-

Posts

664 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by Jesse OBrien

-

-

I suppose I hadn't really considered it before today, but Mighty Car Mods' recent article got me wondering who else is creating video content on YouTube.

Most of our build content on Driven Daily has been going to our YouTube channel and I've been thinking about where we go from here. The hard part is establishing a consistent schedule with decent production quality, and I think we've finally nailed that down. What happens after that, though? There are collaboration opportunities with other channels, potential for sponsorship, paywalls, funding more interesting episodes, etc. I'm very interested to see how more developed channels have solved these kinds of problems and complications.

-

There have been several chunks of progress on several parts of the build, but I'm pretty focused on finally wrapping the quarter plugs up so we can pull a body mold.

This will get us back into 'FLUSH' territory ... possibly a little cheeky.

-

Still just "Taking the piss"

... but I have more cardboard, foam, and fiberglass to make sure everything fits just so.

-

Yeah, it's taken awhile to get some first-hand experience together, but after a few seasons of hillclimbing and autox here's what I've learned:

QuoteUltimate grip doesn't matter unless the car is balanced.

I ran my Miatas with an array of tires, starting with Kumho XS in 205 width on stock tires. Then I went up to 15x8 on 225-50R15 DOT tires. Those went on my na8 Miata, and I decided to bump up to the new 245-40R15 DOT VR-1 tires from Maxxis (mostly for the gearing improvement). After some mounting issues on my 15x8 wheels (they really belong on wider wheels), I settled on 225/45R15 v720's for the 1.8liter Miata.

When these 15x13 m28 throwaways came with the box truck I bought, I was absolutely blown away by how lightweight they are. Spun wheels are similarly inexpensive, and I can get qualifying take-offs cheap through a hillclimbing friend. That seems like a good reason to give them a test, I'm a big fan of reducing unsprung weight while increasing mechanical grip. The 10" wide would probably be a better idea for what I'm doing, but we'll cross that bridge when I actually purchase tires.

-

I'm just going to leave this here.

Tire fitment mockup (27 tire diameter, 13 tire width, 15x15 wheel):

-

It's been pretty quiet around here lately, so here's a new episode for you fellows.

-

I like the lights in the box roof. Right now, there are 21ft of LED strip in there, of which around 15ft still work after being abused quite a bit. I had always planned to update the wiring for them when I removed the plywood on the walls, so I only did a temporary zip-tie installation. Instead of updating this installation, I thought I'd go for something a bit more modular ... and add a bit more lighting as well.

Fast-forward a bit of measurement and math, and I've spent around $50 buying lighting replacements. The end result is 10 1meter strips that fit together pretty much perfectly. The aluminum channel acts as a basic heatsink, the lights are insulated from shorting out on it, and the light is diffused (not a lot, but it's enough). The aluminum channel makes them rigid enough that they could easily be moved and installed elsewhere at an event.

I still need to consider how I want to mount them to the roof spars (ideally to the canopy, on jackstands, etc as well), and solder on the XT-60 connectors I've standardized on ... but this represents a serious lighting upgrade.

To support that upgrade, I've added another group65 battery to the box truck. Each group65 battery is rated for 85aH, so that's around 2000 watt-hours (not counting the box truck primary battery or generator for recharging). With all of these lights running at the same time, they draw a little under 200w ... giving me around 10 hours of continuous use. I'm definitely planning to run some other accessories on these, so the generator is still a must-have, but that's pretty promising.

That 365mm is EXACTLY what I'm looking for. Is the 205mm the lowest surface of the corresponding front mount?

-

I spent some more time working on my box truck today, and removed the remaining murderwall plywood then reorganized, straightened, and bolted down everything else back there. The etrack on the floor will probably end up on my trailer, but it could make its way to the walls after I've insulated and recovered them. We'll see how it plays out, but either way I love that stuff.

The driver's seat is finally getting replaced. I don't know if I already mentioned it, but the roofing tar in this thing got EVERYWHERE. The seat was disgusting. My favorite caption I've seen so far:

Driver's seat before and after blowing a brake line.

-

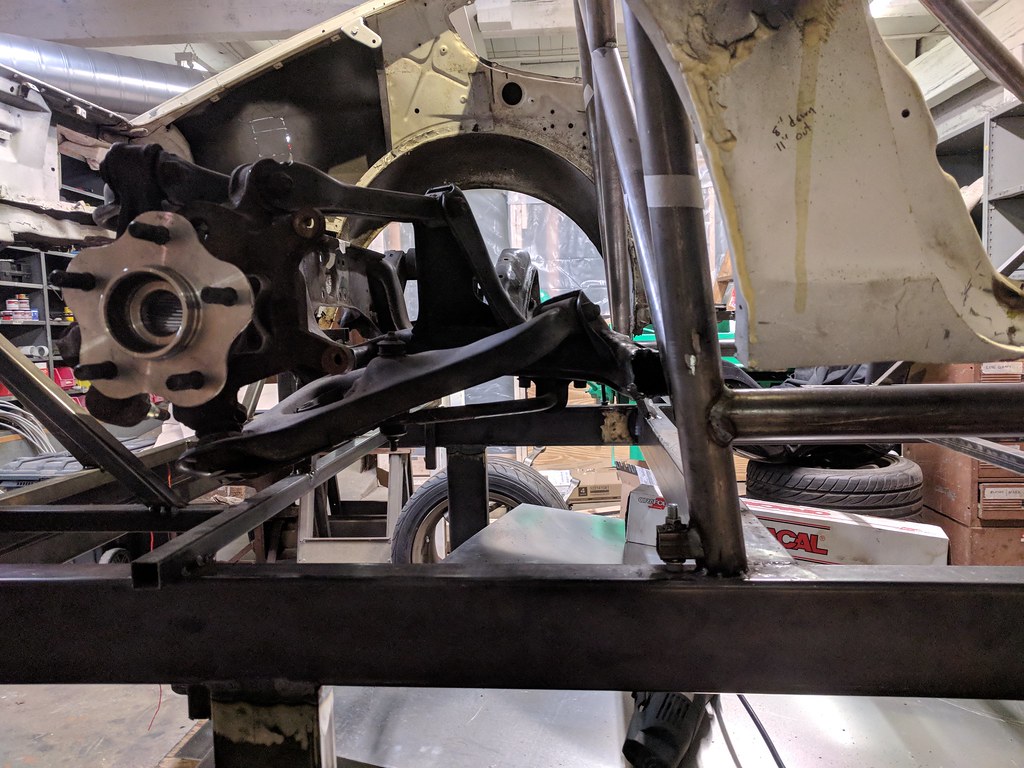

The rear subframe is crudely jigged together, and should be ready to rock in the morning. Centering it, defining my ride height, and setting the pitch required a lot of braining.

Based on the measurements from a friend, the LCA should be at a ~14 degree layback. I'm at 13.75 degrees on both sides, and have decided to call that good. At some point, I'm going to move the arm pickup points anyway, so this'll have to do to get me started. -

I've been banging on the rear suspension quite a bit, building a new jig and chopping bits out. I'm not quite ready to start welding things together, so here's an update on my race support vehicle instead.

We finally scrapped the murdervan-themed overhead door.

We replaced it with some steel-framed swinging doors, which are mostly-good. I didn't realize that this latch was designed to be per-door, not shared across the two. It works for now, but I really need to add a second set of lights. I'll probably add a ridge around the edges of it though. One of the best things about it is that the doors swing ALL the way open (270 degrees) to sit flush with the sides of the box. Pretty snazzy, I'd say.

Swapping the doors negated the need for the overhead door tracks, which negated the need for the murdervan-themed plywood lining the insides. I removed one of them so far, and have started reorganizing a bit.

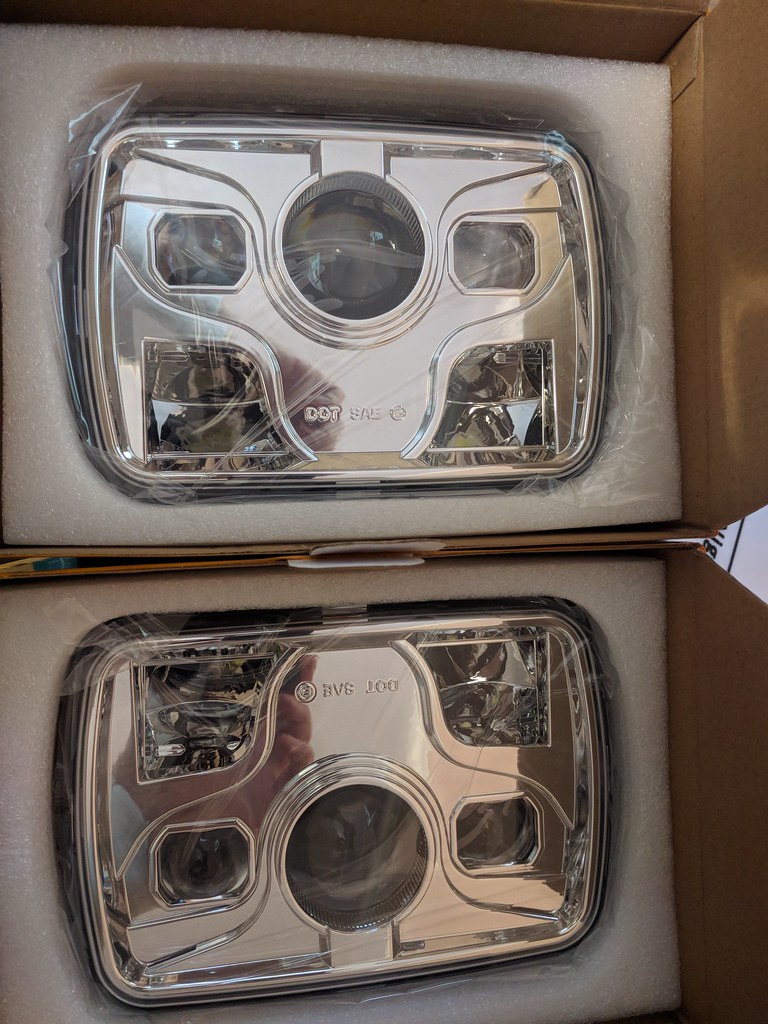

One of the headlights died too, so I decided it was time to upgrade to LEDs. Definitely a worthwhile investment.

Finally, the interior dome light had died at some point, and it was time to replace it. Rather than installing a new mouse-graveyard though, I thought 1/4amp worth of LEDs would be more reasonable.

The result: I could probably skip having headlights now. It's pretty sweet. I'll have some more updates coming over the next month or so, but the more chatter that happens on here the more I'll remember to post. I can't wait for the 2018 race season, and really want to have my support vehicle 110% situated for it.

-

Don't lose momentum now!

-

That 365mm is EXACTLY what I'm looking for. Is the 205mm the lowest surface of the corresponding front mount?

-

Extremely helpful. Even better would be measurements to the bottom of each subframe-to-chassis mount. That would give me the angle of inclination as well, which would be SUPER helpful.

-

We have some catching up to do, but the video series is finally getting edited now!

https://www.youtube.com/watch?v=yMzfChavIsg -

We've been hard at work getting ready for 2018. The Datsun needed the rear wheel centerline moved back 4" in order to clear the main hoop position. I finally made time to mock up where everything should sit, and finish the rear quarter panel profiles. I think it still looks like a 'natural' location for the rear wheel.

This gives me around 6" of ground clearance with the suspension preloaded, which is perfectly acceptable in my mind. Using 300lb/in springs, that would give me 1500lb of load before things start to go a little wonky. With the pushrod setup that I'm planning on, I can tune it to dynamically increase spring rate toward the 'compressed' end of the cam travel too.

The cardboard template is reversible, so I can accurately reproduce the profile on the opposite side ... but I may modify the overall shape a bit before pulling a mold.

This configuration puts the fender line quite a bit higher on the body, and I have the option to move it higher or lower if I don't like the way everything sits when finished.

I'm putting off welding the rear suspension in until I have better calculations on what the static ride height needs to be with the stock control arm geometry. I'm probably going to have to move the subframe up a bit in order to keep the ground clearance I talked about earlier, and I can just chop off the OEM front mounts and weld it directly to the X brace if that's the case. It's good to be working on this again. -

I ended up winning the P4 class for the year in the Miata! Philo was a great time, and the weather was incredibly good.

The only problem I had was that CXRacing exhaust manifold. Several of the welds completely failed, and now I need to make a new exhaust for the Racing Beat manifold I bought to replace it. The $400 one lasted one race, and a friend has been racing for two seasons on the $150 RB model. Figures.

Now that the season is finished, I'm working on minor prep jobs ... like heat/defrost, winter tires, etc. The real goal for the winter is to finish up the box truck and get the Datsun ready to race in Spring.

-

It's been awhile since I updated over here, but the season has gone great so far. With the Miata sorted out and the season being wrapped up, we're ready to turn our sights back on the Datsun.

https://www.youtube.com/watch?v=oGwrGR8upfA

Which is better for you guys? The race footage or the story behind the race?

-

-

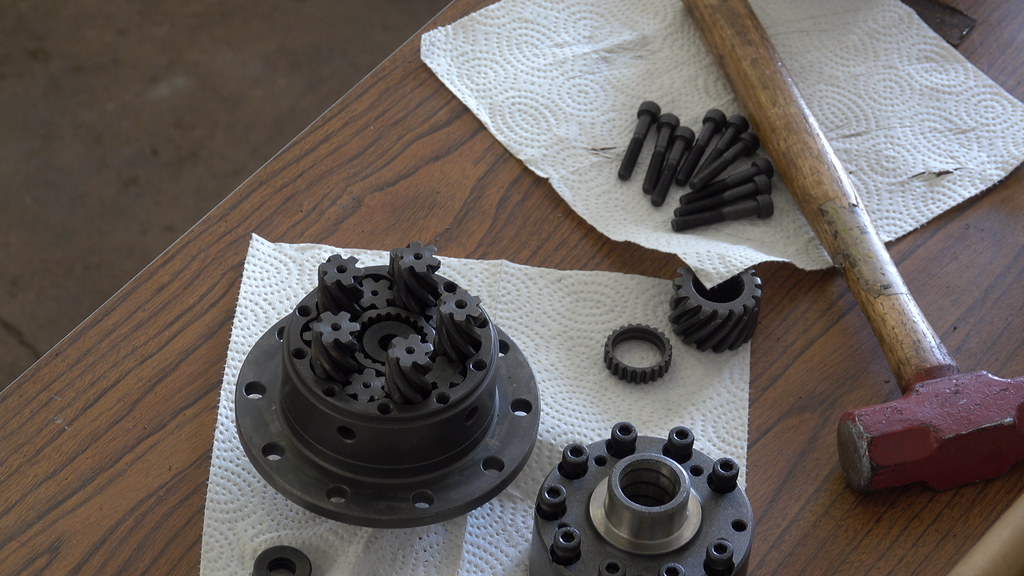

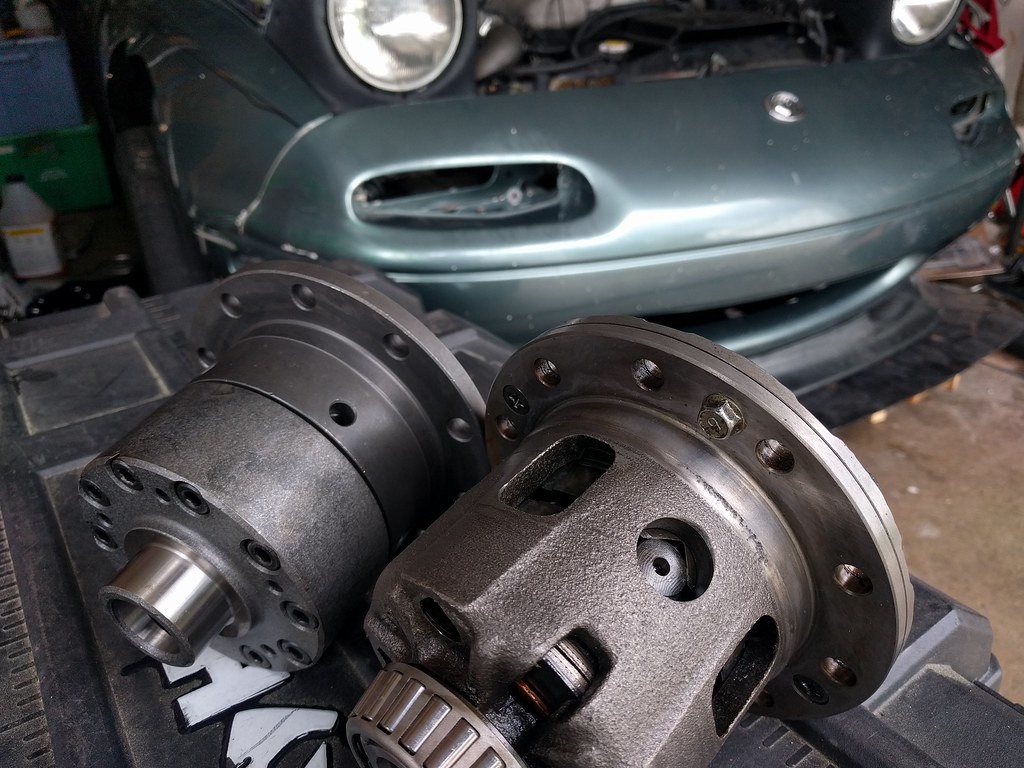

Today, I rebuilt the torsen limited slip.

For now, it lives next to the clutched limited slip, waiting for me to choose which will be installed for Mt Washington next weekend.

We also installed the new VMAXX suspension. This is a pretty fantastic budget setup (right at the $1k mark), and is still pretty compliant. Track setups would be far too stiff for any of the hills we run, so I wanted to find something that was high quality while still being compliant and adjustable. After a rough base tune, we have the car level again. Hopefully we'll have some time to fine-tune before Mt Washingont.

Finally, and most importantly, we beat the piss out of the transmission tunnel. Then we cut a huge chunk out of it. Then we could fit the widest seat I've ever seen in my life ... into one of the smallest cabins available in a production car. It took most of yesterday and today to get it all aligned, get the seat facing forward, get the seat level, and make sure I could sit in the car without my head hitting the cage while also being able to close the door. Seat installation sucks.

-

Prep is well underway. I picked up a spare gearbox, cleaned it up, and replaced the front and rear seals, as well as rebuilding the spare clutched limited slip differential.

I picked up some new 245-40R15 tires from Maxxis.

I picked up some new 245-40R15 tires from Maxxis. I put the car into what I call "service mode"

I put the car into what I call "service mode" Air conditioning and power steering came out, dropping a lot of weight off the front of the car.

Air conditioning and power steering came out, dropping a lot of weight off the front of the car. Then it all came back together for a bit more fender trimming and basic aero mounting.

Then it all came back together for a bit more fender trimming and basic aero mounting.

-

We're racing Mt Washington, but need help from viewers to fund it.

-

This weekend, a friend was clearing out their garage while moving, and had to give away the last few things that they hadn't sold off. I wrapped up a few final projects on my box truck and made a trip down there. I came back with a bunch of tools, and (at least as exciting) storage!

I finally have a toolbox that can live in the race support box truck out of the deal too (this was the main selling point for me to head down).

I finally have a toolbox that can live in the race support box truck out of the deal too (this was the main selling point for me to head down). After unloading it, everything was a disaster. I unloaded the truck and pretty much dumped everything wherever it could fit. I went out for dinner, then came back to tackle the first stage of cleanup.

After unloading it, everything was a disaster. I unloaded the truck and pretty much dumped everything wherever it could fit. I went out for dinner, then came back to tackle the first stage of cleanup. After cleanup, it's still an unusable shop ... but all the filing cabinets are empty. Once I label them and organize stuff into them, I should end up with most of the bay back in floor space!

After cleanup, it's still an unusable shop ... but all the filing cabinets are empty. Once I label them and organize stuff into them, I should end up with most of the bay back in floor space!

-

Well, the s30 definitely won't be ready for the first hillclimb event (Ascutney) but we've been making brisk progress on it lately. This weekend we changed gears a little, and put some time into the race hauler instead of the race car.

I had made the mistake of ordering a gasoline filler neck for it a few months ago, which doesn't accept the larger diesel fillers (I didn't know this until I stopped for a fillup). It's still held up by a bungee cord, but at least I don't have to remove the filler from the tube every time I want to fill the tank any more. Up next: The coolant system had a slow leak for awhile, but it recently became critical (which is why I parked it). We spent some time isolating the source of the leak, finding the right(ish) replacement hose, and breaking our fingers to get them to fit in place.

Up next: The coolant system had a slow leak for awhile, but it recently became critical (which is why I parked it). We spent some time isolating the source of the leak, finding the right(ish) replacement hose, and breaking our fingers to get them to fit in place. Then we turned our attention to the interior. Ugh. Just ... It was disgusting. This used to be a roofing truck, so there's tar everywhere on it. Seats, in the box, all over the dash, steering wheel ... everywhere. The floor had some housing carpet pad with vinyl on top, and wasn't sealed. Everything smelled of mildew and sadness, and the whole truck just felt soggy. After tearing out the flooring, we found enough dirt to plant a garden. It may have been growing, for all I know. That channel above the rockers had around 6" of packed-in mud.

Then we turned our attention to the interior. Ugh. Just ... It was disgusting. This used to be a roofing truck, so there's tar everywhere on it. Seats, in the box, all over the dash, steering wheel ... everywhere. The floor had some housing carpet pad with vinyl on top, and wasn't sealed. Everything smelled of mildew and sadness, and the whole truck just felt soggy. After tearing out the flooring, we found enough dirt to plant a garden. It may have been growing, for all I know. That channel above the rockers had around 6" of packed-in mud. After a lot of cleaning, wire wheeling, and some phosphoric acid, we threw a bit of primer & paint at it.

After a lot of cleaning, wire wheeling, and some phosphoric acid, we threw a bit of primer & paint at it. I haven't decided what kind of long-term coating to put on it yet. I have a bunch of POR15 left over, but I don't know how well it'll hold up to this kind of environment. I'm open to any suggestions you folks might have. Everything's reassembled right now, and the next project will be finishing up the box itself (hopefully this week).

I haven't decided what kind of long-term coating to put on it yet. I have a bunch of POR15 left over, but I don't know how well it'll hold up to this kind of environment. I'm open to any suggestions you folks might have. Everything's reassembled right now, and the next project will be finishing up the box itself (hopefully this week). -

Week07 is live!

Who else runs a YouTube channel?

in Non Tech Board

Posted

That's an interesting question. My hope is that by the time we reach that point, we'll be in a true post-scarcity society and nobody would need to make money creating entertainment. There are plenty of Countries that simply support creators to make good content. It doesn't seem so far-fetched to have something similar to that, where we wouldn't need a paywall or complex digital rights management (which nobody has effectively solved yet).

At least, that's my hope.