Leaderboard

Popular Content

Showing content with the highest reputation since 06/26/24 in all areas

-

I just complete the install of the MFactory LSD in my 1978 280z and wanted to share my experience. First, I am a reasonably good shade tree DIYer and I found the installation to be very easy. I did have to purchase a dial indicator on amazon ($60) to check the lash on the ring and pinion as part of the installation but everything else I needed was standard stuff in my toolkit. I also replace the carrier bearing with ones I found on RockAuto ... TIMKEN 30209C (Standard Replacement) for about $95. I don't know if I was lucky, but the ring and pinion lash was well within the specifications using the original factory shims so no changes were needed there. I also found the ring and pinion gears were in excellent condition overall with good mesh pattern. The most time consuming part of the install was getting the differential out. My car's driveline is largely stock with the exception of the 280zx turbo half shafts using with Milkfab adaptors. So far everything appears to be tight and right. Why did I bother to do this? I bought the car online about 4years ago. Of course I did the right thing and purchased it sight unseen (based on description and pics) and found I had a leaky head gasket shortly thereafter. The car had sat for a few years prior to my purchase so I was not completely surprised it needed work. Luckily the coolant only leaked into #1 piston and I caught it very early. As I sorted it out I discovered the engine was a Rebello stroker (3.1) -- lucky me. Once I got things straightened out I found a drive line clunk and so I was off trying to fix the problem. I tried to work through the lower cost items first so I replaced the diff mount, secured a technoversions diff mount snubber, upgraded to zx turbo half shafts (rebuilt junk yard finds) as well as new 1310 ujoints for the prop shaft. Still no joy as the clunking continued. That meant I needed to check the differential center section. What I found was a lot of slop in the center section but the ring and pinion in great shape. I guess I could have gone the route of a rebuild of the open diff but, truth told, I wanted the LSD option and chose the MFactory option. So far, so good. I would also add that the purchase experience was very easy with the unit arriving within a few days after payment and exlifesaver provided advice on the install. Thanks again.2 points

-

Just to add some closure to this posting, I'm feeling pretty good about having just sold to a Datsun enthusiast who is taking on the restoration of this 240 to add to his 510 and 610 selection, and lives within 50 miles so I can keep up to date how it's going. Thanks again NewZed for your suggestion2 points

-

So far so good! I have 80 miles on the rebuild, and nothing too concerning yet other than a bit of valvetrain noise I'm hoping is resolved by a hot adjustment when I hit 100 miles. Currently the car is at the tint/PPF shop, so I'll get some "complete" pictures in the next week or two after I pick it up. It's been fun getting back into MS tuning after so long, and I'm finding a LOT of areas I needed to improve. So far I've: Upgraded from MS2/E 3.3.2 to 3.4.4. Swapped from don't include to include AFR (used a spreadsheet to convert VE). Swapped from the old to new baro mode (had to retune most of my VE). Dialed back and smoothed my timing, primarily in the idle and cruise areas. Increased my tps, rpm, and CLT/MAT lag factors. I must have had the scale backward in my head originally, as they were in the 90's and barely filtering. Leaned out my idle and cruise areas significantly. Started dialing in my MAT correction, based on Gollum's findings. With all of these changes the car is running better than ever. I've always had issues with low rpm and cruise throttle transition jerkiness, no matter what I did with AE. I suspect I was way to aggressive with my timing, and had some drastic transitions causing the behavior.2 points

-

Last bit of body work was the hatch slam. I did not replace it entirely. After getting a Tabco replacement and then a classic fab replacement, I decided mine was not bad enough to justify changing the entire part out and reducing the originality as the replacement parts are not a 100% The original paint Drilling out the tack welds After drilling out the spot welds and cutting part of it away, I blasted the undelay of framing. There was some corrosion deepen than I liked so I cut it out and patched it. Then ground it back and sprayed it with a weld through primer Next I removed the rest of the panel, blasted it and replaced the little bit of rusted metal. Tig welded it and ground it flat along with some dolly work to make it flat after welding I then tig welded the old spot weld location and ground them flat so it looked like a new panel again. All the underserface of the rebuilt hatch slam got coated in weldthrough primer. I then applied a weld through seam sealer. I used the old pc of metal to mark the exact location of the original tack welds Final to tack weld it in. Looks great and factory original in my opinion2 points

-

Ooof 40 and 80 are really bad. Bad results wet would point to broken/pinched ring, but if your really lucky a sooted up ring. I used something called b12 chemtool in my cylinders when I got the motor. It had been sitting outside at the previous owner's place and got some water in the intake. To my surprise it cleaned up perfectly and had 135-140 compression on all cylinders. Valve sticking would be very obvious to spot with the valve cover off, you would see a valve noticeably lower than the rest, unlikely to be the issue though.1 point

-

Hi guys, I will be working on installing microsquirt v3 in my California edition '76 280z stock car which came with EGR/catalytic converter and an exhaust manifold. The car runs fine with the exception of typical lean conditions which gets resolved with a potentiometer pot. The plan is to do it in 2 stages: Stage 1 (getting "my feet wet" with learning to tune the car with TS): Milkfab's 36-1 wheel (crank pulley mounted) Microsquirt v3 + IAC stepper adapter LM7 truck ignition coils Pro Tunerz fuel rail (14mm) intake/throttle body/GM ICV 14point7 spartan 3 v2 wb keeping stock exhaust + LSU 4.9 high impedance injectors Stage 2 Headers + Turbo upgrade In my infinite wisdom I figured I would kill both birds, aka project stages, with one stone - and purchased the Bosch 440cc 'green giants' injectors EV1 (part 0280155968), length 65 mm, Long style. Flow: 43,5 PSI (3 bar) 430cc / min = 41 lb / h. My assumption was to use them on a stock engine, get a turbo installed later, and re-use them. I got a great deal on them and they are authentic Bosch. After reading the mega manual, now I am concerned about the idle pulse width issues and fighting over enrichment conditions running a stock L6 engine. I spent a lot of time going through this forum looking for anyone running similar injectors on an n/a engine and found that in almost all cases guys are running turbo engines with large injectors (supra injectors are popular). The stock engine needs 15 lbs/hr or 158cc injectors. Obviously the 440cc ones I got are a major overkill. Am I over stressing over the issue? Will i be able to tune these injectors for the time being? Or I should keep on looking for 190-200cc injectors on Stan Weiss's site at http://users.erols.com/srweiss/tableifc.htm ? I found a few leads by cross referencing the part numbers and what rockauto has in stock. A lot of GB reman and BWD ones. Do you have any recommendations? I'd like to keep 14mm/14mm top/base long, high impedance injectors, preferably Bosch. Thanks! Den1 point

-

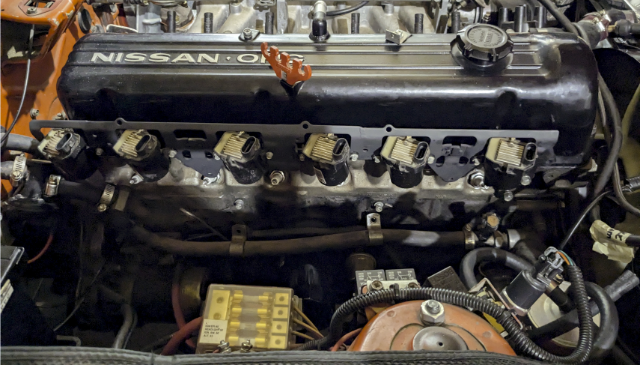

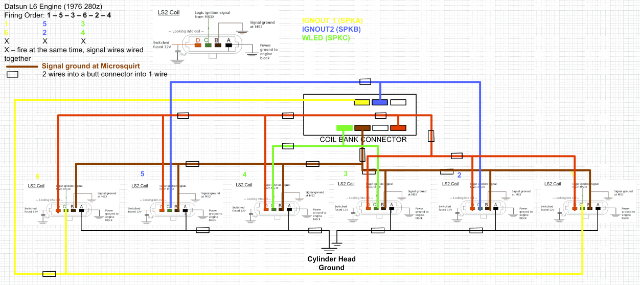

Thanks, madkaw. I might be able to squeeze by with these injectors. I will test them. If they run too rich, I will start looking for a set of cheap smaller injectors. I need to start documenting the progress otherwise I just procrastinate. Last week-end I made the coil bracket out of 2 chevy truck ones (came off LM7 truck), they overlapped nicely to get an idea where to cut/weld together. Fit mock-up, I might need to move it to the right side to align spark plugs better: The coils will be grounded to the bracket to the welded bolt behind, the bracket is bolted on the right side to the cylinder head (black wire, ground to engine block). The coil bank connector will be attached to the same location as where Chevy put it originally (left side, there is a clip between coil 5 and 4). The 1st cylinder's spark plug is too close to the coil, will have to lift the bracket up by 1-1.5 inches to make the spark plug wire fit. I ordered a set of spark plug wires to play around with: And a simple visio wiring diagram for the coil plugs:1 point

-

1 point

-

Not an expert but it seems like you'll need to remove the head to find the cause. The "wet" test might not fix broken rings. As for head gasket, you could use the chemical test to check for combustion gases in the coolant if you wanted to be more sure. Turbo engines are susceptible to detonation when they're pushed. Detonation can cause drastic damage. Worrying about oil type now seems pointless. Good luck. https://www.oreillyauto.com/detail/c/evertough/rental-tools-evertough-combustion-leak-tester/ren1/670941 point

-

interesting. most of my research suggests coolant getting in there. how can i relate the %80 loss in compression to what ever is causing a lean operation? are you suggesting a sticky valve is allowing some leakage? im lost here1 point

-

It doesn’t like my images hopefully this google image link works https://photos.app.goo.gl/GfKMSguQd2BaYS4H7 the order is different then I mentioned but should be obvious1 point

-

update for anyone in the future who may have the same problem. The wheel cylinder was put in the wrong way by the previous owner. I attempted to reassemble the brakes how it came apart, but the way it was installed before was wrong. Putting in a new wheel cylinder in the correct orientation solved the problem.1 point

-

Getting much closer to a maiden voyage. Suspension in and bolted up. Driveshaft shortened and half shafts refreshed. Here are pics of the rear fender wells and front firewall extensions from today. New problem. I was checking the clutch action and realized it does not engage. Which I think means the clutch/bearing has extended into the clutch and did not retract. Its a Tilton internal circular slave. I could have over extended it. More to investigate. Oh and cutting up a cool 280 turbo for some ZG flares and 18x9 wheels.1 point

-

classiczcars.com is where the restorers hang out. I'd try there, you'll get more response. Hybridz is more about performance mods. https://www.classiczcars.com/gsc.tab=01 point

-

1 point

-

Super clean bends! I love the organization. Are you planning on putting some insulation on the AC lines?1 point

-

Amazing work! I definitely don't have the time and patience for this, at least not now, but maybe give it a decade or two when the kids are older and hopefully work is not so consuming. Reminds me of the absolutely entrancing my mechanics 240Z resto videos on YT. I salute the people who have taken the time to get this good at metalwork.1 point

-

Don't tell my wife Like I tell other people. some like to fish, some like to bowl, I like to make.1 point

-

I get this quesiton daily. Assuming you've spent money and time building adjustability into your suspension AND are willing actually adjust then these recommendations make sense. Otherwise, take the car to Pep Boys, tell the tech to "Make it all green", and hope your tires last a long time. Track/Autocross For 225 to 245 width radial DOT tires try these alignment settings: Front Camber: 3 to 3.25 neg Caster: 6 to 7 positive (even on both sides) Toe: 1/8" to 3/16" out Ride height: 5 1/2" to 6" measured at the front of the rocker outboard of the pinch weld seam. Rear Camber: 2.5 to 3 neg Toe: 1/16" to 1/8" in Ride height: 5 3/4" to 6 1/4" measured at the front of the rocker outboard of the pinch weld seam. For tire widths over 245 try these alignment settings: Front Camber: 2.75 to 3 neg Caster: 6 to 7 positive (even on both sides) Toe: 1/16" to 1/8"" out Ride height: 6" to 6 1/2" measured at the front of the rocker outboard of the pinch weld seam. Rear Camber: 2.25 to 2.5 neg Toe: 1/16" to 1/8" in Ride height: 6 1/4" to 6 3/4" measured at the front of the rocker outboard of the pinch weld seam. Street For 225 to 245 width radial DOT tires try these alignment settings: Front Camber: 1.25 to 1.5 neg Caster: 4 to 5 positive (even on both sides) Toe: 1/16" out or 0 Ride height: 6" to 6 1/2" measured at the front of the rocker outboard of the pinch weld seam. Rear Camber: 1.25 to 1.5 neg Toe: 1/16" to 1/8" in Ride height: 6 1/2" to 7" measured at the front of the rocker outboard of the pinch weld seam. For tire widths over 245 try these alignment settings: Front Camber: 1.25 to 1.5 neg Caster: 4 to 5 positive (even on both sides) Toe: 1/16" out or 0 Ride height: 6 1/2" to 7" measured at the front of the rocker outboard of the pinch weld seam. Rear Camber: 1.25 to 1.5 neg Toe: 1/16" to 1/8" in Ride height: 7" to 7 1/2" measured at the front of the rocker outboard of the pinch weld seam. Caveat Emptor: These are starting points for you and your car. Be ready and willing to change them based on your preferences and local conditions. These alignment settings might be a bit tricky in the rain and even trickier in snow or ice. Your tires will wear a bit faster then the stock alignment settings. If that's a concern of yours, stay with the stock numbers and don't ask me dumb quesiton like, "Well... how much faster will they wear?" or "How many miles will the tires last with the Track alignment setting?" If you're asking those questions you shouldn't be reading this thread. Go buy a Honda...1 point

-

O.K. here is a question I have that I could not find in the FAQ section. I purchased the Z31 5lug hubs from Modern-Motor Sports with +40 offset, using the 300ZX vented rotors, calipers are the Toyota S12W. My question is what is the thickness of the spacer that is needed to push the rotor back far enough from the hub so that it will mate up with the caliper. Tried contacting Ross at MMS but to no avail, no response.1 point