mom'sZ

Members-

Posts

686 -

Joined

-

Last visited

-

Days Won

1

mom'sZ last won the day on December 21 2006

mom'sZ had the most liked content!

About mom'sZ

- Birthday 10/06/1962

mom'sZ's Achievements

Newbie (1/14)

13

Reputation

-

1973 with problems! - please help!

mom'sZ replied to cuebandave's topic in Trouble Shooting / General Engine

Ok, wecome to the site. Hope you enjoy your new Zcar, they are great cars. Now I'm going to give you some help with your problems. USE THE SEARCH FUNCTION!!!! opps... sorry for yelling -

Power is only supplyed to the fuel pump when the key is in the start position (while it's cranking) and then once it's running, there is a switch in the AFM that supplys voltage. This is by design so the fuel pump will quit if the engine stalls. (such as in a wreck) so the thing doesn't sit there pumping fuel all over a hot engine. Some later models also have a low oil pressure cut off switch. There are a couple relays involved and running the prolem down will take a little effort and some skill with a meter and detective work. But whatever you do... don't do this The system is design this way on purpose and for saftey. You should be able to put the key in the run position while the engine isn't running and pop the boot off between the air filter and AFM and stick your little fingers in there and raise the flap off it's stop and hear the fuel pump kick on. Parts america has the wiring diagram posted online, do a little searching and you'll find a link (sorry to lazy to do it for you) and check the system. Follow the wiring along, some of it runs along the floor and can get crusty. Make sure the wiring diagram is the right one for your car. They changed it up between years in 76 - 78

-

280z injector/ performance issues

mom'sZ replied to Kingnothing616's topic in Trouble Shooting / General Engine

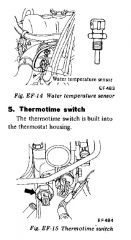

a-HA ... water temp sensor! -

280z injector/ performance issues

mom'sZ replied to Kingnothing616's topic in Trouble Shooting / General Engine

OK... couple things to check. First question, does it smoke? Like blue smoke from way to rich? Anyhow, Kingnothing616: your issue sounds a little like throttle position sensor. Which is not a sensor at all, it's more like two sets of contact switches. The cover on it will pop right off. Check it out with the engine not running, work the throttle and watch the contact switches. One set of contacts should be closed when the throttle is closed completely and open a little off idle. Then there should be a portion of throttle travel when both sets are open and then about 3/4 open or so the second set should close. Under no circumstance should both be closed at once. If they aren't working like this bend them around until they do. Next thing is the water temp sensor. smoorhs02: this really sounds like your issue. When the water temp sensor goes bad, the system goes full rich, idle is horrible / non-existent and the motor only cleans up up high. This sensor is a universal type part and readily available at any parts store for around 15$. Cheap diagnoistics. But Kingnothing616, before looking at any of this, check every connection in the system. The fuel injection wiring harness is a whole separate harness and it only has around a dozen connectors. Take each one apart, spray some electrical contact cleaner in there, give a little scrubbing with an old toothbrush and another good blast of contact cleaner. Doesn't matter if the car only has 55K miles on it, it is still thirty years old and these things have not the greatest wiring harnesses. If the connector on the water temp sensor is really bad, just replace it, it's the same as the one on the injectors and they make a little kit to replace them. If the injectors you replaced have a higher flow rate then the stock injectors the fuel ratio is going to be wacked out. You can adjust the ratio by fiddleing with the AFM but I don't know if you will be able to get enough adjustment. If you decide to try find Blue's tip on Zcar.com or Atlanta Zcar club web site. Also might want to check the carbon trace on the AFM. Requires a volt meter. Again check Blues tips. But first eye ball it, sometimes a big chuck of the trace just falls right off. DOWNLOAD THE EFI BIBLE from link at top of this forum. DO IT.... NOW! read it, read it again. -

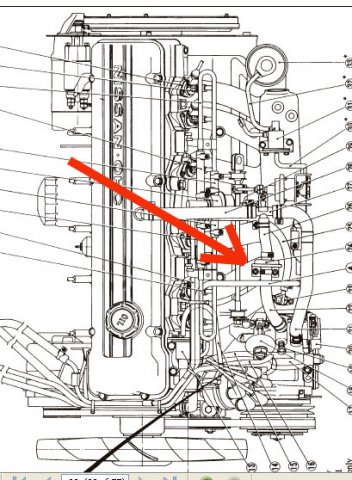

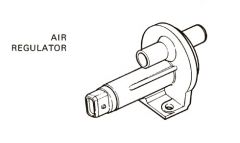

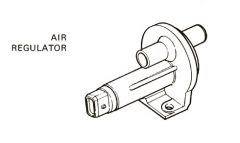

first picture is line drawing of air regulator. Second picture is line drawing of engine from above with big red line pointing at air regulator This picture is of oddmanout84's engine compartment (hope he doesn't mind) showing hose leading to regulator (click the pictures to make them bigger) Aux. air regulator feeds additional air into the intake when the engine is cold to raise the idle. Read up in the FI bible on how it works but, it has a big hose leading to it and coming out the back of it. If the hose is cracked, air could be sucked into the intake. Same with the hose running to the brake booster. One end connects to the brake booster, the other to the intake manifold (on top near the back) with a one way valve mounted on the firewall halfway down the hose. Most likely at the gasket surface between the intake manifold and the cylinder head. This would be more likely if the manifolds had ever been off but could be from manifold warpage. Hard to discover, some guys spray carb cleaner on the area while the car is running, but be careful if you do so as not to catch yourself on fire! Keep trying. Remove the clamps completely. Then peel the edge up slowly all the way around. If they are the original ones they are most likely cracked. Once it's off, spread the pleats and look down inside there. BRAVO!!! Nope... very simaliar problems, good thread title good luck!!!

-

OK... for the original poster (norstar)... you will help us diagnois your problem much easier if you post the year / model car with your question. Also for something like this, whether it is stock carb / fuel injection and if not, what mods. I'm going to guess you are talking about the car in your signature, 74 260z. If so it is a carb car. Since you stated that you've replaced all the vacumn lines, 100dollarz's suggestion that it's a carb problem may be a good place to start. Perhaps a warped throttle plate or bad gasket leaking air until it warms up and seals itself. Also maybe leaky intake manifold gasket. The sucking sound could be bad vacumn booster if you have power brakes or the line that runs to it. Just throwing stuff out there. fisheric: thanks for posting year / model. I'm not super familiar with the zxt's FI but it is similiar to my 77. You also state that you replaced all the vacumn lines. Have you checked the big one that runs to the air regulator? This sort of makes sense because the problem occurs when cold. The air regulator helps during warm up to slightly raise the idle speed when the engine is cold. Check Dareon's sticky for the fuel injection bible at the top of this forum. Download it and read for more info on how the air regulator works and how to diagnois. You stated that this past summer you replaced all the vac lines and it cured it but came back. Could be that during the summer, when warmer, the air regulator wasn't needed and the problem was masked. Even if the big fat line that runs to it looks good, remove and inspect. Sometimes a line can look decent, but if you look close at it, bend it this way and that, it will crumble in your hand. The line to the brake booster could be a similiar issue. Slight crack, seals up when warm. Leaky intake could be your issue as well. Check the boots between air cleaner and AFM and AFM and throttle body. Again, pull them off, spread the pleats and look in there. Post up results, even if you cure it, so to help others.

-

Hey... if any of you 280z owners want to make a few extra bucks, sell me your old bumpers. If they are the big ugly ones, I'll buy them off ya! (need brackets and isolators and all)

-

I had a misguided dodge van owner who brought me a vehicle with just this problem. After hours of messing with it, I finally managed to use a small pick with a hook end to pull the piece out. Lots of cussing and spray penetrant and maybe even a little heat... but it finally came out.

-

On the brake lights, the switch pushes against a little plastic piece that is inserted in a hole in the brake pedal arm. Over time little plastic piece turns to dust and falls out. Switch has nnothing to push against and pokes through hole. Easy to check, just stick your head under there and look. Appropretly sized body plug from any parts house makes good replacment

-

The stock zcar oil sending unit is notorious for going bad and leaking. Not something I would want attached to my new engine. Secondly, the stock sending unit is BSP (british pipe thread). I would assume a SBC would not. So you would need an adapter. If you are so inclined however, McMaster - Carr has em.

-

People please... before you post a problem with your EFI 280z, get a can of electric contact cleaner and a toothbrush. Disconnect every connection in the EFI harness and spray - brush - clean each connection, there are only a few on the EFI harness. (it's a seperate harness from the rest of the car)

-

Sounds like the throttle position sensor might be out of adjustment. It has been my experience that when the water temp sensor goes bad, the system goes full rich. It won't run in gear and smokes badly (blue) won't idle and only runs half decent when you rev it up Check the throttle position sensor. Don't replace it, check it for proper adjustment and readjust if neccesary. Here's how: Pop the cover off. Inside you will find two sets of contact switches. One should make contact when the car is at an idle and the other should make contact when the throttle is about three quarters open. They should not make contact at the same time and there should be some throttle travel between when the idle one opens and the WOT one makes contact. Adjust by turning the assembly (it has little set screws that can be loosened and the whole thing will turn slightly) and bending the contact arms (gently) Also.. this sounds similar to when my stock ignition module went bad. In my case, the ignition module would go heywire when I revved the motor up close to redline. It (the ignition module) would overheat and the motor would barely run. Maybe in your case it is worse and it runs OK when first fired up but once it's run for a little while, module heats up and motor won't run right.

-

L6s have a pressure bypass built into the oil pump that lets them bleed off any pressure higher then about 60 psi. They are, generally speaking, a somewhat lower oil pressure motor. My engine is freshly rebuilt, new oil pump, passageways clean numerous times, engine is fully blueprinted, truely as 'tight' as an L6 could be. It still gets down around 10 psi at an idle when the oil is hot. I don't consider this abnormal for this engine. At anything above an idle it has at least 40 - 50 psi. But this is a brand new motor. I have had a number of L6s (very high milage) that barely cracked 10 - 15 psi ever. And often went down to zero at an idle. If I was going to put a warning light on your car, 15 psi sounds pretty good for a fresh engine. Just be ready to see it flicker at an idle. The point would be that during an on track session, if you see it come on, you would check the gauge.

-

I know this may not make sense logically, but the intake runners being smaller then the port in the head may actually help. Here's why: As the gasses flow thru the ports, as you probably know, there is a period of time when both intake and exhaust are open. The effect of this is different at different RPMs. At some RPMs reversion occurs, in other words flow actually tries to reverse and exhaust gasses try to push the intake charge back up the port. It doesn't actually do so, but it can hinder intake flow. The step between intake manifold and head may actually help inhibit this reversion. Also, any attempt to 'port match' the intake to the head must also include some work making sure the intake mounts positively. Slop in the mount holes may allow some misalignment once the intake actually ends up bolted in place. Your perfect port match job may end up creating a lip on the head side. Understand that porting works different and has different effects at different RPMs. Opening up the ports may help high RPM flow, but create a 'dead spot' at lower RPMs, where the charge actually stalls or has greatly reduced flow. Think about where your engine operates, at what engine speed. With earllier model cars, such as our zcar engines, often great gains can be made by just cleaning up sloppy castings from the factory. There is a lot of information out there about head porting. Lots of good books and stuff on the interwebs. The most improvement can usaully be made working in the bowl area of the port, just behind the valve. If your car is a turbo car (cygnusx1's is I think) opening up the exhuast side and polishing it can almost never hurt.