-

Posts

174 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by ttodhunter

-

-

I have to ask... What is the tap-and-rotate alignment?

-

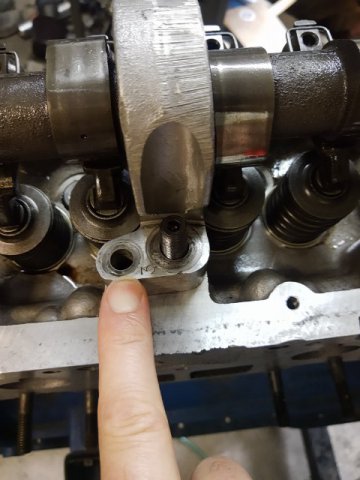

I just went ahead and put helicoils in and put it back together only to find another stripped. So I helicoiled them all. Quick note- if you mess up on a helicoil, if you can pick the end out and grab it with a needlenose, you can pull the whole thing right out.

-

Hey all,

I'm assembling the top end and came across a couple of stripped bolts in the cam towers. These are the bolts directly next to the head bolt, so I'm hoping they are just there for assembly purposes. With the head bolt sharing a deck less than an inch away, does anyone know if these bolts are necessary? Part of me thinks they are there for a reason, another part thinks the head stud will apply all the clamping force necessary.

Thanks!

-

So, I took #6 to the machine shop to check for straightness. He put it on a template and found it slightly off, put the crank end in a vise and a dowel on the pin and did a few rounds of hammer blows. He got it to 'as straight at he could get it'. I took it home and put it in the hole, and it now measures F +4, R +3. This appears to be the root of the problem. The question now becomes: do I have him repeat for all cylinders, or do I get new rods. Would you all have concerns with rods that were bent being straightened in this manner? I worry, and I'm no metallurgist, that when they heat up, they may bend back to their previous state. Or, perhaps, that their strength has been compromised. He did note, as he was hammering, that they were very tough rods.

Thanks again.

-

I went and measured all pistons, Front and rear:

#1 F -1.5, R +13

#2 F +3, R +8

#3 F +3, R +8

#4 F -1, R +10

#5 F +3, R +8

#6 F +10, R -3

I swapped #1 and #6, and the readings remained unchanged with piston assembly #1 in hole #6 reading F -1.5, R +13. Same thing for #6 in #1 hole. I am now suspecting that the rods are bent, so I will take them and get them checked out. I'll post results, but it may be a while. Any other comments or suggestions are welcomed in the meantime. Thanks for all the input so far!

-

Just got back home and will now put some time in. Yes, probably not a machinist grade measuring device, but you can feel the piston over the deck on the rear. These are the ITM pistons. I'm really hoping it's not the rods... I'll post back with results.

-

Yes, higher in the back than in the front. I'm going to spend a little more time with it today and will try swapping #1 and #2 to see if the problem is with the rotating portions or with the hole. Thanks for the reply.

-

Hey all,

I'm putting back together my motor and have found that (especially) the #1 piston, at TDC, is above deck at the rear and at deck at the front. I am measuring approximately 15 thou above deck, but only at the rear of the piston. I don't have a mechanics straight edge, but used a framers square across the top and can't fit a 10 thou feeler anywhere along the deck. I plan to use a standard FelPro HG which should still leave 20-25 thou clearance, but not sure if that's enough. I also worry that there is a problem somewhere that once I fire it up will reveal itself. Has anyone else come across a similar situation? The block was not decked since rebuild. Feel free to make me look dumb.

N42 Block

P90 Head

L28+1 dished pistons

Thanks for your input!

-

Depending on your head, I'd go with +1mm flattops, you can get them at rockauto for $33/ea with rings. I run them on my P90 head turbo setup with no problems, but had lots of detonation with an N42 head.

-

Hi Pallnet,

It's probably about time to upgrade my fuel system. Looking to use FAST injectors with an adjustable FPR and a gauge. What have you got for me? Any other information you need from me?

Thanks!

-

Hi All,

I have a 76 280z with turbo and a mild cam and recently have had a problem with power braking. About 1/4 of the time, I will step on the brakes and they are rock hard. This happens while cruising at light throttle, or after I've let off the gas and have ~15" vacuum. I checked and replace the check valve, but still have the problem.

If the brake booster failed, would it fail all the time or sporadically? What else could cause loss of power braking - sometimes?

Thanks!

-

I built my N42/N42 with flat tops, ported head and 270/280 .464" cam. Calculated compression was at 10:1. With SDS programmable fuel/ignition, I was still having detonation issues and had to back the timing out quite a bit. Power-wise, it was decent, but not what I wanted and I ended up lowering compression and putting a turbo on. Lots of people say "just drop an L28ET in" and I wish that's what I would have done

-

I've got a N42/N42 motor I initially built naturally aspirated- +1mm flat tops, ported head and a Delta grind 270/280 .464" cam (don't remember LSA). Originally had it at 10:1 CR but wasn't happy with performance so got a Cometic gasket that brought it down to 9:1 and put a turbo on it (stock boost, 6-7psi). With SDS fuel/ignition and Methanol Injection, I can almost keep detonation at bay.

My question is: If I switch to a turbo cam (stock turbo cam for now), would I be more likely to detonate or safer? With less overlap, would that lead to increased cylinder pressure making it more prone to detonation? Or would less exhaust gas reversion lead to cooler cylinders? What other physics are at play?

Thanks for any input!

-

IIRC, The 75 and 76 are full size spare tanks, 77 and 78 are for space saver spares and wont fit properly. 280 tanks are for fuel injected setups and have different ports and design. These are used for FI conversions which makes them more sought after and expensive.

-

There's a rubber filler neck that goes from the filler to the tank. If I remember correctly, there's an access panel above the RR tire. If you remove that (3 or 4 phillips screws) you can probably see where the problem is. Good Luck and congrats!

-

Hi all,

I'm looking at picking up a ZX turbo so I can grab the motor (don't need the ECU). After I pull the motor and tranny, I would probably look at scrapping the car since it's a pile. I'm trying to think of everything that can be salvaged before scrapping. I'm looking at keeping:

-the motor

-tranny

-grabbing the rear brakes

-maybe the rear end

-the "Turbo" emblems of course

What other parts am I missing that would be worth saving? Anybody want anything if I do get it?

Thanks!

-

-

I have removed the distributor, running a hall sensor DIS... I'm thinking the thrust force of the crank spinning the drive gear without the distributor in place must have forced the shaft sprocket downwards reducing the mating area. I'm also a few beers deep, does that sound accurate/possible?

-

Got the new oil pump and it measures exactly the same. The shaft still only engages that same 1.08mm. The distance from the end of the shaft to the drive gear is 30mm. On the other side of the drive gear is 5mm, then a notch. Is the gear permanently mounted on the shaft or could it have moved 5mm over the past 38 years? Does anyone have one that they can measure? Thanks!

-

Yeah, I'll check the bearings for damage. The logo is on the rod caps, but I forgot about the arrows on the mains- will check them too (and take lots of pictures for the shop that built it). The cost of towing wasn't an issue, things being rocky at work and being 2 hours late might have been...

-

I haven't looked at the bearings yet... Wouldn't they have had a problem from the get go? Or am I looking for a spun bearing? I did notice the bearing caps didn't all have the Nissan logo on the same side- not sure if that matters, but if I had built it, they would be. I've got a new oil pump on order for comparison. I've read each of your posts for a long time and respect your input.

-

Ok, oil pan has just a touch of metallic dust in the oil. I don't think it's catastrophic. Oil filter is clean as can be- possibly because no oil was circulating... The oil pump has no obstructions, nor does the pickup (which was tight).

The one thing I did notice is: the tang that drives the pump only seats 1.08mm... There is a half inch alotted on both the male side of the shaft and female side of the pump receiver, but it's only seating 1.08mm. This seems wrong to me, like the shaft should sit deeper in the pump. Could a different model year pump have a different size housing which would cause this???

Thanks for all the input, I do appreciate the help!

-

I got ~100 miles out of it with great oil pressure. That's good to hear about the shaft, a little peace of mind. I'll pull the pump and filter and cut it apart tonight for inspection. Thanks for the input!

-

Hey All,

I just put in my built motor and all was well for the break in. I changed the oil and drove to work and back once. On the second trip to work, I lost oil pressure. I checked the oil level, just fine, and drove home (I know, should have towed it) coasting with engine off as much as I could.

The cam was chirping and dry, hopefully salvageable. I pulled the oil pan and didn't see anything disastrous. I'll be pulling the oil pump tomorrow to check for blockage.

In thinking about causes for the loss of oil pressure, I can only think that the oil pump (brand new) failed or there was some crap left in the engine from the build that caused blockage.

The only other possibility is (that I can think of)... I removed the distributor when I put in my hall sensor ignition. I know the distributor shares the shaft with the oil pump. Does the distributor hold the shaft to the oil pump? Is it possible that without the distributor in place that the cog is not held to the oil pump?

Thanks for any input!

Stripped cam tower bolt

in Nissan L6 Forum

Posted

Thanks NewZed and madkaw!