Zcardude

-

Posts

43 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by Zcardude

-

-

Here's a company that makes a complete carbon fiber roof just for this: https://industrygarage.com/products/datsun-s30-carbon-fiber-roof

-

Might be useful to list out what kind of ECU that you're running

-

I've looked at XFI systems before and many of them based on my understanding are fuel-only. I think you'll be in big trouble at 18-27psi without controlling spark timing as well. You're maybe safe at 4-5psi if are running pretty rich AFRs and retard the factory distributor a bit

-

36 minutes ago, NewZed said:

The breaker plate is the part that rotates when vacuum advance is applied. It moves the pickup coil in relation to the distributor shaft to advance the timing. The distributor shaft itself can rotate freely but the breaker plate can be locked to it instead of free. Easiest way to check is to remove the vacuum advance canister and gently try to rotate the plate. If the balls are rusted in place you might break the plastic cage so be careful.

Think about advance curves also. There the vacuum advance and the centrifugal advance. Once you get in to them there's all kinds of small details to worry about.

Thank you, that’s very helpful! I’ll definitely use this info once I figure out the overall spark triggering situation 😄 -

11 minutes ago, NewZed said:

Forgot to say, have you checked the breaker plate on the distributor? Often they get locked up or broken and don't rotate anymore.

You could use a 280Z distributor in its place. Or a 280ZX unit. The ignition module on your 260Z is one of the very first models and those old ignition modules fail on a regular basis. In short, consider the sum of the parts involved. And, the early electronic ignitions were not "high energy". They were just points replacements. Same plug gap,. 1978 was the first high-energy ignition module.

Yep, I have the distributor on my bench and it spins freely and appears to be in relatively good shape outside of the failed pickup.

I was also considering a 280Z or ZX distributor for the car but those appear to not be in good supply so I figured trying out a new pickup for this one might be the best bet. Additionally I was likely going to convert the car to either use an MSD box or 4pin HEI module once I had the pickup working as I’m not sure the factory TIU is in good shape still and either of those options would supply more power to the coil.

-

Hi there,

I recently picked up a non running 260Z. It hasn’t been driven in 27 years and I’m trying to get it back on the road. I’ve traced my issues down to a corroded and dead pickup coil in the distributor. I’ve ohmed it out and it shows that there is no connection in the pickup internally. Additionally I’ve bench tested it trying to get it to fire an MSD box to no avail

I’m not able to find anywhere that I can get a new pickup coil for this distributor and don’t really want to spend $150+ and a long turnaround time having the distributor rebuilt when I know this is a part you can generally just buy for other distributors.

For example I see I can get a new 280Z pickup from rock auto here: https://www.rockauto.com/en/catalog/nissan,1978,280z,2.8l+l6,1209260,ignition,distributor+pickup+coil,7176 But I’m not sure it would work in the 260Z dizzy as I know they are a bit different.

Is there an alternative pickup coil I can install in the factory 260Z distributor? Would the 280Z one work despite being for a slightly different distributor? Is there some other pickup that I can buy at a local parts store and install?

thanks for your help :)

-

Just checking back in to say this thing is running really good, the best it ever has since I've owned it I think, so I don't think my trigger angle is causing any issues at all. I haven't hot rodded on it yet but it drives very very good and I'm expecting it to pull good as well. I'm very confident that my mechanical timing is correct as I spent a lot of time questioning that before looking at the terrible wiring job (see my post history :D)

-

32 minutes ago, Zetsaz said:

Doesn't seem unreasonable. Mine is pretty far off the recommended. Your distributor has it's own adjustment built in, and it's possible to install the wheel 180deg off.... and it's possible to install the distributor 180deg off...

You have to remember, that the computer can literally place your timing at any degree you want, especially if you're running coil on plug. You could clock the distribor in the completely wrong direction, install the disc upside down, and still get things to fire if you happen to get the correct #1 tooth angle on your settings.The most important thing is that your base timing in your settings that megasquirt is expecting, matches with what your timing light is picking up.

Thanks! That all makes sense and lined up with my thinking. Since I have the timing light matching what the spark advance in tunerstudio is stating I'm going to call things "fine" for now

My biggest concern I think was that if I got too weird of a trigger angle, since I'm still using the distributor with a single coil, I could potentially end up in a situation where the rotor is not in the correct position to fire the proper plug or fire the wrong one or something along those lines.

-

Hi everyone,

I'm running an MS2 3.57 running MS2 Extra 3.4.3 on a 1983 L28ET in a 1973 240Z. I just finished completely rewiring the engine with a new harness as the previous install was hack job by the previous owner. I recently did some work on my car, upgrading it to use a diyautotune optical trigger disc as well as eliminating an unnecessary CDI box. I have it running pretty well (just moving it around the driveway so far, haven't driven it fully yet) but had to use a strange "Tooth #1 Angle(deg BTDC)" trigger angle setting. It seems very healthy compared to the previous wiring job: it fires right up dead cold and just sits there and runs, previously it was very angry cold. I was mostly following the information on https://www.diyautotune.com/support/tech/hardware/nissan-trigger-disc/ but I did not create a second input for the cam, I am only doing crank input for now.

For my new setup, I am using a "Tooth #1 Angle(deg BTDC)" trigger angle setting of 285 degrees. When I set this angle, my timing light matches up exactly with the calculated spark advance. DIYAutotune recommends 345 degrees. When I tried 345 degrees, the car would not run at all, I think that the timing was just way too far off. Before installing the DIYAutotune optical trigger disc, looking at my old tune, my "Trigger Angle/Offset(deg)" was 52.3 which I believe was also sort of a weird setting.

So my question is: Is it normal to have such wildly varying trigger angles from what lots of other people have and what online guides recommend? Does this mean my distributor drive is potentially installed improperly? Does any of this matter if I am able to get the correct advance out of my timing light? I ask because I know the engine is a rebuild that was already running on megasquirt when I bought it and I don't know if this is something I need to resolve. It had some weird ignition problems before but the wiring was a disaster. I want to know where to look next if there are more ignition issues or if this can cause problems.

I can post some MSQs if that's helpful.

Thank you!

-

I’m also interested in doing this. What are the part numbers or links to what you’re using there? I see the pressure switch there - is that also an aftermarket clutch slave?

-

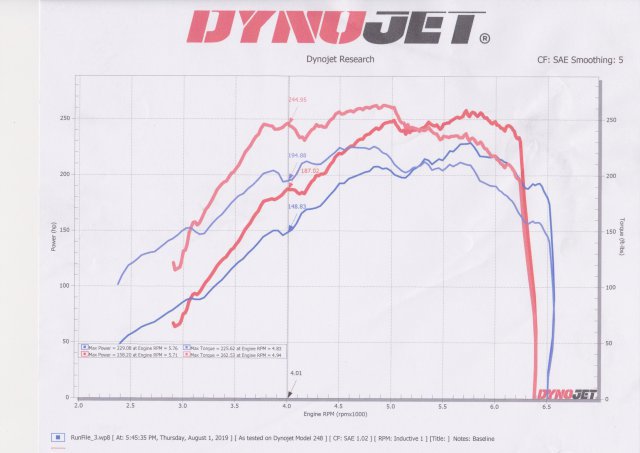

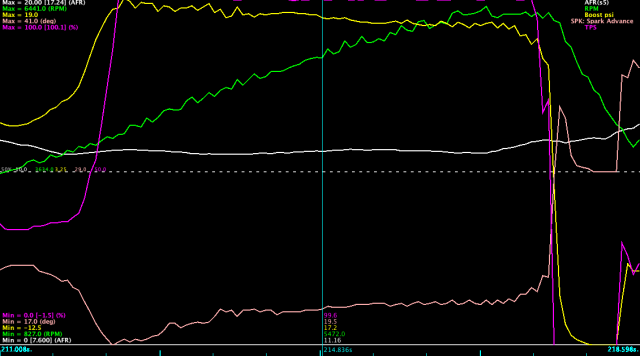

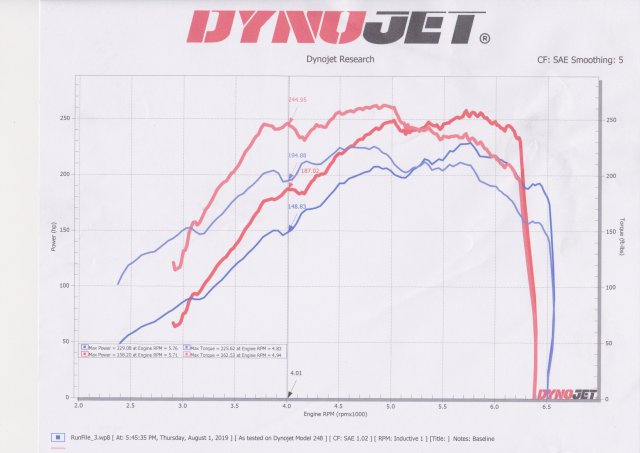

That's interesting that you mention that. I have the same unit triggered by an MS2 and have some weird power delivery issues, where the torque drops off rapidly, then come right back, producing a really oddball (and sorta disappointing? It makes 258whp but should be able to do more) power curve. Did you have the opportunity to dyno yours with the problematic MSD StreetFire? I'm curious what it looked like on your setup. Posted mine below for reference

Some other members here have speculated that it is caused by noise coming in through the optical pickup on my L28ET distributor, but I originally was thinking it might be a problem with the MSD StreetFire unit. Now you've got me wondering... I've got an MSD 6AL box to try as well as a different trigger wheel for my distributor so I can basically eliminate either or both from my setup. Will definitely post back in this thread once I have more information.

-

7 hours ago, dpuma8 said:

My 105 amp alternator is a 1 wire setup. Is there a general safe advance map for an L28et? I see some of the maps in the Megasquirt map sharing section of hybridz but I am not sure if any of them are safe or not.

My voltage issues are better after rearranging things but not perfect. Now MS will read 12V at idle, increase to 14.2V while drivinjg with some moments where it drops to 12 again before raising up to 14.

I don’t think there’s a known “safe advance map” for our engines, but what I said about timing slightly increasing after peak torque is a really common pattern. If you take your car to a dyno and have someone tune the timing, that’s how your spark map will end up. Guaranteed. In the meantime ensuring that your base timing is set right and then reviewing a lot of other tunes and staying conservative is probably alright. But you shouldn’t lose several degrees of timing as you run up through the RPMs.

Also yeah it sounds like you’ve got a problem with your alternator or some kind of wiring issue. I mentioned that you may want to try to relay the megasquirt directly off the battery rather than scabbed into some other part of the electrical system (not that you’ve done that

I obviously don’t know what’s going on with your wiring), that may help if you want to try something that should only cost a few dollars rather than needing to do a whole alternator swap. FWIW I’m running a 90A Gm 1 wire and based on datalogs I fluctuate a whopping .1v over the course of a very long drive, essentially keeping a rock solid 14v constant. That should be your goal and would probably be a decent place to start solving problems with your install.

I obviously don’t know what’s going on with your wiring), that may help if you want to try something that should only cost a few dollars rather than needing to do a whole alternator swap. FWIW I’m running a 90A Gm 1 wire and based on datalogs I fluctuate a whopping .1v over the course of a very long drive, essentially keeping a rock solid 14v constant. That should be your goal and would probably be a decent place to start solving problems with your install.

Definitely post results as you try things out and they get better. I messed with my L28ET megasquirt setup for quite a while before I finally started becoming happy and relatively satisfied with it. Good luck!

-

On 8/14/2019 at 1:25 PM, dpuma8 said:

Not sure why my voltage is so low and I am not sure where to start looking. I have a Z Specialties 105 amp alternator that needed to be rebuilt for bad bearings after not too much use. I don't have any extra accessories like a radio or anything like that. My car is wired with EZ wiring harness.

My boost flutter issue has been fixed by rearranging my vacuum lines. My MAP sensor was hooked up to the #5 intake leg so I moved it to the port between #3 and #4.

I still have an issue though where it feels really flat once I get over 4500 rpms so I can't tell if this is because my P90 cam is losing steam, my ignition timing needs more advancing, or because I have spark blowout.

2019-08-07_20.57.25.msl 2.05 MB · 1 download CurrentTune.msq 119.09 kB · 1 download

Hi,I took a look at your log and tune and have a few suggestions

- Your TPS doesn't appear to be calibrated right. It looks like you are going WOT and only achieving about 85% TPS

- Your spark plugs are the wrong heat range. They are too hot, 6 is an N/A heat range. You should be running a 7 heat range plug like a BKR7E or BPR7E. 0.028 gap should be fine

- Based on logs you make boost really late for such a small turbo. Is this just you only jumping on the throttle later in the powerband or is this where you have to be to make pressure? Do you have boost leaks? You should make or buy a boost leak tester and test. For comparison I am running a older, less efficient, larger frame turbo, and making positive pressure at 2k and start making decent power around 3k.

- I'm not sure how accurate your wideband is but things look a bit fat under boost generally. I'm seeing high to mid 10 AFR's on some of your pulls, low 11s on others. Try to target mid to high 11s under boost if you can

- Your spark map looks too conservative to me. In fact, all of your timing seems to diminish as RPMs go up. This is actually the opposite of what you want: Once you are past peak power, you should look to slightly increase timing to to carry power higher in RPM range. FWIW my tune on my L28ET (that I messed with on a dyno and whatnot but admit is far from perfect) is at 24 degrees advance at 180KPA, yours is between 22 all the way down to 18 depending on RPM. Again, FWIW, messing with my timing, under power, I was able to gain 5-10HP per degree of timing added - if something like that is true on your engine, you could imagine yourself dropping 20-40HP as you remove timing at the top of your powerband. Maybe this is some of the flattening out at 4500 that you're feeling? I'm not recommending that you just jump everything up to like 22 degrees at that load or whatever, but you should definitely review some other people's tunes and whatnot and consider tinkering with this a bit

- I don't recommend running a tiny gap. I thought I was having ignition issues on the dyno, de-gapped a new set of BKR7E plugs to 0.020, and then fouled them out after only a couple of pulls, losing power after every pull. I don't think a single coil setup can reliably run this small of a gap. I slapped another set in at 0.028, got all of the power back, and then did several more pulls without issue.

- Definitely fix the alternator issue or look into something shorted out and drawing too much power. I really recommend swapping to a 1 wire GM alternator. They are way cheaper than Datsun alternators, super reliable, and you can get them at almost any parts store. The swap took my less than an hour after my ZXT alternator failed. Highly recommend. No reason for you battV to be moving the way it is and I'm sure it's making megasquirt pretty angry. Test out your voltage in a few spots on your wiring harness. It might be that you just need to put the megasquirt on a relay more directly tied to the battery if you’re getting 14v elsewhere. According to the megamanual, your megasquirt should be powered off of a relay powered directly from batt positive itself and not from any other source.

- Try a higher averaging lag setting on your RPM input, it might help it smooth out RPM input a bit. It's really shaky in your current setup. I've been messing with this on my tune too

- Move your MAP signal, it looks a bit dirty. You may want to try moving it somewhere on the manifold where a single cylinder's pulses can't affect it so much

hope you find this helpful

wrenching on a megasquirt system can be both frustrating and reeally rewarding once the stars align and it finally works properly!

wrenching on a megasquirt system can be both frustrating and reeally rewarding once the stars align and it finally works properly!

edit: also wanted to note that you should separate your BOV and MBC lines. Generally people put their BOV on a dedicated vacuum line from the intake manifold, and then run the MBC/wastegate off of the charge piping or off the compressor itself if it has a nippleanother note I just thought of: how are your grounds? In my experience, megasquirt gets angry with poor grounding. All of megasquirt’s grounds should be run back to the intake manifold and grounded together, separate from all of the car’s other grounds.

-

It's hard to guess what kind of power an engine might make because there are a lot of variables in play, but you should be able to get a relatively close estimation by using your phone with a "dyno" app like pocketdyno, dynolicious, probably some others, if you can put in accurate weights, c/d, frontal area, gearing, tire size, etc. I'd recommend several pulls and average them together. Otherwise a couple of dyno pulls are usually only in the $50-100.

That said if you are taking guesses before you start to get actual numbers, my shooting from the hip guess is 155whp, having looked at other L series dynos in the past...

-

2 hours ago, KF_Colt said:

Yeah I have MS2 and Ford EDIS working.

Was it running fine before upgrading the injector size? If so, after installing the new injectors, did you update the injector size in your general options in tunerstudio? You will likely need to do a bit of tweaking on the VE table as well in my experience

-

I use a Schneider cam in my 240Z and I heard that they suffer from soft core issues. Because of this, I had my cam nitrided before installing it, and I also use high zinc motor oils, mainly rotella-T. I've got about 5k on my build and currently no signs of cam wear

-

FWIW I have run 550CC RC engineering injectors on a stock ZXT rail without issue, controlling them with a MegaSquirt II unit. Definitely echo what cgsheen is saying about needing an aftermarket ECU. With stock ECU, you need to stay very close to stock-specced injectors and fuel pressure or you are going to have a difficult time

-

On 9/3/2019 at 11:33 AM, Gollum said:

Feel free to send some logs my way to look at. I don't profess to be any smarter than other tuners, but sometimes someone will catch what others miss.

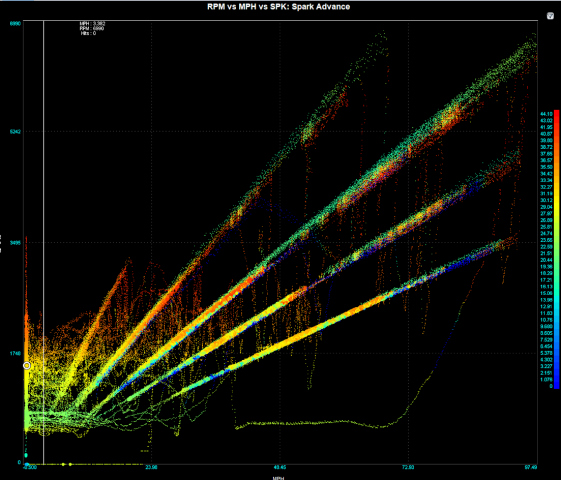

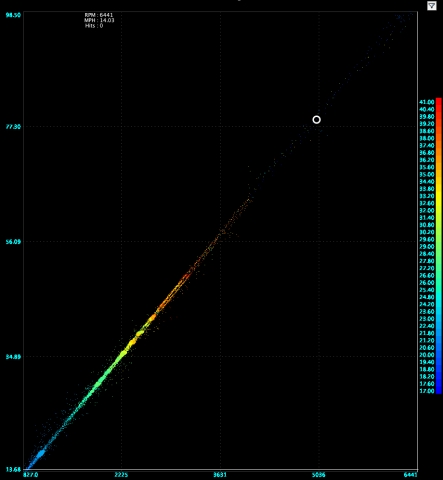

Do you have any VSS or MPH logging? If so, then take a long spirited drive making sure to row through the RPM range in several gears. Then pull up the log in MLV and make a scatter plot of MPH on the X axis and RPM on the Y axis. I use spark advanced as my color axis, but doesn't really matter. Here's what my super sloppy dizzy wheel looked like:

Notice the huge vertical distance traversed in RPM for a given MPH. What's more surprising, is when I select one of those entities, and then move forward and back through the adjacent log entries, it might be going from top to bottom of the spread during a WOT pull. That's a HUGE deviation and the motor itself is utterly incapable of undulating that much when in gear on the road. The only place that can come from is variances in the readings from the trigger wheel.

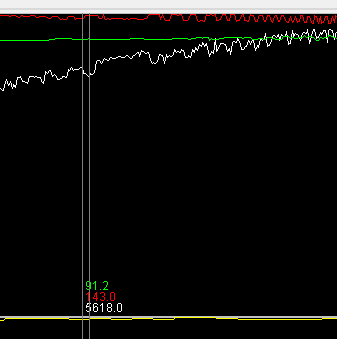

Here's another way to look at the same "noise". Look at my RPM reading during a WOT pull:

SOME variations are expected, and I thought maybe I just needed to turn the lag up on the sensor reading. Then I found some tune files and logs belonging to a LS2, which has a factory crank mounted sensor. The WOT pull was smooth as glass, and lag was turned way down to 10 in his tune.... That RPM signal noise isn't power variance from bad fueling or loss off trigger signal. It's simply slop in the trigger drive leading to bad commanded timing, which just ends up fighting the input to the problem. No amount of having stronger ignition will fix that what the ECU "thinks" is the correct commanded timing might be wrong. Way wrong.

If you dig around you'll find that some people work really hard to remove slop from the system, and they likely fair a lot better than I did. But I say, sensors are cheaper than ever. Just get something crank or flywheel based and call it done.

Thanks for the help!

I took your advice and dropped a recent log file and MSQ in to MLV, which I also attached to this post, and was able to generate the following scatter:

I have MPH calculated for 3rd gear only and no actual VSS input which is why I only get a single line here. Otherwise this is looking to me to have a large scatter, like in the graph you posted. I am guessing this should look more like a solid line? So this would point to slop? I am guessing this is somewhat mechanically tied to the rotation of the distributor, so maybe switching to the diyautotune trigger wheel won't help a whole lot and I should be looking at other triggering approaches.

I guess it's also worth noting that my RPM's jump around in a similar way to the other pic that you posted as well:

edit: also, I did a fair amount of reading this evening and I wanted to note that I think you may be backwards on the lag settings: 100 is no smoothing, 0 is lots of smoothing. The MSQ I posted has a lag setting of 80. I looked around at some other L28ET MSQ files and I'm going to try out 50, which should add a fair amount of smoothing, and will see if that makes a noticeable difference with my setup. I'll also take another datalog and see if the RPMs are smoothed at all

-

2 hours ago, Tony D said:

You're fine on that setup. The lines in the same direction on the turbo are actually correct, depending on what state the engine is...

What size is your turbo cooling line? 10mm? or larger?

I'd eliminate the external bypass straightaway, ESPECIALLY if you have larger than 10mm hoses through the turbo. If you are running 15mm hoses, I'd plug the internal bypass on the block (you can JB Weld in the entry hole in the front cover if you remove the water pump.) There is plenty of recirculation through the turbo to prevent cavitation and aid in warm-up with the turbo cooling line.

As to my first statement "depending on engine state"- what you have is flow from the lower thermostat housing when the engine is running and thermostat is closed (this is why blocking the bypasses can be done--the turbo is now your bypass line.) Once the thermostat is opened, there is still more pressure at the lower housing of the thermostat than at the lower radiator hose, so you will get flow through the turbo.

Once the engine is shut off though, what happens (and this is CRITICAL TO TURBO ANTI-COKING) is that the cooler water at the lower radiator hose is thermally siphoned through the turbo as it is heated and rises to the thermostat housing. This will continue as long as the center section adds heat to the water and the thermostat is open. This is why having a 2mm weep hole in the thermostat disc is important---if the engine cools and thermostat closed rapidly...the turbocharger has the potential to boil the coolant, and that weep hole would allow steam bubbles out...or if not turning to steam still allow the hot water rising off the thermal-siphon effect to rise up through the turbo and out to the radiator.

As you have stated, the plug at the rear of the head is fine as it represents the same flow present when the heater core is shut off. Now, if you like, you COULD take that 15mm fitting and run a 1/2" hardline around the back of the engine to the lower thermostat housing directly. This will let water flow off the back of the head which is quite stagnant, and leads to detonation on L28ET's. There is of course the cooling mods you can do...but in a pinch, running that line aroudn to the thermostat housing to get some flow back there helps quite a bit in keeping temperature on the 5/6 cylinders in-line with what they should be...Thanks for the critique Tony! I really appreciate the detailed response and the suggestions

Currently, the hoses to the turbo are 15mm hoses so I will look in to blocking off the internal bypass on the block. Are there any symptoms that I should expect to be seeing at the moment since I have the internal bypass open still, or is this merely a precaution?

I'd not heard previously that re-circulating the rear coolant port into the lower part of the thermostat housing could help with rear cylinder heating issues. I was actually already looking in to having the costly head cooling mods done as I am noticing that cylinders 5 and 6 are definitely slightly leaner looking when I pull the plugs, which I suspect is due to hotter combustion chamber temps. I am going to try re-recirculating the rear coolant port to the lower part of the thermostat housing before removing the head and going through additional headache having it drilled out, etc, and see if this helps.

-

On 8/18/2019 at 10:08 AM, Gollum said:

Equally important of a mod would be to ditch the 280ZX Dizzy for "crank" signal. Put a sensor on the crank. You might find yourself able to run more timing as well as the dyno showing smoother power delivery. You're on a smoothing factory of 5 on a dynojet, and it's still showing lots of roughness. Imagine what it looks like with zero smoothing... I'd be willing to bet a huge part of that is trigger slop/scatter. Get that solved and suddenly the engine state will be smoother which helps ALL tuning aspects.

Thanks for the info! I didn't know that the dizzy's pickup could be robbing much power if any. I am using a bone stock 280ZXT dizzy with Magnecor wires and MSD StreetFire ignition. I am definitely struggling still with power dips, as was seen on my dyno graph. Originally we thought that the tune was just a bit rich in those spots but that does not appear to be the case any more although I am getting the same dips in power on a re-dyno (no new graph to share, sorry, didn't make much more power although power is up a bit from smoothing out the AFRs and leaning things out a tiny bit). I was beginning to suspect that the MSD StreetFire was not able to produce a strong enough spark, but I'm glad to hear an opinion that the dizzy's lack of resolution itself may be at fault. Are there any simple tests I can do to rule out lack of resolution as an issue?

I get that you're saying I should do a crank-mounted trigger, but as a stopgap, I've ordered the DIYAutotune 280ZX/300ZX optical trigger disc and will be installing it in the next week or two and re-timing the car to see if that helps with the power dips. DIYAutotune claims these are good for full sequential fuel and spark so this should be a worthwhile upgrade in terms of resolution. Additionally, I have a friend willing to let me borrow an MSD 6A box to replace my StreetFire unit to see if a stronger spark will help, but I think I am going to hold off on trying that until I see what the better optical trigger does for me.

edit: Just want to note that looking at the datalogs with a few other people, I've been unable to determine any reasons why there are dips in power - the only things that ever show up on graphs are the dips in hp/tq themselves- AFRs are holding steady, spark advance steady, boost/MAP signal steady, MAT steady, etc so it really does seem like something mechanical or spark-related at this point.

-

28 minutes ago, madkaw said:

No experience with turbo builds , but from lots of reading here it seems that the very first things the guys do is the down pipe increase. You have invested a lot of money in forged pistons and other goodies , but you are choking all your investments with a tiny exhaust.

Timing might also be a victim of your small exhaust. Don’t want to build heat by bottle necking flow. What was your timing at?What was your AFR’s?

Yeah certainly the downpipe was too small and using the off the shelf MSA unit was a mistake. Definitely building a new 3.5" one is on the list and I am fairly certain it will yield a large power increase.

According to logging on this dyno run, timing ranged from 18-20 degrees of timing under boost (it has a bit more advance higher up in the RPM's.) Bigger downpipe could definitely allow for a bit more here as adding another degree produced no more power at this boost level. I think I was likely also being held back to some extent by high MAT temps, which were reaching mid 130F ranges with approx 90F ambient. AFRs were mostly holding steady at low 11's but were in to the mid 10's where the dips in power occurred.

Also want to say that the car is really a blast to drive. Very usable power here, accelerates nicely and pulls hard in every gear. I'm not disappointed by "only" making 258whp but will definitely be back at the dyno looking for more. Mostly I am really happy to have the car working properly and producing good reliable power at this point

-

I've been lurking this thread for a few years and I finally have a dyno sheet to share!

1- car: 1973 240Z

2- State of the engine: L28ET, P90A head converted to solid lifter, 8:1 +1mm JE forged pistons, Schneider/MSA Stage III turbo cam

3- 258WHP @ 5760RPM, 16PSI

4- 262WFTLBS @ 4940RPM, 16PSI

5- short list of relevant mods if applicable: LoneWolf intake manifold, 240SX throttle body, .63/.63a/r 60 trim T3/TO4E w/ stage III turbine wheel, MS2 3.57 running MSNSE, RC Engineering 550CC injectors, Bosch 044 fuel pump, Aeromotive FPR, MSD StreetFire Ignition, Factory '83 280ZXT dizzy, crappy 2.25" downpipe to 3" exhaust, crappy same-sided intercooler getting doused in watermeth

6- anything else you feel might HELP OR HINDER your hp figures: The downpipe is way too small - pretty sure this robbing 30-40hp, needs a much larger intercooler, needs a heavier wastegate spring for more boost. Potentially could use a cooling mod on the head to run more timing. I will do some of these things over the winter and re-dyno next spring. edit: revisiting some of the data logs from these pulls, the dips in power at 4k and 5k are due to the tune going a bit rich in those spots. Those were also noticeable while driving. Obviously haven't been able to re-dyno yet and won't for a while, but I've fixed these on the butt dyno already.

-

9 minutes ago, ZHoob2004 said:

As-is I believe you're taking warmer coolant from the thermostat and looping it back into your water pump, but I don't know where else you could get coolant flow from.

That actually might explain why my coolant temp tends to climb slowly following load, then relatively quickly drop back to thermostat temp after returning to cruise.

Definitely interested in more opinions here if anyone has any

-

1 minute ago, jonbill said:

Why does the line from the pump inlet to the turbo have water flowing in both directions?

Well I guess I should have scribbled that out, really a lot of that is from the original drawing in the cooling diagrams thread. I don't know the actual direction of flow there so that is likely wrong in the drawing (or right meaning my hose routing is nonsense?)

Steering wheel contact ring part replacement?

in Interior

Posted

Hi everyone

I'm putting a standard 240Z steering wheel that I just restored back in my car but I am missing some of the parts. I was able to buy a new horn pad and horn pad assembly, but I can't find a replacement contact ring for the back of the steering wheel, which should be part 16, which is 48495-E4100 COMP-RING CONTACT, in this picture:

Does anyone know of an alternative that will fit? I also think I am missing 5 and 6, but I can't see what those would be used for and I don't appear to have any fitment issues without those.