Dale280z

-

Posts

11 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by Dale280z

-

-

2 hours ago, NewZed said:

Sorry, I missed this part. Looks like you already compared.

No idea. There's a guy on classiczcars.com that has many spare parts. TerrapinZ. He probably has a set that will work.

Best guess would be an R160. They seem to be different, people don't call them R180 or R200 axles. Edit - except that they are bolt-in, not clip-in. There's a hole through the shaft.

I got an answer from dave kipperman the guy I got these from. He said "They came out of A early long snout R200 maybe a 74 or 75?" So who knows why they were different???? oh well they are still useable.

-

6 minutes ago, NewZed said:

Sorry, I missed this part. Looks like you already compared.

No idea. There's a guy on classiczcars.com that has many spare parts. TerrapinZ. He probably has a set that will work.

24 minutes ago, NewZed said:I've not heard of any difference in that part of the axle. They're all the same, the half-shafts are swappable from 240Z to 280ZX. That locating ring is the same size across all of the Z's and ZX's, and R180's and R200's, I think.

It is supposed to be a very tight fit, like very close to zero tolerance. A few mm is huge. Are you sure it's not "almost there", maybe rust and crud are the problem? Old crusty paint? The parts look correct for the way they are supposed to work together. Make sure that they are the same temperature. Aluminum expands a lot more than steel.

Have you compared the dimension of the adapter ring to the raised ring of the half-shaft flange?

That is what I ad finding. I have several axles, adapters, and even stock joint axles. They all fit in the old ones but not the new ones. The one that do not fit are by far cleaner than the ones that fit, no rust, no hardened grease nothing. They have all been in the same garage for weeks so temp in not an issue. I am going to try and contact the guy I bought them from. Just curious since I machined them to fit so I can't send them back.

-

-

I bought some stub axels that are supposed to be for a 280Z. The splines are 29 and fit into my R200. But when comparing them with ones I already have there is one big difference. The indented portion of the flanges on these new ones are a few mm smaller and do not fit into the axel adapters I am using. Any idea what these out of?

-

Yeah my mistake. I did this diff swap many years ago and had to go back and look at my own website. I have a 300ZX turbo R200 with a clutch type LSD with .370 gear.

Thanks for the pict.

-

47 minutes ago, NewZed said:

The new axles probably a have square edge on the circlip groove when there should be a small chamfer.

Looking at both the stock stub axles and these 280zxt axles I see no chamfer on the stock ones but there looks like there is on the new ones, kind of hard to really tell. BTW where exactly is this circlip inside the diff, I see nothing.

-

Well, that was a lot of panic for no reason. The air hammer would not work, chisel is not long enough so I got out the BAH and the 1/2" socket extension and smacked the inside end of the axle two times and it popped right out. Now of course why did it get stuck in the first place????

-

37 minutes ago, NewZed said:

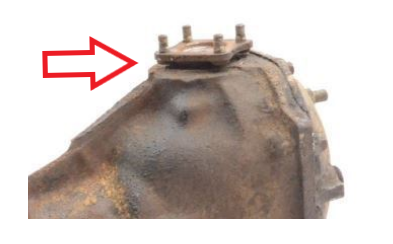

I borrowed this image from an eBay ad. I stuck the chisel end where the arrow points and wedged the axle out by the flange by tapping the chisel in to the gap. Can't remember how the ZX CV's look there.

But I do remember using a long punch through a diff to knock out an axle from the other side in a shortnose R200. It was a viscous diff though and was open through the center. I think you'd have to remove the center shaft on yours to do that. That's the other option where you would have to remove the cover and take the shaft out so that you could get a punch through there.

The 280zxt axle does not have a flange like the stock stub axle has. With both axles out I could see all the way through. The diff is a R200 out of a 280zxT with LSD. I tried using a long extension and beat on the inside end of the axle but nothing seemed to move. I have an air hammer with a punch type chisel I might try that tomorrow. Since the axle has a problem, I think the clip that holds the cage in place fell off. I want to send it back to RockAuto but at this point I will do whatever it takes to get that thing out.

-

1 hour ago, NewZed said:

Probably the circlip jammed in there somehow. An outer groove and an inner groove and a small space in between that is supposed to be too small for the circlip. Even with the diff cover off you'll probably still have to use brute force to get it out. What would you take apart to get to the circlip?

I've used an oiled cold chisel as a ramp (wedge is a better word) to pop out the R200 short axles. Might work for CV axles.

Thanks. I thought something went wrong with the clip. Did you use the chisel from the outside or though the inside with the other axle removed?

-

I am in the middle of switching over to Milkfab's 280zx axles and have run into a weird problem. I have taken the axles out of this car many times with no problems but now I have the driver side stuck. Some back story. After installing the driver side axel I was had problems getting the passenger side to seat and lock in. After several tries it finally seated but it looked like the driver side might have backed out a little. But I continued on with the install. But when I was tightening the 280zx adapter to axle bolts on the driver side something with the outer CV failed. I have tried to pull this axel out but it is stuck about 3/8" from being seated. Any ideas what is wrong and why I can't pop this thing out? Am I going to pop the diff cover to see what the problem is?

S30 Electric Power Steering (EPS) Install How To Video

in S30 Series - 240z, 260z, 280z

Posted

I saw a video on Silvermine's system and they require a wire from the back of the Z tach to their control box. You did not mention that you had to hook up the tach signal, did you have to do that? I have a Chevy LT1 computer controlled engine and the tach signal actually come out of the ECM which I am sure is different than the tach signal in an ordinary ignition system.