odarp240z

-

Posts

13 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by odarp240z

-

-

Assuming you got the correct 10 x 1mm threaded nut on that hard line, and not the very very close (and slightly smaller OD) 3/8-24 SAE nut, then it having some play until it's tight is normal.

The threads have nothing to do with the seal, its the female cone at the end of the line, that mates metal to metal with the male matching cone in the caliper that creates the seal. The nut just provides the push to press them together.

Double check those thread dimensions though, proper 10x1 really has no play in the nut as you thread it in.

z240, thanks for explaining this. I did get the 3/8-24 nut fitting thats why it had play but i should be good since I can tighten it pretty good.

-

Hello everyone, I just want to know everyone's thoughts on this hard brake line that I got off of a local parts store. I recently replaced my brake line hoses to stainless steel braided brake line hoses front and rear. During the process of removing the rear driver side brake line hose I destroyed the nut fitting on the hard line. I purchased a 3/16 size hard line about 40 inches long. When I thread the nut on either the ss braided hose or pressure regulating valve, there is play until it is tight.

I'm curious if this is okay and will it leak. The hard line is copper and it is easy to bend. It's made my NiCopp brake lines.

Thanks in advance

Ernie

-

They just slide on. No need to press or hammer. You'll need to align them as shown on our website while you tack them in place. Then double check their alignment before you weld.

Oh ok thanks you just a little worried but since you guys are using the stance as well it should work fine then. I have it bolted up with your camber plates that I bought. Great product.

-

I didnt get a chance to take a pic but the video you had helped. Thank you

-

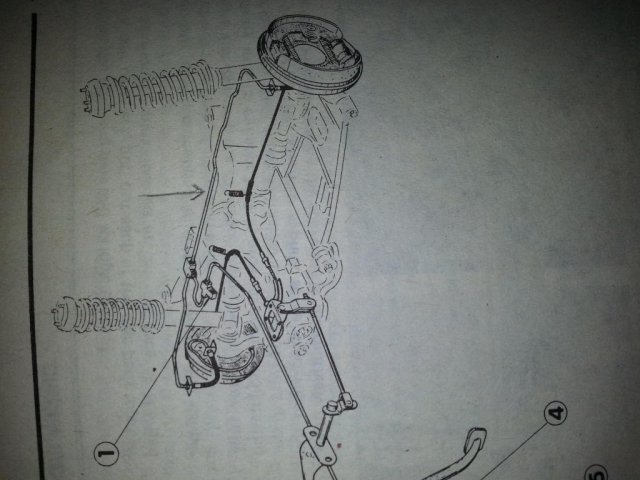

Hey everyone, I just want some opinions on the stance usa weld on adapter tubes that I'm installing on my 240z (02/71). I've cut the strut tube and clean it with a wire brush. I grinded a little bit of a notch on the tube to go over the hump in the spindle forging but, when I put the tubes over the strut tube it just slides right in. I've read some post that I need to press or hammer it in. I am curious if this is ok. Tubes have a 2" ID.

Thanks everyone

-

Sorry, we're not currently selling the camber plates seperately. I'll PM you about weld-on adapters.

Really, man I wanted those for my stance..what is the price on two rear weld-on adapters?

-

im interested in camber plates and possibly two weld-on adapters if that is possible.

-

Pretty much as you suspect, the electric pump will not be a benefit over a mechanical pump. Actually, a mechanical pump will be far better at pulling a vacuum than an electric pump. The only variable is so long as fuel still covers the pick up tube. And for that to really be a factor you need to be really low on fuel and on a really steep grade.

If the OP just wants to put an electric pump on to put an electric pump on, that's a perfectly valid reason. That's basically what I was doing, just did it 'cause I wanted to. But I have no illusion I'm solving some problem that wasn't there.

Oh, and for vapor lock (heat) to be a factor, the mechanical pump is relatively far away from a heat source. The engine would be having other heat issues before you would get a fuel pump related issue.

Thanks for the explanation. Just thought that electric has an advantage over mechanical but as you mentioned it doesn't make difference. Ill keep my mechanical pump for now and maybe in the future switch to electric.

-

Maybe I can learn something here - why would a mechanical pump stop pumping while "driving up the mountain" and why would an electric pump be different? Is the pump failing due to altitude or overheating or "vapor lock"? Just curious, what's your reasoning?

My bad on the previous post and what I was trying to say is, is there a chance that fuel wont reach the engine while going up the hill if I have a mechanical pump.

-

I respect differing opinions but I went with an electric pump too. A little hard to make out but here's a pic of my set up.

What kind of electrical fuel pump and fuel pressure regulator are you running?

-

I have some experience on this issue. I would maintain your mechanical, if it were me. Very little to gain by going electric, except additional opportunity to get stranded. I understand, though, if you have a space problem, or something like that. The electric fuel pump has to have a return line somewhere in the system to allow fuel flow to continue all the time to avoid overheating and seizing of the pump. Initially, the seizing will be reversible once the pump cools off, so just waiting for the pump to cool will get you back on the road, if only to get stranded a few miles further down the road - this can be pretty frustrating. If your fuel system is "dead-headed" (that means no return line) you will have pump overheating and reliability trouble. That doesn't happen with a mechanical pump for some reason. If you need to go electric, look for a fuel pressure regulator with a "bypass" port - I think mine was from Holley. That "bypass" port meters the amount of return that is allowed so you don't have to worry about return line diameter going back to the tank. You do hook a return line to the bypass port - I just used the stock metal return line that Datsun put in my car when they made it. That solved my electric fuel pump overheating problem.

More than you asked for (and you may already know this stuff), but a few other issues I encountered along the way: Clear glass in-line filters are nice because you can see any crap in your fuel filtration, but they leak and shatter, so use them or avoid them with that knowledge. I use them if I have a dirty tank - once my tank is clean, I avoid them. Put them before the pump so they are subjected to low pressures. The cheap Mr. Gasket-style adjustable fuel pressure regulators (I think that is what the previous poster has on this inner fender) fail catastrophically and blow fuel mist everywhere when they do (I've had this happen). Ran one for years without any trouble, then all of a sudden, I had fuel EVERYWHERE-soaked entire engine compartment. I don't know how I didn't have a fire. Never thought that 3 psi could cause such a mess, but it did. My Holley bypass regulator was from Jegs or Summitt and was either $29 or $79, I can't remember - local parts house did not have one. Do yourself a favor and put a gauge on your fuel system near the carb - very helpful for trouble shooting later. Good luck.

Keith

I just looked at your pictures better-my previous discussion was somewhat theoretical. From your pictures you can simplify a lot. Keep your mechanical pump-you can dead-head it without a return line and it won't hurt it. You can dead-head to a 4 barrel, so you don't need a return line there either. All that return line stuff is related to the old Datsun dual carb setup that you don't have anymore. You should be able to just have the one filter before the pump. Then, run a line from your pump to your carburetor (run whatever line fits the fittings). Take the second filter off and throw it away along with the associated return line, cap the stock metal return line with a vacuum cap from the part store just to keep dirt out of it. Fire it up and look for leaks. You can do all that simplification in under an hour. If you insist on an electric pump, all that return line and regulator stuff above applies.

Thanks for the info Keith it was very helpful. The reason I want to get rid of the mechanical pump is I live in the valley and I'm moving to Los Angeles. I'm about 2 hours away and from where I live I have to go through the mountains to get to LA. My concern about the mechanical pump is when I'm driving up the mountain the fuel cuts off leaving me stranded. I want to be able to go back and forth from time to time to visit my families.

I did look for fuel pressure regulator with a bypass or return line and found a couple of them. I found some regulator with in/out inlet and bypass but has no fuel pressure mounting gauge. I found some with the same exact application and has a fuel pressure mounting gauge but has vacuum/boost port. Thought it would be easier to just buy one that has a mounting gauge so I don't have to buy the extra part for the gauge. Any recommendation to what I should use?

ernie

-

hello everyone,

I'm thinking about swapping out my mechanical fuel pump to an electric pump but I don't really know what to do. I have a Clifford 6=8 with a 4 barrel carburetor and the set up is weird. There is two fuel line coming from the tank, one of them is a bigger size fuel line(main line) and the other is a smaller size fuel line. There are two fuel filter before and after the mechanical fuel pump. The bigger size fuel line goes to the mechanical fuel pump and the smaller size fuel line directly connects to the second fuel filter after the mechanical pump. Then connects to the carburetor. I've attached a picture to show how it looks.

If I did change my set up to an electrical fuel pump, do I put a fuel pressure regulator close to where the mechanical pump was. Also, what do I with the smaller size fuel line coming from the tank. I appreciate any help I can get.

Thanks everyone

-

No offense my friend but your information is so vague you might as well ask how to get from here to there. Basically what you've said is you have a car that doesn't run.

Can you see any burned wires?

NewZed is definitely on the right track. If you look in pretty much any of your local papers or magazines, Harbor Freight is giving away digital multimeters with any purchase (coupon). I have three or four of them myself. That is your primary tool in troubleshooting any electrical problem. Get one and learn the basics of how to use it. People here will be happy to help you but you have to be able to give us a starting point.

No worries I'm new to this so I'm learning as I go. Thanks for looking out and I'm going to check out Harbor Freight.

-

I recently got a 71 240z from my uncle but it hasn't ran in a couple months. He said that it might be some wiring under the dash because he seen smoke coming out. I tried turning the car on but i noticed that no lights or any ticking sound comes on at all. The only thing that works is the hazard light. The engine does turn over if I have a wire from the starter to the battery. If anyone can help me please do and I appreciate all the help I can get. thank you

Thoughts on this hard line tubing and nut fitting..

in S30 Series - 240z, 260z, 280z

Posted

Yea it is..and I decide to return it and look for a different size nut fittings.. thank you