Jerminator96

-

Posts

95 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by Jerminator96

-

-

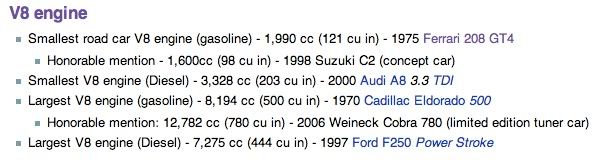

Found this regarding the Ferrari 208 GT4, with its 2.0 V-8. According to WikiPedia, it is the smallest displacement production road going V-8 at 1991cc’s.

http://en.wikipedia.org/wiki/Ferrari_GT4#208_GT4

Courtesy of WikiPedia

I thought you of all people would notice that the Ferrari 208 was already mentioned.

Alfa Romeo had a Coventry-Climax 2.0L V8 in their 67-69 "33 Stradale," a street car based on the Tipo 33 racecars. Their were only 18 produced but it made around 250hp and would spin up to 10,000 rpm, it also had a 6 speed transaxle.

Probably doesn't help if you're still looking for a motor, but if you do run across one you need to mortgage your house and buy it.

-

Thanks. My current plan is just throw this motor in the car as it is and concentrate on sorting out my chassis. Then later build a good motor to replace it with. That might sound like a lot of extra work but I just need to drive this thing before I get completely burnt out on wrenching.

Been there and done that. There is a world of difference between a project stuck in the garage and one you can take out and drive.

-

Ok. How about piston and crank identification? Also do you think it would be wise to tear down the motor and replace the bearings?

The block casting number should give you an idea of the internals, or course, if it was rebuilt with new internals then pull the oil pan and get the numbers off your crank, rods, and pistons. The biggest thing is the heads though, if you have mid-80s factory TPI heads you are going to be severely limited in power.

If it actually has just a few miles on it you shouldn't need to replace the bearings, but that's really up to you. Bearings are cheap, unlike machining the block/rotating assembly after something lets go.

-

Over the next week, I will be discussing intake requirements (if in fact there are any...especially on an unrestricted head (defined as flowing more volume than the engine can physically consume within a given rpm range...which is also defined by the mechanical limits of the components involved.)

That's pretty simple math, just make sure you account for Bernoulli's principle on compressible flows. You can't flow more than 146 cfm per sq.in.

Have you studied anything about high RPM exhaust tuning, i.e. "5th cycle" tuning?

-

It may have been missed a few pages ago but Lotus used flat planes in the LT5 for road racing as there 3.5 turbo V8 wasn't up to the task. I don't know if the LT5, LT1, and 350 share the same basic design. I know they did the heads but I don't know about the block design.

The LT5 does not share heads with the GenI/II SBC. However, it does share bore spacing, which is what matters as far as the crank is concerned.

More info: http://www.zr1netregistry.com/ZR1_specs.htm

-

it's not about just a big displacement, high reving v8

Yeah Gollum was just asking about high RPM pushrod motors, and cup cars are probably one of the best examples of that technology. The motors are relatively cheap and simple, they spin high, and they hold together. All this despite the fact that they have relatively long strokes and heavy rotating assemblies, dual plane cranks, and make a lot of power.

Add a flat plane crank and drop it in a 240 and you might have one of the baddest rides on this forum. After looking over one of the newer R07 motors in detail I would really like a chance to fiddle around with one. I'm also getting closer to my "dream job" so maybe building a 180 degree crank for an SBC isn't terribly far away.

I did recently notice that John Kasse may be turning out some nice canted valve SBF heads with some very impressive flow numbers. If he did then I wouldn't mind seeing a flat plane crank in a 302 with those on top....

-

Gollum if you want to know what the real deal is with high RPM domestic cranks, just buy one.

You won't find a much better example of a big displacement, high horsepower V8 that can last at 9000+ RPM.

-

Excellent thread John, looks like a well documented build. I love that you can build a decent motor most from parts just laying around, someday maybe I'll be that lucky.

I started a 302 build once, but then came across a good deal on a 3.25" crank so I decided that it would be nice to have the extra cubes at the expense of a little RPM. Then I got a good deal on a 400 block so I decided that a 358 would get me my RPM back with more cubes and more power. Then I found a good deal on a 4" crank and 4.155" bore JE pistons with carrillo rods and decided that while I'm at it I ought to build a big nasty 434. Then I couldn't find a decent deal on the heads I wanted so I got bored with the project and sold it.

So more power to ya when you finish this one.

-

Oil change specified in barrels instead of quarts...

So... it's a quad sequential turbo system with two different sizes?

Yes, it's by no means a new idea. The first turbo is smaller and builds boost very quickly, then it's "downpipe" feeds directly into the larger turbo along with the rest of the exhaust. The idea is to keep intake air pressure as high as possible with no turbo lag, with a small sacrifice of the larger compressor's efficiency.

Edit: I'm sure you also noticed the 13-14 quart oil sump.

-

1200cc injectors delivering 2.27 gallons of gas per minute to be turned into 1500 hp. There are just so many things I like about that.

-

Oh yeah baby...

You will be sure and document that build here on HybridZ, wont you?

As Tony so eloquently put it, it will only be marginal at best,

As Tony so eloquently put it, it will only be marginal at best,

In my mind, an SB2.2 build, especially with a monster displacement 434 cid, would be one of, if not the, penultimate N/A SBC's!!!

Oh it will be documented all right. I can't be 100% sure that my next motor is destined for a Z car, but whatever it goes in will be a lot of fun.

Looky what I found, Joe Gibbs leftovers:

-

My assumption for the hot ticket elcheapo acquisition would be the former Chevrolet NASCAR engine that this one replaced...

I mean, that's probably marginally acceptable for our purposes here, right?

Marginally...

That's my backup plan. I want to do a 434 with SB2.2 heads. I can get the whole top end for under $2000 (used of course) and the rotating assembly can all be "shelf" parts, more or less. I might need to either do custom sb2 pistons or custom rods as I'm not sure that a 434 is a terribly common rendition of that motor. Still should end up fairly cheap, then there is just the problem of preparing the rest of the car to handle 1000 N/A horsepower.

-

I agree! It would be a wicked Z car powerplant...

You meant a complete R07 engine, not just the block right? The bore centerline spacing of the R07 is 4.5†vs the 4.4†bore centerline spacing of all other Small Block Chevy’s which should directly carry over to the rod journal spacing as well, unless offset rods/pistons are used for the inner/outer cylinders. My guess is the rods and pistons do not have staggered offsets to accommodate a crank designed for a narrower bore spacing, meaning cranks and cams will not interchange between the R07 and other Small Block Chevy's, let alone heads, and other valve train components. Aftermarket support now and in the near future will most likely be very specialized and limited, probably on a race team/engine builder, by race team/engine builder basis, such as RCR receiving their own specialized R07 components. I’m sure many aftermarket parts manufactures would be more than willing to manufacture the required components for a privateer R07 build up, such as cranks, rods, pistons, cams, etc, $$,$$$.$$

Something else for the rest of us to consider is, this engine was designed from the ground up for one segment and class of racing, NASCAR! Street use or other racing platforms was not part of the design criteria, though I’m sure it would assimilate to other racing and performance arenas quite well, (fingers crossed we'll see more of this powerplant outside of NASCAR...). Add to that its newness on the NASCAR scene, (only 1 year old now). If one could acquire a complete “over timed†Chevrolet NASCAR R07 engine, you can bet the price for entry will be staggering, (unless you have buddy working for a NASCAR race team

). The SB2 variant has been run for some time now, and tons of NASCAR take out/over timed SB2 goodies are available to the general public via race shops, eBay, etc, and even the replaced SB2 is a bit of a stretch to duplicate financially for Datsun enthusiasts, let alone the all new super-whiz-bang R07. (I think the SB2.2 is till being utilized in other racing arenas...)

). The SB2 variant has been run for some time now, and tons of NASCAR take out/over timed SB2 goodies are available to the general public via race shops, eBay, etc, and even the replaced SB2 is a bit of a stretch to duplicate financially for Datsun enthusiasts, let alone the all new super-whiz-bang R07. (I think the SB2.2 is till being utilized in other racing arenas...)I’m not trying to burst anyones dream of owning such a power plant. I’m sure a truly dedicated individual could scrounge a complete R-07 on a budget and make it a reality, especially someone with connections to a NASACAR team,

, I’m merely trying to keep perspective, the depth and breadth of the gap between us Datsun enthusiasts and recently released NASCAR powerplant technology.

, I’m merely trying to keep perspective, the depth and breadth of the gap between us Datsun enthusiasts and recently released NASCAR powerplant technology. I am curious, if these engines are being released to the public on any level of completion, how much $$,$$$.$$?

Yes I did mean a complete engine. Next time I'm in Charlotte I'm going to try to get over to my friend at RCR and stare at some cylinder heads for a while. I doubt they'd let me take any pictures but if they do you guys will be the first to see them.

I would assume that the main journal spacing is 4.5" also, but GM is currently selling a block with 4.4" main spacing that can be machined to 4.5" bore spacing. They can accommodate the "ROX" canted valve heads which I believe are $1300 (each), not astronomical by any means. There is even a guy on racingjunk selling a one of these blocks (new in the crate) for $3400. They are definitely not be quite the "R07s" level of sophistication, but I have a feeling that these motors will be part of the promised redesign of the canted valve heads that the drag racing world has been begging for.

You're right though, these are by no means budget motors and the chances of me picking one up for anything less than my right arm are pretty slim. Heck I'm still in college after all! But, if by some miracle I can get some awesome deal on anything close to a running motor, I've got a 240z that's looking a little empty under the hood.

-

Nascar mandates 12:1 compression. I would imagine that custom pistons would be required as they use 6.2 inch or longer rods, 3.25 stroke cranks and 4.185 bores. The bore spacing is different so the crank may not be the same or the rods have different offset. Would be neat to see one.

Why would you want a flat plane crank when it already turns 9800rpm? Run it like it is.

I thought that I had heard it still uses 4.4" mains spacing with the 4.5" bore spacing, I'll have to check on that. I would also be really surprised if they stuck with the 4.185 bores, unless there is a limit in the rule book somewhere. If they can make the old motors last with .25" cylinder wall thickness than they can make these last and take advantage of bore spacing increase. Of course I guess that depends on how the new coolant passages are designed.

Edit: Nope, looks like they're stuck at 4.185 due to coolant passages. I guess the after market will have to be the ones to give us the 4.25" bore small block.

-

I've got a friend at RCR that is going to look into what it would cost me to get one of those blocks. Might end up being a lightly damaged one or just one that has "too many miles for us" but I'm not picky.

That sure would look sweet in my '71 240z.

-

Well, my 280Z is progessing nicely. By the end of today, I'll have the entire front suspension painted and together.... I'm STILL waiting for my front brake parts from bajaracer (UPS's fault), but then they'll be going back on. I'll be starting the rear suspension this afternoon... This car has cost me much more than I originally anticipated (somewhere in the neighborhood of 5K?)...

Perhaps I'll get some more pics up soon.

If you're already over-budget, what's a little more?

http://www.race-cars.com/engsales/other/1200038700/1200038700ss.htm

Now there's a 1UZ you can be proud of!

-

yea little too far at this point but thanks for the offer.

Yeah it's a drive for sure.

-

I've got one up in Wilmington NC, a bit of a hike for you. It's rough but it's already set up for a SBC/TH350. Used to be a drag car so its pretty much gutted except for the dash and door panels, has a roll cage and some pretty nice stock seats also.

Let me know if you'd be interested. Heck if you wanted a driving one I could probably find a 305 and TH350 to through in there for fairly cheap, but it would definitely be over your $1000 budget then.

Jeremy

-

Jerminator,

Please do some research on the topic. PM me and I'll send you some links to do some basic research before trying to come up with a "hypothetical" dream flat plane V8. Nobody out there that I have seen, even in racing realms, uses a 0% counterweight on a flat plane V8 engine configuration. It would rattle to pieces in a short matter of time. Snap crackle pop.

If I were to build a N/A flat plane V8 engine, it would be in the 3.9L-4.1L range with a short stroke and about a 93-95mm bore. Aimed for about a 340-380hp range and rev to 8500-9000rpms.

A forced induction version would be around 3.3-3.5 liters. Aimed for the 650-800hp range to be realistic. (100hp per piston is not too heavy for a purpose built engine)

Nissan's R92CP with a flat plane V8 was set at about 940hp for races and 1150hp for qualifying. I know there are some pretty crazy videos of its qualifying runs on youtube...

Hey what happened to not arguing about counterweights anymore? You must have missed the part where I said I was certainly never going to design a 0% crank. Though I guess for the sake of continuing this argument, as you seem to want to, I should say that I could successfully design one. No I am not a crank designer, just an engineer.What was the displacement of that Nissan engine? N/A?Gollum: If my old redneck of an uncle can build a 350 that runs at 9000rpm for his dirt track car then you can certainly do it. Crower, Jesel, Isky, and Ferrea should have everything you need.

-

Jerminator, lets not get all up in a wad about counterweighing.

The SBF has better distributor placement for one. Also a smaller bore which is better for a high reving, small bore, small stroke, V8 Braaaaaaaappppp motor.

Agreed, no sense in arguing about counterweights when you will probably never build a 100% counterweighted crank (unless you're really going for longevity) and I certainly have no reason to build a 0% crank.The distributor placement is a valid point but I would almost certainly use a crank-trigger and coil-per-cylinder on this hypothetical engine as I've never cared for Chevy distributors.Somebody is going to have to explain what is meant by 'small' V8. Are we talking 2.4L F1 sized motor, or 4.0L Toyota V8? I think a 4.125 bore on a Chevy 'aurora' block with 8.3'' deck and a 2.5'' stroke makes for a great motor that you could rev to your hearts content. But then again I'm more interested in making power (hence the big bore) than revving over 10k.Gollum:I don't blame you for being a ford guy. I'm a hard core Chevy guy but it always ends up when I want a good reliable daily driver I roll away in a Ford.

-

I figured once I get the specs I'm looking for on the ford small blocks (5.0 in particular as they're everywhere) then I'll spent some time at home working on replicating the block and designing a flat plane crank. I wouldn't really be doing this to actually put it into production, but simply for the entertainment and education factor it presents. It's something interesting enough to keep me working with software I don't completely understand and helps me grow in many ways.

Your design is in many ways far superior to mine.

I must say I still wonder if a 100% counterweighted crankshaft would be necessary, though I understand why it's much safer. Though if we're taking an american V8 and shortening the stroke down to 2-2.5 inches then it can be a pretty light crankshaft ANYWAYS. Reving to 15k shouldn't be limited by the crank...

I don't think he ever meant to say 100% counterweighting was necessary. I'm curious as to why you would choose the SBF over SBC? We all know that a SBC pushrod motor can work at 9500rpm (possibly higher) but maybe the SBF can too?15000 rpm is a lengthy goal. I believe the Chevy blocks failed when they were tested that high in the 80's (something about cylinder walls collapsing).

-

Once again I'll say: find some books on crankshaft dynamics and read them. There is a lot more going on than you realize.

Oh I doubt it's that much more than I realize. I have no doubt of the benefits (and in the need of longevity the necessity) of counter weights, I was just proposing that in a boxer eight they wouldn't be absolutely necessary. Bearing life would be awfully short though, and I don't think 4340 would be quite as rigid as you would need it to be.But then there is always the 360 degree crank that would have even less need, but that is getting counter productive in terms of engine speed.

-

Crankshaft counterweights are a must. Before talking about not having counterweights and having an uber light weight crankshaft, one should read some books on crankshaft dynamics.

Even with a boxer engine?

-

Why don't we just use boxer engines, then counter-weighted cranks become unnecessary. Porsche sure did well with their 917/30. I believe that was a turbocharged 5.0L flat-twelve, making upwards of 1400hp in qualifying trim if I'm not mistaken.Maybe not the pinnacle of low maintenance, and certainty not an easy package to cram into our little Z cars....what was my point again? Oh yeah, 1400hp!

Exotic "SOUNDING", high revving V8! Read "ENTIRE" thread before posting!!!

in Other V8Z Tech Board

Posted

That FSAE car is absolutely impressive. I wonder what kind of power it would make if it wasn't limited by FSAE rules, I believe the intake diameter is cut down to 20mm.