-

Posts

247 -

Joined

-

Last visited

-

Days Won

14

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Invincibleextremes

-

Ford Super 8.8 irs swap thread. Rear brakes too

Invincibleextremes replied to Invincibleextremes's topic in Drivetrain

- 277 replies

-

- disc brakes

- suspension

-

(and 7 more)

Tagged with:

-

Ford Super 8.8 irs swap thread. Rear brakes too

Invincibleextremes replied to Invincibleextremes's topic in Drivetrain

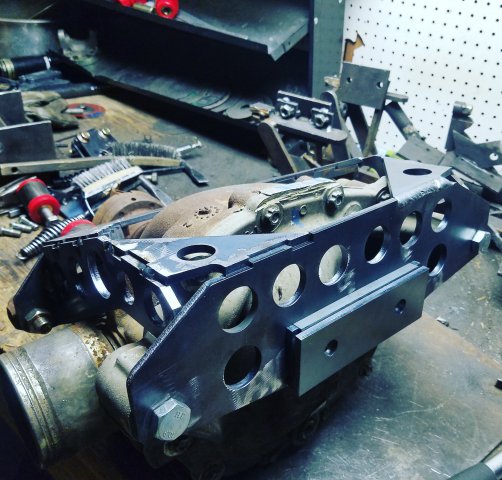

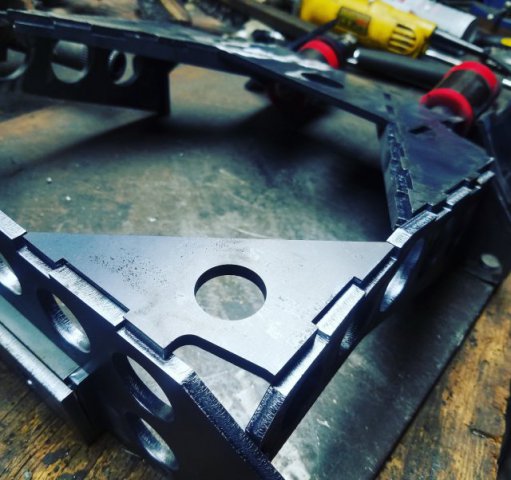

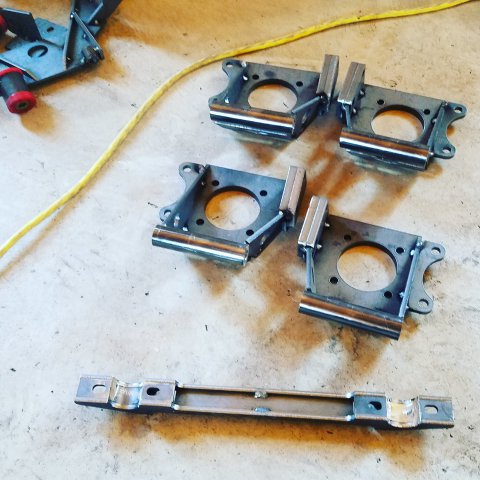

Version 5 has some updates that allow it to be welded better. The tabs are all half the height of the slots. There has also been a lot of weight shed that doesn't compromise the strength this setup is known for. Showing version 5 may not mean much since this entire batch is spoken for and I'm already brewing ideas to improve version 6 with, but it's all part of the story and everyone's feedback is very appreciated and taken seriously.- 277 replies

-

- 1

-

-

- disc brakes

- suspension

-

(and 7 more)

Tagged with:

-

Ford Super 8.8 irs swap thread. Rear brakes too

Invincibleextremes replied to Invincibleextremes's topic in Drivetrain

Video of Andrew's 900hp supercharged v8 datsun hooking up and surprising a nitrous straight pipe fox body which had problems hooking up on this surface. Couple pics of a different customers install I did over the weekend. Something I wanted to point out... the axles for this swap are readily available, extremely strong and VERY affordable. The custom length shafts use common OEM v8 mustang cv donors. I'm pointing this out specifically because I've run across several people who've reached out to me because they had been burned on the axle situation from other companies. One had broken no less than half a dozen axles at 500hp, and is now using the super 8.8 and the axles I provided without issue at 700hp on a turbo 2jz. The other is someone who asked me to solve his axle problem because he has the weaker 31 spline (vs 34 spline super 8.8) explorer 8.8 and the company supplied him with shafts specifically designed around autozone axles that have since then undergone a design change, leaving him without usable axles for his swap. Mustang gt cv axles do not interchange with explorer oem axles, nevermind the aftermarket ones, so there's nothing I could do about his problem.- 277 replies

-

- disc brakes

- suspension

-

(and 7 more)

Tagged with:

-

Flipping the control arms moves the inboard pivot back so it doesn't bind up when the tension rod is tightened to move the ball joint back.

- 90 replies

-

- suspension

- 240z

- (and 5 more)

-

Moving the top of the shock mount backward allows for caster to be useful. Not moving the top and only moving the bottom backwards will be bad for handling because it further takes away the already barely existing caster these cars come with.

- 90 replies

-

- suspension

- 240z

- (and 5 more)

-

Yes, but wider. So factory 280z tie rods won't work, but aftermarket ones do.

- 90 replies

-

- suspension

- 240z

- (and 5 more)

-

Just for clarification the new t3 tie rods are the exact taper needed for 2014 mustang control arms. No drilling needed. They bolt right up, gold car did exactly that. And as to the caster, only way this mod works well is if the camber plates up top are rotated and used to move the shock backwards the same amount or more then the entire control arm is moved down below. Or in David's case with the blue car, he did the caster up top but kept the control arms the same, and cut the fender to clear his tires since he flared the car anyway. Here is a picture of the gold car and the t3 clearance style tie rods.

- 90 replies

-

- suspension

- 240z

- (and 5 more)

-

Gold car did exactly that, and he swapped control arms left to right so bushing wouldn't bind up.

- 90 replies

-

- suspension

- 240z

- (and 5 more)

-

I've seen aluminum parts fail. There are two aspects about apex that I personally like, their steel tie rods, and bumpsteer spacer thing. I personally prefer moving the mounting points of the control arms instead of adjusting the toe with control arms that adjust, but if adjustable control arms are your thing, the Apex one with the floating link is the way to go. There's the issue of a short diff in a long space if using the shortnose r200, but that's been discussed. I come from a muscle car background, and those cars have serious camber curve and bumpsteer issues that aren't solved with big brakes and 18 inch wheels. They all exclusively have double control arm suspension. Almost every modern version of those cars handles exponentially better and uses regular McPherson strut suspension. I can't honestly say one is better than the other in that regard, it comes down to each individual design and how it interacts with every aspect of the car.

- 7 replies

-

- 280z

- technotoytuning

-

(and 4 more)

Tagged with:

-

Yes, gold car, and blue car just used t3 and apex tie rods and kept their datsun rack. Rock steady at insane speeds.

- 90 replies

-

- suspension

- 240z

- (and 5 more)

-

Ford Super 8.8 irs swap thread. Rear brakes too

Invincibleextremes replied to Invincibleextremes's topic in Drivetrain

- 277 replies

-

- disc brakes

- suspension

-

(and 7 more)

Tagged with:

-

Ford Super 8.8 irs swap thread. Rear brakes too

Invincibleextremes replied to Invincibleextremes's topic in Drivetrain

How to disassemble the cv axles to replace the shaft. As you can see it only takes a couple minutes. Here's another thing I've come across... I buy the donor cv axles in bulk from Shelby America. Half of them are unusable pairs because they're gt350 axles that have the left shaft with a different cv and shaft... meaning the custom shafts won't work in that axle. Some guys have stumbled across this and now have a gt350 left shaft just hanging out after purchasing another left shaft off the 2015-2017 v8 cars or 2018 and newer v8 automatic transmission cars. I'm going to to contact some companies and see if they can continue the splines and hack the extra length off of half of my growing pile of gt350 axles. Thereby converting left inner stub shafts into right ones, making a complete donor pair that would utilize the stronger larger cv joints from the gt350 left axle. This will accomplish two things. 1. Gt350 left shafts can be shortened unlike the right side, or the hollow standard v8 shafts. For guys not pushing the hp limits this opens up a very economical option for guys doing the swap who can then enjoy silky smooth 8 ball cv axles. No idea what the theoretical limit of cut down gt350 shafts will be, but they are substantially stronger than the solid shaft found in explorers, and that's not even comparing the cv itself. 2. The gt350 cv joints themselves are substantially stronger than the regular v8 cv joints currently used for the swap... which themselves are no slouch. I can have batches made of the larger diameter custom shafts to fit those larger joints... and at a price point for a usable pair of axles that still don't come up to the price of custom length DSS race axles. This layered approach drives the cost of the swap even lower while substantially increasing the hp potential for pennies on the dollar for guys who want the peace of mind of the bigger diameter hardened shafts and bigger cv joints. Another option would be to get a pair of gt350 left axles cut and splined to the smaller v8 inner cv specs and run gt350 cv joints on the outboard side and regular v8 differential stub shafts. This again would be very economical since i buy the axles in bulk.- 277 replies

-

- disc brakes

- suspension

-

(and 7 more)

Tagged with:

-

Kyle is building a v12 swapped 2+2 and here's what he used up front... 2014 mustang ball joints. 2014 mustang spindles 2014 mustang GT 13.2 inch brakes 2004 mustang outer tie rods, we cut half inch off of them, they're fully threaded so we didn't see any issue with that. 1985 Camry inner tie rods. 2004 Subaru legacy steering rack. He used silvermine coilovers. We rotated the camber plates and used them to add caster, and flipped control arms left to right... Planning on using adjustable tension rods to move the wheels back about half an inch.

- 90 replies

-

- suspension

- 240z

- (and 5 more)

-

Ford Super 8.8 irs swap thread. Rear brakes too

Invincibleextremes replied to Invincibleextremes's topic in Drivetrain

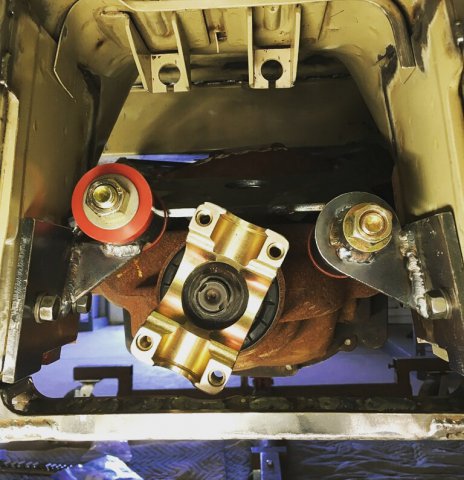

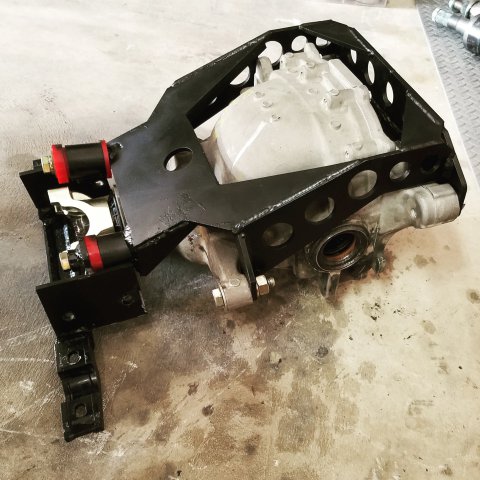

Catching up on everyone's kits as fast as I can, here's what the complete cradle looks like with the optional crossmember. Snapped the picture before we bolted it back into Kyle's v12 datsun project.- 277 replies

-

- 1

-

-

- disc brakes

- suspension

-

(and 7 more)

Tagged with:

-

Settling on two rear end options...

Invincibleextremes replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

I've sold the uprights seperate from the rest of the kit to some guys btw. They bolt up to 2004 neon lowers and use 2014 or 2015 mustang brakes, and hubs. Just drill them for whatever hubs you choose. I also sell the tabs to convert any strut to neon style... But the complete kit is dirt cheap, and guys have been unable to break them. 165+ mph and no vibration issues or anything either. -

He's talking about Apex outer tie rods. That's if using the non sti rack, Volvo s80 inners and 240z outers. T3 outers that they currently offer bolt right up btw. The sti rack can be used with 1985 Camry inners and 2004 mustang outers.

- 90 replies

-

- suspension

- 240z

- (and 5 more)

-

260Z 2+2 Tesla MoTeC etc

Invincibleextremes replied to Johnny Smith's topic in S30 Series - 240z, 260z, 280z

Yes I have no issue with just the hub uprights. Just ask. -

Ford Super 8.8 irs swap thread. Rear brakes too

Invincibleextremes replied to Invincibleextremes's topic in Drivetrain

Here's the thread involving the front end swap using 2014 mustang spindles and the front coilovers off the neon. This allows you to buy a complete set of neon coilovers and use them. Takes a few mods to make it work up front but it's straightforward. To summarize the rear end setup and answer a couple questions I'll post some key points. The bracket in the way is on the left side of the trans tunnel in the back, it's not part of the parking brake assembly so I can only assume it's for the factory exhaust. Factory mustang track width is 64 inches... therefore the axles cannot be used as is. But the shafts needed use factory v8 cv parts so wear items are a non issue. This setup converts to 5 lug, but retains factory track width of 53 inches. Works with 2014 mustang or 2015 mustang brakes. Both readily available and dirt cheap. Dust shields for the rear will need work because the factory 2015 hubs are used but obviously not the spindles. About the custom shafts... to date, there have been no less than 40 shafts purchased and delivered to people. Only thing custom about them is the length, so you don't need to go through me to get custom shafts in the future. Granted your prices may vary but you can send a pair of v8 axles to any reputable axle maker and ask for shafts to fit your needed application. Also, custom high hp axles are available that are advertised to 800hp and 2,000hp. I've contacted them and asked if custom lengths are an option and they are happy to provide them. Most people opt for the DIY version of the kit, they get hardware and cradle and two uprights that are all tacked together but unfinished. They then finish the kit and add whatever custom touches they want. Yes it's designed around an r200 mustache bar but you can just as easily weld on tubing and use bushings to avoid paying for an r200 mustache bar... Noah literally did exactly that.- 277 replies

-

- disc brakes

- suspension

-

(and 7 more)

Tagged with:

-

David has been driving his for about half a year, I'll ask him for any specs. He may have eyeballed the alignment. I'll ask Andrew as well and see if they can get us numbers. Maybe noah...

- 90 replies

-

- suspension

- 240z

- (and 5 more)

-

Ford Super 8.8 irs swap thread. Rear brakes too

Invincibleextremes replied to Invincibleextremes's topic in Drivetrain

Raising the diff up can be done, but you're going to have to notch the frame rail above it. Plus you'll run out of room unless you plan on getting rid of the factory parking brake assembly.- 277 replies

-

- disc brakes

- suspension

-

(and 7 more)

Tagged with:

-

Ford Super 8.8 irs swap thread. Rear brakes too

Invincibleextremes replied to Invincibleextremes's topic in Drivetrain

- 277 replies

-

- disc brakes

- suspension

-

(and 7 more)

Tagged with:

-

Ford Super 8.8 irs swap thread. Rear brakes too

Invincibleextremes replied to Invincibleextremes's topic in Drivetrain

Pinion angle was measured and it came out to be a couple degrees. This is why the crossmember needed to be notched, otherwise the pinion angle will be too much. Another option would be to cut the body of the datsun similar to an r230 swap and tuck the diff itself higher on relation to the car. This would require moving the rear plate down on the cradle and tacking up in a new location. Would also require breaking a couple tacks on the front mounts and matching the angle of the diff or at least the location. Most people don't need that since it's a tight fit, but works as is. And most aren't interested in cutting up ththe body of the car itself either.- 277 replies

-

- disc brakes

- suspension

-

(and 7 more)

Tagged with:

-

Ford Super 8.8 irs swap thread. Rear brakes too

Invincibleextremes replied to Invincibleextremes's topic in Drivetrain

Shown here is the optional crossmember used to create clearance for the pinion without having to notch the factory one. Both are viable options and I recommend tying in the verticals for maximum strength regardless.- 277 replies

-

- disc brakes

- suspension

-

(and 7 more)

Tagged with: