-

Posts

145 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by Meatwad

-

-

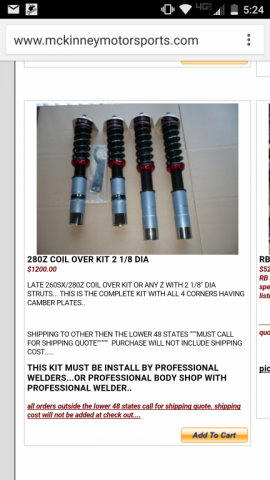

Wow, it has been a long time. Over the past almost 3 years. A little has been done to the car since the last update. Ive moved homes and took on 2 kids. The turbo hotside has been fabbed up. I decided to go with a ford 8.8 IRS 31 spline from a ford explorer. I used the t3 backing plates and rear coilovers that came from their q45 doff conversipn so i could run z32TT hubs. Corbeau A4 seats were mounted. The wiring harness was depinned. A fuel cell was put in. I just recently bought fuel line. Pretty much at this point is a domino effect. I need front coilovers and the front 5 lug conversion, brakes all around, wheels and tires (likely just do steelies to be able to drive it around for the time being), exhaust, axles and driveshaft, charge pipes, finish the cooling system, charge piping, and a few odds and ins just to make ot driveable. Still trying to figure out if some flex pipe should be done on the hot side and how to go about supporting the turbo to keep some strain off the pipes.

-

Hey everybody, i know there are loads of information on these brakes on the s30 chassis, but where can i get the spacer for 5 lug? Ive searched the forum and I can only seem to find the 4 lug spacer. Looking to put s12w calipers on my datsun, but im 5 lug.

-

Heres some videos of daniels and davids z cars as lsfest

-

Where did you get your ac mount and what compressor did you go with? Sorry if I missed it earlier

-

If you don't mind me asking, what exactly did you do to center the wheel?

-

You won't get 450rwhp out of a streetable 5.3 NA, even if you go 11:1 compression ratio. Lq4 can get you there, but the if you're going NA, you'll need to bump up compression. if you decide to go NA, then decide to go forced induction, then you'll want to drop compression ratio a little bit. To save you money in the long run, if you think you're going to go forced induction, chances are you will eventually. Building a mean NA engine will eventually cost around the same price as a FI engine. I say get the lq4, build it for boost. Do it right the first time and save money

-

LS engines looooooove long tubes

-

Yeah, I'm sticking with a 4 point roll bar as I don't like side bars and it is a street car

-

The inside will be bare for a long time as it will get a roll bar in so on, but yeah, I plan on it

-

Yeah, I'm so thankful for that!

-

I'm glad this post showed up. I'm thinking about getting these. Ordering 1, does it include both sides of the front suspension or do I have to order two? Arizona sells the sides separately, not sure how ttt packages their products

-

Has anybody tried out the Pegasus racing roll bar? They claim they make them for the s30 cars and the design of this one is more appealing that other roll bars (more importantly it looks functional). If you have, how was the fitment?

https://www.pegasusautoracing.com/productselection.asp?Product=2403

-

I'd love to do a center exit exhaust

-

i Used the fbody one, sits about flush with the k member

-

I was thinking about using them, but didn't want to possibly wastd some cash. Decided to just make manifolds for my application

-

Lmao^ his words, not mine

-

Mine has a half dash cap, not sure how old it is, but it definitely needs to either be repaired or a full cap. Bondo is dinosaur technology. There's body filler with little fiberglass strands embedded in it and it is flexible

-

Can't tell by the pics and maybe I missed it. Is that a dash cap or a perfect oem dash?

-

Now that it has cooled down, progress on the car has been made.

I scored some free simpson 5 point harnesses for free. basically brand new still,

It was time for the first fitment test. she fit in there almost perfectly. of course the old trans mounts were in the way.

The engine fit perfectly as soon as the trans mounts were cut out of the transmission tunnel. The shifter even sticks perfectly through the stock hole.

Also, before it was too late, i decided on buying a new turbo. I upgraded to an 88mm turbo. The smaller turbo had an turbine wheel too small for the 6.0, so i figured it was best to upgrade while i can.

before engine mounts were made, i decided that none of the stock fuel system would be reused. The stock tank is being replaced by a fuel cell. the stock fuel lines and pump were no longer going to be used either. So i tore out the entire fuel system, including where the tank vents to. The worst part of this was separating the fuel lines from the brake line that goes to the rear passenger brake and then cutting the fuel lines into pieces, trying to remove the lines from around the rear suspension.

Engine mounts are made and supporting the engine.Huge thanks to my dad doing the fab work!An angled plate was welded to the frame rail to reinforce the frame rails, but 4 holes in each frame rail was drilled in order to make room for a threaded nut that was welded on the plates before being welded to the frame rail so that the engine mounts could still be removable. with the plate welded to the frame rail, another plate, similar to the one welded to the frame rail, was welded to the post of the engine mount, also with 4 holes drilled in the same locations as the other plate. with this, the mount will be able to bolt and unbolt from the car.look at the picture for reference. With attaching the engine mount to the frame rail, the original mounts on the K member will be cut off so there is more room for the turbo exhaust to exit.

The original plan was to use the stock exhaust manifolds, but the only way to get them to fit was to cut some of the manifold off and weld pipe to it, which is not what i wanted to do for cosmetic reasons. I looked into up and forward headers, which also can be used for down and forward headers, but i was unsure how well they hug the block and did not want to be stuck with a pair of headers that would also not fit. Instead, exhaust manifolds and the rest of the hot side is just about ready to fab up. I have my water pump temporarily installed and am waiting on the fbody alternator bracket to come in so fab work can begin on the exhaust. Mild steel is the choice of material as it is cheaper, plus it is very rarely humid out here, but the exhaust will be ceramic coated anyways to prevent corrosion and for cosmetic reasons.

Before a trans mount can be made, I ordered bad dog frame rails to reinforce the flimsy OEM ones. To prevent risk of fire, the interior had to come out,

The seatbelts, seats, carpet, center console, and some other odds and ends had to be removed. None of what was removed was being reused. Earlier in the build, I mentioned how rust-free this car was. as i was about to pull the first section of carpet, i was really expecting to see some major rust on the floorboards or something, but luckily, the car has really solid floorboards and it was a huge weight off of my chest!

-

Which champion one do you suggest? JTR called me and said they don't sell them anymore, so I got a refund

-

Went with the JTR radiator

-

Hey guys, I'm looking for a radiator option for my s30. While I have found plenty of radiators that are the right exterior dimensions, I have yet to find a crossflow radiator with the proper inlet/outlet diameters for the LS water pump. What radiator are you guys running and/or what would you suggest? Temps in the summer reach 115+ degrees here in Vegas. All help would be much appreciated.

-

-

So a little update. Not much has really happened lately. I have all the materials for engine mounts and a trans cross member. Not much will likely get done until around October because of the 115+ degree heat we see in the summer.

1977 Turbo LQ4 280z Build

in Gen III & IV Chevy V8Z Tech Board

Posted

Theyre home-built manifolds