All Activity

- Past hour

-

Problem still persists. Changed fuel counts from 70-200 still does the same thing for top two fuel rows

-

I agree and sure if like to not spend money but I posted this to figure out if I need bigger injectors. Below the top two rows of my fuel table my afr reads 11 then spikes lean. Do you think that's actually lean? Or just out of range. 12 psi on the factory turbo didn't seem to be an issue at all for the factory injectors.. hell I pushed 14 on that turbo before with steady 11 afr. These are factory turbo ones not NA ones.

-

Okay so in the top two rows of my fuel table my car bucks quite hard. I've changed ve table numbers from 70-200 No matter the number my car does the same thing. Rich or lean. While graphing afraid goes down to 11 and then spikes like it goes out of range or something. 82 L28et Intercooled 15 psi on he351c bored out Wastegate hole 255 fuel pump Factory spark Ms2 ECU 240sx throttle body Factory turbo injectors turned up a few psi to like 40 or so Lc2 wideband 3 inch straight pipe I thought I would run out of injector with this turbo but I was previously told I should be ok. Ive been tuning it and I cant figure it out. Does seem rich or lean necessarily it just stops making power and reads out of range.

- Today

-

.jpg.b34f27553f5960421801c8ab2cbf5db3.thumb.jpg.7889e8073010b6a0d8d6aae0626e768b.jpg)

Warning - poor R&D and customer service + credit card dispute

G-Tech replied to idiot280's topic in Non Tech Board

Glad i didn't start a whole thing here. FWIW i also agree that a bumper delete is an excessive thing to overlook or not mention. Like i said, it's a valid point to bring to peoples attention. Happy Building in the future! -

Warning - poor R&D and customer service + credit card dispute

idiot280 replied to idiot280's topic in Non Tech Board

I don't disagree with a single thing you wrote. In this very specific case, their marketing was clear. They fit. Hood hinges are almost always direct replacements unless otherwise specified. These shouldn't be complicated or require modification. For these hinges to fit a 240Z, the grill mount must be completely removed. It would be a total grill delete. That's a significant asterisk to "bolt on." -

Thank you but I've purchased a head.

-

G-Tech started following Warning - poor R&D and customer service + credit card dispute

-

.jpg.b34f27553f5960421801c8ab2cbf5db3.thumb.jpg.7889e8073010b6a0d8d6aae0626e768b.jpg)

Warning - poor R&D and customer service + credit card dispute

G-Tech replied to idiot280's topic in Non Tech Board

Sucks to hear you had such an issue. I have had problems similar with other companies also. It's super frustrating. I know i have purchased a handful of things from Apex Engineered. Some were fine but the rear subframe for a s130 chassis i got from them certainly had some modifying to be done. I have learned very rarely is something "Bolt-on". Even when they say it is. My Brakes from Arizona Zcar had to be modified, my Custom stub axles from whitehead performance interfered with the shock mounts and i had issues with the rear coilovers from T3. I guess my 2 cents is every company tries putting out parts that aren't 100% I would say be careful buying those hood hinges til you talk to them and see that the problem has been fixed. All these companies are small and trying to do more then they can handle. Hence mayb why their customer service sucks. It's tough out there and i hate to see post like this. There are certainly worse companies that don't deserve to be in business but i just don't feel this is one of them. I'm thankful for this company making what they do. FWIW, I have absolutely no ties to any company. I'm just an enthusiast Good luck with your build. Not trying to stir shit up (even though i feel i just did) -

I have one I might be willing to let go. Its on an engine I bought and haven't taken apart. Id need to take it apart and see what condition its in first though. Let me know if your interested.

-

Warning - poor R&D and customer service + credit card dispute

idiot280 replied to idiot280's topic in Non Tech Board

Yeah. You're right. Not helpful to be nonspecific. I don't need a fake account to tell the truth though. Post has been edited. -

Warning - poor R&D and customer service + credit card dispute

NewZed replied to idiot280's topic in Non Tech Board

RTPD = Read the post disappointed You should have created a fake name that at least leads to the mystery company. https://www.google.com/search?q=Flex+Engineered&rlz=1C1SQJL_enUS862US862&sourceid=chrome&ie=UTF-8 -

Trying to decide on metal fender flares or not. Love the look, but does anyone regret it? I'm thinking the 2 inch universal flares on front and back, then use 2” wheel spacers. 240z street car, 16x7 panasports, so I’d have to add spacers to make it look right and maybe a wheel upgrade one day. Sti Torsten LSD R180, stock halfshafts. LS swap. any advice if appreciated, I got a thick skin

-

Warning - poor R&D and customer service + credit card dispute

A to Z replied to idiot280's topic in Non Tech Board

"it's the Russians" -

TLDR; Vendor sold a "bolt-on" part that didn't fit. They ghosted me after I asked about it. I filed a credit card dispute and won. Be careful this holiday season. --- Just a heads up for anyone considering buying from "Flex Engineered" during their Black Friday sales. No, that is not their real name, but you can figure it out easily (fabricators of suspension parts and other things). I don't wish to even give them the SEO. I recently had a pretty frustrating experience with them that I feel the need to share. I was going to keep this to myself, but as they are advertising Black Friday savings - I hope to save at least one person from their hassle. I bought a set of “bolt-on” hood hinges from them, advertised as compatible with the Datsun 240Z. However, when I tried to install them, it was clear they hadn’t properly tested these for the 240Z. The hinges wouldn’t fit because they interfered with the grill mount, which is placed differently on the 240Z than on the 280Z. After some research, it became obvious that "Flex" didn’t take this difference into account. Basically, they used me as a test mule for a product that wasn’t fully developed or properly tested. The worst part was how they handled it. After I contacted them with photos showing the issue, they initially responded but then went silent for weeks. They even quietly started changing the product page and removing photos to cover up the problem instead of addressing it directly. It wasn’t until I filed a dispute with my credit card company that they sent a return label - no explanation, no apology, just a blank email with the label. If you’re thinking about purchasing from them, especially during their sale, I’d recommend being cautious. Your purchase might go off without a hitch. But my experience showed they might release products before they’re properly tested, and they don’t handle customer issues very professionally. There are other vendors who prioritize quality and honesty with the Datsun community - "Flex Engineered" just doesn’t seem to be one of them. --- Edit: Apex Engineered

- Yesterday

-

Draw Through Turbo project for my 2.9 Stroker L series

A to Z replied to A to Z's topic in Turbo / Supercharger

-

Draw Through Turbo project for my 2.9 Stroker L series

A to Z replied to A to Z's topic in Turbo / Supercharger

Thanks mate. -

Dual L6 knock sensors using the stock block m6 hot water pipe mounts. They are actually about perfectly placed! These are just ti prototype. I am designing my own and will be adding them to the things I make and sell.

-

Congratulations you have finally gotten a "I must have that" out of me. Great job.

-

Draw Through Turbo project for my 2.9 Stroker L series

Enzo250gto replied to A to Z's topic in Turbo / Supercharger

Hello from Australia, back in the early 80's I was a distributor for Normalair Garret turbo kits. The crown kit is similar to what we used. SU and CD Stromberg carbs were the preferred carburettor for a drawn through system. Being a constant velocity carburettor which had a butterfly and a piston. Air velocity raised the piston which had the correct turbo needle fitted to it for correct fuel air mixture. If you stood on the accelerator and the butterfly was fully opened the air flow was restricted till the piston started to move up and allow more fuel/air to enter the turbo. To keep the compression ratio at about 7.5:1 a decompression plate was fitted between two head gaskets. Boost was limited. Carbon seals are necessary because a fuel/air mixture is being drawn into the turbo, unlike a blown through system or EFI with the fuel being injected after the turbo. We ran SU's and CD Strombergs on our street cars and usually DCOE Webers on race cars. The Mikuni HSR are a great carby. I have a pair on my 260Z. By the way. With a draw through system, don't use an intercooler. The metanol injection will keep the fuel/air cooler. We were new to turbo's in the early 80's so we used reservoirs with water and methylated with a windscreen washer pump to inject through the air cleaner into the compressor to keep the air/fuel charge cooler. It worked. Good luck with your project. Keep the compression down and keep it simple. Cheers David. - Last week

-

I’d say it’s a toss up . Most wouldn’t run the MN head because of the liners . Better NA head for sure , but it would work .

-

Draw Through Turbo project for my 2.9 Stroker L series

A to Z replied to A to Z's topic in Turbo / Supercharger

Performance Parts - Vintage Performance Developments -

Draw Through Turbo project for my 2.9 Stroker L series

A to Z replied to A to Z's topic in Turbo / Supercharger

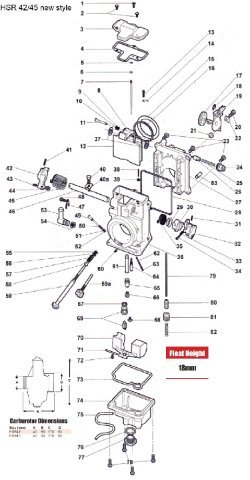

11-06-2024 Turbo project update: I have decided to not use the SU carburetor....I am switching to the Mikuni HSR 45mm carb. It's a motorcycle carb, and some of you have seen how guys use multiple ones instead of sidedraft carbs. I reached out to John at V Performance, and he is going to build and prep one for my setup. NO BUTTERFLIES! Butterflies in a draw through turbo cause a real vacuum problem, and is terribly hard on turbochargers, especially the seals. For years, guys have been adding "carbon seals" to combat this issue...this should combat the issue, and it has the benefits of having an accelerator pump, it's a true 45mm bore all teh way through and many other benefits. Here is an excerpt from a Corvair Forum from guys using it on their draw through Turbo Corvairs: Mikuni HSR carbs were last used in O.E. applications on Harley motorcycles and also Yamaha's. kmart356 over at Corvair Center has been a pioneer in using this carburetor, and he worked with the folks at Vintage Performance to make it happen! Slide carbs have always been a better carb than butterfly types because the fuel air ratio can track the actual airflow over a wide range of throttle openings and flow much more air for their size than a butterfly type can. They have a natural variable venturi as opposed to a fixed venturi and variable area like butterfly types. Also, because of the slide movement, area is gained in a proportional way instead of a wild magnetic hysterisis type curve that is typical of a butterfly opening. They were the last carburetors used in F1 before going to fuel injection!! Perhaps these would have been used in automotive applications more often long ago, but the big bugger in the old days was that the only other application for them were small displacement motorcycles and those did not need accelerator pumps so they didnt have them! The HSR's do have accelerator pumps and do lend themselves to automotive use. The HSR45 is an ideal fit for use on the F-flow Corvair Turbo, as it is nearly the same size as the turbo inlet! -

Twin cam head for the L6 from Derek at Datsunworks

jeffer949 replied to Derek's topic in Nissan L6 Forum

What i forgot to say is that must mean IM OLD!! But my back slightly bulging a disc when I sneezed a few weeks ago should have informed me of that! -

Evergreen Building joined the community

-

Its staying turbo. I have a n42 block and I'm likely going to throw some itm turbo pistons in it. So the question is which would you use for an unconventional turbo setup

-

zach134 joined the community

-

Crazy fast

-

Well drive by linkage is fast and accurate. Pretty darn stoked. I might try a few more actuators. Since the one I picked is being discontinued (BMW S54 13627840537) This should make anyone doing ITBs life much easier. Cold starts, traction, AC, intelligent throttle curves. This is just hooking it straight to a 12v source. So it’s just on or off. Actually when wired to the ecu, closing will be faster. This is returning via springs. When hooked up to the ecu. It’s powered open and closed.

-

Who's Online 2 Members, 0 Anonymous, 410 Guests (See full list)