Leaderboard

Popular Content

Showing content with the highest reputation since 03/19/24 in Posts

-

Don't tell my wife Like I tell other people. some like to fish, some like to bowl, I like to make.5 points

-

He's saying although we are launching a DOHC head in 2024 we readily admit it will be pale in comparison the mighty KN20 from Datsunworks. At least that's what I'm hearing.4 points

-

It's not the votage drop that matters it's what the voltage drop indicates. No spark will be created if the current through the coil is not stopped. You could also disconnect the coil negative at the coil and check the wire for continuity to ground, key off. Disconnect the wire, put one meter probe on the end and the other probe on a good bare piece of metal or the engine block. You should get OL or infinite/huge ohms on your meter.2 points

-

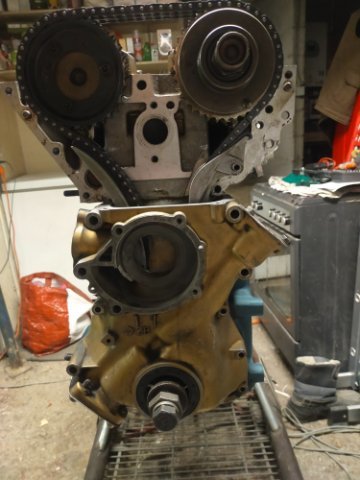

well yes , stock guides , just to make lower axes in the block, and the stock cover is modified to make some space, electric water pump ( davis Craig ) , and tensioner on the right side, in place of the water inlet ( spring and lock without oil pressure ) no need for oil pump drive or distributor for i put dry sump pump system and megasquirt ignition and injection EFI with yamaha bike itb's So simple and cheap , just a little of brain storming ! oh ! and a little joke for the head cover !! Lol !2 points

-

There is no swap hardware to put the Z transmission behind a V8. It wouldn't handle the torque anyway. The 260Z engine is about 158 cubic inches, compared to 350 for a SBC. The old Z transmission bearings are typically ready to fall apart besides that, not uncommon even with the stock engines. It would probably last about one pull. I haven't done it myself, but I wouldn't even try it just based on what I've learned.2 points

-

You have packed a lot into your intro. There's some good advice below to consider in the posts to your question. But I have to ask you what is it about the 280 you love? I don't mean that coyly or as some flippant remark. What is it you really like? I'll give you why I like the Zs. I grew up around them when they were new, my uncle was a general manager of a Datsun dealership so we got to try out the new cars. We raced with my uncle at autocross and hillclimbs (I was a kid so I just went along). Back then the Z cars were fast and sounded awesome (I have the hearing loss to prove it), and were amazing at cutting through the corners both stock and modified. Our local racing club had about 10 people driving stock to all-out racing versions. 50 years pass and a lot of that coolness has mostly worn off except for the look of a lowered S30 with an airdam and rear spoiler. I have to admit the sound of a modified Z makes me happy when I hear it. But this site exists to help people get the most out of them. And the reality of that is as cool as the L28 engine is you're looking at spending a lot of money and you'll have an engine that makes 200 to 250 HP. Sure you can get more but then all the other parts that connect to that engine are starting to get pushed past their limits given the age. While I don't disagree with any of the posts below you should still read about a lot of the mods and why they were done. You'll find that in many cases they were driven by it costing too much, parts NLA, etcetera. A bit of advice from me. Never by an engine, transmission, or rear end unless you plan to use it within a few months. Even if you plan to use it that's not the same as ready to bolt in. If you want a street car with a certain coolness and triple Weber carbs, then build it. But when you spend 10K on an engine and find it's somewhat finicky to drive but cool all the same. But for less, you could have 350 HP V6 in the DI Chevy LV3. It won't sound the same as the L-motor but it's lighter, a lot newer, and will get excellent mileage, It will start anywhere if it's hot or cold by the sea or at altitude. This site has a ton of info on how to do the same for the suspension and how to get a cheaper rear diff, especially if you want an LSD. I could write a lot more but this is probably too long as it is. Welcome to Z ownership. Cary2 points

-

Yes, with the carbs you can get rid of the ECU and EFI parts. The complete EFI harness can be removed. The guys that know on the site (from the past) say that the exhaust system is restrictive and opening it up helps a lot (see John C posts from the past) , and that if you decide to use a performance cam go big (see JMortensen posts from the past). The typical "Stage" 1 or 2 cams don't add much, apparently. So, the simple and effective way to add some power is with a better exhaust system and a big cam. Cams are more expensive than they seem because you need to buy lash pads and rocker arms along with the cam. The collection of parts costs can add up. But it's a pretty simple operation to get it done. Many people like the lighter flywheel. It takes more finesse on the clutch pedal but they say it's worth it. Fidanza is a good choice. For street driving an LSD doesn't add much. You might wait on it and see if you have traction problems. There is a ton on the site from the old-timers, around the 2000 to 2015 time range. Things have slowed a lot on the site as people have moved on. But their contributions are still here. Many of the guys were racers and/or engineers/mechanics/machinists and spent a lot of time and money on their projects. Today's car hobbyists really only know turbos and EFI since that's what they were raised on. Good luck.2 points

-

2 points

-

Even if 100 people commited to purchase, its still tiny small numbers vs an OEM production. Its got to be done out of passion and at least not to lose money. This is why this is such a huge acomplisment for someone like Derek, We are fortunate the passion runs deep. I cant imagine the hours of "un-billed" time2 points

-

I dont want any filler, so I fit each part perfectly with a butt joint, dolly it out where possible, then grind it flat and smooth for an original fit. before any welding I prime all parts on the back side and pinch points with weld-thru primer the arc and inner rocker are new in this picture then the rear of the rocker, putting back the spot welds in the OEM position Some more primer to look super clean and blend in tot he original rocker which was perfect everywhere else Finally fit the outer skin and tig it in small steps so no warping Some more smoothing of the welds and original spotweld locations used Just a small skim coat of filler on the upper weld seem, but making sure to leave all the factory spot welds to show through the paint. Other side is the same, so on to the front fender next1 point

-

Hello everyone, I was thinking of starting a thread about my LSA swap but i know there are several but if you are interested i'll post😀. I have a 260Z bought three years ago, drove it with the Inline 6 for two years. I started with the brakes as they were not so good so to speak..... I bought Porsche boxter S calipers from a 2016 and discs from a BMW F30 335i made new brackets and twin master cylinders. At first i made new hubs in aluminium but have now changed to hubs from a S13 as i had some flex that made my brakes a bit unpredictable 😱.1 point

-

1 point

-

VINTAGE CARBON Pre-order Opportunity - NEW S30 CARBON FIBER FRONT GRILL! We have been cooking here at Vintage Carbon! We are going to be coming out with an ALL NEW Carbon Fiber S30 Grill! To our knowledge, this will be the First Ever Carbon Fiber Grill made for the Datsun S30 Platform! We are going to incorporate the Thick Outer Border similar to the Fairlady 432 Style Grille, while keeping the OEM "V" shape and OEM style straight across Slats all made completely of Carbon Fiber!! The slats will be thicker so you can really see the Carbon Weave from the front. We are also going to extend the overall height about 3 inches to make sure it covers as much as possible with a front air dam installed. We are going to ensure the vents are spaced equal to OEM so air flow will not be affected. It will be different from anything out there, more aggressive yet reminiscent of OEM but made of Carbon Fiber right here in So Cal, USA!! These will really add style to any S30 Z Front End!! What do you guys think? We will be accepting pre-orders for a heavy discount off Retail cost for the first 10 people. Contact me if interested! Message me or Email me at andrew@zociety.org ! We are currently working on a high quality render as we speak! Hoping to have that ready by the end of this week.1 point

-

Nice-looking piece. Can I suggest you move your post to the Vendors' Forum? https://forums.hybridz.org/forum/27-vendors-forum/ Thank you.1 point

-

1 point

-

1 point

-

1 point

-

I'm sure they're great parts. Years ago Bad Dog was really your only option. They were decent but I think fitment has gotten a lot better on stuff like this as new people have tried to make them in better volumes1 point

-

They're also the same ones that T3 has. T3 even lists in their description that they're made by Capital Metal Works. Pretty sure cap metal works makes them all and T3 and Apex are just resellers. It happens occasionally. Same way that T3 has Skillard parts on their storefront1 point

-

1 point

-

Happy Easter to you all, Steering rack was moved to the left 5mm to make more room for the primary tubes, new extension made to the right side. Most of the primary tubes are now welded, stainless is a pain as they tend to bend in their own way....😐. Some reinforcements are made around the hatches in the fender. As battery is moved to the rear i'm using this place for expansion bowl and fuse box for the engine plus coils. on the left side there will be clutch master cylinder and coils and maybe washer fluid bowl.1 point

-

I would say to you " it comes apart a lot easier than it goes back together". What I mean by that is, don't touch anything you don't have to. Trust me on that. I started this project as a young man of 20ish. I just turned 51. I still haven't driven it.1 point

-

I would start by specifically not redoing literally everything. Videos online make people think this is like legos and things can get put together quickly. There are almost always hangups. Other than the engine rebuild, I would recommend seeing which stock parts absolutely need replacing and start with just that. Get the engine finished and drive as much as you can and see what sticks out that might actually be worth upgrading to you. There's nothing worse than tearing a car down then not getting to drive for several years because you can't keep up with everything you took off. Unless you have the budget to just dump at everything T3 sells and brand new interior parts all at once, it's just not worth trying to rebuild everything all at once.1 point

-

An upgrade I did was the 280zx close ratio 5 speed with matching 3.9 diff. completely bolt on swap for both parts. Quick, easy, and somewhat cheap upgrade that really does pack a punch.1 point

-

my hood mold is made for racing only, no inner reinforcement and no stock mounting hinge supports, design for hood pins mount only.1 point

-

First project now that I'm home is getting the new ignition coils in. Just had to swap out the stalks along with the new spring provided by Duffy. Taped the harness I got in two spots just to keep it a little tighter. I'm not the biggest fan of wiring that branches off in only one section, much prefer it to T off in multiple spots as it goes down the line, but I know that's a lot more time consuming. Regardless I'm actually really happy with the little subharness I got. A few pics included here show the shorter stalks, taped up, finished fitment and the before and after. Already got the dwell times adjusted. Updated my megasquirt firmware for the first time in 4 years, and did some very mild adjustments. Feels like it's running much smoother than before - maybe that's full placebo effect happening, but even if the actual performance difference is negligible, I'm WAY happier with how much tidier and more serviceable this is than the previous setup. Second mini project was just 30 seconds of adjusting the dampers on my coilovers. I softened them up after reading a post. I think I was overdampened for my spring rates, especially at the front and small but abrupt dips and other holes felt like they were pounding the whole car. Feels much smoother now. I think I'll be doing a lot of small projects again while I'm here, but I think within the next year I want to completely upgrade all my wiring, move to a nexus R3, switch to electric fans and reroute the hot side intercooler piping, and color match the engine bay to the exterior while the engine is out to rebuild with flat top pistons. In the meantime I'll cleanup major spots that need some attention and tidy up anthing from the transmission back that's causing little rattles or discomfort.1 point

-

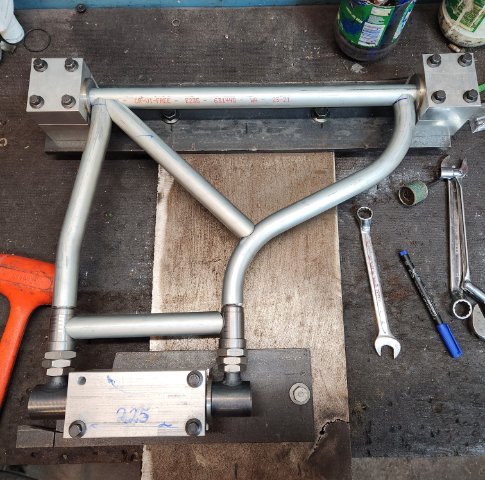

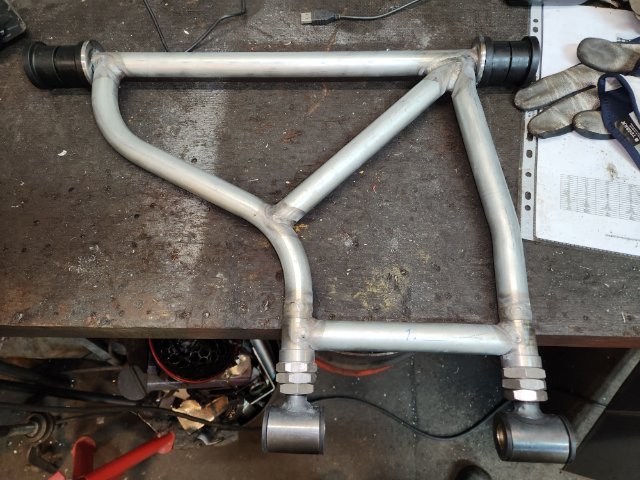

As i'm half way in in this swap things that i post is mods that i already have done :). Another thing i did when i did the brakes was building new rear control arms, narrowed down track with with 16mm/5/8" to accommodate modified Rota wheels. That included shorter half shafts, narrowed in my lathe, they were hard so i have to buy some expensive inserts/tools. I also made a jigg to get angles correct when welding. They are now adjustable. I'm going polyurethane bushings as i want this to be a fast road car and not a track car only. With them i could go with the R180 for last summer to sort out the brakes. With the now mounted R200 i have to make new ones again🤣. /Christian1 point

-

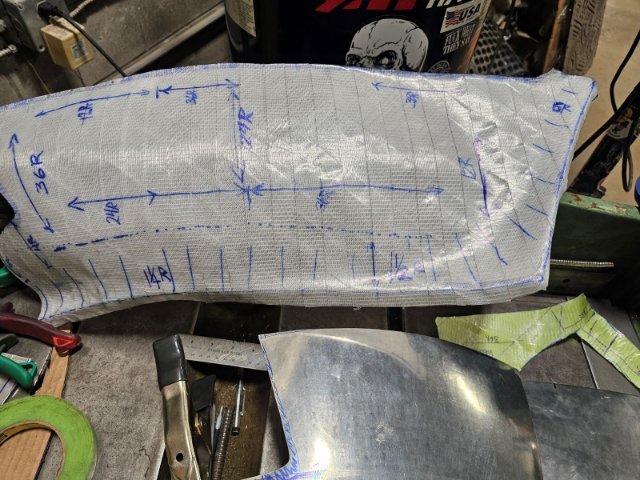

@jhm Thanks John! Really appreciate all your support through the years. It’s been a long road huh! I have definitely added track, as you suggested. I’m at EP spec at the moment, which is 56.9/56.6 (F/R). The added track is certainly factor. After reading old posts and talking to Greg, it’s clear that with the added track and much lower ride height, it’s common to have way too much negative camber with the strut centered in the tower. Thanks for the part suggestion I think I’m going to have to do some modification since the shock adjustment nib is going to strike the tower hole anyways. We’ll get it figured out! If I can get the air dam and shock tower modifications done In time, my next event will be in late May at Big Willow again. This time with NASA and their HPDE sessions. gotta say, once the terror of approaching a turn at 115 faded, the adrenaline is absolutely addictive.1 point

-

Updates below. Tracking info should auto populate in PayPal. Started at the top and am doing Tshirt only orders first since they go in bags and are the fastest to prep. Will keep the list updated as I go. 1. 7d2jz 2. MAG58 - PAID - SHIPPED 3. MAG58 - PAID- SHIPPED 4. Crespo79 - PAID- SHIPPED 5. Jeffrox - PAID- SHIPPED 6. jhm - PAID- SHIPPED 7. onthego- - PAID- SHIPPED 8. onthego- - PAID- SHIPPED 9. pepper - PAID- SHIPPED 10. pepper - PAID- SHIPPED 11. ModernS30 - PAID 12. Masonvonritchie - PAID- SHIPPED 13. rxx2rxx2 - PAID 14. rxx2rxx2 - PAID 15. Sonethirty - PAID 16. S30TRBO - PAID 17. S30TRBO - PAID 18. Kennysgreen280zt - PAID 19. Kennysgreen280zt - PAID 20. Kennysgreen280zt - PAID 21. ElliottOhZ - PAID- SHIPPED 22. Oki570Z - PAID 23. lowrider - PAID 24. lowrider - PAID 25. lowrider - PAID 26. jnjdragracing - PAID 27. jnjdragracing - PAID 28. OldAndyAndTheSea - PAID 29. OldAndyAndTheSea - PAID 30. JonRHD - PAID 31. JonRHD - PAID 32. 75280z - PAID 33. 75280z - PAID 34. CalZ - PAID 35. CalZ - PAID 36. LanceVance - PAID 37. LanceVance - PAID 38. Stunt 39. Stunt 40. _akuma_no_zetto_ - PAID 41. _akuma_no_zetto_ - PAID 42. 1 tuff z - PAID- SHIPPED 43. 1 tuff z - PAID- SHIPPED 44. Zlost - PAID 45. AydinZ71 - PAID 46. AydinZ71 - PAID 47. zredbaron - PAID 48. zredbaron - PAID 49. zredbaron - PAID 50. airbrush-ed 51. Chris Damato (FB) - PAID 52. Chris Damato (FB) - PAID 53. evildky - PAID 54. torqen2k1 - PAID 55. torqen2k1 - PAID 56. torqen2k1 - PAID 57. torqen2k1 - PAID 58. torqen2k1 - PAID 59. torqen2k1 - PAID 60. Mayolives - PAID 61. Mayolives - PAID 62. Mayolives - PAID 63. bkz72 - PAID 64. Wizzurp - PAID 65. Wizzurp - PAID 66. Leon - PAID 67. Gollum - PAID 68. Gollum - PAID 69. Gollum - PAID 70. AB240z - PAID 71. AB240z - PAID 72. AB240z - PAID 73. AB240z - PAID 74. AB240z - PAID 75. AB240z - PAID 76. AB240z - PAID 77. AB240z - PAID 78. AB240z - PAID 79. Zetsaz - PAID 80. Zetsaz - PAID 81. Zetsaz - PAID 82. Wedge 83. 24Oz - PAID 84. ihavearustedz - PAID 85. clarkspeed - PAID 86. niner11 - PAID 87. 1970 240z - PAID 88. 1970 240z - PAID 89. 1970 240z - PAID 90. 1970 240z - PAID1 point

-

Just got yours shipped out as the first one!1 point

-

1 point

-

I can't say that I've seen a turbo mounted rigidly to the body of the car. A couple of thoughts come to mind. Your bracket is going to transfer quite a bit of heat into the strut tower from conducted and radiant heat. Be prepared for paint to burn off and rust appear if you don't isolate the mount and protect the strut tower from with radiant heat shields. It's hard to tell from your pictures but the flex pipe you have leading up to the turbine appears to be one of those flexible tail pipes (not bellows). I don't think those are designed to take much or any pressure, especially when flexing due to the engine naturally moving on its engine mounts. I could be wrong but it may not last long. Anyway, good luck with it and let us know how it works! Maybe I'm full of shite, it would be the first time1 point

-

1 point

-

1 point

-

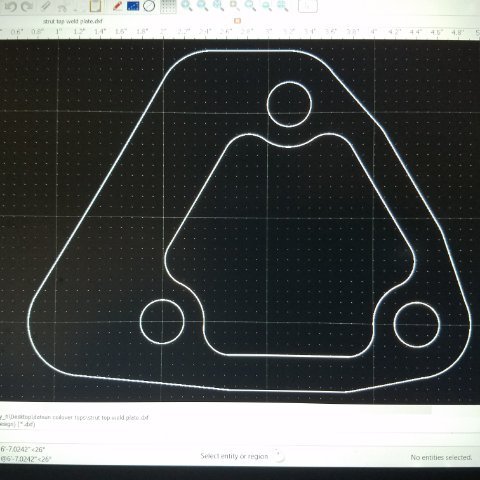

Weld in plate to get the max caster and bring strength back to the shock tower. The reason for the needed caster mod, is the mustang spindles have an offset bearing, and were designed for 8 degrees of caster in general. Proper wheel placement in a Datsun s30 requires the offset balljoint and shock top. David in the dark blue car just cut his front fenders instead, and kept his ball joint in the normal location.1 point

-

1 point

-

Thanks, man! I appreciate the suggestion. I've subscribed.1 point

-

1 point

-

The project has been revived 😊 There is lots of good advice above but the used engine market in Oz is a lot different to that in the US, basically more expensive with limited availability. So I decided on a Toyota 2.7 2TR-FE with matching 5 speed Toyota auto, both low mileage which is important. There is an aftermarket controller available for the auto which was a crucial factor. Motor will be stripped for forged pistons and con rods, not sure about which turbo at present, ECU will be a Haltech Elite 1500 which will run the VVT. Might start a build thread some time.1 point

-

Felt like I should finally post on this thread. 1977 280z 2+2 1. Junkyard 2004 LS1 from a GTO completely stock 2. T56 with stock clutch and new throw out bearing (from the junkyard GTO) 3. JCI motor and transmission mounts and headers. Really great kit! 4. Tanks inc fuel tank and in tank pump. DIY 7 circuit fuse block with stock GTO engine harness. 5. Started October 2018 finished April 2020 (this includes a full restoration but still got some little stuff to do) 6. Eibach lowering springs, Toyota truck front breaks, Maxima rear discs, stock diff and axles, Vintage Air AC/heat with JCI compressor kit. Thanks to everyone on Hybridz answering questions and posting stuff. This site is a great resource.1 point