FlatBlack

-

Posts

1212 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by FlatBlack

-

-

Hello all.

Due to an unfortunate installation error, this happened:

I am on the lookout for a spare R200 rear cover, I was wondering if anyone had one laying around they'd let go for cheap.

Thanks.

- Mat

-

And that's all I got for yal today. If you managed to make it this far and actually read everything I thank you for caring about me(Or its probably just my car) that much. Look forward to more progess coming in the next few weeks, school starts back the 21st, and the Datsun will be up there(Hopefully lol).

-Will

I have to come to HBZ to see what you've been up to

Bring the Honda. DO IT. Or bring the Datsun and I'll drive the Honda up.

-

My "Gen 2" RBRyant stack ended up looking like this:

()()()()

With a stack height of 0.7240"

The bolts had about 0.75-1.0 turns to full tight.

My threads were SUPER buggered on the lower case - I had to go buy some 50mm bolts after spending ~2 hours yesterday tapping out the holes.

Stock are 45mm M8x1.25, the RBryant bolts are 60mm M8x1.25. I ended up with 50mm bolts, which added 5 threads into the case. I'm using blue locktite as well.

-

I took pictures of all the measurements I took, I'll try to get them up today, but all the info you need is in that spreadsheet:

I would need to know:

1) The "assembled length" in between the flats of those two "stars" when the diff is assembled.

I measured the height of the stacks:

Full Rbryant Stack )()()()()( 0.8875

Full OBX Stack )()()()( 0.8840

2) The "ID" of the lip inside the "stars" that would dictate the maximum diameter of the possible spring.

Largest Diameter:

ID Washer Retainer O 1.2620

Smallest Diameter:

ID Retainer "Lip" o 1.1390

**edit for pictures:**

RBryant stack:

OBX Stack:

Greater ID of washer retainer [or star piece as you call it]

Notice the variation from my measurement yesterday - I'd try to get something that would be right in the middle of the range between the greater ID and the lesser ID. [Maybe somewhere around 1.200?]

Also, JMort suggested leaving a washer in there to act as a secondary retainer for the spring if you went that route, I'm assuming to prevent the spring from accidentally coming off that retainer 'seat.'

-

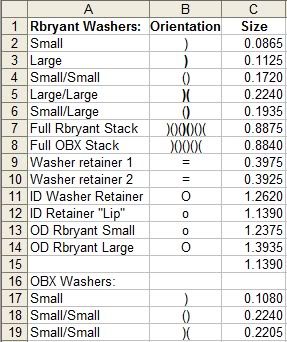

Measured the washers and washer stacks with some Mitutoyo calipers this morning.

Let me know if you need any other dimensions, I'm going to measure the casing, planetaries, and sun gears later this morning.

**All sizes are "flat height" unless called out as 'ID' [inside Diameter] or 'OD' [Outside Diameter]**

Rbryant Washers: | Orientation | Size

Small ) 0.0865

Large ) 0.1125

Small/Small () 0.1720

Large/Large )( 0.2240

Small/Large () 0.1935

Full Rbryant Stack )()()()()( 0.8875

Full OBX Stack )()()()( 0.8840

Washer retainer 1 = 0.3975

Washer retainer 2 = 0.3925

ID Washer Retainer O 1.2620

ID Retainer "Lip" o 1.1390

OD Rbryant Small o 1.2375

OD Rbryant Large O 1.3935

OBX Washers:

Small ) 0.1080

Small/Small () 0.2240

Small/Small )( 0.2205

fff. Formatting fail. Here's a screencap of my excel file.

-

Problem with a spacer is that you can't really have any pre-load. Not a terrible thing. Alternatively, I was thinking about some sort of heavy duty coil spring...and I mean heavy.

If anyone can measure the "space" where the bellville washers sit (length and diameter of the pocket), I can look up a heavy duty die coil spring that might work.

Mine is apart, I'll try to get some measurements when the new washers come in.

I'm assuming you want the length of the retainer set with the washer stack installed?

-

What axles are you using? Also, will you post your washer stack orientation? Thanks.

240SX CVs [this is in my S14]

Go here:

http://rbryant.freeshell.org/obx_washers.htm

And scroll down to the "R200 Differential Only" section. It's a good write-up.

-

Just got one photo below courtesy of FlatBlack.

Where did the watermark come from? lol

I'll be up at the shop today if you need me to grab anything, but I don't have tools with me.

-

At it again...

Took it apart today, and flipped the gears. Just waiting on the RBryant kit to get here, then I can ditch the stupid welded R200.

Oh, and one of the bolt came pre-stripped :unamused:

-

Med School happened.

He's running MS3 on a M104 sans CIS in his 190 IIRC.

-

Can't wait to see this come back to Fayetteville with an LS1!

-

Currently working on the 240SX, and I'm needing to lower the CLT filter value, but my current version does not allow me to use the Advanced settings.

I flashed my laptop's OS, so I lost the older version that had an open VE Analyzer.

Hoping someone here could help me out and send me their MLV program that has this feature.

My address is flatblack280 at gmail

Thanks.

-

I've had no issues with my flipped gear/upgraded washers/bolts OBX unit, and I'm running 275s on it [if that makes a difference]

My diff has Rbryant's new washer stack with the larger washers.

-

I think subtledriver said alot of man hours in his first post. With the cradle/mount installed with the engine by vildini motorsports(great place to get it installed). It took me a total of three whole days(estimating) to get mine running, Ka-t and all. It was a great experience, but i do miss the sound of the l24, all i hear now is an open wastegate. Subtledriver looks pretty well sorted out. Cant wait to see the next project.

Going to second this one - if noise matters to you at all, you won't be happy.

I dearly miss my L28ET exhaust note, even though my friends said it sounded like a UPS truck. Inline 4s leave much to be desired in the sound department.

-

Yeah... def bought 4 17x9.5s for my car, I hate the staggered look.

Check out Ness's LS3 build - he had 255s on 17x9.5 RB-Rs and they looked like sh*t, super stretched. He took them off it was so bad.

Pretty sure sticky280ZX likes the herraflush look, so anything over a 225 on a 9.5 is going to not looked stretched to him lol

*edit* found the picture

http://forums.hybridz.org/index.php/topic/80157-ls3-build-thread-z-vette/page__st__60

If you want a small tire, why not just buy a 8" wide rim?

-

This is one of the most under-rated engines, ever.

I picked up a S14 with a KA-T, and I loooove it. I'm running E85 and soon will have megasquirt installed [definitely ready to ditch the SAFC2]

-

There is nothing "school" about college anymore.

Agreed.

Clepped [sp?] out of Comp 1 and 2 at LSU from my ACT scores, UA forced me to take them, even though I had "pass" credit for both, and a really high English ACT score...

Go to a Comp 1 class at a public University. I thought it was amusing how a student could be that dumb and be attending college, but as the semester dragged on, it was just scary/sad.

I was being re-taught things I had learned in Middle School - these people shouldn't even have received a High School diploma!!!

Kinser - keep the faith, my good buddy, you'll be fine. I didn't really get as frustrated as you are until my 3rd year. Stress kills, man. These are just hoops you must jump through to start a career. A Bachelor's degree is the new High School diploma, as sad as that is.

-

I can swap between MS1E and MS2E by just swapping the CPU, but I used all GM sensors. It should be just that easy, maybe if you used easytherm and the stock sensor it could be disagreeing with you.

GM IAT and GM CLT.... 83 CAS dizzy, L28ET/P90A stock rebuild, 3" mandrel bent exhaust, Evo 8 FMIC with 2.25 pipes, VR4 390cc injectors. We're really close, actually - I thought you were N/A.

I'll try it later.

Would you mind emailing me your tune? flatblack280 at "google mail."

-

Went here [http://www.msextra.com/doc/ms2extra/upgrade.html] to download the latest MS2E code, and uploaded it onto his ECU.

He's running 3.2.1 now.

I don't know enough about MS2 to make older code versions work with this - this was not a problem on my MS1E install, everything went smoothly.

The test car is wired up and running on a L28ET MS1E setup with a 83 CAS Dizzy, and when I switch over to dudebrah's box, it doesn't recognise all the sensors. The DIYAT writeup shows the same relay board wiring harness for both MS1E and MS2E.

*edit* Linux?? Get Windows like everyone else, ya damn hipster.

-

I haven't been on here in forever, but I'm waiting on this trigger wheel - somewhat impatinetly

Thanks for workign on this for us Matt!

Some time ago, I remember seeing a "rack" for the LSX coils that bolts up to the passenger side of the valve cover - are those still being made? Whatever I would fab up will be horrendously ganky I think

-

Sign me up. Very reasonable price!

Will you have trigger settings for this wheel for MS1E?

-

What kind of track? Straight or curvy? For street/road race/autocross duty you might want to look at the Dunlop Direzza Sport Z1 Star Spec for about the same price.

They don't make Star Specs in 275/40/17.

I have some Kuhmo SPTs on my RBRs. They were cheap and have a decent treadware rating.

I'm going Nitto NT-05s next year [most driving is done on AutoX courses and driving to/from events, but I drive it to work some times]. But didn't get them now because I won't be racing again until next spring. The treadware is 200, which I will have burned off by next spring or summer.

I have some Nitto 555 on my GTO, but in 245/45/17. I have been quite happy with them.

I would have done Kuhmo XS in 275/40/17 if I was not on a budget right now. I've heard many good things about them, and seen some fast runs at local autocross events on them.

I've heard mixed reviews about the KDWs, but I wouldn't buy them myself, I think they are mostly for 'tire bling.'

-

What are you using this for?

-

I have been running my injectors with high-Z settings (aka 75% current limit) in Megasquirt, as the low-z settings wouldn't let the engine idle. Thoughts?

Keep all the settings on this stuff how it should be, I have blown drivers and fuses trying to "bandaid" problems like you are doing.

Glad you found the source of the problem. Make sure you don't have any air in the line from the tank to the fuel pump - I had that problem on the new 78, it would cause the pressure at the rail to drop to 0 very quickly after running.

If you need to take a break, take a break!! Don't get burned out, it's very easy after dumping so much money and time into a project like this. It'll get better when you hit full boost in third gear

WTB R200 cover

in Parts Wanted

Posted

I found out the Z diffs are not the same as the S14 diff.

Thanks everyone.