Search the Community

Showing results for tags 'carbon fiber'.

-

VINTAGE CARBON Pre-order Opportunity - NEW S30 CARBON FIBER FRONT GRILL! We have been cooking here at Vintage Carbon! We are going to be coming out with an ALL NEW Carbon Fiber S30 Grill! To our knowledge, this will be the First Ever Carbon Fiber Grill made for the Datsun S30 Platform! We are going to incorporate the Thick Outer Border similar to the Fairlady 432 Style Grille, while keeping the OEM "V" shape and OEM style straight across Slats all made completely of Carbon Fiber!! The slats will be thicker so you can really see the Carbon Weave from the front. We are also going to extend the overall height about 3 inches to make sure it covers as much as possible with a front air dam installed. We are going to ensure the vents are spaced equal to OEM so air flow will not be affected. It will be different from anything out there, more aggressive yet reminiscent of OEM but made of Carbon Fiber right here in So Cal, USA!! These will really add style to any S30 Z Front End!! What do you guys think? We will be accepting pre-orders for a heavy discount off Retail cost for the first 10 people. Contact me if interested! Message me or Email me at andrew@zociety.org ! We are currently working on a high quality render as we speak! Hoping to have that ready by the end of this week.

-

*Finally getting around to documenting my build. Will continue to update the text as I go. Happy to answer any questions. Feel free to also follow along on instagram for more frequent updates. I fell in love with the S30 chassis at around the age of 13 and tried to buy one or two as my first car. Unfortunately, being from the north east, anything I could afford had rust holes in structural areas you could put your hand through. After watching the price trend over the last few years, I decided I better act before I missed the boat. -Purchased sight unseen in October, 2018 from another member here. -The car started it's life in California, was shipped to Florida by the P.O., and then I shipped it back to California. I was living in Germany at the time, so the plan was to store it with my family and make trips to work on it whenever I found the time. -I purchased it as a roller since I'd always planned to do a swap anyway. It came with a lot of T3 and AZC suspension bits already in place, most of which I sold.

-

Hello Z enthusiasts, My name is Brian Joseph, owner of BHJ Automotive, many of you may not of heard of us but some of you have. We specialize in custom Asian auto parts starting with the Datsun Z. Currently we are the primary seller of Retro-Spec products, we can guarantee all Retro-Spec products with a 4-6 week lead time, and we also hold some of their products in stock having a 2-3 day lead time before shipment. We sell other brands as well and are looking to design and manufacturer our own parts for all Z generations. If you are interested in our brand or have any questions feel free to visit our site www.bhjautomotive.com or contact us at sales@bhjautomotive.com, thank you for taking a look at our thread, we hope to hear from you all soon!

- 11 replies

-

- skillard

- retro spec

-

(and 2 more)

Tagged with:

-

Hey everyone, I decided to replace my center console for my 73 240z. The old one has some cracks and chips and the previous owner went at it with a drill and some wiring to install some custom switches that apparently he never got around to connecting. Anyway, I decided that since I have some carbon fiber manufacturing experience that this was as good an opportunity as any to try my hand at some design work and try making a custom carbon fiber part for my Z. I started with a scan of the old console- a couple buddies of mine have a free 3D scanning software that we used to get a really rough scan of the part- Converted to an STL and imported to solidworks: Next up I went about roughly reconstructing the old console. I had to do this all visually in solidworks since STL doesn't allow you to modify or "work on" the existing geometry. They were great for reference though! I spent a while using a measuring tape and the old console and the inside of the car and making absolutely sure that what I had in CAD was going to fit in the car. Next up I started making some modifications. First off was the shifter cutout: I decided to imitate the gauge "lenses" from the dashboard: Next up I modeled in some indents for my push button start, in addition to changing the shape of the rear section of the console: And of course, another shot with everything cleaned up, shifter, switches and push button added (those were modeled in somewhat loosely): I'm still at a loss for what to do with the back section- cup holder maybe? We'll see. I'll be 3D printing the mold Wednesday afternoon. I'm also open to suggestions on better ways to incorporate the push button start- although I've decided that I won't place them directly behind the shifter (wouldn't want to accidentally bump the ignition switch and shut the car off while shifting). PKZ

-

Does Anyone Know Of A Webise Where I Can Order A Carbon Fiber Air Dam For My 1978 Datsun 280z 2+2? All Of The Ones That I Have found Mount On To The OEM Air Dam.

- 1 reply

-

- Carbon Fiber

- S30 280z

- (and 5 more)

-

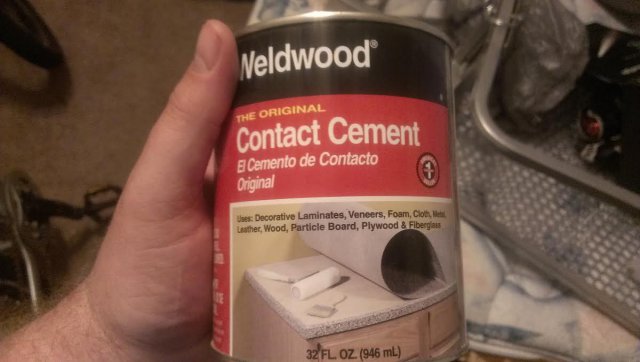

Hi everyone, I wanted to make a little "how to" for how I reupholstered the T-top inserts (dont know the actual name) on my 280zx. I had already completed the part once, but thanks to a sick cat, I had the pleasure of doing it again. Since I was going to do it all over again, I figured I could at least document it, with a few little tips I figured out myself (that apply to other interior pieces as well). I know when I first started messing around with interiors, I had trouble finding information, so I am hoping someone may find this useful. I will be doing my sun visors soon, if anyone wants a write up, let me know. First off, the part has to be removed, FSM or just looking at it should explain how it comes off, mine was already off and not installed (and covered in cat hair and snot): The first thing you want to do is remove the existing fabric, the plastic pieces are attached with pegs that fit through holes then are melted: take a knife and you can snap them pretty easily to get the parts off (I'll discuss putting them back on later): Most of these pieces on our cars is just chip board with a vinyl attached using adhesive, rivets, and staples, the staples in this case need to be removed: Now remove the material: Vinyl usually comes off relatively easy, be careful not to destroy the chipboard piece, since I used headliner material on mine....it tore apart and was a little more difficult, to make it easier you can use acetone and a knife to scrap the stuff off (works really well for headliner pieces). Once done you should have a "clean" part: If you are recovering with vinyl, you may want to run coarse sand paper over the piece to make sure and get everything even and all original fabric off. Any little piece left can be seen or felt through vinyl. I purchased some headliner fabric at Joannes, it's really easy to work with and relatively inexpensive. Lay the part on the fabric and cut to size...well, close to size: I prefer Super 77 for attaching light fabrics, it is somewhat forgiving and, if used correctly, makes a pretty strong bond. I coat both the fabric and the part in glue and let set for about ten minutes until they are both tacky then stick them together: Check to make sure that there are no large bumps in the surface and that it looks nice and even: If it looks good, trim off the excess on the parts where the fabric sits flush and the other edges keep about half an inch to a quarter of fabric hanging over so that it can be securely fastened to the bottom. The Super 77 and other spray adhesives I have used are all really good at clinging to surfaces, as long as there are not too many bends or complex curves, but if there are they seem to want to release over time. My solution to this is Weldwood contact cement, my personal choice, there are others that work just as well I am sure. You can attach the excess to the back of the part using staples if you wish, but I could not find any more really shallow staples, so I went ahead with my contact cement. I added the cement to the excess fabric on either side and to the back of the part itself. (not very noticeable) Then I waited about thirty minutes for it to become quite tacky and rolled the excess onto the part as tightly as I could. Normally you would want to start from the middle and work your way out, since this was a smaller piece it really didn't make that big a difference. Let this set while you go and tend to your plastic pieces. . . . . . . .. . This feels like one long run on sentence, sorry for that, . Now to the plastic pieces, I had cut the little pegs off of the parts, now I need to fix that so that I can reattach them. First you need materials: I could not find ABS rods, but I was able to find 1/8th inch styrene rods, a plastic "glue" a power drill with ~1/8th inch bit..some flexibility here and the part. The glue is actually a solvent, Instead of sticking the pieces together it actually "welds" them. It dissolves the plastic into a paste, when it evaporates out you are left with a rigid plastic once again. If you have a crack in a plastic, or a chip, you can dissolve some shavings with the solvent and use it as a filler, just do not go on too thick or the solvent cannot dissipate and it will look horrible. I use to use acetone for attaching a lot of plastics, it works extremely well for acrylic, but doesn't seem to hold as well on abs and other automotive plastics (for me). This particular solvent is mostly MEK based, which you could buy at most home improvement stores, MEKP is used as a catalyst for lower end fiber glass resins and I have heard that it works to weld plastics, but I have never tried it myself. Take the piece and locate where the peg was, then drill this area out Spot found Be very careful to not go completely through the piece, we are just trying to increase the surface area that is being contacted as well as aid in holding the peg in place long enough to stick. You should end up with a shallow divot Now add a large drop of solvent into this hole and let set for a few seconds While the solvent is setting, go ahead and cut a piece of the rod off, longer is better than shorter, usually I start with a little under a 1/4" Now shove the peg into the divot, twist it so that it will conform to the shape of the divot then hold it in place a good twenty or so seconds, until you can let go and it does not move: Now add some more solvent around the base of the peg, I like to push shavings around the base to build it up a little and hopefully make it a little stronger: That's one down, now go ahead and do the rest. I sometimes take my chances with the original pegs if they were not broken completely off, but it is probably best to go ahead and replace them all. I let the solvent do it's magic for a little bit then I do a test fit to make sure that the pegs line up with the holes on the part, as long as you do not wait too long (time varies with conditions), you can still move them around a little. Then I let them set overnight..because that's what the bottle says to do. . . . . . Next day: The best part, putting it all back together. Take the pieces you have added pegs to and put them in their appropriate places and trim the pegs down a little (if needed): ] Now take a soldering iron, wood burning tool, hot piece of metal, whatever works and melt the pegs to the part. I use a small butane torch and spoon....which is probably not the most innocent looking way of doing this....I heat the spoon up then press it to the peg until it melts flat. Be careful when melting the pegs, they can catch fire, the fabric is flammable as well. Once done it should look like this (or hopefully better): Continue for all the pieces you removed, also give a little strength check to make sure everything is holding firm. As long as everything is holding well and it looks good, you are done, now all that's left is installing it back into your car. I hope this helps some one. In the mean time I'm going to continue with my interior and slowly customizing everything.

- 2 replies

-

- upholstery

- carbon fiber

-

(and 3 more)

Tagged with: