-

Posts

68 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by Timecode

-

-

Calm down boys, babies aren't dying here. I'll run the fancy bolt/washer. I'm so deep into this car anyway, whats an extra $20.

-

1

1

-

-

I'll go with a new stock bolt and washer with some loctite and call it a day. Thank you all.

-

31 minutes ago, NewZed said:

By whom?

By the posts I read here and on other Z forums, most of which are from the most experienced members this forums has. I have nowhere else to go to get better info than this place, other than maybe the OEM service manual and all the Z modify books we all know of. Going off the OEM service manual might be good for a stock car with the stock pulley but they might have completely changed the way they did things if the 280zxt was making 400 hp from the factory. With the power levels my car now makes, I'll gladly take the communities advice when it comes to higher HP Z's and emulate what works for them.

-

OK, thanks for the tip.

Has anyone here experienced issues revving to 7k and the OEM bolt backing out? My current OEM setup hasn't given me issues backing out, my concern is with my old damper, which I feel will explode soon.

I'm guessing most who run an upgraded damper usually run the stronger bolt setup as well.

I know the stronger bolt allows more torque so less chance of the bolt backing out but is the OEM torque specs also accounting for the crank snout thread strength as well? Rebello told me a new OEM bolt/washer works fine and they do 20+ engines a month the same way with no issues.

Thread-lock companies say the bolt usually will break before the thread-lock gives way, hence my inquiry from others experiences. Typically, up to what size bolt needs heat to come loose without failure? I always use blue thread-lock but have little experience with red.

-

I ordered the BHJ damper for my 1983 l28et. The damper bolt from the common Z vendors say for model years 80 and below. Some even have a spicific washer for 280zx vs other year Z's. I was under the impression they all shared the same bolt size/type and washer. Is a different setup needed for the later 280zx model?

Also, I was planning on getting the Kameari bolt or Nismo but the stepped washer, possibly creating clamping issues, scares me. Flipping the washer around mimics the OEM setup, so....

I did look into the KA bolt and Volvo washer setup JeffP did but after talking with Rebello, deemed it unnecessary.

I know red Loctite is recommended for the install. Has anyone tried removing their damper after applying this? I imagine getting the bolt up to the required 550F to remove it would do some damage to the damper itself, am I correct?

-

I'm looking for a complete s15 helical lsd. Inculding the pumpkin and stubs.

-

It is the same car. That was a intermitint tps fauilure causing the flames. Standalone is another can of worms that I can't tackle right now. I'll just keep the boost down and enjoy it. It's a hoot at 15#'s, so I'm good with this setup for now. Later down the road I'll get standalone or a new flash from JWT.

Interstingly, my evo x runs in the 9-10 afr from the factory with no smoke as well. Thanks for all the help everyone.

-

Dang! I never knew that about Torco. I will stop using it. I can tell you that the plugs do have a slight red- brown to them.

It has a brand new o2, it didn't fix the issue.

-

Some companies recommend different locations for their coolers. Mine is an 1"-2" in front of the rad. I can't get temps over 190 no matter how hard I try. I saw no increase in my water temp by adding the oil cooler so the location works, at least on our cars.

On a side note, I was experiencing oil pressure drop on tight corners. I was going to get an accusump but thought that the cooler oil will let the oil maintain its viscosity and it did. Now there is almost no pressure drop.

-

Knowing exactly what fuel you are running is extremely important with AFR meters. Less so with Lambda meters. They are NOT the same thing.

WB O2 sensors output Lambda values. Stoich is always 1.0 Lambda However, depending on fuel, a Lambda value of 1.0 can vary greatly when converted to AFR. AFR meters convert the Lambda value to a table for a specific fuel. Usually pump gas. Some has switchable tables for E15, E85 Diesel etc. There lies the problem. Even pump gas varies quite a lot in formulation. A Lambda value of 1.0 with Shell pump fuel may output a different AFR reading than Chevron pump gas.

Race Gas does not have the same AFR values as Pump gas at Stoich. That of course affects values at WOT when mixture is richer.

The following article explains the difference between Lamda values and AFR. Be sure to read the complete article. It's very interesting, and shows why AFR meters should be taken ONLY as a guide and not an absolute.

http://www.ultra-gauge.com/customer_support/knowledgebase.php?article=29

Hope I'm not confusing things to much... but accurate data and accurate data interpretation is all important. Bottom line. Always give the engine what it wants. Instruments can lie... the engine won't.

Chickenman, thanks for your patience and perseverance. When I found out that race gas did read richer, I thought that was it but, strangely, I notice the same AFR's with 91 pump as I do with my race mix. No major change that I can see.

-

Chicken man is onto something although one would assume your AFR gauge and your ECU are reading off the same o2 sensor.

You have to answer the questions man, questions that have been fairly repeated at this point.

I think I'm out here.

What am I not answering? Sound like all of this is upsetting you. I have a life outside of this forum so give me a little time to reply to all the questions.

-

Obvious question, but is the Race Gas Lead free? If not O2 sensor is likely contaminated. What race gas is it. Is it E85 by chance?

How close is the O2 sensor to the Turbo? You may need a Heat Sink for it. WB sensors are more sensitive to excess heat than NB sensors. I'll try and find a link.

Another question, and we need this one answered please. What was the exact pressure that the FPR was set to at idle and was the vaccuum reference line to the FPR disconnected or connected when you set the Fuel pressure?

Curious. If you have a Lambda gauge and the minimum reading is 1.0. That equals 14.7 AFR with Gasoline. So how are you measuring any numbers less than that?

Fuel is 91 with Torco race additive. O2 is 10 " away, LC1 is 30" away.

The gauge is not in lamda, its in AFR. Min is 10 max is 20 AFR.

Fuel pressure is set correctly as stated before, 30 psi with vacuum 36 psi without.

-

That makes so much more sense now. You are tuning via FPR...

Also the reason why you can't supply duty cycle numbers voltage correction etc. You don't have access to them.

Where is your boost reference to the boost gauge and to the FPR from, are they from the same spot?

Have you checked the oil? If the excess fuel isn't coming out of the exhaust via black smoke then it is being washed down into the oil.

If you aren't going to switch to a tunable ECU which I think nistune would be the easiest and if AFR bothers you, turn up the boost. Granted if the ECU has a boost scalar then you are never going to get ahead of it. Keep in mind if this is for a Z31 then it is for a different motor the VG30 which is going to have a different efficiency not to mention different displacement off the bat.

It really isn't running strong. Most turbo cars make the most power from 11.5-12.5AFR so you are definitely in the rich camp and probably leaving power on the table. You could actually be hurting the motor with that "tune" by washing the cylinders of lubricating oil and diluting your oil supply, I hope you change the oil often.

Of course it could run even stronger, but right now it scoots, I just want to lean out the tune which, hopefully will be done by fixing all known issues first. I'm on fuel delivery right now hence this whole thread. I don't want to blame JWT for a bad tune until I know all is well on my end. I sure hope my gauge readings are correct or this is going to be a pain. I did happen to replace the fuel pressure sensor and it is reading the same as the old unit. Precision Z verified my Wideband/gauge matches there test equipment so.....

You guys rock by the way, I've been so busy lately I needed an army to help me with this.

-

I agree with ZH. I wonder if you're chasing ghosts. Car seems to run strong?? You see no black smoke from tail pipe. Could be an instrumentation error.

I've had O2 sensor get contaminated and give false readings before. It doesn't take much. Silicone used in the wrong place, leaded fuel ( race track fuel or Aviation Gas ) of course, over heating of WB sensor ( this is often over looked on Turbo cars ) will all cause inaccurate readings and drive you nuts.

If it's really that rich (9.5 to 10 ) the plugs should show it. Pull the plugs and take a picture with a good quality camera. No flash. Flash will skew the colors.

Have you ever done a WOT plug cut with fresh plugs? That will tell you what's really happening in the engine.

For the gauges. I'm only seeing a Lambda gauge. ( Top dash panel left gauge ). Can't tell what the minimal reading is... but it looks like 1.0. Is that correct? As for the FP gauge, that is the left hand digital gauge in the passenger foot-well correct?

Its see's nothing but race gas and I'm sure I heat it up the sensor plenty. All plugs look the same, semi dark brown. I'll find a pic. I want to do the WOT plug cut as I hear this is the only true way of determining how the burn is.

All the gauge info you said is correct, min is 10 AFR.

-

By old I mean I don't have a recent one of higher boost levels, The car still runs the same in the video as it does now.

-

You said it runs great, doesn't smoke, no real problems except an AFR number (the LED's on the gauge - my joke) that makes you uncomfortable. But it's uncomfortable on the safe, rich, side. I didn't go through your math, but at least two people did and said that there's no great mismatch between fuel pressure and boost pressure. The numbers are right. Basically, it looks like you don't really have a problem to fix. And the only solution to fine-tuning your AFR's is to get a tuneable engine management system.

There's nothing that can be done here. Stop looking at the AFR gauge and enjoy the car. Or get a tuneable system. That's all I'm saying.

It definitely is better than lean and is why I still drive it. In most of my experiences the issues I have are usually my fault. Ben at JWT says it should be around 11.5-12 AFR on boost. I still have an issue, at 8 psi you will see fuel pressure ramp up too much. Look at 20 psi, fuel should be at 56 psi but its at 61. That's not correct.

Most of the electrical systems have all been replaced/upgraded with new wires, relays, and a 70 amp alt.

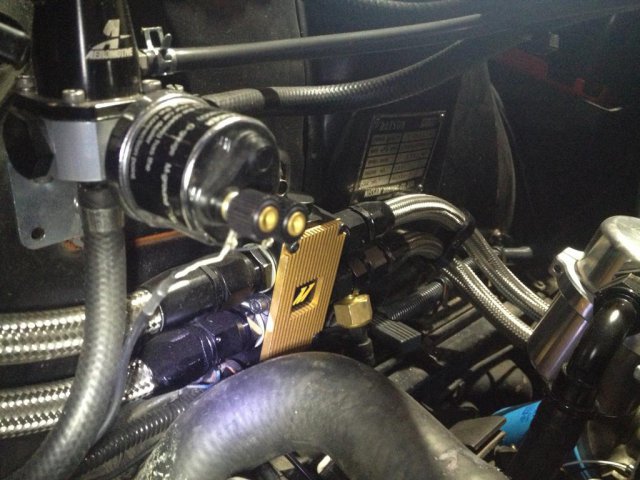

My setup: 83 auto F54 block, fresh stock p90 head, ARP bolts, unknown forged dished pistons, stock rods and crank, 2mm MLS head gasket, 7.4 cr, ported-polished-port matched intake manifold and exhaust manifolds, 2X Moroso oil separators, 240sx throttle body, Nismo 555cc injectors, Turbonetics TO4B, internal wastage hole enlarged, widemouth downpipe to V band stainless 3" with a Borla XR1 muffler, , Synapse BOV recirculating, Ford lightning MAF with my own custom intake with 6"velocity stack and 7" Amsoil air filter, Godspeed intercooler, Griffin super thick 2 core radiator, my own custom charge pipes, Setrab 25 row oil cooler with Misimoto thermostat and AN stainless lines, Aeromotive 1:1 FPR, 240x fuel filter, nissan 71c trans, larger than stock Spec clutch, alum flywheel, aluminum driveshaft, z31 CLSD 3.7 with cv's.

There's more but my fingers are hurting.

-

Seems like your best option might be to just stop looking at the AFR gauge. You're tuning to an LED.

I don't follow.

-

The video is kinda old. I have been slowly raising the boost to find the point of detention, I haven't found it yet, at least with race gas. My point was that it still feed adequate fuel at that boost level. It is scary fast at 27 psi, power unknown. From third gear and up it pulled hard on a new ZO6. My GPS speedo clocked a 10.9 1/4, that was at 25 psi I think. I have turned it down to 23 psi because thats fast enough. The turbo is kinda small, T3/T04b turbocharger with a T04B compressor housing and V trim compressor wheel. Ceramic ball bearing unit with a 57mm turbine wheel. The turbine housing is a .63 a/r. Water cooled as well. It's not that much psi for that size turbo.

-

Video clarifies a lot of things. FPR seems to be working fine. No over pressure that I can see. 22 lbs boost and 62 lbs FP. Perfect. Turbo spools quickly and FP keeps right up with it.

Fuel Pressure at idle with Vacuum hose disconnected is 40 PSI correct? Add 22 lbs boost and FP should be 62 lbs. which is what we are seeing.

Not seeing 27 lbs of boost in this video. Boost to FP correlation seems correct,

1: How tunable is the JWT ECU? Can you plug in, data log and tune with a Laptop or programming pad? I'd be looking at injector duty cycle closely. I'm not familiar with this ECU. If you can't program it with a Laptop or Pad, then you need a better ECU for a modification of this level.

Edit: Found some info on the JWT 550 kit and reading . Looks like no data logging and no real time programming. In other words, 1990's technology. Not good. IMHO, get a better ECU. If budget can afford it Haltech , AEM, MicroTech are all very good. If you're on a budget, go Megasquirt. Lots of good technology available these days. You sometimes find a good deal on used HalTechs on E-Bay. The Honda crowd are always updating to the latest and greatest systems.

Most systems these days have " AutoTune" where you set the AFR required and system will self tune to that level.

PS: Love how you've integrated the gauges. What pod did you use on the lower right side.

Not looking to go standalone as of now. The JWT tune runs so strong, its hard to justify right now. The gauges are from Depo Racing, they come with the pod. Good company that backs up their products.

-

1: Do not mount the oil cooler falt against the Rad or AC condenser. Space it away by a minimum of 1" . Flush mounting reduces air flow considerably. Same with Auto Trans coolers or PS coolers. Those through the Rad zip ties that come in some kits are a quick, but inefficinet means of mounting. You need some gap for proper airflow. Lots of room in the Z nose to make a proper mounting bracket.

Thats not what these guys say

http://www.mocal.co.uk/FAQ.html

But mine is mounted how you describe and its fine. All components where mounted via factory holes that my car isn't using anymore. Very basic aluminum brackets. Works extremely well. Never seen oil temps above 190 yet.

-

So data points from what I can see on the video:

30psi fuel pressure off boost

62psi fuel pressure at what I am guessing is 30+lbs of boost, tapering to 61 psi as boost tapers down to 30psi (hard to tell on the gauge)

The only thing that seems odd is that when you hit what looks like 34-35lbs of boost your fuel pressure gauge does not go all the way up to 64psi it stays at 62 psi. Suggesting maybe you are maxing out your fuel pump or as mentioned above you are dumping fuel.

Have a duty cycle table we can look at?

The pressure seems correct for the level of boost you are running assuming you are running a RRFPR or a FPC.

Its a 1:1 FPR. If I turn up the boost more, the fuel pressure goes up accordingly, 1 psi per pound of boost

-

No, I set fuel pressure to factory. In the vid it peaks at 23 psi and tapers to 20 in the higher rpm. It turns to plaid at 30 psi

-

Yeah, went as low as the FPR could go and it didn't get better.

-

Fuel psi is bottom right gauge. AFR is top left. Boost is center top. Even though the AFR gauge gets pegged I have logged AFR's with the Innovate software to confirm my gauge was correct, it was very accurate.

Fuel pressure regulator location matters!!!

in Fuel Delivery

Posted

Just wanted to share a fix to an issue I had. Car would get terribly lean when boost was ramping up, in my case 3800-4000 rpm. AFR's went to 19 for that moment, not good at 20+ psi!! I'm using the stock rail and had an Aeromotive FPR mounted to the passenger side front fender of the engine compartment, with 2.5 feet of vacuum tube to it. Took me a while to find the solution and it was in part due to a post I read, can't recall who it was, who had the same issue but never fixed it technically. He happened to replace his stock rail with a Perrin and it fixed his issue.

All this got me thinking why Nissan put the FPR on the rail in the first place. I thought I needed a fuel damper but Nissan never used one originally, so....I moved the Aeromotive FPR back to the oem FPR location, and have a 8" vacuum line now. Now that it's there, acting as a damper as well (like Nissan intended), you can guess what happened, cars runs great now. Thought I'd share since I see so many people mounting it in the same place I did.