All Activity

- Past hour

-

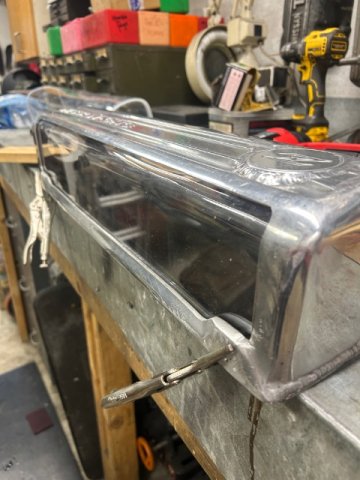

Well much rain is forecasted so I’m taking her off the road to attend to issues as in exhaust leak somewhere and # 3 port pulling more air than the others . Of course the only way to see the butterfly in the ITB is to remove it . I think the exhaust leak is at the header flange so that’s a remove project - ugh . I also think I might have pulled off my air box scheme . Taking me a while to get better at forming the plexiglass but the new buck is spot on for the most part . Hopefully I get all these issues resolved during the downtime . The engine is really running good but I’m hoping longer stacks will bring me into the sweet spot . A friend is printing out the 75mm stacks and I’ll probably also do a set of 90’mm . I think I have plenty of room to fit 90’s without impeding flow around them .

- Today

-

My Z car log....small jobs done and fun things

A to Z replied to A to Z's topic in S30 Series - 240z, 260z, 280z

-

I agree, I reached out to Apex earlier this week asking about feasibility using the existing shock stroke with 400-450# springs. Yes, loading the outside tire on burm and then hitting an imperfection on the track seems like it would decimate one of these shocks (same with hitting kerbs/rumble strips) unless I find a way to get more travel. If I could get 5inches of travel I would be very happy but I will try for a full length (~6.5") shock design if I end up copying MMI's Mod 2. Very interesting, would definitely prefer welded to bolt-on but if everything fits up right I could end up using it as a way to test different upper wishbone lengths. The Griggs conversion looks like a pretty strong structure but I don't want to jump to conclusions quite yet. Do you have any photos of your work? Interested to see what your mounting solution looks like. If I can avoid trimming the strut tower and still get the full stroke shock I will.

-

I'd probably start in the 400 to 450 range given the tires then. The struts were stock-style reinforced 280Z bodies. Spring rates were for springs but if I remember correctly MR should be 0.97 or close. I can't find my notebook at the moment. It's all detailed in buried threads on this site. There's a lot of it in the shock/unsprung weight FAQ I think 5 inches should easily be enough for a track car. By burm do you mean a banked corner? I know a few people on this site run their cars at tracks with high oval-style corners, and perhaps they can chime in on what they see for travel. My wife has a '65 Mustang. That's a sweet kit from the look of it. My mock was very similar, except it used a Joe's style front 2-piece a-arm. So you only needed to have two holes for the A-arm to poke through. I was doing the upper mount similar to what Griggs uses on their Fox body conversion. It comes down from the stock Datsun upper strut mount.

- Yesterday

-

Tire selection is Nankang CRS 200TW 245/40R17 front, 275/35R17 rear, I would use their AR-1 100TW however they do not offer a 275 section tire for that model. Car will be almost exclusively a track car but despite my spine's best interests it'll probably see a very occasional Sunday drive. Were these rates with OEM-style strut type suspension? What were your wheel rates? Maier's issue with the shock travel was that unlike an autoX/hillclimb car, a road course car would see burms and 3.5" total shock stroke just isn't enough. Great insight still, thank you. The kit just shipped about 3 hours ago (for better or for worse), when it arrives I'll be able to get those measurements to see. When you say "adequate travel" I'm assuming a that refers to just enough travel for the ~3 inches of travel you've needed for your own car? I'm assuming if I want something closer to 5-6" travel, the upper arms would need to be closer to a foot long. That's what I'm finding as well just looking at Maier's Mod 2 front axle suspension kit. Complete replacement of the front strut towers moving the pickup points slightly upward and a few inches inward to increase clearance between the coilover and upper control arm. I'm not opposed to doing this and I could even keep most of the Apex kit except for probably both the wishbones. Ah yes, old stockcar components on eBay, a true goldmine for (hopefully) decent parts. Definitely have looked at sourcing a fuel cell and oil coolers from there. Luckily I have access to rapid prototyping equipment and fabrication tools so I'm good to go. Not the best welder or anything but I know a few. Thanks for your help tube80z. Only other gripe I have with this design is on the rear subframe; the differential and control arms mount on the same structure and that seems like an exceptionally suboptimal design choice. Time will tell I suppose.

-

A musician's therapist (The $300 Z)

Zetsaz replied to Zetsaz's topic in S30 Series - 240z, 260z, 280z

Car is finally back on the ground after waiting entirely too long on mismatched parts and alternatives when the flare on one brake hose broke. I was worried about the E brake capability based on some reviews but it seems like it's plenty capable on even a gentle hill after adjusting. at worst it's comparable to the original parking brake ability, but with less adjustment to do not. Not that drums were terribly complicated, but adjusting them properly was tedious. -

Hi Carlton, A lot of this has been hashed out over the years. There are some helpful stickies available in the FAQs for selecting damper and spring rates that you may want to refer to. Before you get too far into recommendations about springs, etc., would you tell us what you intend to use this car for (track only, dual purpose, autox, street, etc.) as this will help give you better recommendations. It would also be helpful to know what you intend to use for tires, as this is one of the most important factors to know. Low-profile radials will require softer springs than a higher sidewall racing tire (such as a slick, R-compound, or HP 200 TW). The more grip the tires can generate, the higher the spring rate needed to be able to deal with the forces that take up suspension travel. I'd agree with Mike Maier's criticisms of the Apex upper A-arm on the front suspension. It is going to always limit the amount of available suspension travel that can be used. With regards to how much travel you need, that will depend a lot on tires and the use of the car. On my autoX/hillclimb 240 that weighed 1850 or 2050, depending on class, I ran Hoosier bias-ply racing slicks and some of their radial slicks. The spring rates I typically used were 400 to 600 lbs/in on the front and 400 to 550 lbs/in on the rear. This car was droop limited, and front suspension travel on the roughest hill was typically less than 2.75 inches in the front and 3.5 inches in the rear. I experimented with softer and stiffer rates but found this range worked best. A friend's street legal dual-purpose car running on 200 TW or R comp low-profile tires weighed 2400+ (LS and T-56). This car was happier with 375 on 450 spring rates. It was also droop limited and I found out how horrible this made the car ride on normal street drives. So if you go down this path I'd recommend a quick disconnect when not needing the limited travel. My personal feelings on the Apex upper a-arm are that it should be about 7 inches long to get adequate travel. On my a-arm mock ups, the only reliable way I could see doing this was to use holes or pockets on the inner fender that allowed moving the inner pickup to the center of the frame rail. Then it looks more like a '90s to 2000s Mustang strut to a-arm conversion. The parts to do this are that bad if you use circle track components, and you can source used parts from eBay for trying out different ideas. This requires you to have access to fab equipment, so if you don't, this isn't a road to go down. Cary

-

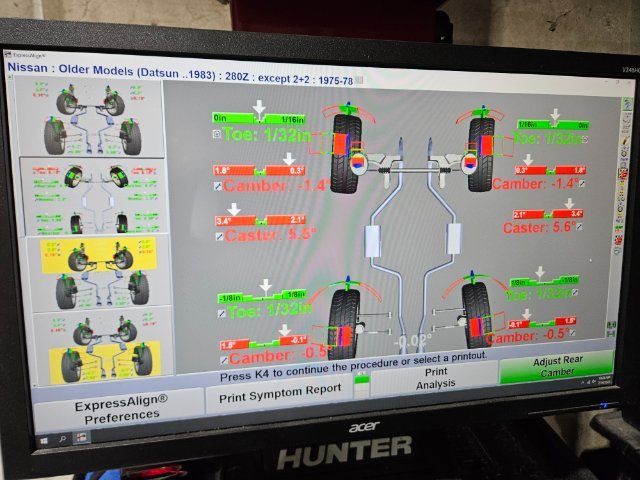

Got an alignment done after adjusting everything. Front: 1/16 toe in -1.4 camber +5.5 caster Rear: 1/16 toe in -.5 camber

- Last week

-

TestaRossa joined the community

-

Spoke to Mike Maier today seeing as the front suspension is most similar to that of an old Mustang. I wish I could write notes faster because holy hell that man is a wealth of knowledge. Suggested the reason for high spring rates is to prevent the upper control arm from camming over (poor arm design) and that the 3.5" of travel is definitely not enough for a road racing/track car (burms). Looks like my next steps are installing an adjustable upper ball joint that can move up/down to change the coilover angle and shock pot it at ride height looking for the lowest load value. If no substantial gains can be made there it's either back to the drawing board to make a push/pull rod cantilever or cut out the shock towers entirely and try to copy MMI's own Mod 2 strut tower modifications as well as new control arm(s) to gain the ability to mount a full length shock to the lower wishbone. This is becoming more and more of a fully custom project by the day.

-

TR's 260z L28 Build Thread

TrumpetRhapsody replied to TrumpetRhapsody's topic in S30 Series - 240z, 260z, 280z

Tisk, late again! Back in early June I took the plunge and ripped out MS2 and EDIS, to completely rewire for MS3 Pro Mini with LS3 COP, a dedicated relay box, flex fuel, dizzy signal from a Jeep CAS for sequential fuel, and more sensors. I ran into some interesting issues. On the MS3 1.6 firmware I found a bug where Fan Control would not work properly on the PWM-Idle output, so I had to run 1.6.2 beta2. Oddly, having swapped to directly feeding MS3 from my crank VR sensor (instead of EDIS), triggering the fan was causing a phantom RPM signal to fire the injectors and coils thinking the engine was starting. I suspect my troubleshooting of that may have fried the firmware on my LC1, so I ended up upgrading to an LC2 which reads much smoother! I still need to figure out what's causing that, but so far I'm not seeing noticeable effects when the fan kicks on and the engine is running. To get my E85/Flex going I still need to cut bend and replumb my engine bay fuel lines through the new sensor, and I haven't wrapped the harness so no pics just yet. Eventually I also need to modify the Jeep CAS to fit the L28 slotted drive so I can get going with sequential. Still, it's running so much smoother on semi-sequential rather than batch mode. The AFR and fuel pressure safety features are also a godsend! -

What is your Rear End Gear Ratio? You probably should be running 4:11 or lower. Also, what size slicks do you have?

-

A simple solution for door slamming problem? I finally finished my 8.8 Super Duty 8.8 Differential Conversion so I had time to handle all those small detail work. During my restoration work, I used Precision Weather Stripping to my worn OEM ones. But the Precision Weather Stripping always seemed too stiff for its job. So anyway, I gave them about 4 months but still had to slam the door to seat the weather stripping. It never got better so I know some members used late model KIA weather stripping from Amazon and good results. So I tried the Kia weather stripping. It was a lot softer but still had to slam the door. I decided to remove the Door Latch and study its operation. After removing it, I cleaned it and lubricated it with White Grease. Everthing seemed tested fine when it was out of the car. But after installation, the problem was still there. The Door Latch seemed like it still needed a little more inward movement to function properly. So with the Door Latch installed, I watched the Locking Mechanism operation. As the Door Glass was not installed yet, you have a good view of the Locking operation. this is when I noticed that one of the Latch Mounting Phillips Screws( 6mm x 1.0) was hitting the Linkage. This Screw is 4MM too long. The Easy Solution was to cut off about 4MM of the threaded end of the screw. Pic of the Long Phillips Screw-Inner Bottom Mounting Latch one. ". , Pic of "Corrected Phillips Screw" I really don't know when the Phillips Screw is mistakenly replaced with a Longer One. Owning the 240Z for 54 years, I am sure I removed the Door Latch at least 4 times. Anyway, if you having Door Slamming Problems, check the LATCH MOUNTING SCREWS. It was a Simple Solution for me, maybe for you, too.

-

Update From Apex: Front • Motion ratio: 0.92 : 1 (wheel : shock) • Wheel rate: 0.92² × 600 lb/in ≈ 510 lb/in • Wheel travel with 3.5" shock stroke: ≈ 3.2" Rear • Rocker motion ratio: 1.00 : 1 • Wheel rate: 700 lb/in • Wheel travel with 3.5" shock stroke: 3.5" Some confusing design and hardware choices here. Using a bellcrank/rocker with a 1:1 motion ratio doesn't take full advantage of the system. I will end up designing and having manufactured a new billet bellcrank/rocker with a lower motion ratio to get more shock travel. Highly likely I'll source a Hyperco spring at a different rate but that'll be handled during the bellcrank redesign and is a straight forward task. The front axle is giving me some headaches. The lack of suspension travel could be fixed by adding a bellcrank/rocker, but there isn’t enough space to fit one between the top of the strut tower and the hood. Making room would require major cutting and fabrication to the strut towers. Mike Maier Inc.'s solution to a similar problem was to completely replace the original shock towers with a custom design, allowing a full-length shock to mount higher and further inboard. On the Z, moving the strut tower further inboard could create enough clearance between the upper control arm to let a coilover mount to the lower control arm. But by that point, I'm only a few steps away from designing a fully bespoke 1:1 double wishbone kit, making the OTS kit a useless purchase. I've been drawing up some concept sketches on how I could possibly do a pull rod but that would render the OEM strut tower essentially useless. Alternative to implementing a front axle rocker would be to modify the upper wishbone where the bottom of the coilover mounts to be further inboard which would lower the motion ratio more but I'm not keen on trying that solution. I think I need a sanity check, I'm used to working on strut-type suspensions that have decently high shock travel to the point where coil-bind is a more pressing issue at low ride heights. Is there another solution to a short shock stroke and high spring rate I'm not considering? Or is this a case where the problem is all in my head and having 3-3.5" of shock stroke isn't that big of a deal? I've spoken to Rob Fuller from ZCarGarage regarding this problem who had some great insights on Z suspension, unfortunately he wasn't able to help me much past confirming that the wheel rates are ludicrously high. I'm aiming for a front axle wheel rate in the range of 300# to 450# and even then 450# still seems extremely high for the front axle.

-

IMSA GTU vintage racer build

clarkspeed replied to clarkspeed's topic in S30 Series - 240z, 260z, 280z

I'm back! Sorry for the long delay on posts, family, work, and travel have sucked up time along with losing a laptop that had a large number of photos. I have restored most of the photos now and will try to catch back up. Polycarbonate windshield ready to mount, firewall extensions, and rear fender liner. -

Those hairline rotor cracks are common when running giant rotors. Even though you are getting very little rotor wear due to the size of the brakes, the heat cycling eventually forms the cracks. I've ran them on track probably about twice as bad as your pictures.

-

zcarjunky joined the community

-

I was considering their hood and hatch replacements instead of patching mine up. Does anyone have any experience with those items?

-

A musician's therapist (The $300 Z)

Zetsaz replied to Zetsaz's topic in S30 Series - 240z, 260z, 280z

Small jobs today- Replaced that short hardware on the front rotors to hubs I mentioned in a previous post. Included Pic is the size difference. Brakes didn't feel particularly unsafe on my few drives around town, but always better safe than sorry with the most important things like brakes. Second pic shows how the new hardware actually goes all the what out to the wheel mounting surface to engage as many threads as possible Next small job before the correct rear brackets arrive is re-adhering a part of the headliner that is sagging a bit. I think the adhesive didn't cure properly when I installed it forever ago and the intense heat on the roof at one show made it droop. Only fix is to reapply but fortunately it's easy since the rest of it is already adhered well and lined up. Hardest part of the job is centering it -

Hello, Are you using fresh fuel. Fuel will go off over time.

-

chaidez10 joined the community

-

My Z car log....small jobs done and fun things

A to Z replied to A to Z's topic in S30 Series - 240z, 260z, 280z

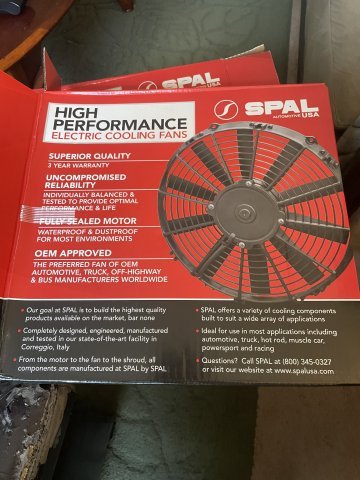

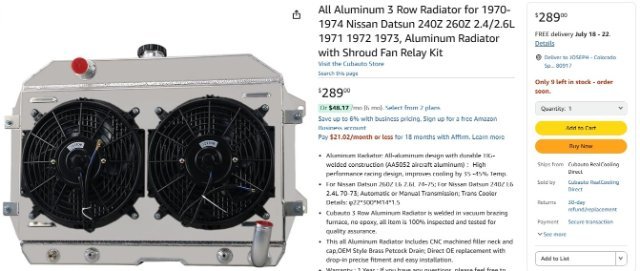

So, the heat issue has caused me to go ahead and order a 3 row aluminum radiator with dual electric fans. I decided to get one I found on Amazon, made by CB Auto - which is in CHINA. So, half price of others and looks to be okay. I also went ahead and got an anode made of zinc that screws into the drain petcock. This is what allows the minerals to attack it instead of the aluminum in the radiator. I also will be switching my thermostat to a 160 degree one I ordered. Since I have had good luck with the chinese parts I have used, we will do this. factory video, click here: https://www.amazon.com/vdp/048db201f503475ea5ee22731531c6e1?product=B0BQGTGGL4&ref=cm_sw_em_r_ib_dt_8D3hq5NBWLJy6 -

I have, in the past, placed the plug wires on my L28 280Z engine in reverse rotation order. #1 was correct but the rest were placed in clockwise rather than counterclockwise order. The engine started and ran but it ran terribly. Since I had only replaced the wires as a tuneup on an engine that ran well I knew immediately that I had screwed up the firing order somehow. It must have been running on only two cylinders. 1 5 3 6 2 4 1 4 2 6 3 5 In short, maybe doublecheck your plug wire placement. Good luck.

-

I have not tried bypassing the box yet, but that’s a good call.

-

A musician's therapist (The $300 Z)

Zetsaz replied to Zetsaz's topic in S30 Series - 240z, 260z, 280z

Small update from T3 - Called today about the bracket issue, and their service guy on the phone told me the new brackets would get shipped out today. While bleeding the brakes yesterday to get a head start on some of the work left so they'd at least be close I noticed some fluid dripping from the opposite side. After inspecting it looks like the flare for the -3 end on one of my hoses was cracked. I ordered some new ones myself since I don't know if it was an installation error, but it's just one more thing wrong with the rear end. Despite shipping today I know they might be getting it out late enough that it won't actually leave California until tomorrow. Hopefully by Thursday I have a driveable car again. Two weeks until I leave on a road trip -

Thanks, Tom, will add a little more fuel. I noticed my cold -> warm cycle follows a pretty predictable AFRs curve per the table and my manual tuning I did at idle a while back (I was aiming for 13.5-13.7). Things go out of wack somewhat when I restart a hot engine, the AFRs are leaner until they stabilize later on.

-

REDSHFTZ joined the community

-

Have you tried running w/o the MSD box?

-

Some of their stuff is good and some is hot garbage. Max the owner doesn't stand behind his product and has a tendency to try and blame "modifications" to your car as the reason. I have a lengthly (4 page) post on classic z car about my problems with his door assemblies. Resurrected Classics door problems I have their door weather strips and their fuel filler neck and the are excellent. My advice is no matter what you buy test fit as soon as it arrives and go from there. The doors were so bad that I ended up not using them. Max refuses to refund my money so I make sure to take the time to tell people about my experience. Do not trust what he says as he says whatever he needs to to get out of doing the right thing. Caveat Emptor with this guy for sure.

-

Who's Online 0 Members, 0 Anonymous, 453 Guests (See full list)

- There are no registered users currently online