-

Posts

302 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Naptown Dave

-

Need the genius LS guy opinions

Naptown Dave replied to mattd428's topic in Gen III & IV Chevy V8Z Tech Board

Your car looks pretty mean already but 345s would be a sick addition, along with an 80mm turbo! -

Need the genius LS guy opinions

Naptown Dave replied to mattd428's topic in Gen III & IV Chevy V8Z Tech Board

Thanks Rebekahsz, I've been stuck working in southern GA for the last 3 months so I've been catching up on my hybidz reading! I'm headed back home on Saturday and am going to take a week off work to really get going on my Z. On the plus side of being down here I got a pretty good deal on a fresh T56 and got a set of Rota D2's for a song. The wheels are 17x8.5 with 245/40s. I THINK with a 20mm spacer they will fit. I started forming +2" wide rear qtrs to try to fit 295s but that may have to be a winter project and just get on the road I'm with you on keeping the tires inside the fenders unless its a baja truck. 345s? thats like 13.5" wide. Mattd thats what you should be running! -

Need the genius LS guy opinions

Naptown Dave replied to mattd428's topic in Gen III & IV Chevy V8Z Tech Board

Gotcha, I don't know that much about drag specific stuff. Am I wrong thinking you could fit a little fatter tire in the well? Or does the diameter tighten things up some? What do you run on the street/autox? I've been stalking you and wfritts for a while, love both of your cars. With a little luck I can get back up north this weekend and really get started on mine, I'm sure I'll have all kinds of dumb questions! Thx Dave -

Need the genius LS guy opinions

Naptown Dave replied to mattd428's topic in Gen III & IV Chevy V8Z Tech Board

Are they 15" wide? That sounds like a pretty good starting point! -

Need the genius LS guy opinions

Naptown Dave replied to mattd428's topic in Gen III & IV Chevy V8Z Tech Board

That would be nice, I plan on doing a 50's custom for the wife if the Z ever gets finished. How wide a slick can you get rebekahz? -

Need the genius LS guy opinions

Naptown Dave replied to mattd428's topic in Gen III & IV Chevy V8Z Tech Board

I found one on craigslist about an hour north of me for the bargain price of $1700! I should have asked the guy if he wanted to rent it to me -

Need the genius LS guy opinions

Naptown Dave replied to mattd428's topic in Gen III & IV Chevy V8Z Tech Board

Yeah I need to make friends with someone that has an english wheel. Anyone, anyone?? -

Need the genius LS guy opinions

Naptown Dave replied to mattd428's topic in Gen III & IV Chevy V8Z Tech Board

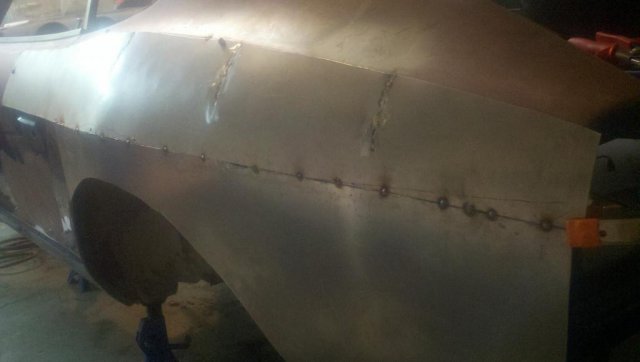

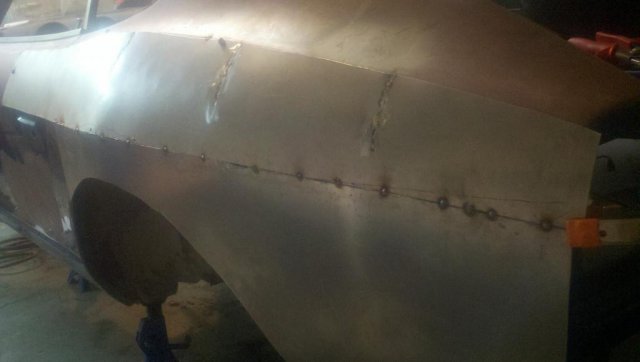

They are pretty rough right now but I don't have a whole lot of time into it. Basically I cut paperboard templates of the existing qtrs and added about 1/2" and then started beating them out with a poly hammer and pad using a profile gauge to match the factory qtrs. I had to make a couple shallow pie cuts to get the lenghtwise profile. I have a little more trimming and hammer work and then I'll hit it with a shrinking disk, hopefully I don't have to use a gallon of filler! -

Need the genius LS guy opinions

Naptown Dave replied to mattd428's topic in Gen III & IV Chevy V8Z Tech Board

I'm far from a genius in anything worthwhile but it would seem that flares would be the simplest option. I have put a little time in forming 2" wider qtrs. I have a long way to go on them but I think they will work out. -

Yeah, I assumed I would have to cut some of the height out of the tubes in order to tuck the collectors up as tight as possible. My thought is at 200 bucks it's a pretty good start even if I have to buy some additional bends to fit. I have a mig welder and metal cutting bandsaw at the house and easy access to a tig welder and a non mandrel tube bender as well as other pipe fabrication tools. Are you guys running shorties or are there LT's avaliable? I'm trying to manage my costs on the things I can build so I can send more money to Texas Speed!

-

I am probably months from from needing to get my exhaust system started but while I am away from my project I'm doing all the 'bench building' I can. While ordering my clutch bleeder from Speedway Motors I noticed they offer a 1.75" LS header kit. http://www.speedwaymotors.com/Chevy-LS1-Header-Kit-1-3-4-Round-Port-3-Inch-Collector,33271.html I was wondering if anyone has tried this kit on their S30. I think my other option would be to find some F-body longtubes on craigslist and cut and weld to fit. I have worked for many years as a pipefitter/welder so any fabrication is not really a concern but by the time I'm working on the headers I should be close to finishing the build and probably will want to get 'em done asap. I am leaning toward the Speedway kit, if for nothing else than the builders pride, unless someone says 'yeah that kit is junk'. If anybody has any thoughts on the F body modded vs. the Speedway header kit let me know.

-

I painted my first car last fall, it turned out much better than I expected. All said an done it took about 80 hours to complete and around $800 for the gun, paint and misc. supplies (sandpaper). It was a Corvair Convertable so it's about the same size as a Z. The car had old laquer paint so I stripped it to bare metal to avoid adheasion problems. Here's a few things I learned; 1. Dust control 2. Dust control 3. Bug control Almost all the visable flaws I have came from dust or bugs.I swept my garage twice then put up plastic sheeting on all surfaces and taped and stapled all joints then vacuumed the floor yet I still came up with some dust in my finished product. It must have come from the car itself or from my clothes (I didn't wear a tyvac suit). After my second clear coat I noticed a giant mosquito stuck to my hood! I painted at night and the lights in my garage drew bugs in. 4. Ventalation I had a box fan with a furnace filter upstream set up to blow air into my paint booth. It was not enough. While I was clear coating a dense mist almost obscured my vision. Next time I will rent a ventalator or two like they use to dry wet carpet, they move a lot of air. 5. Practice Watch a lot of utube videos and practice on whatever you can. I had an old washing machine that is now a nice silver/blue semi metallic. 6. Don't do a metallic for your first paint job. The counter guy chuckled at me when I told him my paint code and it was my first time. It turned out well though, a little 'tiger stripe' on the hood where my coverage wasn't perfect ( I'm the only one that sees it). Refer back to #5. 7. No paint can cover poor prep. Prep is where 70 of the 80 hours went. 8. Beer will NOT prevent paint job issues, only ease the pain once it's done I will definely paint more cars, the diy pride is really worth the work. I crused the local Maaco holding area and their work looked flat and lifeless where mine shines.

-

Pic request: 23" tall tires on an S30

Naptown Dave replied to rturbo 930's topic in Brakes, Wheels, Suspension and Chassis

I'm fabricating a +2" widebody with a very small inner lip so I'm not too worried about the outboard side, more about the inboard. It's tough to find much fat rubber in 16" so it looks like 17" is the way to go. I'd love to fit a 275/40 that is 25.7" diameter. Planning a 1.5" drop as well. I have a LS1/auto sitting on my hoist waiting to go in. -

Pic request: 23" tall tires on an S30

Naptown Dave replied to rturbo 930's topic in Brakes, Wheels, Suspension and Chassis

Domsz Are you running 527's? If so did you have to add a spacer for the back? I've been looking at wheels all day and keep coming back to the XXRs. I would want to do the 17x9.75 with a 275 if they fit but that's probably a 1.5" spacer and I don't know how comfortable I am with that. How much clearance from the suspension do you have? -

I have started an all metal wide body rear mod. Fiberglass would probably be easier but I've been involved in the welding industry for more than 20 years so 'glass wasn't really an option. I like the Subtle Z look and really want to put some fat rubber to connect my LS1 to the ground but I don't really like the abrupt bump out at the back of the door. I started the transition about 6" in front of the door handle (shaved door handles are also on the menu). I am looking at adding 2" per side and transitioning back to the factory rear end.

-

Thinking of swapping the tails.

Naptown Dave replied to The love of JDM's topic in Fabrication / Welding

Here's a pic of my work in progress. It will be flat black with recessed LEDS. Except for the fuel filler all the back panel structure is intact so the factory lights could be reinstalled. I will also be building an under pan to hide the gas tank and have the exhaust penetrating the rear valance. -

Had sunroof, now hole. Patch hole or replace roof?

Naptown Dave replied to ccwade81's topic in Fabrication / Welding

I have to ask, why is it an issue to just patch the hole left by the sunroof? Are you guys worried about not maintaining the arch of the roof or the possibility of 'oil canning' or is there a structural issue? I removed the old sunroof, complete with the alien sticker, cleaned up the hole itself and the surrounding metal and then traced a pattern on poster board. I then transferred the pattern to the doner roof in the same position and cut it with a little room to spare. I then carefully trimmed the patch to a consistant 1/32" gap and tacked the piece in. I completed the weld,just tacking and jumping from place to place to minimize heat build up. After completing the weld I sanded most of the weld reinforcement and did some initial hammer and dolly work. It still needs some additional sanding and hammer work but looks like after some minor filling and blocking it should come out fine. I am going with a matte or flat paint, by the way. -

Will these wheels fit

Naptown Dave replied to stony's topic in Brakes, Wheels, Suspension and Chassis

Stony Did you ever take a look at the XXR wheels? I'm interested in the same ones and also have the stock struts (for now) but will have 1.5" flares s well. It sounds like zero or negitive offset may be a better bet for me. Let me know if they worked out. Thanks -

I am away from my project right now so I'm doing some bench building. Does anyone have any experience with lowering a 280 with QA1 springs? I may end up installing adjustable coilovers but in trying to keep within my budget and completion goal I think lowering springs are my first step. I would like to drop the car 2" and think spring rates around 220 and 200 would be a decent ride for a non daily driver. I checked the FSM for the stock free length and lbs per inch but don't have any idea how to calculate the new springs length to get the results I want. If I get close to the stance I want I wouldn't have a problem sectioning the strut tubes to fine tune the height as needed, avoiding the cost of adjustable coilovers. Also any recommendations for 2" shorter struts?

-

Had to share spindle pin love story

Naptown Dave replied to str8pipez's topic in Brakes, Wheels, Suspension and Chassis

After reading all the horror stories about pulling the pins I rolled up my sleeves to give it a try. The first one practically fell out (slight exageration). The second one, not so much. 18" breaker bar, home made puller broken and rewelded once, 3# hammer, mapp gas and pb blaster fumes it is out-and destroyed.