the gap on my spark plug? What is the smallest gap I can run? and I had problems with revving past 3200 rpms. I changed the gap to .025 and I can now rev to 4300rpms before I run into the revving wall.

-

Awesome! Thanks for the link! So it looks like for me and the stock 280zx turbo distributor, the only change is I don't have to add a resistor on the B/W wire.

-

Hi everyone, I had my L28et with Megasquirt II 3.57 for a while but I had problems with revving above 4,000 rpms and bad TPS noise. I ripped all the wiring out in October 2018 to redo my wiring routing to hopefully cut down on the noise. I am back at it again but I am wondering about the 280zx turbo dizzy wiring diagram we see on the internet from 20 years ago. Is this still the way to wire the distributor? If not, how should I wire it?

-

I bought a 3000 CFM electric fan from eBay years ago for maybe $30 and it really helps sitting in 110 degree weather at a stoplight. I do not have a shroud either so maybe your fans are not strong enough or there isn't enough electrical power to really power them up? When mine come on, you can really hear them and the engine cools down pretty fast. Years ago I changed the radiator to my Nissan Maxima and I immediately had a problem with overheating so the fix was to let the car idle with the cap off to get the bubbles out. The radiator fluid would burp a little and then I would just add more fluid. Just an idea.

-

Was there a typical size for sunroofs? Mine blew off

dpuma8 replied to dpuma8's topic in Body Kits & Paint

How much did it cost you and what shop did you go to? Just wondering since I am 30 minutes away from the Sacramento area. -

My rear tire blew out so while the car was being towed backwards, the sunroof glass blew off so I am in need of a replacement. I am hoping to get a direct replacement rather than having to completely recut the hole for a new kit so I was wondering if there was a general kit or size that was installed back in the 70's. I know dealerships and not Datsun did these modifications but I still was hoping for an easy way to deal with this. When measuring the hole where the glass would have sit, I came out with measurements of 14 1/8" by 29 1/8". Is there a kit for this?

-

Been busy with my kids' sports and family visiting but here is at least a picture of my setup. This all is mounted in stock location. The feed hoses are 3/8" and the outside return lines are 5/16". Removed both G3 filters.

-

Hi guys, Let me clarify my situation better and what I am running. L28et with GT3076r, MS2 with relay board, RC Engineering 550cc injectors with inline resistors, and Aeromotive Fuel Pressure regulator. My fuel system is Tank>>Fram G3 fuel filter>>Carter Fuel Pump (wired to my EZ Wiring kit, no relay, 14 gauge wire)>>External Surge Tank with submerged Bosch 044 (Wired to the MS Relay Board)>> Engine>> External Surge Tank>> Tank. I set fuel pressure to be 36psi with the aeromotive FPR vacuum line off, reattached the vacuum line to the FPR, and then drove around to tune with Chickenman's tuning start points. I will drive around for an hour, turn the car off for 30 minutes, restart it, and then struggle home with fuel pressure at 10 psi. I am now adding a Bosch relay to my car and hooking the Bosch 044 directly to that rather than going through the MS relay board. The Bosch 044 was wired to the relay board with smaller gauge wire and the fuses did not pop. Since I have had the car in the garage for some time, the battery might be low so I will charge it tonight. My Bosch 044 came with a check valve but I did not install it with the pump.

-

I am using the stock fuel lines for a 75 280z. My issue I was having was fuel pressure would be near 10 psi all the way home making it a difficult drive. The next day when I start the car up again, the same scenario happens where fuel pressure is fine until I shut down and restart the car. I think maybe my battery is low because when trying to start my car, the engine fan kept turning on when really it doesn't work until the engine is 200 degrees. The return line from the front of the engine flows back to the surge tank so that it doesn't go dry. There is another return line from the surge tank back into the gas tank so I don't think it is a plumbing issue. I pulled the fuel pumps, gas tank, and surge tank from the car and I am making changes to my wiring. I am skipping using the Megasquirt relay board for fuel pump control since it seems like 30 amps is pushing the board. Redoing my ground locations and adding two relays for both fuel pumps. Few more days and I will know if this all worked. Thanks for the help, guys

-

Hi everyone, I have a Carter P4070 feed pump that feeds into a surge tank that has a submerged Bosch 044 fuel pump. I have had a problem where after shutting off the car for 30 minutes, the fuel pressure will drop to around 10 psi. I have read on the internet that the Bosch needs a 10 gauge wire but the Megasquirt relay board doesn't have an opening large enough to connect the 10 gauge wire to it. So after realizing this, I have the 14 gauge wire connected to the relay board and after a few inches, it connects to the 10 gauge Bosch wire. So after doing this, the problem I am having is either the fuel pump fuse or the main fuse will pop immediately. I changed the fuel pump and the main fuse to 30 amps for both but after a few minutes, those fuses will pop again. 1) Fuses didn't pop when I had 14 gauge wire connecting to the Bosch pump but now it does. I changed the ground wire from 14 gauge to 12 gauge and is now connected to the same frame grounding bolt as the Carter pump. Is grounding both pumps to the same frame bolt a bad idea? 2) The recommended main fuse for the Relay Board is 20 amps but do I need a larger main fuse? Or do I have other issues?

-

Hi everyone, I bought a Xenon air dam for my 280z and while the fit is nice, the middle of the air dam is angled upwards. Do I need to adjust the bolt holes again or does the air dam eventually rest into the correct resting place? Mine looks very similar to this picture

-

Hi everyone! I have an L28e with N42 head on a new to me car. I cold adjusted the valves to .10 exhaust and .08 intake but the engine still seems loud. Do I need to worry about anything if the engine is loud like this? I can't find any exhaust leaks, the oil pressure is around 10-70 psi, and the car runs well. Here is a video of the noise after adjustment and a little 15 minute drive

-

Dead time for low impedance injectors with resistors?

dpuma8 replied to dpuma8's topic in MegaSquirt

Darn, so no solid answer. I will try higher dead time numbers but my AFR problem happens at all RPMs, not just at idle. This makes me wonder if anyone here in this forum actually has a solid tune. -

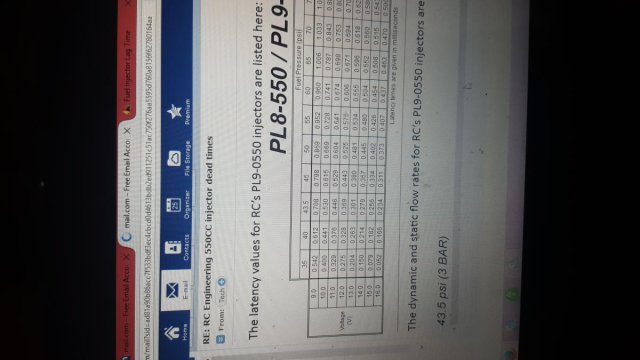

Hi everyone, I have RC engineering 550cc low impedance injectors with resistors wired in and I am having a tough time getting consistent AFRs after using Auto Tune. I will tune to get a 13.5 AFR at idle but then the next time I will see 12 or 15 as my AFR. From what I am reading, my injector dead time amount could be affecting this. I emailed RC Engineering and they sent me this document in an email. I asked if these values were for low impedance with resistors and he said they were. For Megasquirt, I am entering .263 for 13 volts @ 40 psi of fuel, correct? It seems to me that these values are too low and should be near .900, right? Any insight?

-

Was the coolant drained completely and then replaced with new fluids? If it was, you might want to try letting the car idle with the radiator cap off for awhile. My Maxima overheated after the plastic radiator blew up and after repairing it, my car would get near the red on the coolant temp gauge while on the freeway. When I let the car idle with the cap off, it pretty much burped out all the air and my car was fine after that.

-

Coolant Banjo Bolt sealing woes on turbo. Any suggestions?

dpuma8 replied to dpuma8's topic in Turbo / Supercharger

I replaced the Banjo Bolt Hose fitting and added the aluminum washers a few weeks ago and no leaks. Thanks for the advice. -

I have a shop built L28ET that I am ready to drop into my Z car but do not have my tune completely figured out yet. So to save my new rebuilt engine, I bought a P90 head and ARP head studs to put on my current N42 block. Now that the swap has been made, there is a lot of exhaust smoke coming out of the tail pipe even though the car is warmed at 180 degrees and holding. I did a compression test and cyl 1 was 122, cyl 2-5 were around 130, and cyl 6 was at 138. The Vacuum idles at 19 -21 inches. So assuming that I am leaking coolant into the engine and that is burning through the tailpipe, is it still safe enough to hash out a decent Megasquirt tune through this leaky engine for my new engine? The car feels fine driving although I haven't driven longer than 10 minutes anywhere. Let me know what you guys think! Dom

-

Coolant Banjo Bolt sealing woes on turbo. Any suggestions?

dpuma8 replied to dpuma8's topic in Turbo / Supercharger

I heated the copper rings until it got red and let it cool off. That didn't work so I bought 10 new copper washers and it steal leaks ridiculously bad. I have the copper washers on both sides of the bolt but it is always the same result. The top crush washer leaks at a rate of a drip a second. Can I use the rubber washer in place of the top crush ring that is further away from the turbo? How tight do I need to tighten the fitting? I have them tightened pretty tight and am afraid I will strip something if I go too hard. Bought a new banjo bolt and more washers so let me see how that goes. -

I have a GT30 turbo and the coolant feed banjo bolt leaks. I tried to anneal the copper washers that came with the bolt but it still leaks so I bought these washers that have rubber on the inside of them http://www.torkteknology.com/14mm-banjo-seal-washers-tork-tek-cummins-bs14mm/ Will these work or does the turbo get too hot to run these rubber washers so I need the copper ones?