-

Posts

758 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by S30TRBO

-

-

+1 for Isky Cams

-

Got it: KAV

edit: woops should have read your reply on the last page. Oh well it's gonna look schweet...

-

Clive,

I sent a message to my friend that works for Nissan Japan.

-

Sweet Jesus, how many cans of Gunk or Simple Green did it take?

Coming along nicely Dave..

-

I just read the whole thread nice job, looking forward to the n/a progress.

-

I brought the catch can to my local machine shop, it sat all this past week. He didn't know when he can get to it "drill and tab one hole it needs a drill press and I don't have one" so I picked it up yesterday heard about this Amish Machine Shop, brought it by he'll have it ready on Monday for $10 bucks.. I think I will start to go there hahaha.

Allergies are kicking my butt going to try to get in the garage and at least finish the heat exchanger install this weekend.

-

Yeah while you in there replace both the top and bottom o-rings too.

http://www.courtesyparts.com/280zx-parts-s130-1979-1983/fuel-injector-and-parts/-c-7002_8669.html

-

Hey guys,

Just cracked open my oil pan and discovered the mesh screen on my oil pick-up is trashed. I've looked for this part on MSA and rock auto, but can't seem to find it. Does anyone know where I can get my hands on one of these? Thanks!

Your local Nissan dealer, http://www.courtesyparts.com,'>http://www.courtesyparts.com, http://www.courtesyparts.com or post in the want ads someone might have a used or new one.

-

On what Z and where did they come from? I have FAST and can try to track it down?

-

Post some pictures of the pins and the calipers. I am not familar with what "brake kit" they sell but I might have an idea.

-

On the low side, to have a long block completely assembled using your parts would be anywhere from $1-8k depending on the shop and their experience with the L-series.

with hoov100. The key is finding a shop with experience. Do you have any Z guys with experience around?

with hoov100. The key is finding a shop with experience. Do you have any Z guys with experience around? -

I hope you upgraded your headlight harness. Also, pull and check your headlight fuses, and your fusible links. 30 plus years tends to corrode everything electrical.

If you've blown a fuse the Z's headlights will still work just be very dim.

-

This would be a short runner Mikuni:

-

I'll play. I say timing chain guides. Take your scope and listen near the front cover.

-

Dave,

Looking good man. From your comment in the video about the turn signals not working. There are 2 relays on the 240Z one for the turn signals another for the hazards. If they are the originals they are barrel shaped; the turn signal one is on the steering column under the dash (not inside the plastic column surround) or it might be bolted right near the column. The hazard relay is mounted on the passenger side kick panel almost even with the underside of the dash, near the top of the kick panel to the left of another relay.

-

Laminova said it has no bracket for it, I can weld it just remove the guts or I can mount a bracket to the end where the screws are. I think I will be ok if I just hang it on the side and use the bolt hole on the block to built a bracket to help support it, even though it may not need it.

-

Clive,

You have a couple of DD already the red one for sunny days and the silver one (when its done) for rainy days. Now buy a cheap DD just for winter, save for the house and big garage to accommodate a lift and you are all set brother. Never settle, I built my first house when I was 25 (close to your age) it was all me, my credit, my savings. You can do it!!! Tony is right it's a buyers market now.

-

Travis,

Read this and throw some money to hybridz.

-

Exactly. I've seen plenty of people with good intentions take an L28 apart to "rebuild" it, just to end up with a big pile of sh*t in the end. The last one was an L6 that couldn't retain it's bodily fluids on the dyno (blowing coolant and oil everywhere). But boy, that metal head gasket he "had" to put in was working great. There is nothing you need to do to the bottom end of these engines to produce a reliable 300WHP. And guess what, the folks at Nissan that built these motors knew what they were doing.

What about cylinder ridges? Are there any? If not, you are wasting $ doing anything to that short block besides seals and gaskets. Check the rod and main bearing cap torque, put in new seals, gaskets, core plugs, and timing set (if needed), and spend your money on the head, turbo (if you are going that way), and engine management.

Pete

its all in the head work save your money and send that head to Braap (shameless plug Paul) that is what I plan to do in the future. Dtsnlvrs will vouch too since he is lining up his to send to Paul.

-

Mocking up the Laminova oil to water heat exchanger. This thing really doesn't weigh that much at all. I am either going to mount it to the inner fender well or even try to mount it inline along side the block.

I emailed them to ask about a bracket since it came with none. Also I asked if this thing can be welded on since there is no place to bolt a bracket to it. If they have no brackets or method securing it and I can weld on it, back to Ship Point and I'll have them make me a couple of aluminum brackets and weld to it.

-

Looks good.

Two quick comments.

1) The Greddy unit is not really efficient as a catch can. It is not internally baffled and is just a big can.

2) You have the crank case breather connected to one side of the can and the valve cover vent to the other? If so, that is a big no no. You need a vacuum source on the catch can as well as a PCV valve on the crank breather. You are going to pressurize the valve cover with the crank case pressure.

Bo,

Thanks for the comments. As for the Greddy unit, this sucker is 10 years old and owes me nothing. I have a slip on pipe thread fitting that I need to drill and tap the side of the unit to hang a breather off I should be good after that. I know once I hang the turbo in another year I will need to change the config all together, maybe even incorporate an actual PCV valve.

The tape is just holding it, I wish it was that easy.

-

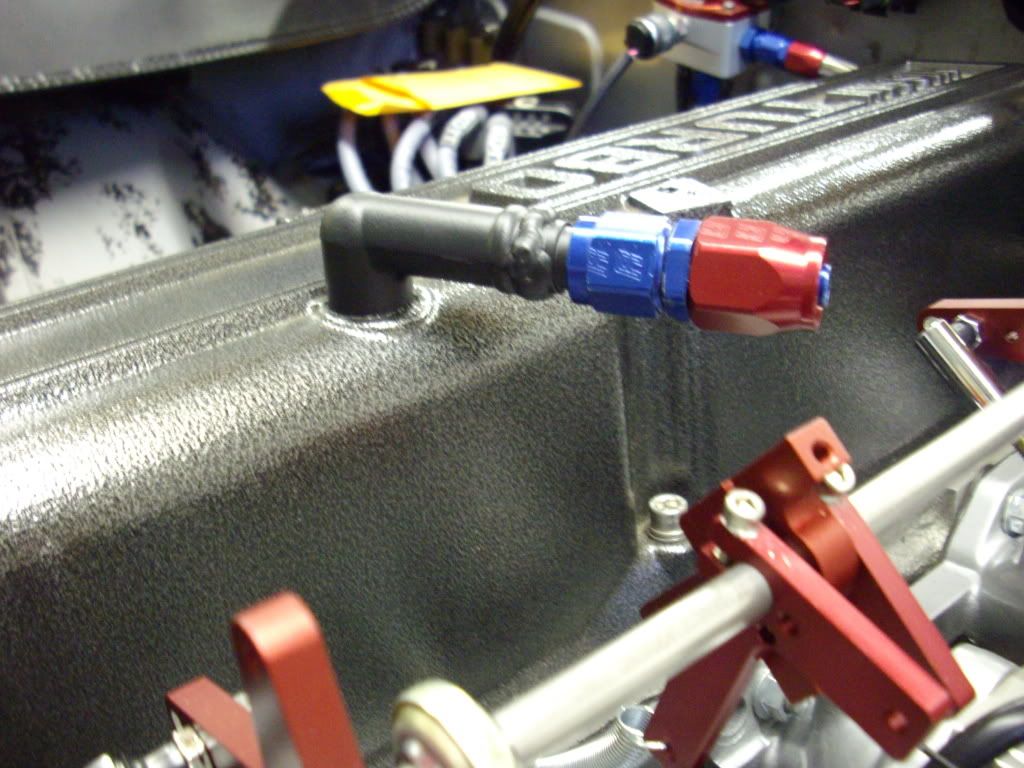

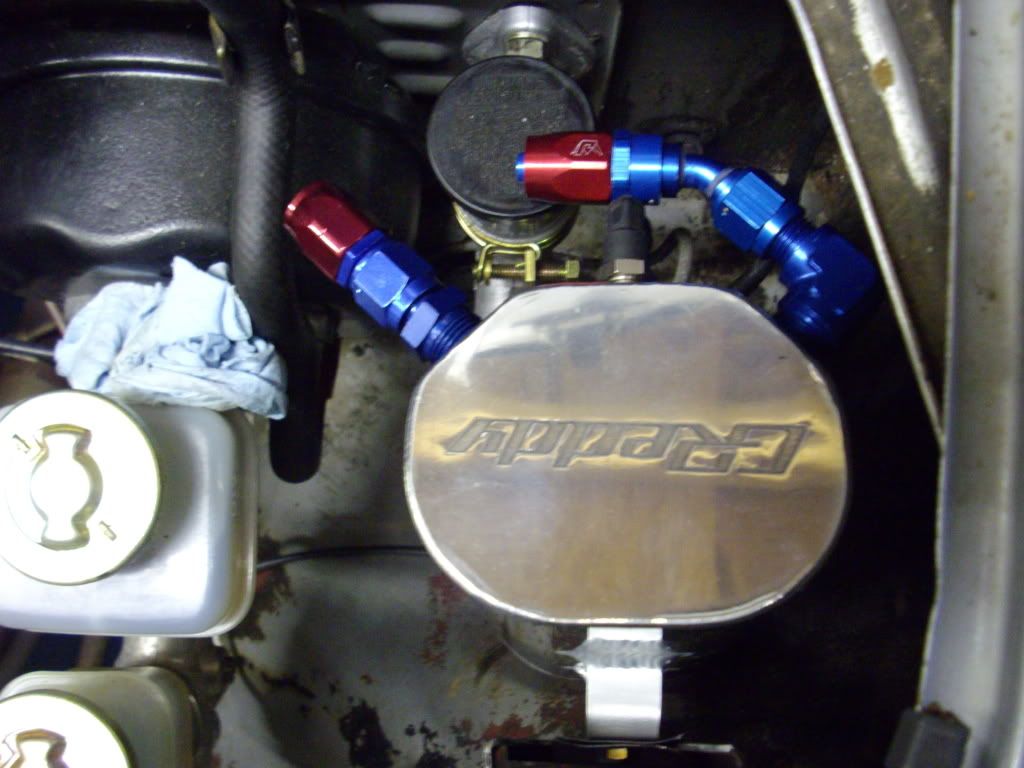

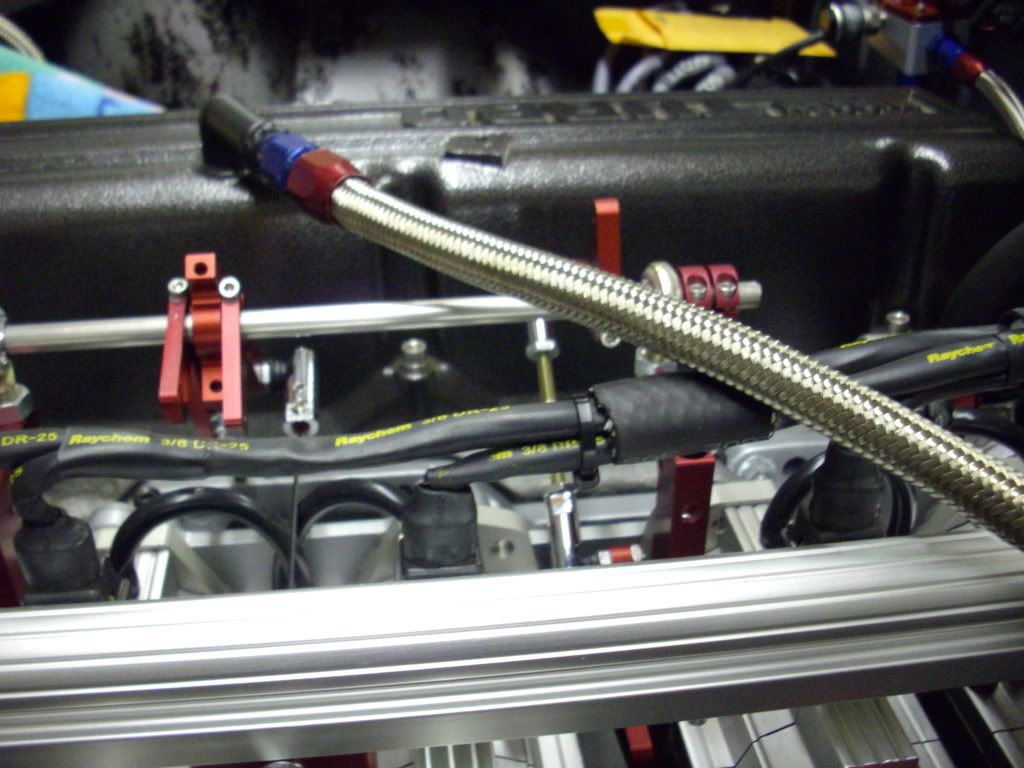

Well I converted that nasty Greddy clear hose and changed it out to braided. I was having problems finding a AN fitting for the valve cover breather and I didn't want to weld on it or have it drilled for a larger fitting so this is what I came up with.

Before: Stock aluminum breather pipe.

After: Courtesy of Ship Point Machine shop on a Saturday, I had my Aeroquip fittings purchased by Henry's Engineering welded. The Aeroquip AN aluminum adapter was welded to the stock valve cover breather pipe.

The same goes for the crank case breather pipe. I swapped out my 240Z breather and had a Aeroquip AN steel adapter welded to the stock L28ET crank case breather pipe.

Before:

After:

Also converted the Greddy catch can to AN fittings instead of slip on:

All work welded with a Miller Syncrowave 351 TIG Welder, as I like to call it "The Big Daddy"

Finished:

Tomorrow I will be working on the Laminova Oil to Water Heat Exchanger...

-

Dead Hooker

Dead Hooker

that and

"Pipe Camera"

"Pipe Camera"

"the last thing I need is a damn midget clogging my drain."

-

Back when Dan, Mike and Pete ruled the show.

You got that right, talk about memories. I joined zcar in the mid-90's in Japan then after coming stateside stony told me about this site in late 2000. I haven't looked back since...

Feb 08, 2000 First day online for HybridZ.

Feb 08, 2000 First day online for HybridZ.That's my birthday I feel great now!!

Craigslist Z

in Non Tech Board

Posted

FYI there are places for CL ads.

Pinned at the top: http://forums.hybridz.org/index.php?/forum/73-parts-wanted/