Chunky

Members-

Posts

28 -

Joined

-

Last visited

Profile Information

-

Location

VA

Chunky's Achievements

Newbie (1/14)

0

Reputation

-

Eureka!!! So I went back out today to give it another go. I think I got all the adjustments dialed in! My problem was I was adjusting for pedal feel, I'm used to having a solid pedal. I was trying to get a solid pedal and then adjust the rest to work. I found that with everything adjusted properly, my pedal actually doesn't feel all that great BUT it seems to work. Reverse is actually smoother than first now (which has me worried that something is going on with that but that's for another day). With everything adjusted my pedal feels "weak" but reverse doesn't grind, all the gears work and I don't feel the hesitation associated with clutch slippage. I tested it driving around the block a few times. I even tested shifting into reverse several times in a row and it worked each time, previously reverse worked the first time immediately after adjustments then started grinding on subsequent attempts. Fingers crossed. (I realize most of this thread is me talking to myself... so thanks for listening! Haha)

-

Actually this is a habit I picked up when I was first learning how to drive. I've always gone into first then into reverse, for some reason it always "felt right" doing it that way, even in more modern cars I still do it. Last night I drove it to the gas station to fill her up, she'd been sitting near empty for a while. Just for the hell of it I decided to test reverse again, I went into first, then slowly tried to get into reverse. I could feel it was starting to grind so I didn't push. I drove it home. At home I wiggled it in neutral then tried to ease it into reverse (no first that time I wanted to try different things), it started to grind. So I tossed it into first, then I started going into reverse and it started to grind again. I went back into neutral, went into first again then I went for reverse a second time... this time I slowly & gently eased it into reverse and it went in! But it did take some finesse...

-

PROGRESS! I decided to reset everything back to zero and start over. I Set my pedal a touch lower than before but still higher than it was, 7.75". I adjusted the Master push rod to take out the slop. Set the slave cylinder to have just a touch of play in it. Went back and readjusted the master again since it looks like the slave adjustment introduced a little more play in the master push rod. Drove the car around, and it felt great! I didn't feel any clutch slipping BUT I noticed that reverse is still a little picky. I have to slowly/gently put it into reverse. Sometimes it starts to grind, I just wiggle it around in neutral a bit then go in gently again and it will work. Sometimes it takes 2-3 tries. Forward gears work fine. Ideas? I'm thinking of trying to adjust the slave again to lessen the amount of play OR do I need to adjust the pedal outward to give it more throw? Not sure.. if either or both will work?

-

Thanks for the reply! I went out and checked the rubber boots on both master and slave. I peeled them back and felt around. I felt some grease but there was no fluid in the boots. I'm thinking of resetting everything back to zero; pedal, master and slave. Start over and adjust everything one by one. Pedal first to get the height set and master adjusted to that. Then I'll try readjusting the slave and re-bleeding it over again. From another forum... "Also, if you keep backing the nut inward towards the slave cylinder (towards the front of the car), with the spring off you should reach a point where there is play in the clutch arm. Keep going in several more turns. Now with the clutch depressed, you shouldn't be able to shift gears at all. Then, put the spring back on and work the nut outward, towards the back of the car a couple of turns at a time. Have your wife push in the clutch and see if she can change gears. When she gets the gears to change, you should be able to go a couple of turns further. Take off the spring, and see if you have play in the arm. If not, back off 1 to 2 turns and see if you have play. You need to have some play or your throw out bearing will be in constant contact with your clutch plate." I'm still open to other ideas though...

-

Hey guys! I'm having some trouble. I've tried adjusting my clutch; master, cylinder, pedal. I've done some research, this is what my adjustments were based off of. Recently I replaced my clutch master cylinder and since then I've been unable to get the clutch working properly. Shifting into first is a little notchey, sometimes needs a little "persuasion" but it doesn't make nay grinding noises. Shifting into reverse it grinds, I test it out by slowly shifting into reverse. If I hear it starting to grind I back out immediately, I'm not going to try forcing it in. I'm not sure if it matters but I'm able to shift into all gears with the car off. Here's the weird part... sometimes I'll test it out and it works fine, reverse and all. I'm able to drive it around the block just fine. Then I'll park it and come back out a few hours later and it will grind again. Pedal: I read it's supposed to be about 8.75" from the firewall. I noticed mine was at 7.5". I tried moving it out to 8" and it seemed to work. I drove it around the block. I then parked it came back out a few hours later and reverse was grinding again. I set the mater cylinder rod to bolt up with the pedal then adjusted it some to remove the slop in the pedal. I remember the pedal not feeling very firm anyway when I first got the car. Unfortunately at this pedal height I'm at the end of the adjustment range on the clevis. Should I move it back to 7.5" like it was before? I'm thinking having it at 8 gives me more throw than 7.5. Master: As noted above, I installed the new unit. Then attached the rod to the pedal. Once it was bolted on I noticed there was some slop in the linkage. I went ahead and turned the rod to tighten up the linkage to the pedal. I did this by hand just until there was no more slop and then another extra turn, however, I'm now at the end of adjustment. I was thinking of measuring the amount of travel in the rod, How many inches of total travel should it have? Slave: I've bled the system numerous times. I've found that each time I get no air coming out, just straight fluid at this point. I have the older slave with the adjustable rod. Is there a good step by step for adjusting this? How much should the slave cylinder/fork move when the pedal is pressed? Here's what I did: -Bleed system. -Remove spring. -Push clutch fork out as much as possible by hand. Towards firewall, away from slave. -Adjust rod until it touches the fork. -Tighten it a few more turns. -Reattach spring. I've tried to research this and I had my helper push in the clutch and hold it. I watched the slave cylinder move it held it's position with the pedal pressed. So I'm thinking there's no leak. I'm hoping my adjustments are just off. I have a 71, so it's the older version where adjustment is made at the master and slave. I've read that it's kind of picky trying to get them both adjusted together properly. Sorry for the wall of text, I try to give as much information as possible.

-

Weird clicking sound from rear, u joint or diff maybe?

Chunky replied to Chunky's topic in Drivetrain

Sorry about reviving this post from last year but I wanted to share the conclusion. I finally got around to going under the car. I started grabbing and shaking stuff. I found that my u joint on the drive shaft had a lot of play and shaking was making the clunk also the nuts had worked themselves loose which I'm sure didn't help any. I pulled it out and had a drive line shop replace the joints. This issue's been resolved. Thanks, Ray -

I got the driver side installed Wednesday evening. I did notice that with the driver side there is a hump in the trans tunnel that the reclining knob will not clear. I had to remove the inside knob, but it's fine because the other side knob is still present and it works just fine. Sitting in it with a steering wheel as reference, I had a better feel for it all. It sits a little bit higher compared to the fake-aro seat, but not enough to say that it's "too high", at least not for me. Over all I like it! The seats with the center console as reference, hopefully that will help show how high the seat sits. From a lower perspective to compare the seat to the door jams. (pls excuse the surface crud)

-

Hey guys! I just wanted to share my experience with fitting Recaro seats in my 71 Z. I have 2 sets of seats for the car. First set is a pair of the ebay fake-aro sidemount buckets. The second set is a pair of LX reclining, old school style. Starting with the stock seats, I replaced the driver side with a fake-aro leaving a stock passenger side. I then installed the passenger side, leaving me with fake-aro driver and LX passenger. That's what I'm basing my comparison on. I never had both fakes or LX installed at the same time at the time of this post. I will do the driver side later though, too tired from the heat and twisting my body in ways I didn't know possible. Relative to the stock seat placement and height: (I'm about 5'9" 164-ish pounds)... Comparing fake-aro driver with stock passenger; The fake-aro's sit about even with stock. I have them side mounted to universal sliders then the sliders are bolted straight to the attachment points for the seat. I used some flat pieces of steel to get them situated. Sitting in the seat was nice, it was like a glove. Unfortunately there was some flexing. I'm thinking that was due to the nature of ebay specials. I didn't feel comfortable driving around like that although I did sometimes feel like a race car driver. Driving with them, I felt that they sat about even the stock seats. I didn't feel like I was much lower or higher than before. The shoulder bolsters are very prominent on this seat, they sit very close to the door jams although they don't interfere with the doors at all. The LX seats; I have them mounted to a set of Recaro non-tab sliders (which you must use due to the weird 6 bolt pattern) which are then bolted to Planted seat bases. Overall they sit very close in height to the fake-aro seats. From the top of the headrest is about ~4 inches to the headliner. Def enough room for me. I'm able to slide the seats all the way forward and back. The bolts I used are short enough that they don't interfere with each other inside the slider. The round reclining spin handles fit fine on both sides and are functional from either side, although the side against the trans tunnel is a little tight but it doesn't interfere. I can even recline them all the way back until the back of the seat is really close to the "ledge" where the compartments are. The sides clear the door jams just fine. The passenger seat was a night and day difference in comfort and stability compared to my stock seat, of course my stock seats were pretty worn out as well so take that into account. I'm hoping the driver side will produce similar results. Recaro LX bottom mounts + Planted seat bases w/ recaro sliders do not sit overly high, which was my fear going into this. I was worried that the seats would sit so high that I would feel like I was 4 wheeling. That is not the case. This isn't a seat review so I may not be very in depth, I just wanted to document my experiences installing the seats in case somebody's interested in doing a similar setup and is looking for info. I kept all the little baggies for the nuts and bolts so I'll post up a list later. I can't wait to get the passenger side in and take it for a spin. Sorry no pics yet, I literally just got done. I wanted to type this up while it was still fresh in my head. After I get the driver side in I'll post up results from that experience as well, either tomorrow night or Thursday. One question... I used home depot bolts, would that cause a problem? I hit up the grade 8 section. ======== Washers, Nuts & Bolts Recaro slider -> seat: - m6 (x1.00) cap screw, socket, plain steel, 16mm. (x6 per seat) 20mm will also work. Can probably sub for shorter as well but 16mm looked like a good length to me at time. My seats had the pattern with 2 bolts up front and 1 bolt in the rear. I read somewhere that some seats use only 4 bolts and for those use m8. (confirm?) - m6 lock washers. Not sure if needed but it sounded like a good idea at the time. recaro slider -> planted bracket/base: - m8 (x1.25) cap screw, socket, plain steel, 16mm. (4 per seat) - m8 (x1.25) socket cap screw, plain steel, 16mm. The combination of cap screws enables the mounting bolts inside the slider to move without interfering with each other. Seat base -> car: -m10 (x1.25) flange bolts. Zinc plated (4 per seat) On my car these size bolts fit the holes in the original seat mounts perfectly. Although the length was a little off. I used 30mm for the front and 25mm length for the rear, because I purchased 30's originally. To keep it simple shorter bolts can probably be used all around. -m10 (x1.25) flange nuts, Zinc plated. -m10 lock washers. The cap screws are the most important. But for the flange bolts regular style bolts can be used. The main reason I liked the flange bolts is they had serrations on the underside of the head to help grip the mounting surfaces. I don't think it really helps that much, but it sounded like a good idea at the time. If you see something wrong, please please please speak up. I'm not an expert, just sharing my experience. I'm open to learning if I've made a mistake. (Will post pics tomorrow after driver side install in the next day or so) Edit: Added nuts & bolts list.

-

Hey guys! I recently called a local drive-line shop here in town. I asked about getting my half-shafts rebuilt with Spicer joints, it seems to be the common consensus that Spicer or OEM are the 2 best bets. I remember looking them up and finding actual part numbers from Spicer. When I called, however, the drive-line guy informed me that Spicer doesn't actually manufacture the u-joints themselves, they are manufactured by other companies and repackaged by Spicer. Is this true? I was under the impression that the Spicer joints were...well.. Spicer joints. If this is the norm then I'm cool with it since it's the way everybody else goes but is this guy FOS? It bothers me that he would say this because the drive-line shop has been around a while(it doesn't necessarily mean anything, but I'd like to think it does). Thanks, Ray

-

Weird clicking sound from rear, u joint or diff maybe?

Chunky replied to Chunky's topic in Drivetrain

Hey guys sorry about the delay. I've been slammed at work and don't have much time to really get in there since I (and the car) am moving in a few weeks. As a result I'm a little hesitant to start tearing too deeply into anything since the car will need to be moved shortly. Once I get the car over to it's new home I'll have no problems really tearing into it. Thanks for all the advice. I was able to get the car up and wheels off. I noticed that the passenger half-shaft does have a tiny amount of play when I yank on it, not rotational but pulling the half-shaft in and out motion from the diff. I also checked the bolts on the drive-shaft itself and they were all tight BUT I noticed that there is some rotational play. Pulling on it in and out it's solid, as well as wiggling it. However, I'm able to rotate it slightly both clockwise and counter clockwise. It's not a lot but it's enough to be noticeable. Is it normal for the drive-shaft(shaft between trans and diff, in case I have my names mixed up) to have some rotational play? I might have to check again, but it seemed that the rotation was not from the u-joint itself but from the input flange. Ray -

Weird clicking sound from rear, u joint or diff maybe?

Chunky replied to Chunky's topic in Drivetrain

Thanks for all the advice guys! My research continued after my posting. I did find some interesting things. I was able to spend some time today looking at it more today just before it got dark. I jacked the car up and took the wheel off. I checked the bolts that hold the half-shaft to the hub, they are all good and tight. With the wheel off, I was able to better inspect the half-shaft itself. I'm squatting in the wheel well looking straight at the half-shaft. When I grab it and pull it towards myself there's definitely some play. Pulling it towards myself makes a small clunk sound. I'm thinking that may be part of my problem but I want to hear from others that have experienced the same thing... that small amount of play and sound be an indication of something wrong with the shaft? Or am I convincing myself that that's the issue based on what I've read and it's normal? Off to more reading... thanks guys! Ray -

Weird clicking sound from rear, u joint or diff maybe?

Chunky replied to Chunky's topic in Drivetrain

Doh! Sorry, I was so focused on trying to be as descriptive as possible I left out the obvious. Its a 70 240z. Mostly stock as far as I know; r180, drums. It is lowered with springs in kyb inserts. Actually one other thing I noticed... The rear passenger side does sag compared to the other corners. I figured it was a blown shock bec I've heard kybs are not good with springs but they were cheaper. -

Weird clicking sound from rear, u joint or diff maybe?

Chunky replied to Chunky's topic in Drivetrain

My bad I just realized that the link I posted was to another site. If this is a problem please let me know an I'll remove it. Doing more research I came across a post(on another site) where somebody mentioned changing diff fluid solved their problem, the issue was from the lack of fluid in the diff. Thinking about it now, I do recall seeing that the diff did have fluid all over it. Possible that it's low on fluid? I'll look into that next. Ray -

Hey guys! I'm hoping to get some advice. I've tried searching so I have a few ideas based on that research. Here's what happens... when I reverse it's fine. No noticeable sounds. When I move forward there seems to be a sound that comes from the rear passenger side. It's a soft of clicking, like a "dut-dut-dut-dut" sound. As I accelerate the sound gets faster, not louder. When I hit a certain speed, around 10-15 mph, it goes away.Now when I come off gas and I slow down, when I get to a certain speed slowing down the clicking sound comes back. It only seems to happen when going forward, the little time I spend going in reverse hasn't caused any weird sounds yet. Here's what I've checked so far... - I noticed that the 4 bolts holding the axle to the hub came loose. I tightened those. - I also read the possibility of u-joints. After tightening the bolts above, I grabbed the axle and gave it a good wiggle. It felt solid. I grabbed the diff-end of the axle and gave it a good shake. There was a little bit of play, a very very small amount. I figure that would be enough to be an issue. I checked the bolts between the axle and diff output shafts. I noticed that the wiggle seemed to almost be coming from the diff's output shaft, or the universal joint maybe? I thought I read somewhere that a tiny bit of slop is normal in these older diff's and that there is no slop when spinning.(http://www.zcar.com/forum/10-70-83-tech-discussion-forum/96436-wheel-differential-bearings.html) What's a good way to isolate the wiggle? a pry bar maybe to leverage the axle? I'm just trying to pinpoint the issue before I start "fixing things." I'd hate to spend time and $ on something that's not even an issue. Thanks guys! Ray

-

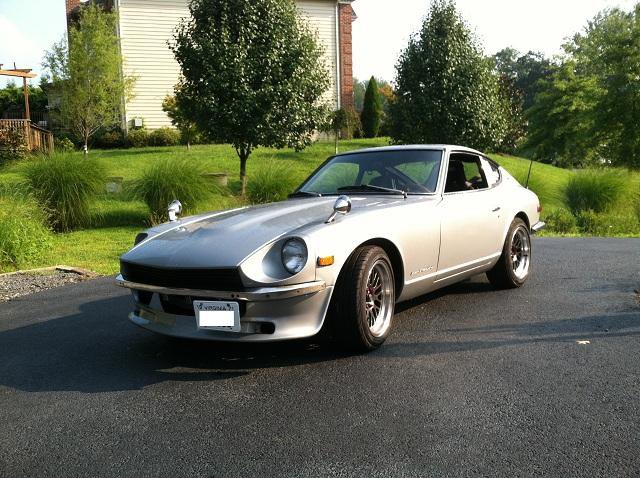

Wheel Show! Post your pics of you wheels

Chunky replied to k3werra's topic in Brakes, Wheels, Suspension and Chassis

I LOVE Comicartist's fitment!!! Shooting for something similar flares and all... one day... For now, here I am on XXR 531's. 16x8 +0 w/ 205/50/16 + Tokico Springs & KYB Struts