-

Posts

190 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by PalmettoZ

-

-

That actually looks pretty good. Almost looks like "Fleckstone" texture.

Hey-

I wish it were smoother. The guy who did it said it was hard to get a smooth texture out of it, but at least I know it won't crack. I wanted to do the bottom of the car tinted body color, maybe later on down the road.

-

I could use one too (260/280) style, I have seen them on Yahoo Japan, but shipping is high.

Hey ArnZ-

I have a suggestion for the dash that might work for you. I didn't like the look of a cap, so I decided to try to refinish mine. I had big cracks in it which I sanded down with a block and filled with bondo, after that I sprayed it with sealer primer and then had it Rhino lined.

Cost a total of 50 bucks. Putting the gages back in was difficult, I had to trim the inside of the holes out to get them back in. Check out the photos on my car domain site ( 2nd page ) and let me know what you think.

-

If you're talking about the Pee Dee show, it's outdoors and HUGE. As in, you can't see it all in one day. Usually the weather is cool but nice, say 60's.

jt

Here's the link:

-

Bump

Hey-

I am from Charleston originally, and the downtown area has lots of historic things to see and restaurants out the wazoo. I will try to go to the car show in Mrytle Beach, but might have to work that weekend. You can call me if you like and I can try to show you around some. 843-607-0058.

-

OK. So that brings you up to date. We're working hard. Thanks to Guy and Scott at Miller Brothers Hot Rod Barn in North Wilkesboro, NC. Guy did all the work. I stood around and pointed, thought really hard, and took pics. The Z will be at a show in Myrtle Beach, SC at the end of March. However, it probably won't be finished. We're getting there though! I never thought that it would cost this much time and money to get a perfect Z. When it's running, I'm going to build the stock L24 just to have on a stand in the garage. I think that's cool.

Hey-

Awesome work on your car, I would like to see it at the show in Myrtle Beach. Do you know the date in March ?

-

There is nothing but benifits to lightening pistons, considering you dont take away from the strength of the piston. LIghter piston means a stronger rod, strogner crank, stronger rod bolts, stronger main caps, stronger main bolts, etc. It also takes WORK to stop and accellerate an object, the lighter the piston, the less work it takes to accel and decel that mass. Therefore more "work" can be transposed to the flywheel. Acceleration time is purely dependent on mass. My stroker pisons bare weigh 300 grams after I am finished.

Hey-

I had read your previous post on this and would like to do all of this as well, except there is quite a bit of work for a machine shop and it wouldn't be cheap. I have access to a lathe so I could shorten the skirts up myself, but think I am going to leave them alone. Worried about piston slap if they are too short. Just curious, do you remember the weight you started out prior to machining ? Did you take any off of the skirts ?

-

I will be using 240 9mm rods in a L28 block. This will be a turbo build. I will need to have custom pistons made. Tell me if my math is off.

Also - tell me if these measurements are off. I got them out of the "How to Modify" book and I've heard some grumblings that all their measurements aren't exactly correct.

My machinist measured the two rods and they were close (within .09") to what the book said.

240 rod = 133mm length

280 rod = 130.2mm length

280 pin height = 38.1mm

so subtract the difference 133 - 130.2 = 2.8mm

Being that the 240 rod is longer - I'd want a shorter pin height.

So 38.1 - 2.8 = 35.3.

I'd need to get a custom piston - 87mm bore (I'm going .040" oversize bore) with a 35.3mm pin height.

Is this correct?

I know folks have done this before, but searching through all the "crap" on this site is sometimes like finding a needle in a haystack.

Hey 280Z4me-

I agree with what you say about the search function as well as the search Nazi's that get into telling you about it. Here is a thought-

I am building a 3.1 stroker motor right now, and had thought at one time about taking the 280Z piston and taking 3mm off of the top? Since it is a dished piston, I think the first 1.5 or 2 mm or so is just the dish part and you won't be taking off too much of the actual top of the piston. You probably have some 280 pistons around since you have a motor that you are building, get your machinist to measure the piston thickness at the bottom of the dish before and after machining to see how much is actually taken off of the piston. I don't think that the crown will actually be reduced that much.

The only problem this might have is the top ring getting too close to the top of the cylinder bore. But this is a money saver for sure.

-

Why, Are you thinking that lighter pistons will let you rev your engine harder?

Personally I suggest you don't do it.

The piston skirt is designed to prevent rock or tilt of the pistons as they move up and down the cylinders. Shortening the skirts will upset ring seal with the bore, so you get more blowby and greater oil consumption. This situation is worse with engines with a smaller (numerically) rod/stroke ratio, like the L28 and L26 engines.

The piston skirt is designed to prevent rock or tilt of the pistons as they move up and down the cylinders. Shortening the skirts will upset ring seal with the bore, so you get more blowby and greater oil consumption. This situation is worse with engines with a smaller (numerically) rod/stroke ratio, like the L28 and L26 engines. If you think that you can free up some power because of reduced 'drag', you're wrong. Virtually all the friction is from the rings, not the skirts.

Cheers.

Hey Ozconnection-

Looking more for the weight reduction without removing material inside the piston. It would be easy to just turn down the skirts on a lathe is what I had in mind. I have heard of some people drilling holes or milling out sections of the skirt to reduce weight. Most of the competition pistons that you see are very short, although I agree with you with what you brought to mind about the piston movement side to side.

Wasn't trying to rev harder, just thinking lighter revs up quicker. The crank that I have has the counterweights reduced and I will be using a ligher dampner with single groove.

-

I just got a set of 89mm pistons for my 3.1L build and am considering shorting the skirts to lighten them up a bit. Has any done this previously with success ? These are stock 89mm KA24 ITM brand pistons. I believe that they are cast pieces. Not very light.

-

tensioner did pop out. had to play with it to get it back in. didn't have to fight it though. are those things that sensitive? its difinetly in though. timing marks lined up on the dot. using #1 mark notch on sprocket.

Hey-

One way you could check to see if the tensioner is working is to take the valve cover off so you can see the sprocket and chain. Turn the motor by hand clockwise so that there is tension on the straight side.

Now take your finger and pull on the slack side of the chain and see how tight it is. If it is flopping around, chances are the tensior is not installed correctly.

Of course don't check the slack and turn the engine simultaneously, but I think you know that.

-

Hey-

When you installed the cam did you keep the chain tensioner compressed over to the side ? If not it could have popped out and that might be a source of noise. Also did your timing marks line up correctly at TDC at the top with the cam sprocket ?

-

It's a Schneider Cup / Trophy aircraft - the entire racing series was specifically for seaplanes.

That thing is a piece of work, I didn't know that counter rotating props even extisted on an airplane, unbelievable. Look at the pitch angle on the props as well, serious angle on it. It almosts looks like it is in a feathered position, but I don't think you can have variable props combined with counter rotation like that. I wonder if the front engine has a hollow crankshaft on it ? Take those floats off and I bet it would really scoot.

I have always wanted to go to one of those pylon races and watch those guys run, I love the sound of those big V-12s.

-

Hughes H-1

This plane was bad ass back in the day...

It was the first aircraft model produced by the Hughes Aircraft company. Many groundbreaking technologies were developed during the construction process, including individually machined flush rivets that left the aluminium skin of the aircraft completely smooth. Also it had retractable landing gear to further increase the speed of the plane. It was fitted with a Pratt & Whitney R-1535 twin-row 14-cylinder radial engine of 25.2 liters, putting out over 1,000 horsepower (750 kW).

The H-1 first flew in 1935 and promptly broke the world land-plane speed record with Hughes at the controls, clocking 352 mph (566 km/h) averaged over 4 timed passes.

-

Thats not a picture of HIS Injector mount. He just posted from a website he got some of his info off of. I do agree that the one pictured is a bit too long though.

OH. Doohhh...

-

Too late!

Since I opted to go with the procedure I mentioned earlier the manifold won't even accept an injector with a pintle cap.

I guess we'll just have to see how it runs.

Derek

Hey Derek-

Tony is right, the pintle cap forms part of the spray pattern.

-

I didn't think I would be this interested in it. I have an all new respect for diesels now...I don't think I'll put one in my Mustang buy my friend is talking about selling his 383 S10 for a Mustang so maybe I could talk him into putting a diesel in that, lol.

Hey Grim-

This will really blow your mind. Just to show you the potential of what the Diesel is now able to do.

-

The attracting figure is that they usually run 16:1 compression, don't they? And they're built strong so they can probably take a lot of boost and I don't know if diesel fuel has the octane limitation like with gasoline so that maybe you can run like 50 lbs off a turbo and still refuel at a common gas station. Just guessing there because I don't know.

Check this out:

http://jalopnik.com/347346/2010-45l-duramax-diesel-has-shockingly-brilliant-design

-

The attracting figure is that they usually run 16:1 compression, don't they? And they're built strong so they can probably take a lot of boost and I don't know if diesel fuel has the octane limitation like with gasoline so that maybe you can run like 50 lbs off a turbo and still refuel at a common gas station. Just guessing there because I don't know.

Hey Grim-

Compression is very high, I think around 22:1 or so, Diesels love turbos. But of course you can overdue it as with anything. But in general the rods and crank are much larger and heavier for strength. Diesel fuel (basically kerosene) has totally different burn compared though compared to benzine. Although the new Diesel fuel has the sulfer removed from it for emission purposes. GM is actually working on a new modular Diesel that has unbelivable technology in it coming out in a few years or so. I will try to find the link again and post it, great reading.

-

Diesel engines aren't balanced as they would be in a gasoline engine. so first would be to balances the crank and internals of the engine in question. Maybe a lighter flywheel.

I think thats as far as you can get to raise the rpm on an existing affordable engine. The reason why they are able to get higher rpm is because of direct injection. they can affect ignition timing by when the fuel is injected directly into the cylinder, unlike the tradition injection, where the valves does it.

Also you can try turboing. thats probably how they got such high HP out of the duramax.

Hey-

Actually all diesels are direct injection, only air is going into the intake manifold and thru the valve.

-

Hey everybody. I've thought about having a diesel engine in my Mustang for a while but never looked into it because I couldn't live with being under 3000 RPMs all the time. Then today I youtubed it and saw thisIt runs tens and the info on the side said it got 33MPG getting there so it kinda intrigued me again. I'm not motivated enough yet to research anything, just got a general question. Can the RPM potential be increased? What's limiting it and would about 5000 RPM be doable? No details needed but articles about it would be cool

Hey-

Diesels are designed primarily for torque at low RPM's, not high end horsepower. Especially diesel truck engines. There are diesels out there that turn higher revs, but in the states you would be limited to getting one. Diesels are very long stroke engines, with low end torque as the goal of the engine design. Mercedes has current diesel engines with 4 valves per cylinder and CRI (common rail injection) which is basically electronic fuel injection for diesels that turn upwards of 5000 rpm I think. Very quiet and smooth as well since they are designed for a car, not a truck.

If you get one of these engines from a junkyard you would need the ECU and wiring harness as well. They won't be cheap. As far as truck engines go, Dura-max and Cummins Turbo diesels are in the junk yard as well, and late model types are also CRI type motors. You would need the transmissions as well to go with them. There are lots of tuning bits out there for these motors as well to get more power out of them too.

Basically if you want more power out of a diesel you don't need to turn it higher, just install a bigger turbo and re-calibrated ECU to go with it ( Banks engineering has kits ).

-

Hi Tony

I based my injector mounting on this info

We usually make these out of 1 inch bar stock. We like to seal the vacuum side of the injector with a 5/8 ID- 3/4 OD O-ring slid over the nose of the injector body. This will work on any standard injector. You can pull off the stock O-ring and pintle cap. Bore the bar stock to .640-.650, straight through. This allows a slight air gap between the boss and injector to reduce heat transfer and fuel boiling. A .740 counterbore, .040 deep is machined at the end for O-ring retention and sealing. We usually cut off the bosses at 45 degrees so that they are about 1.35 to 1.5 inches long. This is a good entry angle for many injectors into the runner and is an easy angle to saw at.

Taken from this site http://www.sdsefi.com/techinta.htm

At the time it seemed like the best way to go. There is quite a bit of air gap between the manifold and injector. The base of the injector body is sitting on an o-ring . I'm afraid if I don't have the injector clamped down I'll have a vacuum leak at the base of the injector.

After putting together a few CNC retrofits I'm a big fan of multi conductor shielded wire. I'm using it on everything. injectors, sensors, the works. And single point grounds as well. I learned one thing early on, noise sux.

Derek

Hey Derek-

Your project is looking awesome, really nice machine work and design. I think that the injector is going to be spraying on to your bar stock though. It is way too close and you would loose some atomization. It will work like that but it would be alot more effecient if you did not have all of that stock around the pintle.

Scott Holcombe

-

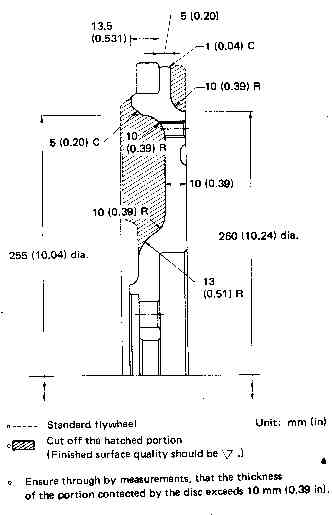

This is from a website for lightening Datsun 510 flywheels. I think they are the same. Tony D can you confirm ?

-

Hey John-

I flew as a flight engineer on the 747 and 727 for 9 years or so, and I promise you that every pilot in commercial aviation knows that scene from the movie word for word. It's like the standard runnning joke in the cockpit to recite it.

Scott

-

I've owned the book Race Car Aerodynamics for a while but never got too far into it because I always got lost in Chapter 2. But I'm about halfway done with it now after deciding I'll read through it and just do my best to get a general idea and not giving up after not understanding the small details. I just want to know if I got some of this right. Concave shapes create higher pressure while convex shapes create lower pressures. The longer something is the less drag it has. Laminar boundary layers have less surface drag but seperate easier while turbulant boundary layers have more surface drag but stay attached longer which in the back of the vehicle can cause less total drag. If you have the beginning of the wing taper towards the stagnation point it allows you to have more attack angle without detaching the airflow but works for cars because they are constant and not for planes because they're always adjusting lift. With the "V" shaped wings, if the ends go towards the front it creates more lift in the center therefore good for cars but planes have the ends go towards the rear because they make more lift at the ends and that makes it easier for a plane to turn since they use the airflow over the wings to manuever. End plates on the end of the wings pretty much just make it so air doesn't creep off the ends and around the wing. Vortex generators turns a laminar boundary layer into a turbulant one so it stays attached longer allowing you to create more attack angle on the wing. These are the things I want confirmation on whether I have it right or wrong, where I'm at the rest I either understand or I don't feel I need to worry about (such as the windtunnels because I'll never afford anything like). Ok, now everybody tell me how wrong I am, I can take the criticism.

Hey Grim-

The "V" shape wings you are talking about I think are what is called swept wing design for aircraft. These are simply a much faster aircraft wing than a straight wing. Swept wings have less lift than straight wings and higher stall speeds, this is why jet aircraft take off and land at much higher speeds than prop driven straight wing aircraft. This has nothing to do with the aircrafts turning ability though as you stated.

The end plates on the wings you are talking about are called winglets on an airplane and are only there to reduce drag created by vortices off of the wing tip. Again these are common to swept wing planes.

Need a source for a Fairlady dash cap

in Interior

Posted

Hey-

Thanks, I see your point on trying to keep it original. I would probably try to do the same if I had a rare car like that one.