pirate87

-

Posts

30 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by pirate87

-

-

I have the EXACT same pressurized sprayer container.

I put WD40 in it. did you put your degreaser on it?

Raff.

Yeah, about a 1:1 ratio of degreaser and water.

-

could the rb26 input shaft be used?

It has always been my understanding that the RB26 Bell housing and input shaft can be used.

-

ahhh, I almost forgot:

The good,

I have never seen cleaner coolant passages in any head I've worked on...

and the bad,

it appears the turbos are fried, as neither turbine will rotate. Any suggestions? The wheels seem locked in place.

-

I got mine for $163 shipped from http://www.energysuspensionparts.com/

-

May 12th, 2008

Finally got the car down to the bare chassis, and loaded it up to be taken to the sand blaster. A week from the 12th I would be leaving for China for a month, so I was thrilled to have made some worthwhile progress.

June 10th, 2008

After returning from China, I took a few pics of the sandblast job. Unfortunately the light coat of primer was not adequate for the shell's outdoor storage, and some surface rust began to form...no biggie though.

The battery tray:

Overall, no surprises (ie. Bondo, etc) and the rusted areas were all well highlighted.

Also, at this time I began working on the front and rear suspension. Tearing these pieces apart is frustrating and time consuming, but I wanted to refreshen every part on the car.

Before:

After:

Still having trouble on the tie rod end and ball joint...any suggestions?

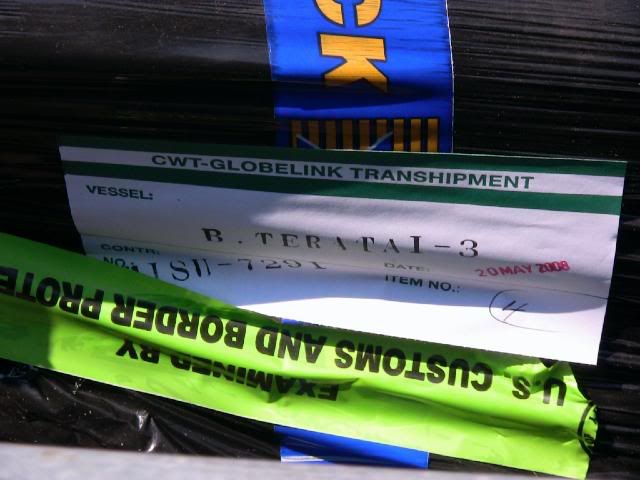

July 2nd, 2008

Picked up the RB30 Blocks from port in Wilmington, NC.

US Customs inspected:

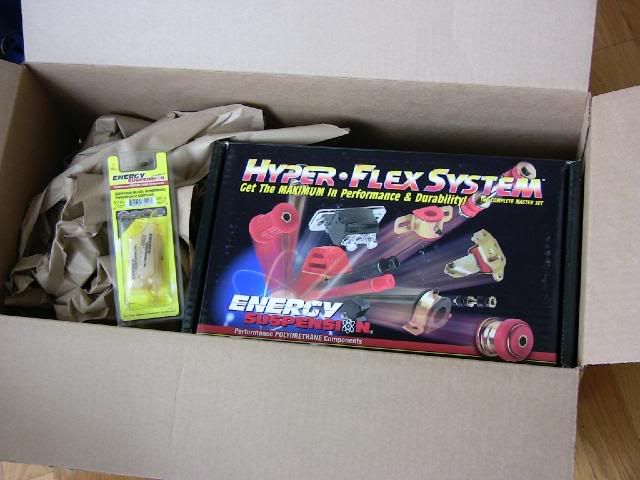

July 5th, 2008

New ball joints and Energy Suspension Bushings arrived!

I also set up a makeshift spray booth in my shed to coat the suspension pieces. All were sprayed black with a few coats of clear to make them really shine.

July 9th, 2008

Rode up to Winston-Salem to pick up my RB26 long block. And of course had to make a pit stop at "cookout".

July 12th, 2008

Went to Harbor Freight at 8 am to finally purchase an engine hoist of my own (I'd been borrowing for all of my other projects).

Took the RB26 out of the P'up and mounted it on the engine stand to begin the degreasing/cleaning process.

My all time favorite cleaning product, "Oil Eater" available in bulk from Costco.

-

lol neat, your 77's the same color as my 78.

517 XD I guess all the 517's that are around are all painted over.

Ya know, I don't even mind that color. I do like neutral tones, so when the car gets painted I've been thinking silver/dark grey? Or, if I'm in the right mood: Avocado Green.

-

Gotta love those 280zs! Looking at your pics takes me back to the day i picked mine up. I just remember saying to myself "Those bumpers are absolutely hideous!" Needless to say they were the first to go haha. I'm doing an RB25 swap, I cant afford an RB30 at the moment, it would be nice!

When I stripped the car, those were definitely the first things I tackled. Not my style.

So, my RB26 long block arrived at the shipping terminal on wednesday and I drove to pick it up in my Isuzu P'up. Only problem- I was without an engine hoist, so until I finally went and bought one early yesterday morning, the long block sat in the back of my truck. Anyway, I began the RB26 disassembly yesterday...with some surprising results. I'll post pics later today!

-

Since I wanted to finish things up by the end of the summer, I began working like a madman. From the middle of May until mid June I was going to be in China, so that would take out almost a month of good working time. My goal was to have the car stripped and sandblasted before left the country.

April 19th, 2008

Interior mostly stripped:

And I got a better look at the rust:

-

Since early April I've been tearing apart my 1977 280z in preparation of an RB30e bottom end mated to an RB26DETT head. I purchased the Z for $1200 locally and though it ran fine, the alternator was fried so I had it towed home to begin the process. Here's how it sat the night I went to check things out:

Flat black primer all around, and pretty shotily done too. Rust in the typical spots. But regardless something felt right about this car. Let the build begin!

-

yep. notice the 25 inake.

My brain can't handle such trickery... Pretty baller though!

JDM_Rice-

if you haven't already, I suggest you get on Nicoclub.com and head over to their RB section. Guys there are great, anytime I needed motivation with my swap someone always had helpful advice.

Not that Hybridz guys aren't great too, just an additional resource.

-

ohh, thats bull sh't... I was thinking something like this:

-

...the pine tree thing is kinds gay but hey...

HAHAH, I looked at the pic before I read that and thought:

"man, that pine tree is pretty f'in dope"

I gotta ask though... what scent is it?

-

Just keep at it! Not uncommon for RBs to be in the project phase for years.

Quick question- whats up with the valve covers? 26 on a 25 head?

-

I was under the impression that the R34 RB25 transmission was a pull-type clutch...not that this solves your problem, but it may help you prove that what you were sold isn't an R34 tranny.

-

Hey Z_GTR-

I love it! I have a lot of respect for someone who buys the engine first, then the car to follow...well done sir. I look forward to following the project's progress.

-

Most aftermarket rods include those very bolts. I would definitely not consider rod bolts alone a "quick fix". At 600+hp everything starts to become an issue, especially dependent on the quality of your tune. I would also worry about the stock RB ring lands at those power levels, regardless of the tune.

-

haha, I see what you're saying cygnus... complicated, but clever. Basically using the best source possible to control the BOV.

-

Ok, I think thats what I was getting at. The issues described are entirely separate, correct? I mean, the compressor surge Mark described is a totally different occurrence than the compressor surge I described. Or is the engine's inability to use the pressurized air, and thus forcing it back through the compressor (what I assume the fluttering noise mark described is), like closing the throttle- which causes the compressor surge I described. In this scenario the engine's capacity acts like the throttle plate in my scenario.

I apologize for not offering any real discussion to the topic, I'm still just trying to understand exactly what is happening in mark's situation.

-

I will be using the RB30 mounts, but I'm going to be cutting them and welding them to 1/4 inch plate with mounting holes and a thin sheet of rubber that I will epoxy to them. I want the rubber to remove any chatter, but it will be thin so that it will be somewhat more rigid than standard ones.

The RB30 mounts are pretty damn beefy from the looks of em

Careless, just curious as to which mounts you are talking about? The stock RB30 mounts or the Infinity Machining mounts? In my searching I have yet to find a dedicated RB30-S30 mount, and I have reservations about using say the McKinney RB mounts for an RB30...would the actual motor height be an issue? If you were talking about Infinity RB30 mounts where can I find more info on them?

-

Sound s like compressor surge. I'm sure the port shroud compressor covers will clear this issue up for you.

Regards,

Justin

Mark, I assume the problem occurs at partial throttle to WOT, and not just when the throttle is released? That being said, is there anyway for compressor surge to occur when the throttle is open? I would think that instead of sending the building air pressure back through the compressor wheel, it would be easier for the set up to force the "boost" into the cylinder head, which is attempting to pump it in anyway.

My last setup, a Holset HX35 on an RB25, ran without a BOV so compressor surge was definetely noticable when the throttle was lifted, however the "choo choo" sound never occured during WOT or even partial throttle under booost.

Also, the HX35 runs a ported shroud, and the issue was still present. I would think the twin setup would offer a different dynamic, but just adding that info to the discussion.

-

some pretty Z's! Whos BRE-spec Z is that in the 7th pic?

-

first, this thread makes my brain hurt, but instead of asking you to search here are my answers:

RB25 does not make 285 hp stock. Try more like 250 at the crank, or a conservative 215-220 to the wheels. The swap is not hard- if you've done your research and have some motor swap experience, neither of which your questions indicate you having.

The stock turbo can pump about 12-14 psi before the ceramic wheel becomes an issue. I can't give you a reasonable answer as to how much "boost" the stock motor can handle, thats a really open ended question.

The car itself will handle as good as you build it, obviously you'll have to account for the change in setup, but its nothing that cannot be corrected.

Never heard of neo-tech.

Its quick.

-

Its hard to beat the PowerFC for its ease of installation and use. When paired with the FC Datalog-it, it in my opinion is the best combination, and most cost effective solution for your application. However, prices have gone since the PFC for the RB25 was discontinued.

-

Just as a heads up, I have 6 RB30s awaiting shipment to the states. I was planning a build and decided to order a few extra while I was having mine shipped over. They are being cleaned and packaged in Aus. right now, thus they have not been shipped so I do not have an exact date of arrival.

I was not interested in waiting on a group by, thats why I acted on my own. They should be in the states soon, and I only plan to keep 2 (maybe 1, still up in the air). They are all Series 2 short motors, so they already have provisions for the oil and water feed lines. Let me know if you'd like me to reserve you one.

RB26DETT build up

in Nissan RB Forum

Posted

Sorry for the shameless plug, but I have a couple of RB30 blocks left. Pm me if you are interested.