adam.

-

Posts

19 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by adam.

-

-

L28 with 45mm OER carbs

-

So the solution to my lean hesitation with the #55 pilots installed was to simply adjust the pilot screws/idle adjustment screws out another half turn or so.. Putting them around 2.25 turns out from full lean (ideal is 2 turns +/- half a turn).

With the #55s installed, 29mm fuel float level and 2.25 turns of the pilot screws, the car cruises with an AFR of 13.5, idles rich around 12.5-13, but light acceleration is now smooth being around 13:1 AFR and creeping up to about 14:1 in second gear.

Although idle is a tad rich, drive ability has improved which I guess is more important in this situation. OER pilot jets do not allow you to change air hole sizes like Webers to assist idle mixtures and cruise mixtures independently so this will have to do.

WOT is currently around 12.5-13 which I think is spot on but goes a tad rich in the upper rev limit which is telling me I need larger air correctors which I currently don't have, but that's easy in comparison to slow speed accelerations and cruise stuff.

That is all. thought I'd give you all an update!

-

Yeah, I am aware of the float adjustment as well as the accelerator pump adjustment screws but if I must be completely honest, I thought the pump adjustment was more to do with its 'load' or amount of fuel it releases, not duration of its fuel release.

I will have to have an experiment with that though to confirm. Been too busy with work to really have a play.

-

What confuses me is that it may run lean on acceleration but it will run rich at 12.5:1 AFR on cruise..

I will need to double check timing, float levels, throttle position etc.

-

Is that so? Interesting because I did not know that..

It is leaning out while my foot has been down for a few moments.

I will have to experiment with it also.

-

I will need to double check using a different timing light as the one I'm using is a bit dodgy actually.

And I'm running a 280zx electronic distributor.

I don't think increasing the pump will do much as the lean is a few seconds after the throttle is pushed.

I will need to have a play around with the float levels I think.

And it may be hard to tune now but that satisfaction of having done it will be worth it. I could have easily paid someone to set these up but money can't buy experience.

-

Update:

I checked the timing and I don't know how you guys do it but it seems like the motor is reving too fast to tell what exactly the timing is at 3krpms.

I have received #55 and #57.5 idle jets, the #55s are still too lean to even accelerate, while the #57.5s have a cruise AFR of 12.5 and acceleration is in the 13s - 14/15 which cause stuttering (around 2.3-3krpms). Idle is about 13.

Any ideas what could cause this lean spot causing the stutter? I cannot get my head around it. I have tried checking timing and best I can do is 15 degrees at idle.

It seems like I can't get cruise any leaner without causing hesitation on acceleration.I'm guessing it's that dreaded transition to the mains..

-

OK, noted Steve, regarding adjustment of floats for idle jet.

And you can definitely run the car without the mains installed.

There has been a delay in ordering and receiving of the new jets so no new information to be mentioned. It should hopefully be here by early next week.

I have access to a dyno at work again which will help dial everything in.

And I think my OER emulsion tube and jets should do for the moment! Will get too expensive otherwise

-

Hahaha it's all part of the fun though, isn't it.. Building a car, you're in it for the journey, not the finished product.

And I have seen/read that method of tuning.

You first remove the air corrector, emulsion tube, and main jet assembly, block or remove the accelerator pump and drive with just the idles. Note the AFRs at cruise and adjust float levels to up to richen the mixture or down to lean it out. If you cannot achieve a good AFR with the range of float settings, either go up or down a jet size depending on which way you need to go.

It is only then that you reinstall the mains and check AFRs. Once they're done, you reinstall the accelerator pumps. And make sure cruise is still where they need to be.

Of course there's more to it than that but it's the basic guide to setting it up. This way, it allows you to focus on just the idle jets and you'll know for sure the mains haven't 'come in' yet.

-

Yep, that makes perfect sense. So when I was running the #50s, they may have idled on their own, but only because I 'turned out' too much, using fuel intended for the progression holes on idle. Therefore when I got to rev the motor, it dies due to running lean.

Excellent. Thanks for explaining that.

-

I have been mentioning 'full turns' which I think is pretty obvious as being 360 degrees, but I understand your frustration. My 'turns' are 360 degrees.

And the main question of this thread was whether a #60 - #50 idle jet was big. I wasn't sure whether the AFRs reacted the same as say going from a #140 main jet to a #130.

I thought since the #60 was producing AFRs of 11/11.5 at cruise, maybe the #50s should run and produce 13/14 AFRs (and maybe the #55 and #57.5 would produce in between around 12 and 13). But my result was that they didn't run at all and I wasn't sure whether that was right.

I have ordered some #55s and #57.5s so we'll see what they produce when they're installed.

And I will get onto the timing first thing next time I go tinkering, Steve.

Thanks all.

-

Okay, just another quick question.. With the #60s installed, my acceleration is now a tad lean in the high 13s range, causing hesitations and misses, but cruise is still rich at 11.5-12.

I am only suffering from the lean acceleration when take off is very slow, in the progression port area. Solution?

I think I might need a weber idle jet..

Thanks

-

The mix screws on O E R carbs are not the same as weber they are a fine thread so they need to be out about 2.5 turns to be the same as the weber 1-1.5 turns. I have 55 f9 with a ported head and a bit of a cam on a 2.8 and it is still a little rich. You probably need a 55 F8 for a little more air, that is what I will be going to after winter decides to leave. O E R brand jets are a little different than the weber equivalent as far as air hole size and how they sort them. I gave up on the OER idles because they are one piece unlike the weber set up that lets you replace the jet in the housing piece. PierceManifolds.com can help you out with the OER stuff they know what weber stuff fits and does not. They are great carbs and if you are familiar with webers then the learning curve is small.

Hmm interesting.. I have an old SK-Racing manual here and they mention that it only needs to be unscrewed 3/4-1 full turn from full lean. I would have thought OER basically being the newer model carbs of SK-Racing, it would have been the same. But at the same time, depending on which Weber DCOE model you have, they also require 2.5 turns. Newer models required 2.5 and older models require 1.5 or vice versa.. So it might depend on the actual carbs?

I will try the #50s again with a the mixture screws out a little more and see if it makes a difference.

As for OER idle jets, I have noticed that they seem to have fixed air hole sizes, they only offer different sized fuel holes. From size #55 and up however, their increments are by 2.5, ie. #55, #57.5, #60, etc.

Thanks mate, you've given me something to think of and experiment with.

-

From about 3krpms, afrs increase to ~12.5-13 which is spot on. I have not yet checked to see what they are above 5krpms.

-

I have got onto ordering a set of #55s and #57.5s from OER. I will throw them in when they get here.

As for timing, I have thought about giving that a crack. Have just been a bit lazy with measuring and marking out, and thought idle timing was enough. I will see how that goes.

I am running an electronic distributor from a 280zx.

Thanks

-

Hello all from Australia,

Long time browser, first time poster here because I finally can't find the information I'm looking for!

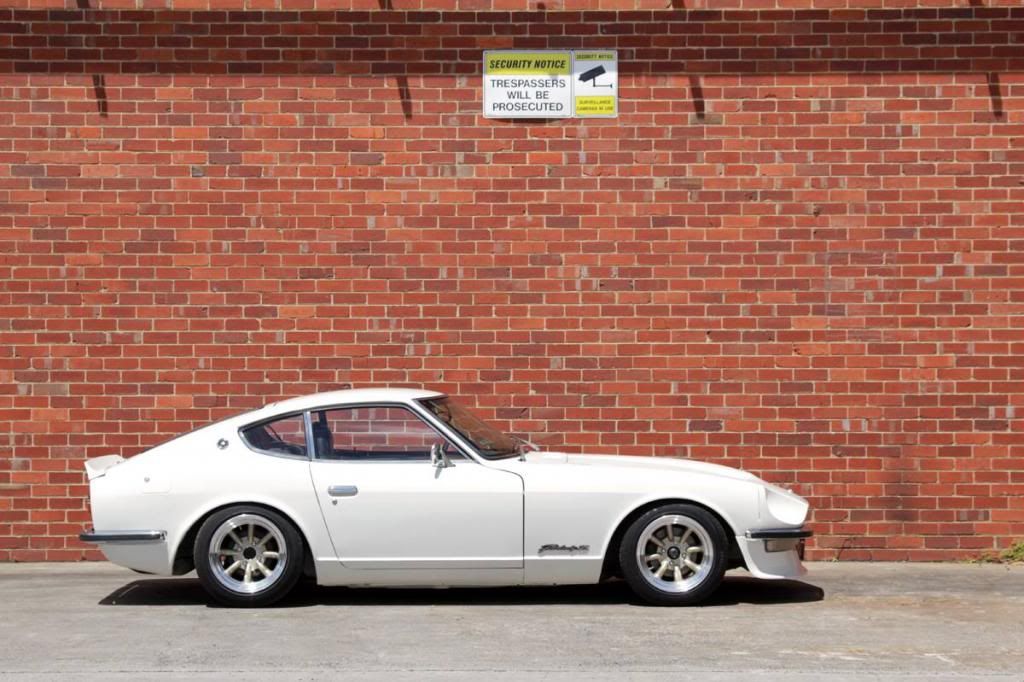

First off, my name's Adam and I have a 1973 240z which is currently running a standard L28, N42 head/block combo, with brand new triple 45mm OER carburetors, and Trust headers to a twin 2" exhaust system.

I have just installed a new set of OER carbs I purchased from Japan and am having difficulties sorting out the idle/low speed cruise setting.

Bit of details into the setup,

45mm carbs

34mm venturis

#190 air correctors (not yet tested to see if these are the best)

#130 mains

#60 idles

#40 pump nozzle

#1.8 needle valve

3.5psi fuel pressure from the mechanical fuel pump into Holley regulator

31mm fuel level using the OER level gauge.

Idle screws are setup so that the first progression hole is just 100% covered looking through the brass cap/inspection hole. Carbs are balanced the best I can using a unisyn.

I have a wide-band O2 sensor probe in the tail pipe. I am running 98 octane fuel. Timing is at 15 BTDC with no vacuum advance connected. Valve clearances have recently been adjusted.

Now, onto the problem I am having..

Driving with the #60 idles installed, 1 full turn of the mixture screw turned out, slow acceleration and cruise is very rich, 10.5 and 11.5 AFRs respectively.

I also have #50 idles on hand which I have installed to try and improve the current rich scenario and I cannot even get them to idle. With mixture screws out 1.5 full turns (recommended range is only 3/4 to 1 full turn), they cannot idle on their own, only when I blimp the throttle which I believe is activating the pump jets.

With the #50s installed, AFRs are off the scale in the lean area. They can't idle let alone drive.

My question is, is going down from a #60 to a #50 idle jet that big of a jump that the car can no longer idle on its own? Or is there something wrong with my idle screw setup? I would have thought that with the #50s installed, it would at least idle and drive albeit a tad lean..

OER offer a #55, but I would like to double check with the experts out there first before spending that money.

Any help would be appreciated. And please let me know if I am missing some information, I tried to be as detailed as possible.

Thanks,

Adam

-

adam your car is quite the role model for mine so excuse me if I had stalked your site a little bit. Coincidentaly I have the same exhaust. I removed it from a fairlady z parts car I bought a while back. Did you have any trouble fitting your carbs? I thought I read somewhere that SUs will not work with the trust header because they sit too low. The parts car had tripple webers on a FET manifold which raises the carbs up a little. Also what size engine do you have in there? Just curious.

Thanks mate

I purchased the car with the L28 (N42/N42) swapped over and running the round top SUs from a 240z.

I too had heard of issues with people running certain extractors with different carb setups but I didn't have any issues with the SU and Trust setup. I did have issues with the size of the washers due to different thicknesses in the intake and exhaust flange thicknesses (exhaust leaks) but that's fairly common with anything aftermarket I believe.

Let me know if there's any other questions, I'm more than happy to help out.

-

I'm glad I went with this system. Twin 2" so can flow more than enough on a turbo motor.

-

Some of mine a mate took a few weeks back.

Tacho (not idle) fluctuating

in Miscellaneous Tech

Posted

Gday all,

Hope you guys could give me an idea into what could be happening.

Bit of background, I have a '73 240z running an L28 with a 280zx electronic distributor, MSD 6A ignition, stock tacho with MSD tacho adaptor/booster.

My issue is the tacho fluctuates with every indicator flash, drops dramatically when the headlights are on (relays installed) or if my heater blower is on.

Note, driving/revving does not change, purely a tacho reading issue.

I have just bought a new battery and had a 280zx internally regulated alternator installed about two years ago.

Any ideas what is causing this fluctuation? It's bloody annoying!

It's getting to the point where it just hovers around the 1krpm mark all the time now.

Cheers,

Adam