-

Posts

269 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by tec280zx

-

-

-

Just use s14 coilovers so you don't have to modify the strut towers

-

Looks good, but yea the front does seem a bit high. Have you driven it around yet? Maybe things have to settle. Happened with mine. Car looks good though, got any more/better pics?

Heres an old pic of mine with Tokico blues after a few months of driving. Seems to have a bit more rake than yours.

-

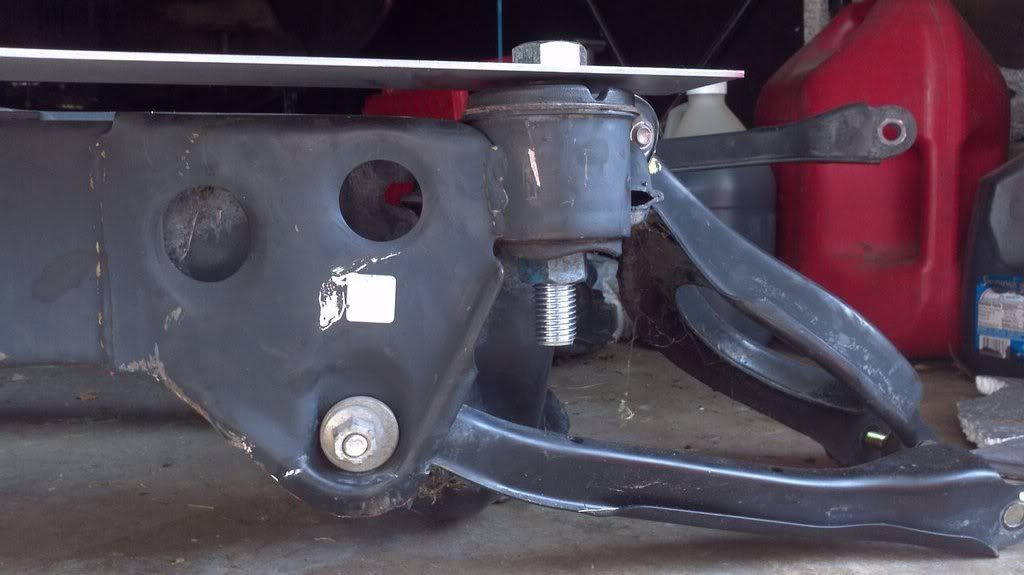

Front mounts tacked on for test fitting. So far so good.

Probably gonna need a .750 to 1.00 spacer for clearance. Maybe not though.

Crappy pic but here is how it sits for now. Many tweeks still needed. Hard to get good photos as I'm working out of a 1 car garage.

-

A little peek at the front mounts. Can't get the subframe all the way up yet because of the fuel/brake lines. I still need to sort that out.

3 in tube will be welded to the subframe at these locations.

Problem area. Need to relocate this little cluster of fuel and brake lines. Once thats done I can move the subframe all the way up. The transmission tunnel may need to be massaged a bit to get it all the way up.

-

Pull the hood, front bumper, and radiator and sit cross-legged in front of it...like working at a bench, perfect height!

Yep, that what doing right now. Got everything out of the way so I can dig in tomorrow.

-

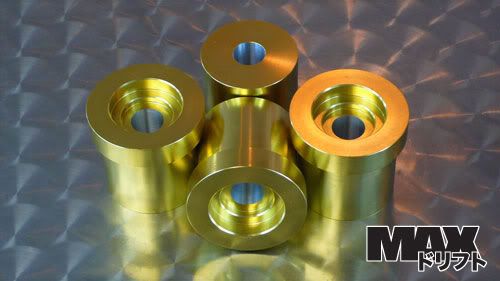

A little progress so far. Gotta loosen up the rust on my welding, but heres what I've got so far. The gold colored spacer represents the subframe bushing. Same insert actually.

-

Its been awhile, but I don't remember having to mess with the screws to get the steering wheel off. I know I had to do that to remove the lock assembly, that sucked. Should be able to just loosen the wheel nut and remove. Can't answer the spline question though. Just try the fiero one out, you never know. But it probably won't fit.

Getting the wheel off is a pain though, I just had a flashback about that from when I installed my momo. Good luck

-

With everything being solid mounted I'm glad this won't be my daily driver...

-

True, very few of our roads where I live are smooth. I might stitch weld, clean, paint and call it a day.

-

What do you guys think about doing some bracing like in these pics? Overkill? I think I might do something similar plus stitch welding since I have the subframe out. Got my welder back yesterday btw, yay.

-

BPR6ES is what run in my Z too.

-

Hello Gents!

Don't have access to my Z right now and I need some measuring help for something I'm working on.

I need the measurement in inches across the back hatch window, at the top. Just the measurement on how wide the glass is at the top.

Any help would be greatly appreciated!!

Not sure exactly where you need the measurements, but I measured across the top in between the weatherstripping and it is 37.75 in

The actual width of the glass is around 39.25 in.

Hope that helps.

-

I can check later today if nobody responds sooner.

-

Also to bring up the S13 R33 comparison again I don't think I will have as much clearance issues on the front with the R33 rear. As the LCA front mounting point on the R33 does not stick up as much potentially hitting the frame rail. Also because I have a S13 rear in the garage at the moment it really looks that extra bit wider :S so guard clearance is going to be fun

That's interesting about the mounting points being different. Sounds like the r33 might be similar to the z32. I've read the track is much wider than the other subframes.

Does guard = fender? If so, then yea, have fun. Carbon fiber zg flares might look good on my flat black Z.

-

It is around my area

Are you intending on stitch welding that to your chassis rail? Also to bring up the S13 R33 comparison again I don't think I will have as much clearance issues on the front with the R33 rear. As the LCA front mounting point on the R33 does not stick up as much potentially hitting the frame rail. Also because I have a S13 rear in the garage at the moment it really looks that extra bit wider :S so guard clearance is going to be fun

Yea, my plan is to weld the bolts to the 1/8th strip, then weld that piece to the frame. It seems like the easiest way to get it straight before welding. I'll mock up the front extensions then stick the cross piece with the studs into the subframe before welding. That way I can move the subframe around and make sure it is as straight as possible before I tack it up. My friend borrowed my Lincoln welder to stitch weld his track car, but I'm getting close to needing it back. I hope to have it in the car in a few weeks then I'll need to save up for new wheels. Oh and I need s14 coilovers since the s13 are too short. Hard to find just the rear, I just need something to test it out so I'm not trying to fork over the money for a new set just yet.

-

Lol, guilty as charged. I though that was a requirement for hybridzers.

-

A rough first draft of the rear mounting.

-

Loose rotor maybe?

-

Definately. Here is some good reading from an R/C car manufacture but it directly relates to 1:1 scale cars.

http://www.teamxray.com/teamxray/showfile.php?file_id=6143

and a good reference to how much each item affects handling (eg what to change first for the largest effect).

http://www.teamxray.com/teamxray/showfile.php?file_id=2531

The R/C cars are extremely adjustable but if you are doing custom stuff things like the sub frame orientation roll centers will affect anti squat and anti dive, etc....

Wow, I didn't know those little RC cars were so involved! I never had ones that cool when I was a kid.

-

Fabrication/welding section may be the best place to go for good structural mod advice but to get a reasonable ride height the rear mounts should be up against the Xmember and not spaced down. Remember too that the angle of the suspension subframe front to back affects anti squat, generally speaking the lower the front/the higher the back the less anti squat effect. When doing this job its a good idea to be aware of the effect different alignments will have, it's not simply a 'how can I fit this' job.

Yes the alignment of the subframe will definitely affect things, I suppose it will be a lot of dialing in once I mount it. I plan to have the sub frame right up against the body of the car, its just a matter of getting things out of the way. Another issue now is the hard brake lines, specifically where the hard lines slit off to either side of the car. That piece needs to be relocated in order to get the front up another half inch.

-

For the plate that will house the new rear studs, what thickness do you guys think I should use? I have some 3/8 x 3 inch wide steel that I have lying around that I was thinking of using, but it seems like it might be too thick (and heavy). Never welded on the Z's chassis before and it seems pretty thin. Maybe more along the lines of 1/4 or so?

Also, I plan to get some solid aluminum bushings for the rear and have the machine shop bore it out for the 7/8th bolts to slide into.

-

The good thing to know is that the rear cradle mounts line up with the S130's rear Xmember, the one the diff mounts on. Having a rear structural member right where it's needed is a big plus for a lot of reasons.

Yup, it works out pretty good. You pretty much have to mount it right where the rear frame piece is in order to get the wheel centered.

-

Yes but there is nothing saying that you have to weld it on at the same angle as the Z31 guys do. I wonder if the front bracket could still be used just facing inwards instead of outwards.

I think at best this is a good refrance and the same affect could be achived using similar methods. (especially for Australians I think this could be "copied" and done cheaper than for us to buy one and have it shiped here)

True, there is definitely more than one way to skin a cat. I'll be doing the fronts a bit differently than the group buy linked above.

how to spend

in S130 Series - 280ZX

Posted

ebay intercooler, some piping and good connectors/clamps. Then work on a custom downpipe. I would say 3 in exhuast all the way back but your current one is okay for know. What boost are you running right now?