-

Posts

335 -

Joined

-

Last visited

-

Days Won

5

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by mtnickel

-

FS: Z31T axle adapter flanges for S30 + R200. Slim design

mtnickel replied to mtnickel's topic in Parts for Sale

Got a new batch of flanges all done. Some of the costs went up marginally unfortunately. Now $205 Shipped and request you pay via friends/family to cut down on my fees. Jig rental cost down to $20 from $30 however. Total $225 with Jig rental, plus you ship jig to next user. -

Fuel shouldn’t be much different than regular as the high pressure pump is in the engine. Just a standard return style fuel system feeding will work. Oe is returnless, but this can be adjusted in the tune. Other concern is is the security of the oe ecu. Has what’s called PATS. Won’t start without key signal which usually interfaces with the stock cluster. So you’d need Custer as well if you want to retain a working ecu. We put a 5.0 coyote into a friends 79 Volvo. For the 2014 model we were able to ship the ecu to a guy at hp tuners and have him delete the pats. Old models you could delete it in the tune, but new ones require a physical advancded mod/programming of the ecu. Alternatively you could try and load a performance pack firmware which has no security, but they don’t run nearly as well as oe code. I looked at the engine as an option, but the sound of the I6 swayed me.

-

FS: Z31T axle adapter flanges for S30 + R200. Slim design

mtnickel replied to mtnickel's topic in Parts for Sale

Roger that. Will try and get on them ready for first or second week of Jan -

FS: Z31T axle adapter flanges for S30 + R200. Slim design

mtnickel replied to mtnickel's topic in Parts for Sale

Just sold last set, but I’m ordering a new batch. -

Messaged. Let me know. Previous user waiting to ship. You’re next.

-

We’ll have to figure out whether it’s the SS axles or some other discrepancy maybe between 240 and 280 models. One thing I overlooked is that my rear struts are sectioned about 1”, so my “full droop” may not be as long as others. But I thought the 260/280z sat higher with a bigger isolator which would somewhat negate that. I’ll see how other regular nonVlsd guys fare. So far no other complaints. Thanks for the post!

-

I believe I had a FS post started if you search the classifieds. They are available

-

So you run the 6258 on the L28ET? i'm debating between the 6758 and 7163 on my RB25. From the numbers, it looks like the 6758 can get me pretty close to my 370whp goal (little over 425 hp). Plus it will spool quicker than the 7163, however it will probably be a power band that dies off in the higher RPM. Additionally, there is something to be said about turbine efficiency...the 7163 will probably make more power at a better pressure ratio with less back pressure. Decisions decisions.

-

I ran the same Volvo Fan. Built a shroud from fibreglass...sort of a fun project. If you can find a parts volvo, The relay system on it is very robust; comes with nice connectors already and also provision for high and low speed fan control.

-

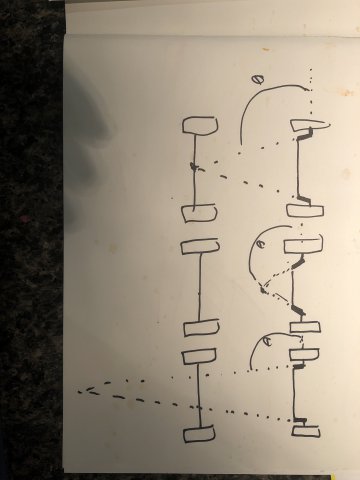

Ya, weld on adapters aren’t an ideal solution, and we are at the mercy of stock stubs. But all in all, it was the cheapest decent solution I could come up with. Newzed With my adapters, it’s still a close fit at full droop and I would recommend flipping the cages. But that only takes about 10 minutes to do. Saves the 3.5 odd mm. And they are maybe a little more outboard of Joe’s since they even require to grind the stub axle down a shade. Joe may have been able to make his even more outward provided you could trim more of the stub off. You’d lose the staked portion, but the newer ZX nut is a locking nut that would alleviate it.

-

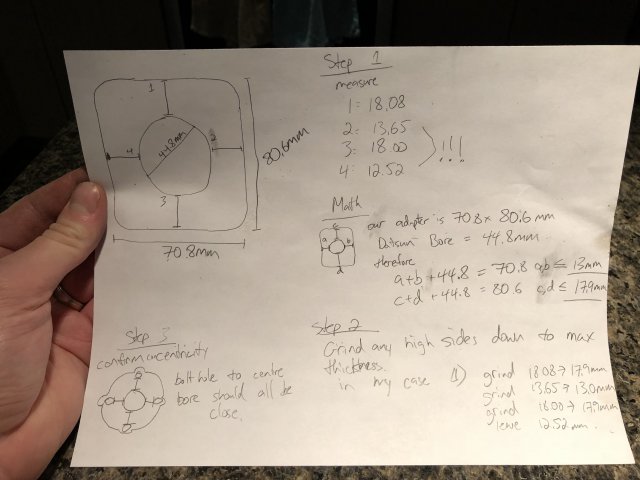

Great questions. We found out the hard way that the square flange isn’t concentric. It’s a rough cast and can be off almost 1mm. The z31t axle centers on the locating ring of the adapter. The adapter sits flat to the machined face of the stock flange. That takes care of 2 orientations. To weld the adapter on correctly we made the square a touch small. That way you can strategically grind the edges of your square flange to be equal from the Center locating ring. We recommend using a dial indicator to verify you get it reasonably close. If it’s a little big, you can use feeler gauges, shim stock, or even paper as stock to shim it true before tacking. Or you can rent the jig we made to locate it. Haha both options shown in pics

-

Here’s what our slim welded adapter looks like. Basically converts the stock flange to a larger one. Stock z31t axles fit like this. 4 fasteners a side = winning.

-

If you're resourceful enough to find some original Z31T axles, I still believe that's the nicest swap. The main benefit is that there are no fasteners on the diff end...the axle plugs right into the diff. It's just a matter of getting a companion flange on the outboard side to bolt it in. I'm biased perhaps as I sell weld on adapters...but adapters are $195, used Z31T cv's will run you 250-280, and welding the adapter in probably another $100 if you can't do it. So $550 all in. They are known to be very strong too. See my post in the Drivetrain section. Encouraging that Z garage has made a better set. I don't see how theirs don't have adapters though? Still looks like 930 style with adapter...maybe they weld them? I bought the wolf creek setup first hoping it was just a bolt it, but like Z garage found, the CV's they use are terribly sloppy. I then bought true Porsche 930 CV's, but the idea of 20 fasters for axles didn't appeal to me, so I figured out the Z31T setup.

-

FS: Z31T axle adapter flanges for S30 + R200. Slim design

mtnickel replied to mtnickel's topic in Parts for Sale

You could weld em shut if you want. To machine that would make them thicker and add a lot of machine time. For cosmetic reasons only. -

Electric Power Steering Information Compiled

mtnickel replied to seattlejester's topic in Fabrication / Welding

Much appreciated for this info! I have been mulling this swap over. I think i can live without (or rather maybe not live) the collapsable column and plan on a simple install. Due to size and ease of availability, I was going to try the Yaris non-abs with VSS signal. First I may try just using a pulse generator to vary the VSS signal to see if i can find a static point that works well...or alternatively, I've bought a GPS speed sensor on ebay and will try to run that (may need to scale the speed up or down with either an arduino or 555 timer or something). My only fear is the load with 205 sticky tires and a heavy turbo engine swap. But anything is better than nothing. Look forward to the updates! -

FS: Z31T axle adapter flanges for S30 + R200. Slim design

mtnickel replied to mtnickel's topic in Parts for Sale

Welded set sold. -

S30 RB25DET T4 Twin Scroll Turbo Manifold Design

mtnickel replied to Jeff9727's topic in Fabrication / Welding

I’d be interested in one of these. I also commend you on your ambition. As has been mentioned however, is that I think the welding and working with the welder, planning assembly and order of welds will be key. Have to remember this will be HOURS of welding. Plus machining both flanges. It’s a lot of work. Hard to keep cost down. The CX racing one is even $600us and they hardly pay for labour. Haha -

Ford Super 8.8 irs swap thread. Rear brakes too

mtnickel replied to Invincibleextremes's topic in Drivetrain

All in the name of weight and cost savings. Heck, my 93 and 97 accords had double wishbone front and rear!- 277 replies

-

- disc brakes

- suspension

-

(and 7 more)

Tagged with:

-

Ford Super 8.8 irs swap thread. Rear brakes too

mtnickel replied to Invincibleextremes's topic in Drivetrain

Ya, it’s all a bit of a mess. The original poster does seem to have a pretty good handle on it I gather. The inner pivots needing to match only holds true when the spindle is held static. But like he said, since the tie rod moved outboard it’s ok that the inner pivot moves as well since our main goal is to have the control arm and tie rod be parallel and roughly the same length. Exciting stuff. If I wasn’t so deep into my setup, I’d be exploring this a whole lot. Brake, suspension, cheap and readily accessible beefy diffs. Lots of pluses.- 277 replies

-

- disc brakes

- suspension

-

(and 7 more)

Tagged with:

-

Ford Super 8.8 irs swap thread. Rear brakes too

mtnickel replied to Invincibleextremes's topic in Drivetrain

makes sense. These are, I believe, the different ways Ackerman changes. But as I said before, since wheelbase and track width are both decreasing, then Ackerman is Probably still in a reasonable range.- 277 replies

-

- disc brakes

- suspension

-

(and 7 more)

Tagged with:

-

Ford Super 8.8 irs swap thread. Rear brakes too

mtnickel replied to Invincibleextremes's topic in Drivetrain

I was under the impression ackerman is based not on the distance from ball joint to tie rod, but rather the angle between the spindle (wheel axis) and steering arm. Additionally, to correct bump steering it's the inner pivot (ie inner control arm mount point) that has to match the inner tie rod joint. The outboard tie rod mount will mainly dictate how long of a tie rod you need.- 277 replies

-

- disc brakes

- suspension

-

(and 7 more)

Tagged with:

-

Ford Super 8.8 irs swap thread. Rear brakes too

mtnickel replied to Invincibleextremes's topic in Drivetrain

Ah, I failed to remember that track width has also decreased, so if the track width and wheelbase descrease at close to the same amount, then the ackerman probably is pretty close. My bad. But good food for thought!- 277 replies

-

- disc brakes

- suspension

-

(and 7 more)

Tagged with:

-

Ford Super 8.8 irs swap thread. Rear brakes too

mtnickel replied to Invincibleextremes's topic in Drivetrain

I wasn't talking about track width. The mustang has a wheel base (distance from front wheels to back) of 107.1" The 240z has a wheelbase of 90.7". The ackerman usually changes depending on the wheelbase. It might be a little off...but perhaps won't be an issue for most driving situations, but could cause an increase in scrubbing in low speed parking lot maneuvers and tighter low speed corners.- 277 replies

-

- disc brakes

- suspension

-

(and 7 more)

Tagged with:

-

FS: Z31T axle adapter flanges for S30 + R200. Slim design

mtnickel replied to mtnickel's topic in Parts for Sale

welded set pending. -

Ford Super 8.8 irs swap thread. Rear brakes too

mtnickel replied to Invincibleextremes's topic in Drivetrain

True enough. Going to all the work, may as well gain all the other benefits for not much more. So the ackerman is the same too? Interesting considering the different wheel base. Steering ratio not changed either (ie steering arm is same length?)- 277 replies

-

- disc brakes

- suspension

-

(and 7 more)

Tagged with: