Boosted12

Members-

Posts

15 -

Joined

-

Last visited

About Boosted12

- Birthday 12/09/1983

Profile Information

-

Gender

Male

-

Location

Fairfax, Virginia

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Boosted12's Achievements

-

Fresh air / inner fender wire duct

Boosted12 replied to fusion's topic in S30 Series - 240z, 260z, 280z

Yes, I ran my wiring through these in my 280Z, it worked a treat. -

Great, thanks for the screwdriver analogy. Makes much more sense now. I guess I have my answer now as far as timing goes.... next upgrade I'll be going with a CAS for sure.

-

Xnke - I had sort of the same idea... I'm replacing all components related to this to be on the safe side. We'll see the result when I get the car started back up. John - I was asking where on the shaft you applied that strip of brass. I'm having trouble visualizing where you put it.

-

John, Where on the shaft? The actual input to the pump, or at one of the locating areas where it goes through the timing cover? I don't plan on going above 6k RPM, and I only expect to make ~350WHP maximum. I do plan on buying a new shaft and pinning it, would you recommend a new crank drive gear as well? I was able to visually inspect mine, it doesnt seem deformed.

-

Tony - Yes, I've verified compression at ~120PSI for all 6 cylinders, which is normal for this engine so far. Jeff - Thanks for the confirmation - I was going to pull the pump drive/gear and pin it anyhow, but your advice makes me doubly sure. This headache and your valid concern in regards to the timing possibly wavering under high boost makes me want to convert to a crank angle sensor a la EDIS... Maybe that's in the cards after pinning the pump drive. IF I do convert to CAS, would you still recommend a new crank drive gear for the oil pump, or will the slight slop be ok, as the pump will be driven regardless? Thanks!

-

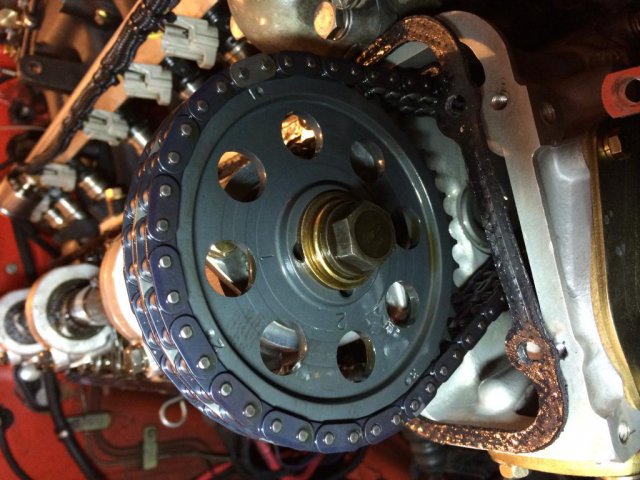

Hello all, I'm a long time lurker here and am having issues with my fresh (600miles) rebuild. The engine is an 83 L28ET, using MS1 V3.0 with spark control, Holset HE351 turbo, mild turbo regrind cam, forged pistons (~8.5 to 1 CR). I did a WOT throttle run to redline testing a higher boost setting while datalogging, near redline (6k in my case) the car sputtered, missed, and backfired badly. I got off the throttle, coasted to a stop, engine is dead. Cranked it back up, only ran while applying throttle. Still backfiring and sputtering, I pulled over and got the car towed home. Removed spark plugs, verified even compression in all cylinders ~120PSI. Verified static timing, verified fuel pressure, plugs are clean and not fouled. I had a helper start the car and hold the throttle while I watched with a timing gun - the car is now firing 1 at ~33 deg BTDC. I then checked the distributor shaft - it looks slightly off, but not a huge discrepancy. I then rotated the dizzy to "account" for the extra timing and get it back to 20 deg BTDC. Car idles without throttle input now, but is still running like a pig, stutters, doesn't want to rev, etc. I decided to not risk any possible damage and starting documenting everything. Valve cover is now off, I've attached pics of the cam position and the hash mark, the harmonic damper's position relative to TDC, and also a pic of the distributor rotor and the shaft tang below. After plenty of searching, the only thing I can come up with is the oil pump drive gear has slipped several degrees, but that doesn't account for why the car still runs bad even after i artificially fixed the timing by retarding the distributor position. My next step is brand new fresh plugs, perhaps a new fuel filter to eliminate that possibility (car is getting 35 PSI at idle, but who knows might not have enough to run more?) Any ideas guys? And I apologize in advance if I've overlooked anything obvious... I'm naturally very worried and easily may have skipped over something. Also, please let me know if you need me to take pictures of anything else. Thanks!

-

Harry's LapTimer worked well for me. Its definitely not 100% accurate but it works well enough for my purposes. And yes, it had Shenandoah already loaded. http://www.youtube.com/watch?v=xF7DRvR76OA

-

ShaggyZ's 2J8Z: 280Z + 2JZ-GTE

Boosted12 replied to ShaggyZ's topic in S30 Series - 240z, 260z, 280z

DO it! -

Painless Wiring Harness - Ignition Relay Needed?

Boosted12 replied to Boosted12's topic in Ignition and Electrical

Here is a diagram I came up with integrating the stock Ignition relay. Conversely, I can just connect directly from the painless fusebox to the ignition switch. Which seems to make more sense? -

Painless Wiring Harness - Ignition Relay Needed?

Boosted12 replied to Boosted12's topic in Ignition and Electrical

Kaito, I also verified the relay on the harness is indeed for the horn. This is for the 10101 12 circuit harness: 10.5.1 Connect HEADLIGHT SECTION A wire #924 (grn) to the Horn's hot terminal. TURN SIGNAL SECTION wire #953 (blk) was connected in the Turn Signal Connector section of these instructions. The Horn Relay is pre-wired into the Fuse Panel. This brings back up my previous question - Should I rig up a relay for ignition? -

Painless Wiring Harness - Ignition Relay Needed?

Boosted12 replied to Boosted12's topic in Ignition and Electrical

I found this post previously: http://forums.hybridz.org/index.php/topic/29786-painless-harness-to-z-column-harness-headlight-combo-switch/page__view__findpost__p__236215 The wire colors, however are not consistent with my car, nor are the numbers of wires consistent. My ignition switch only has 4 connections, not 5. Here is what I came up with for my car (78 280Z Ignition Switch) Datsun Wire | Painless Wire | Purpose ______________________________________________________ White/Red | 12ga Red - 934 | Battery B+ Black/Yellow| Purple - 919 | Starter Solenoid Black/White | Pink - 931 | Coil/Ign Power (Will go to MS Relay board, since my coil is driven by MS) Blue/Red | Org+Brn - 932+933 | Accessory Power -

Painless Wiring Harness - Ignition Relay Needed?

Boosted12 replied to Boosted12's topic in Ignition and Electrical

So did the Battery Master relay replace the Datsun Ignition relay? Or did you just use the Battery Master as a means to provide power to the rest of the electrical system? -

Painless Wiring Harness - Ignition Relay Needed?

Boosted12 replied to Boosted12's topic in Ignition and Electrical

I only saw the Painless Harness to Combo Switch harness Stickied - Is there one for the ignition somewhere as well? Sorry if I overlooked it. -

Painless Wiring Harness - Ignition Relay Needed?

Boosted12 posted a topic in Ignition and Electrical

Hello all, I'm in the process of installing a Painless 10101 12 circuit harness in my 78 280z. The car is running an L28ET controlled by MS1, so all the engine harness/fuel pump relays, EFI relays, etc, are not an issue. I've decided I'm going to wire relays for the headlights, one for high one for low, just to keep power through the switch at a minimum. The fuel pump relay is controlled by the MS, the Horn relay by the Painless Harness. My questions are related to the ignition switch and ignition relay. Do I need to keep the ignition relay? How have you gone about doing this in the past? Also, does anyone have wiring tips for the ignition switch itself? What relays have you ended up using/installing/keeping from the stock harness? So far the only one I can think of keeping is the ignition relay. Thanks in advance for any and all help.