jrd

Members-

Posts

49 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by jrd

-

Yes, Z-ya has sent me a map that really helped me I am still fooling around a little bit and figuring things out. I am still up at a 70% PWM which is a problem, but I will try a couple of new settings today. I think that the problem has flat out been trying to set too low an idle. We will see I will try somemore today and post the results. Joe

-

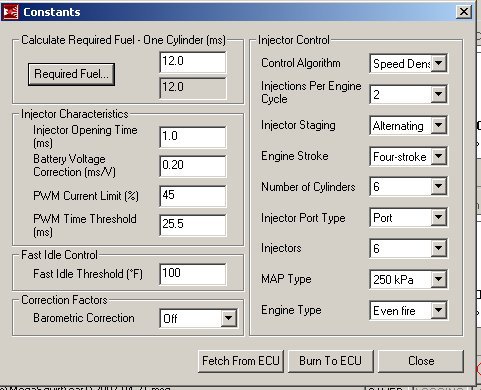

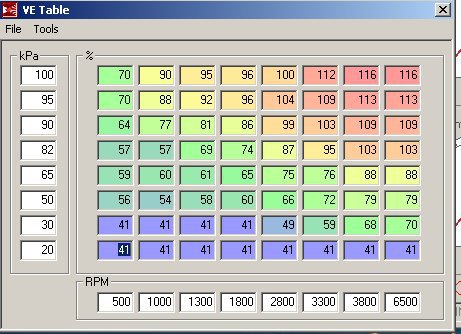

OK, I tried adjusting the required fuel in steps all the way up to 30ms with the PWM at 35% and I just couldn't get it to not hesitate or stall right off of idle. I also noticed that my O2 reading was moving to richer and richer - which is good because this thing has been running lean accept on decel. The best settings so far have been (with three squirts). TPS Threshold = .5 v/s Accel TIme = 0.2s Cold Accel Enrich = 9.0ms Cold Accel Mult = 100% Decel Fuel amount = 100% Acceleration enrichment bins 2 v/s = 1.0 4 v/s = 4.0 8 v/s = 8.0 15 v/s = 15.0 I have a required fuel = 14ms injector opening time = 1.3 Battery VoltageCoorection = .20 ms/V PWM Current limit = 85% PWM time THreshold = 1.3 ms What am I doing wrong? Joe

-

Z-ya, Yeah I am doing fuel only. I PM'd you my e-mail address. Thanks for all the help. Joe PS any particular reason to do three squirts over six?

-

So with a 180 cc.min injector I am getting a required fuel for my 2900 cc motor of 18 ms per cylinder - sound right? I am using 6 injections per cycle with simultaneous firing....based on Z-Ya and Mack I have the following settings I have a required fuel = 18ms injector opening time = 1.3 Battery VoltageCoorection = .20 ms/V PWM Current limit = 45% PWM time THreshold = 1.5 ms The car wouldn't run with a PWM Current limit setting of 35%. Right now at 45% it will lean back fire if I step on the gas but at least it idles. Can I just keep upping this until it doesn't backfire or hesitate off idle? Is there another setting that could be causing the issue? Thanks for the help. Joe

-

Ok, mobythevan was correct, my PWM sttings were way off: It is running much better with the following, but still not perfect - does anyone know what the actual size of the stock NA fuel injectors is? TPS Threshold = .5 v/s Accel TIme = 0.2s Cold Accel Enrich = 9.0ms Cold Accel Mult = 100% Decel Fuel amount = 100% Acceleration enrichment bins 2 v/s = 1.0 4 v/s = 4.0 8 v/s = 8.0 15 v/s = 15.0 I have a required fuel = 14ms injector opening time = 1.3 Battery VoltageCoorection = .20 ms/V PWM Current limit = 85% PWM time THreshold = 1.3 ms No stumble off of idle when warmed up, but still not running well enough for me to call it done. Joe

-

OK, as is usually the case I am finding different values for everything and having trouble getting my car running. Acceleration from half throttle is noticably improved now that I have switched from SUs to MS1 - however, I still can not get a decent off idle acceleration - it stumbles and lean backfires on occasion. I actually minimized the off idle lean backfires by adjusting the Acceleration enrichments TPS Threshold = .391 v/s Accel TIme = 0.2s Cold Accel Enrich = 9.0ms Cold Accel Mult = 100% Decel Fuel amount = 50% Acceleration enrichment bins 2 v/s = 5.0 4 v/s = 10.0 8 v/s = 15.0 15 v/s = 25.5 THis is for an NA motor 60mm TB with the stock injectors. Anyone else have values similar to this? Are they reasonable? These are the stock injectors I am assuming they are 240CC/min I have a required fuel = 13ms injector opening time = 1.0 Battery VoltageCoorection = .20 ms/V PWM Current limit = 45% PWM time THreshold = 25.5 ms Are these settings reasonable? Any ideas why I am stumbling off of idle? Thanks, Joe

-

OK, reading some other posts I am confused about the ego read out....when the dots on the Megatune screen are green is this rich or lean???? I was assuming that the green dots meant lean since the car was backfiring through the intake and that into the red dots meant rich...do I have this backwards? Thanks, Joe

-

OK, I got my NA L28 with a 60mm TB and stock injectors (no resistors) running on MS 1:icon10: - but she runs like crap!:icon_frowLots of lean backfires out the TB off the line. On cruising the O2 sensor is modulating between way rich and way lean...what could cause that? On deccel I am getting a way rich condition. I am posting some screen captures...any help or suggestions would be appriciated.

-

I am trying to set up my MSI V3.0 and can't find a jpg of the enrichments table (shown below). I think that I have found everything else. This is for a NA 2.8liter with a 60mm throttle body and the standard 260CC injectors and no resistor pack. I live in Glendale CA, so not too much -40C weather. Thanks! Joe

-

OK, I spoke to Matt this morning and everything is much clearer. Turns out that the schematic includes the wires for the MSII - wires that are not connected up to anything in my case. The coil wire (pin 24) does indeed go to the negative post of my coil and the sheild is left un-connected at that end (grounded at MS 1 box). My fan control is on Pin 25 since this isn't an MSII set up. Also, for FIDLE I will just us a five position relay (Matt's suggestion) so that I can have the idle bypass only heat up when the engine gets to some temperature (i.e. turning off the the FIDLE at the MS unit will actually heat up my FIDLE and shut it).

-

Well, today I got 90% of the wiring done on my 1970 240Z MS1 V3.0 upgrade (from SUs) and got the new 5/16" fuel lines almost in. I will post some pictures when it is done. Swapped in a 75Z tank, a R200 rear end while I had it all apart - plan on swapping in some chopped springs tomorrow as well. THis is my daily driver so I have to get it back together as quickly as possible. I am swapping up to MS to try and get better gas millage....it is currently 21 mpg around town...anyone think that I can hit 26 mpg...or better? I am still stuck with the wiring for two items: the sheilded ignition wire from the DB37, pin 24 - where does that go? the negative terminal of the coil? Does the sheild connect to the positive terminal of the coil then? Also, what is pin 36 (which is labelled Ignition module/Coil) supposed to connect to? I am running a Dizzy from a 79ZX - the one with the ignition module on the side. Is this my fan control wire? Are there any issues with my not using a heated O2 sensor? For the FIDLE control, does that default to ground on power up? I mean what is the FIDLE logic? Does it look at the air and water temp and "decide" that it is too cold so it doesn't pull that terminal to ground? I was going to wire up my FIDLE so that the relay would switch it on when the FIDLE terminal was grounded.... Thanks

-

Hi all, THe megasqirt instructions show two wires from the DB37 going from the MS box to the reluctor of the distributor. I assume that on my 79ZX dizzy these two wires connect to the red and green wires coming off of the reluctor - my question is this - does it matter which wire connects to green or red? Thanks, Joe

-

I was having trouble stopping the oil leaks on my daughters Volvo. I replaced front and rear seals and numerous gaskets then a friend told me that a common problem on that engine is that the flame trap in the crankcase vent plugs up and the positive pressure in the crankcase will blow out the seals....sure enough, the crankcase vent was plugged. I cleaned it out and the thing quit leaking oil..... Joe

-

Hi all, I just ordered a Megasquirt I V3.0 and I am first going to fuel inject my 240Z with it and then I am going to have it control the ignition. From this I will write up an article. My confusion is this: how does it control spark timing? Is there enough slop in the overlap within the distributor cap that you can vary the spark timing 10's of degrees? That doesn't seem possible. Under 10 degrees I can buy. I currently am using a distributor and ignition module from a 79zx. Thanks,. Joe

-

Brake Cooler Testing (i.e. what not to do)

jrd replied to jrd's topic in Brakes, Wheels, Suspension and Chassis

Yeah, I used to race Pro-7 at Buttonwillow - what a blast. I had to sell the Pro-7 though to start this business. Hopefully I will be back at it when sales pick up. Have all the necessary equipment, just need to set up a Z and take SuperSchool again..... JRD -

Brake Cooler Testing (i.e. what not to do)

jrd replied to jrd's topic in Brakes, Wheels, Suspension and Chassis

That is a good idea, and youare correct, safety is the primary reason. It has allready seen track use...check out http://www.fourproducts.com/FSBC.html and click on FSBC Racing. JRD -

Brake Cooler Testing (i.e. what not to do)

jrd replied to jrd's topic in Brakes, Wheels, Suspension and Chassis

-

Brake Cooler Testing (i.e. what not to do)

jrd replied to jrd's topic in Brakes, Wheels, Suspension and Chassis

Having a cooler on one side, but not the other and then switching them and repeating is the best way to take accurate data. The "safety" issue comes from me pushing the car hard on a mountain road. The proper way to do it is to spend $2k and get Buttonwillow Raceway for a day. Now, jsut so all are aware, I am not speeding through corners on this mountain road, just the opposite. I am just waiting late to brake and then I am braking pretty hard. I don't think that I ever go over the speed limit and I have yet to squeal the tires in a turn. I am actually taking the turns pretty slow...you know, setting up properly for them. Slow in, fast out. JRD -

Brake Cooler Testing (i.e. what not to do)

jrd replied to jrd's topic in Brakes, Wheels, Suspension and Chassis

By the way - the ducting is attached to a BRE spoiler up front that I just installed. Having my Z as a test vehicle makes all these accessories a write-off. I think that my accountant even said something about research tax credits. How great is that???? Of course write-offs are no stinking good if you aren't making any money! HAHAHA JRD -

Brake Cooler Testing (i.e. what not to do)

jrd replied to jrd's topic in Brakes, Wheels, Suspension and Chassis

Yes, both calipers have the same ducting. With the side without the coolers I try to aim th air at the pads. I have to take some photos of the ducting for a gentleman who bought some FSBCs - I will post the photos -

Brake Cooler Testing (i.e. what not to do)

jrd replied to jrd's topic in Brakes, Wheels, Suspension and Chassis

For all those interested here is the raw data from testing. Red is the passenger's side without a cooler and black is the drivers side with the cooler. Unfortunately, something happens to the passengers side thermocouple after it hits 440C and it becomes very noisy - I haven't had a chance to look at the car yet, but it appears that I will have to take the data again - but not until I am running some Super Blue. -

Brake Cooler Testing (i.e. what not to do)

jrd replied to jrd's topic in Brakes, Wheels, Suspension and Chassis

Jon, do I need to replace the seals to do this? I assume that I need to flush out the DOT 3 completely before the upgrade. Thanks, Joe -

Hi all, Had a bit of a scary ride this morning. As some of you may know, I have set up my 1970 240Z with thermocouples on the caliper pistons so that I can use the car to test the effectiveness of the Fade Stop Brake Coolers. I put a pair of coolers on the drivers side caliper and leave the passengers side stock, then I drive down Hwy 2 from Mt Wilson into Glendale (Los Angeles). It is an altitude change of more than 3500 feet. While I did this before with the prototypes, I am now using the manufactured brake coolers and some Hawk HB Plus pads. These pads are capable of much higher temperatures than the Sumitomo pads I was using with the prototype. While I drive down the mountain, I record the temperature data on a data loger from the two sides while I descend...I get on the brakes A LOT so that I can get them nice and hot. The data logger has a screen that shows me the data while it is being recorded. Here is what happened: as I hit the bottom of the mountain, the passengers side caliper piston (no cooler) hit a temperature of around 420C while the drivers side (w cooler) was somewhere around 250C. What was going through my brain at the time is "this is GREAT data!" What should have been going through my brain is "WAIT, DOT 3 brake fluid boils at around 210C!" Luckily, I was actually going quite slow at this point, 'cause when I stepped on the brakes, my foot went to the floor. If you have never had this happen to you then be thankfull - it is NOT a pleasant sensation. I frantically PUMPED the brakes many, many times and still nothing - I had REALLY boiled the fluid in that passengers side caliper. I then grabbed the O-Crap handle and pulled...the emergency brake did what it was supposed to do and I used it to limp over to the empty parking lot of a nearby strip mall. I then slowly drove around a shopping area until my brakes returned - it took over 20 minutes! Those cast iron calipers retain the heat for a long time. I then drove into work without any trouble. What is next? Well, I need to do it again. For the data to be complete I need to put the coolers on the passengers side and leave the drivers side stock and retake the data and then average the results. I think that I will replace the DOT 3 with a racing fluid at this point though. It shouldn't affect the data at the piston/brake pad interface and there are some pretty significant drops along Hwy 2. Once I am done, I will put the data on the fourproducts website - it looks like it will show some significant differences.