Turbo6.0

Members-

Posts

72 -

Joined

-

Last visited

Turbo6.0's Achievements

-

Project 1973 240z, LS/T56, S14 Suspension, Tube Chassis

Turbo6.0 replied to Turbo6.0's topic in S30 Series - 240z, 260z, 280z

I was itching to see this thing on the ground so earlier this week I got it done! I also tacked in some door bars but I might be changing those in the future. -

Project 1973 240z, LS/T56, S14 Suspension, Tube Chassis

Turbo6.0 replied to Turbo6.0's topic in S30 Series - 240z, 260z, 280z

I decided to build a custom front sway bar that integrates into the frame. I purchased the splined bar and arms from speedway engineering. They offer MANY different options for just this type of build. The arms were straight when I bought them so I used my buddies iron worker for the bends. -

Project 1973 240z, LS/T56, S14 Suspension, Tube Chassis

Turbo6.0 replied to Turbo6.0's topic in S30 Series - 240z, 260z, 280z

Y-pipe from headers to the turbine inlet built and welded. Just need to add the wastegate(s) Full 3.5" exhaust with kooks "muffler". I am not sure how the exhaust will be exiting. I am considering 3 different options. High exit through the fender, low exit through the fender or removing the rocker panel and running a side pipe under the door. -

Project 1973 240z, LS/T56, S14 Suspension, Tube Chassis

Turbo6.0 replied to Turbo6.0's topic in S30 Series - 240z, 260z, 280z

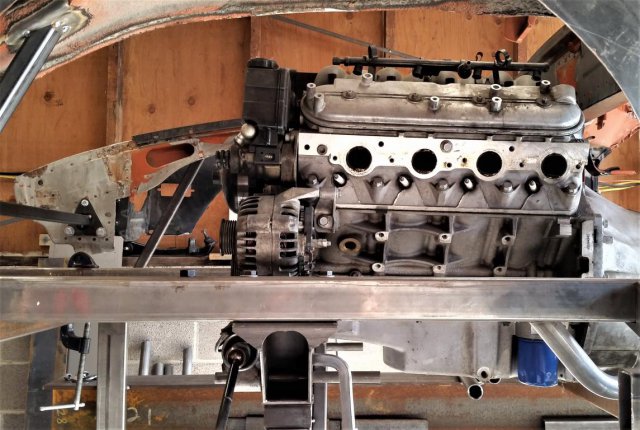

Once I finished a majority of the welding on the cage I decided to switch gears and start building the hot side of the turbo system. I built a mock up mount to hold the turbo in place. I upgraded the intake to raise the throttle body a little but also because it looks a lot better than stock. I am building the headers out of 304 stainless. The head flange is 1/2" thick and the tubes are all 14 gauge (.080) thick. Driver side Passenger side Headers all finished! -

Project 1973 240z, LS/T56, S14 Suspension, Tube Chassis

Turbo6.0 replied to Turbo6.0's topic in S30 Series - 240z, 260z, 280z

After looking at a few options I decided to go with a Kirkey "drag race" seat. I was blown away by how comfortable the seat is! At this point I felt like a majority of the main structure of the cage was done so I decided to remove the body and start welding everything Chassis stripped down and ready to weld! I also added a few removable supports from the rear of the shock tower to the firewall. -

Project 1973 240z, LS/T56, S14 Suspension, Tube Chassis

Turbo6.0 replied to Turbo6.0's topic in S30 Series - 240z, 260z, 280z

Removed the front structure to make way for more tubing! I built a mount to hold the front suspension in place First shock tower tube in place Both front shock mounts tacked in place along with a bunch of supports. I decided to swap the mustang steering rack out for a 240SX rack which was a MUCH better solution for me. -

Project 1973 240z, LS/T56, S14 Suspension, Tube Chassis

Turbo6.0 replied to Turbo6.0's topic in S30 Series - 240z, 260z, 280z

Lots of progress over the last couple years! Main hoop mocked up Rear cage structure and coilover mounts going together I also made some changes to the rear subframe structure while adding support for main hoop and harness bar Added some bracing for the shock towers. You can also kind of see the A pillars and dash bar -

Project 1973 240z, LS/T56, S14 Suspension, Tube Chassis

Turbo6.0 replied to Turbo6.0's topic in S30 Series - 240z, 260z, 280z

I really like this bender! I looked at many different benders before deciding on the JD2 and I couldn't be happier. This unit has some unique features, it's easy to upgrade and the die selection is HUGE. I also have the "Beast" notcher from JD2 which is probably one of the best fabrication tools that I have ever purchased! -

Project 1973 240z, LS/T56, S14 Suspension, Tube Chassis

Turbo6.0 replied to Turbo6.0's topic in S30 Series - 240z, 260z, 280z

-

Project 1973 240z, LS/T56, S14 Suspension, Tube Chassis

Turbo6.0 replied to Turbo6.0's topic in S30 Series - 240z, 260z, 280z

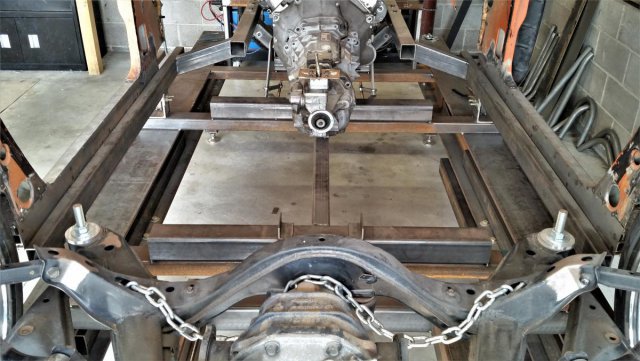

I cut out the rusted rocker panels and installed a new/modified set from Z-car depot. I filled the inside of the new rocker panel with 18 gauge sheet metal to allow it to sit flush against the new 1.5” x 3” rectangular frame rails. I finally bought a tube bender! It's a JD squared model 32. Now that the perimeter of the frame was in place I started on the trans tunnel using 1.5” DOM tubing. I tied the trans tunnel to the perimeter rails with more 1.5” DOM. The front and rear tubes fit to the underside of the frame rails and will also act as jack points. The center tubes are bent so that the end is flush with the bottom of the frame rails. -

Project 1973 240z, LS/T56, S14 Suspension, Tube Chassis

Turbo6.0 replied to Turbo6.0's topic in S30 Series - 240z, 260z, 280z

I started building the front frame rails with 2.5 x 2.5 square tube. I decided to build a new front crossmember to fit the 240SX control arms and a mustang steering rack. I will need to build a new bracket for the alternator to clear the steering rack but everything else seems to fit nicely and the motor sits almost completely behind the front crossmember! I also picked up a set of drop spindles. -

Project 1973 240z, LS/T56, S14 Suspension, Tube Chassis

Turbo6.0 replied to Turbo6.0's topic in S30 Series - 240z, 260z, 280z

That was my reasoning as well and I feel no remorse! Killer build you got going there! Skyline motor? I have not weighed them but they are on the heavy side. I will have to find a scale and post up the weight. -

Project 1973 240z, LS/T56, S14 Suspension, Tube Chassis

Turbo6.0 replied to Turbo6.0's topic in S30 Series - 240z, 260z, 280z

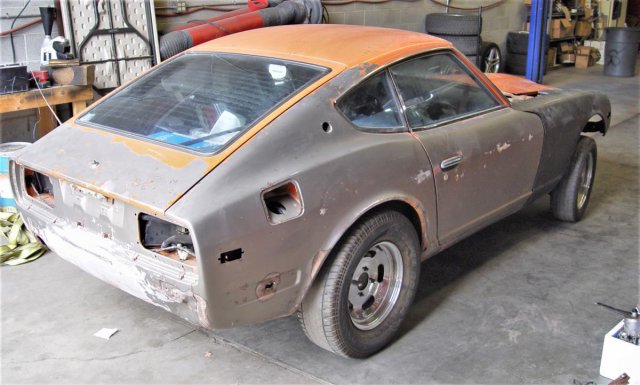

Thanks for the link I will admit that I kind of felt bad cutting up a such a solid car but I got over that quickly! I did save all of the good metal to sell or to use on a future project. -

Project 1973 240z, LS/T56, S14 Suspension, Tube Chassis

Turbo6.0 replied to Turbo6.0's topic in S30 Series - 240z, 260z, 280z

I built an adjustable fixture to hold the 240SX subframe at ride height. Tires are Nitto NT05 275/40 front and 315/35 rear. For wheels I went with a set of the American Racing VN477 with reverse barrels and custom offset. 17 x 9.5 up front and 17 x 11 in the rear. The current plan is to build a set of 911 style flares out of steel and weld them or out of aluminum and rivet them in place. -

I started with a 1973 240z for the body, LS1 & T56 out of a 2002 Camaro, 240sx (S14) front and rear suspension and will be building a tube chassis to tie it all together. Here is the car the day I got it. Relatively rust free and very complete. I decided to build a chassis table out of an I-beam and 3 x 3 square tube. I will also be adding casters to the table at some point. After a substantial amount of cutting on the car I mounted it to the table with some simple pinch weld clamps.

.jpg.8481c5eabaab3575e1b23cbd089fc388.jpg)

.jpg.f643c761a5a4108293a786c6512aaf58.jpg)

.jpg.368a24e0620c379df49949ace4d3cf2e.jpg)

.jpg.0fb987a23b792a31fb1ffb5e5ae2c1ce.jpg)

.jpg.43924586b6134e071d0d8a5853a3b145.jpg)

.jpg.42194d41e6980eac1c780139a58c365a.jpg)

.jpg.d9ab69e3e0c7a33b1445a3ead4b6f4ed.jpg)

.jpg.9f914fbb7027e93f295ae94909ce259c.jpg)

.thumb.jpg.1686a87a43944de4e137d9a1bc6b6d84.jpg)

.jpg.17e7c9c5c7d5fd384e6201b3aa1574c3.jpg)

.jpg.9abdb71461e989ca1f1381b3d95535f8.jpg)

.jpg.796852a936a08246249ec1baf5c839b3.jpg)

.thumb.jpg.5a9a13efc1035181937a5185d45d5674.jpg)

.thumb.jpg.1c62e6242887e9a3078327eb1f8eed4a.jpg)

.thumb.jpg.fd3978fc202c9931b9738c3b3e7690ec.jpg)

.jpg.fb952846feadff8cf27c03f343e6078e.jpg)

.jpg.4f743bef1b1281a11f2781c2ba2d4eed.jpg)

.jpg.f12b9e86414d42d781c3a64442358d53.jpg)

.jpg.ca2a70671f68a7a492d64aff2b238b50.jpg)

.jpg.5e10d8596f11c675e65435ed6db33049.jpg)

.jpg.8c82c7c502311806f7e4b3110c88c1f1.jpg)

.jpg.5566e812d069ea240b8a90bdf695360e.jpg)

.jpg.b76d62627843eaa46ce32a67b00cb5cf.jpg)

.jpg.5741b96abb12bc31430979cd534f17f3.jpg)

.thumb.jpg.e8090b74af623f6572054010826ae180.jpg)

.thumb.jpg.1f7b9e71ffef394b64deb379bcb458b9.jpg)

.thumb.jpg.bf6fc85bef13e1372daf04d2f8018212.jpg)

.jpg.9790a1428a99622d5c3cb4a573cc3b39.jpg)

.jpg.4ea2a77312ad1792020f5edc07d1008f.jpg)

.jpg.5acdbbc5b5d4443d35fb57c97fcfab62.jpg)

.jpg.1ed5561f1dd640a8015c9f7909a40c95.jpg)

.jpg.bf8d1a628460cece05b457b90fb88cd8.jpg)

.thumb.jpg.c30f2bbf3551dd06ee967e3aa9fb58e1.jpg)

.jpg.a54fd7df85b2fd105aff5f6d376e49e9.jpg)