darom

Members-

Posts

135 -

Joined

-

Last visited

-

Days Won

6

darom last won the day on July 3 2025

darom had the most liked content!

About darom

- Birthday 04/02/1970

Profile Information

-

Gender

Male

-

Location

Madison, WI

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

darom's Achievements

-

I believe this is the part: https://www.autohausaz.com/pn/16111103603 or here: https://www.fcpeuro.com/products/bmw-fuel-tank-cap-2002-2002tii-1602-16111103603-1

-

I installed 10-12 years ago, the fuel prices were high and there was some gas theft going on in my area. I needed a lockable gas cap

-

Sorry about the confusion. I bought a 2002 bmw gas cap which I installed on my '76 280z.

-

I bought a gas cap for a 2002 bmw for my 280z (MSA used to sell them, it is showing out of stock: https://www.thezstore.com/product/4445/locking-gas-cap-70-76-240z-260z-280z ) The cap fits tight. Not sure if this is something that will work for your racing events.

-

I removed the cylinder head, N47, didn't find any torn pieces of the gasket. After ordering a new set of valve springs and valve seals from zcardepot, I took the head to the machine shop.

-

My current issue is with leaking oil and coolant. My head gasket is leaking coolant - this is between cylinder 1 and 2 on the RH side. I can see the coolant right at the edge of the engine/cyl head. When I installed the new timing cover, my head gasket got torn at the top. I made a gasket and used some aerobic silicone. The oil is leaking a little on both sides. The plan is to remove the cylinder head, take it to the shop to get it reconditioned (new stem seals, check the springs etc), put a new set of ARP stud fasteners with an OEM gasket. The new gasket will also stop, hopefully, the leak at the top of the timing cover. I checked the prices on the Nissan head bolts - they are in the hundreds now. Not sure what happened. The MSA is basically recommending to go cheaper ARP route (which used to cost more in the past, now it is reverse).

-

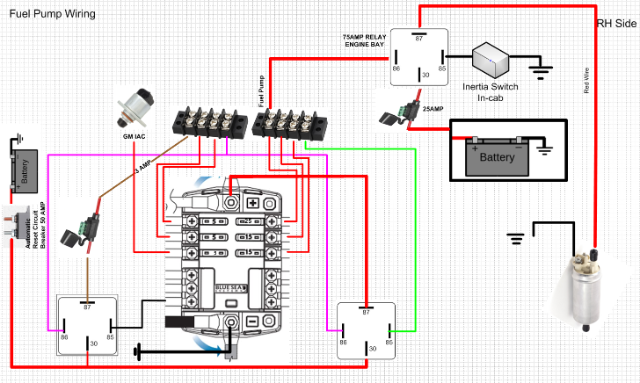

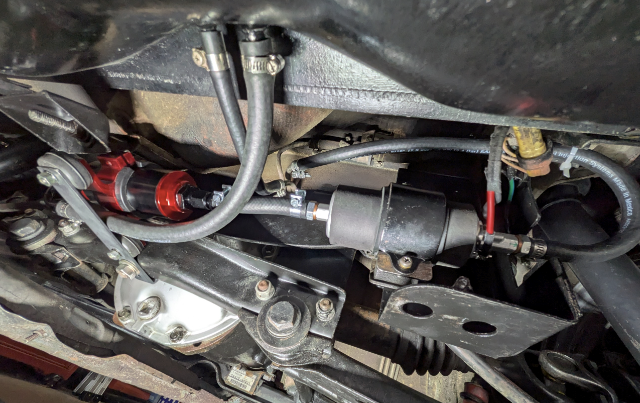

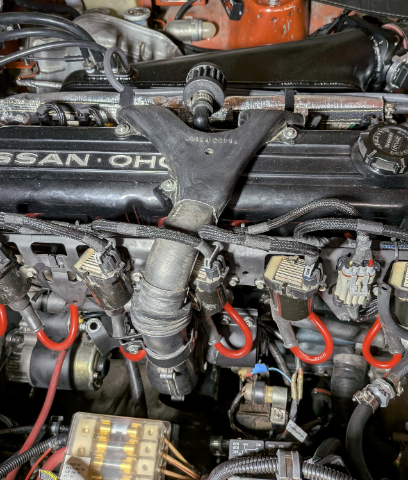

I also decided to re-address the lean condition on hot restarts. When it happens, the fuel pressure would bounce around, 18 - 22 psi. The FPR is set to 37-38 psi (w/o vacuum), at idle normal psi is around 31-32 psi with the vacuum attached. The FPR is an Aeromotive unit. Started with the fuel pump's (Walbro 255) voltage. 1. My original design - battery -> circuit breaker -> microsquirt's fuel pump relay -> main relay -> 30AMP relay (Inertia switch) -> Fuel Pump All wiring is 14 gauge. The voltage delta between the battery's and the fuel pump's was 1.5 Volts! 2. Re-did the ground - dedicated negative to the back panel's ground point where the tail lights get grounded. The delta was 1.2 Volts. 3. Installed a dedicated FP relay in the engine bay (Tyco 75Amp, with a 25amp fuse), with direct run to the fuel pump. The microsquirt's relay provides a trigger on post 86, inertia switch (in cabin) - ground. The delta is 0.3 Volts. Here is a diagram: Another possible issue might be related to the pre-pump's G3 Fram's filter being too restrictive (40 micron). Installed a 100 micron pre-filter: The pump is very quiet. The hot restart ends up with 14-15 AFRs for about 40 seconds, then it scales back to my pre-configured 13.5 at idle. I don't see a lot of fuel pressure fluctuations any more. As a precaution I added a 1979's 'hair dryer' to cool my injectors. I found it at a junk yard. I am using a time relay board which is set for 15 minutes. When I park the car, I can engage it from inside. I will test it on a hot day:

-

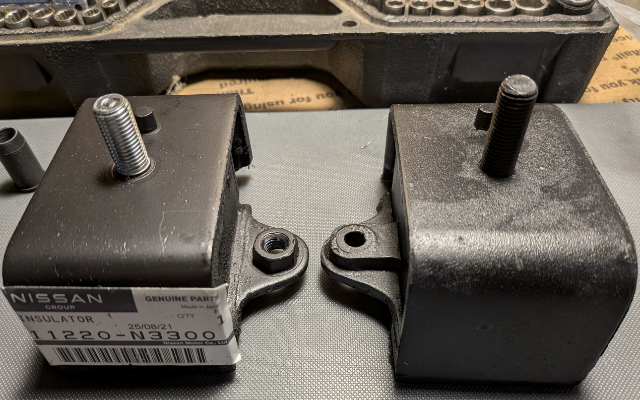

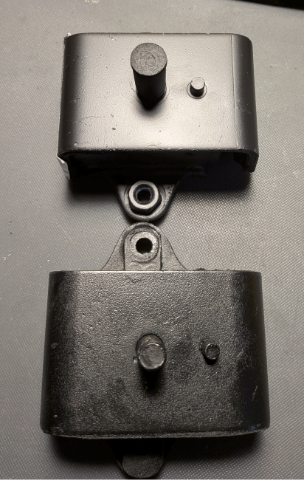

Installed a set of OEM engine mounts. They are still available, the cheapest ones are shipped from Japan (ebay source), about $120 total. Originally, I figured I would save some money and ordered a $20 special for a pair + s&h. Then I found some posts on classiczcars about their poor fitment, SAE threads (not with the pair I purchased), misaligned locating pins etc. Here are some pictures for comparison. The center bolt is longer on the after market one: The locating pin is way off: The OEM mounts fit like a glove, no issues.

-

It was the rear main seal leaking, I removed the transmission and could clearly see the oil around the seal:

-

After priming the engine oil and starting/warming up the car, there is a small leak around the rear main seal. It is either my side seals or the rear main. Considering how easy it is to bump the seal while installing the rear cap, I wouldn't be surprised. I guess it is time for a tranny drop operation. I will check with my endoscope.

-

Hi CalZ, It is https://www.amayama.com/en

-

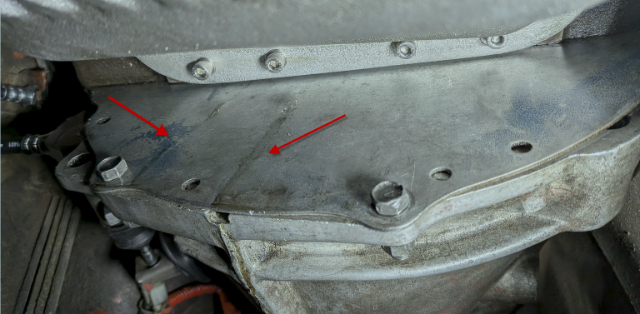

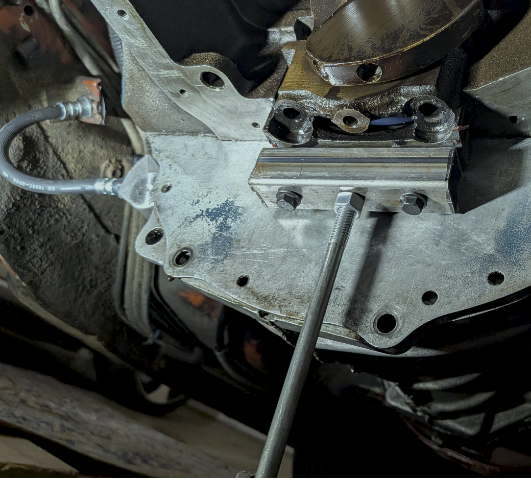

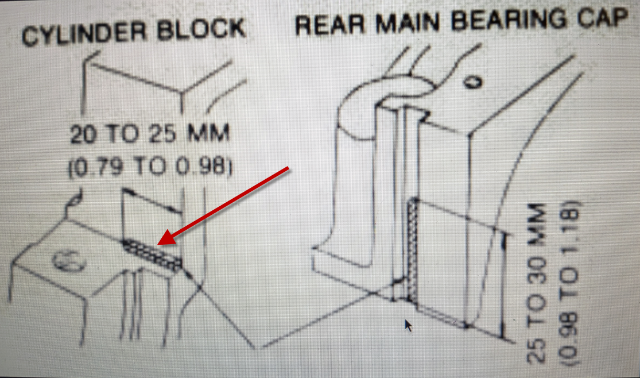

I have been dealing with some consistent oil leaks around tranny/engine block, and front RH lower part of the timing cover. The worst leaks would happen when the car was parked at an incline. I replaced my original TC with a new unit (there is a company selling them from Japan), total shipped was around $100. My original cover had some stripped threads. The water pump's long 80mm M6 bolt (at 10 o'clock) was broken inside the block. I had to weld a washer with a nut to remove it. The oil pan gasket that I sealed 10 years before, with permatex gray/gasket sandwich started leaking on the RH side. The removal of it was a major pain. I decided to get an aluminum pan from AZC since I am considering a turbo upgrade in the future and that pan already has provisions for the oil temp sensor and turbo oil return fitting (I went with the 8AN fitting). The pan is solid and straight. I 'glued' the cork oil pan gasket with the permatex black to the pan to prevent the gasket movement while I was installing the pan. My hope is the fact the pan is a solid aluminum piece, there is not going to be much flexing/worrying about dimpled surfaces etc. While the pan was off, I also replaced the rear main side seals. Mine looked old/brittle when I removed the rear main cap and inspected them. I tried pulling the metal inserts with a pair of needle nose pliers, but they were stuck really good. The rear cap was removed using an improvised slide hammer (the taped part is a bunch of heavy washers): It took about 10 minutes to remove the cap: I didn't see any sealant in the corners in my engine. I am hoping this might explain the oil leaks. Per FSM: Before the cap installation, I put a bead of gray ultra in the corners on each side. The side seals got a coat of gray as well when I inserted them. The rear main cap was in a freezer. Its installation went smoothly. I haven't filled the engine with oil/coolant yet. If I see more of oil leaks around the rear part of the engine/tranny, I would probably pull the transmission and replace the rear main seal along with the transmission's gasket/seals.

-

Hi @Mike280zx, if you don't get answers on this forum, i'd advise to post on https://www.msextra.com/forums/index.php Regards and good luck with your project.

-

Thanks, Tom, will add a little more fuel. I noticed my cold -> warm cycle follows a pretty predictable AFRs curve per the table and my manual tuning I did at idle a while back (I was aiming for 13.5-13.7). Things go out of wack somewhat when I restart a hot engine, the AFRs are leaner until they stabilize later on.

-

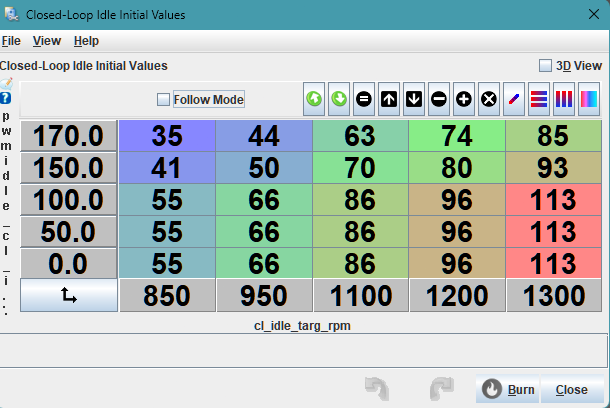

Update: Today I worked on correctly setting up the initial target RPM table. Took two readings per each rpm step, in my case, 850, 950, 1100, 1200 and 1300, when the car was semi-warm and hot. Then added another 10 percent per: https://www.diyautotune.com/support/closed-loop-idle-pwm/ Then from 100 to 170, interpolated vertically. Since I didn't know what steps would be at lower temps, left them the same at the bottom: I switched to using CLT table (not MAT) since I am still clueless where I can find it (unless TS uses the same table for both and it will be just different temp ranges there). I also noticed at hot restart, the AFRs are very lean, 15-16 range due to the injectors getting heat soaked. Searched on the msextra, found some posts about guys using a band-aid fix by adding ASE and taper at higher temperature. I experimented with mine and added some: It does help somewhat in the beginning. I added EGO correction of 8 percent above 800 rpms. This helps as well, and my AFRs get back to normal range. I am posting my updated tune, plus the idle log. I haven't taken the car for a test drive yet. 2025-07-06-v106.msq 2025-07-06_10.40.07.mlg