-

Posts

1161 -

Joined

-

Last visited

-

Days Won

10

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by 74_5.0L_Z

-

22mm front sway bar

74_5.0L_Z replied to 74_5.0L_Z's topic in Brakes, Wheels, Suspension and Chassis

Thanks for the info. If I could time warp back to 1982, I could go buy one. It would be nice to find one someone has laying around. -

I am looking for a 22 mm front sway bar. The bar can be originally intended for the S30 or from something else as long as it is compatible. I may have to modify it regardless.

-

Does anyone know of a readily available 22mm sway bar that fits the S30? I already have 18 mm, 20 mm, and 25.4 mm sway bars. I currently have the 20 mm bar installed and would like to add a little more front roll stiffness without adding additional spring rate. I know from previous use the 25.4 mm bar is too stiff for my needs.

-

Stance coilover kit, front woes :(

74_5.0L_Z replied to sileightygx's topic in Brakes, Wheels, Suspension and Chassis

Is the drivetrain (engine/transmission) installed? It will ride high if there is no weight in the front. -

Here is a good link that covers the gear ratios and rated torque capacity of the mustang T5. http://www.allfordmustangs.com/Detailed/349.shtml You will notice that all the T5s for the 3.8 V6 were rated at 265 lb-ft of torque while the V8 World Class T5s were rated at 300 to 330 lb-ft. If you go with the GForce or Astro Performance gears and shafts then you can get 500+ lb-ft of torque capacity. Also the V6 T5s have the crappy 3.35 to 1 1st gear.

-

You need the V8 version period. At a minimum, you should get the T5Z transmission. You can buy them new or get a good one from Astro Performance. For the Z car, gear ratio selection is paramount to making a fun driving car. When I first built my car(circa 2001), I used a stock T5 from a Mustang police car and it had the following gear ratios: 1st: 3.35 to 1 2nd: 1.99 to 1 3rd: 1.33 to 1 4th: 1 to 1 5th: 0.67 to 1 It held up decently behind a stock 5.0L, but I hated 1st gear. At the time I had a 3.54 rear gear and ran 24.7 tall tires, but 1st was uselessly short. In street driving, I just generally started off in second gear. Later when I upgraded to a 331 stroker making 400 hp / 400 tq at the wheels, the stock T5 died a very quick death (during an autocross I sheared all of the teeth off second gear coming off a corner). When I pulled the transmission I discovered that I had also twisted the input shaft and output shaft as well as the stock slip yoke. So, I upgraded to Gforce gears and shafts. At the time I was only autocrossing, so I opted for the stock fifth gear. The new gear ratios were as follows: 1st: 2.94 to 1 2nd: 1.94 to 1 3rd: 1.33 to 1 4th: 1 to 1 5th: 0.59 to 1 I really liked the new 1st gear, especially with the new 3.36 rear end that I installed at about the same time. Unfortunately, when I started doing track days instead of autocross, I really hated 5th gear. The 4 to 5 shift dropped the rpms way too much and totally killed acceleration. So I pulled the transmission and installed the S80 fifth gear set from Modern Driveline (0.80 to 1). I now really love fifth gear. It pulls like a freight train all the way to redline in fifth now, but it might not be a good choice for a street car. My recommendation is this: If you plan to build any significant power then pony up for an Astro Performance A5 with the following gear ratios: 1st: 2.94 to 1 2nd: 1.94 to 1 3rd: 1.33 to 1 4th: 1 to 1 5th: 0.80 to 1 Be aware that the GForce and AstroPerformance T5s use a 26 spline input shaft and will require a different clutch disk. The stock input shaft is a 10 spline.

-

300 ZX Turbo CV shaft disassembly and reassembly

74_5.0L_Z replied to JMortensen's topic in Drivetrain

Can you post a video showing exactly what you are trying to explain? -

300 ZX Turbo CV shaft disassembly and reassembly

74_5.0L_Z replied to JMortensen's topic in Drivetrain

Are saying it doesn't plunge in and out like the outer? If so, then that is alright because that is the way it is supposed to be. If you are saying that it doesn't articulate freely in angular motion, then there is something wrong. The outer joints are the only ones that allow the in / out motion to accommodate length change of the axle. -

Bringing this one back from the dead because someone asked a question regard installation of the T5. This is my current set-up: Tilton 75-875U master cylinder (.875 diameter) Tilton 60-6104 Hydraulic Throw-out Bearing Tilton 61-612 Adapter King Cobra Clutch (5.0L Ford) Centerforce Dual Friction disc Fidanza Aluminum Flywheel Steeda Tri-Ax Shifter I have also upgraded my T5. I have the G-Force gears and main shaft with the following gear ratios: 1st 2.94 2nd 1.94 3rd 1.33 4th 1.0 5th 0.80 If I were to do it again, I would just contact Astro Performance and get there A5 with the 0.80 fifth gear. I have the engine and transmission out of the car right now for a rebuild of the engine. I plan to upgrade the pressure plate to the Centerforce LMC aluminum unit.

-

I just split the inner passenger side boot on my car as well. I have a very similar setup (Z31 CLSD R200 with CV axles). My inner passenger boot split at Daytona while I was doing about 155 mph, so I had grease everywhere. Luckily I inspect the car in between sessions and found it before the CV joint burned up. On mine, there is no evidence of the CV boot contacting the LCA even though I have about the same clearances that you do (my LCA are painted and clean so I would be able to see rub marks if there was contact). I attribute my boot splitting due to age and the centrifugal forces caused by going 155+ mph for an extended time. So, because I attribute the major cause of failure to be age related I decided to replace all four boots and clean and re-grease the CV joints. I ended up using the EMPI boots (P/N 86-1170-D for the outer boot and P/N 86-2127-D for the inner). They fit well and seem to be well made. I did reuse the factory retaining rings where possible, and used Redline CV-2 grease instead of the EMPI grease that comes with the boot kits. I haven't run them at speed yet. I'll test them this coming weekend on the Sebring long course where there are two straights where I will see about 150 mph.

-

300 ZX Turbo CV shaft disassembly and reassembly

74_5.0L_Z replied to JMortensen's topic in Drivetrain

Thanks. I had been perusing their web-site yesterday. I think the size I need for the Round Wire External Retaining ring that keeps the inner CV from pulling through the cage is CRS-30. I have requested a few samples. I haven't been able to find an exact replacement for the Flat Constant Section External retaining rings that are on the other boot side of both CV joints. I don't need those right now, but it would be nice to have a few spares laying around. So, I will follow Jon's advice and hit the local Nissan dealer to see if they can still get them. -

Looking for New Steering Rack Feedback

74_5.0L_Z replied to Samurai7one's topic in S30 Series - 240z, 260z, 280z

The stock rack that I pulled out of my early 260Z was the slow (1.59 inches per turn). I have measured three 71-73 240Z racks, and they were all the faster (1.81 inches per turn). I cannot swear that all 240Z racks are of the fast variety, but that appears to be the case. The stock 240Z rack has the aluminum pinion housing. Some 240Z cars that I have seen have had their racks replaced with newer units that came from a 260Z or 280Z. So, verify that the rack you buy is 240Z original equipment. -

Also, +2.9 would be about what I would expect for a stock 240Z.

-

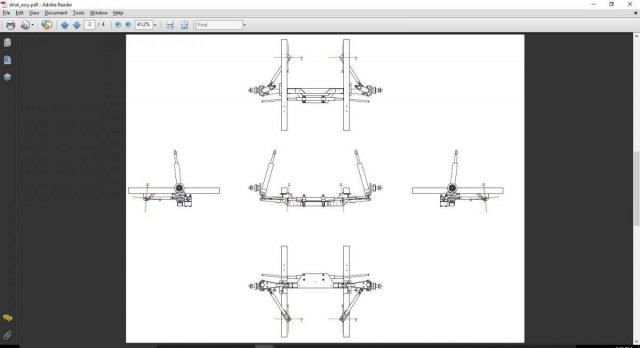

Are you sure that the negative caster numbers are real? If they were, the car would be almost undriveable. A quick way to check is to jack up the car and remove the wheel. If the strut top is behind the lower ball joint, then you have positive caster. This is what 6 degrees of positive caster looks like:

-

300 ZX Turbo CV shaft disassembly and reassembly

74_5.0L_Z replied to JMortensen's topic in Drivetrain

Jon, I just disassembled my inner CV on the passenger side and mangled the circlip. Do you (or anyone else) know of a good source for the circlip? -

I don't think any of these cars ever sat perfectly level, so if it is not grossly tilted then I wouldn't worry about. However, springs do sag with age and the rubber strut isolators do separate. So, if the springs and isolators are in good shape then the only real option for leveling (other than coil-overs) is to use spacers between the isolators and the body. Again, its is more important that car is level with you in it than without you in it. If you have stock spring rates then the ride height will change significantly with you versus without you.

-

Those number look much better than I originally thought from your hand written picture in the first post. I thought that the front camber was -.8 on the left and +2.0 on the right. So, you really don't have that bad of numbers for the front camber (for a street car). You should however try to fix the caster. If the T/C bushing are worn, then replace them. You can increase the caster with adjustable T/C rods, but don't get carried away. With stock control arms without a spherical bearing at the cross member connection, you will bind the control arm movement if you try to add too much caster. You could however get both sides equal and get about 4 degrees of caster. Were these number taken with you in the car? Have you verified that the car sits level? I always sit in the car while measuring the alignment. If you are in the car (left hand drive I assume) then the left front camber will become more negative. If you don't verify that the car sits level before performing the alignment, then you are applying a band-aid where surgery may be required.

-

Looking for New Steering Rack Feedback

74_5.0L_Z replied to Samurai7one's topic in S30 Series - 240z, 260z, 280z

Yes, you can install a 240Z rack in a 280Z. You just have to use the 240Z bushings. I have the standard length steering arms, but have looked into using the quick steering arms. With the 280Z rack, I felt the steering was too slow for autocross. So, I installed the 240Z rack and I am happy with the responsiveness of the steering. The steering effort did increase, but I do not find it difficult even with 10 inch slicks (at least while the car is moving). I do not try and turn the wheel with the car sitting still. It is my opinion that if you want to have faster steering than the 240Z rack with the standard arms and also have big sticky tires, then you will need power steering. -

Looking for New Steering Rack Feedback

74_5.0L_Z replied to Samurai7one's topic in S30 Series - 240z, 260z, 280z

Would you please measure the rack gain? To do so, perform the following: 1. Start with rack all the way against one of the end stops. 2. Turn pinion exactly one turn. 3. Measure amount of rack shaft exposed (between end stop and end of housing). For reference, the stock 240Z would move 1.81 inches per revolution of the pinion gear, and the stock 280Z rack would move 1.59 inches per revolution of the pinion gear. So, the 240Z rack is faster but requires more effort to turn. I would love to see how this rack compares. Thanks. -

Did the alignment shop give values for SAI and included angle? If your SAI is very different left to right then you may have a bent strut or body damage that is making it difficult to achieve equal camber left to right.

-

I have to agree with Jon on this one. Those alignment numbers need some help.. Jon made a good suggestion regarding loosening the bolts holding the cross member and shifting it to try and equalize the camber in the front. You could even slot the holes in the cross member further to give more adjustment. You could also make or purchase adjustable T/C rods to make caster adjustable. Either way, I don't think you will be happy with the handling with the current alignment. Mine is a highly modified track car, but here are my current alignment settings: Front: L R Camber: -2.0 -2.0 Caster: 5.9 5.9 Toe: - 1/16" -1/16' Rear: Camber: -1.5 -1.5 Toe: +1/16 +1/16 All readings were taken with me in the car.