Fairlineguy

-

Posts

22 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by Fairlineguy

-

-

So it seems slipper piston skirt contact isn’t unusual can’t say I’m convinced of longevity of them in road applications

I’m using a 15/50 synthetic oil as recommended by the piston manufacturer but wondering if a zinc additive might be worth

adding ?

-

20 hours ago, AydinZ71 said:

That is unusual. If there was something specific to the piston that would cause this, your machine shop would have been able to catch it during assembly. The piston is centered inside the bore via your rings. The piston can not contact the cylinder walls unless:

1) Piston installed is too large relative to your final bore. Machine shop would have checked that.

2) Your ring gap is incorrect, which is causing your piston to move around.

3) I have also seen skirt slap from damage due to detonation. Are you using forced induction? Did you experience anything that may indicate your engine was knocking?

I have Kameari forged racing pistons in a motor I am building, but the head is not finished yet so I have not run.

So a bit more info

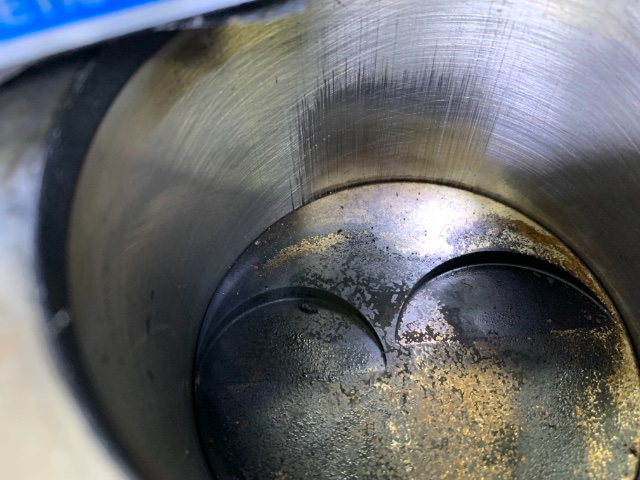

I build the l28 last year with the Kameari pistons the second clear picture is of that engine at 150 mile when I had to have the head

back off. At the time I was a bit concerned to see evidence of skirt contact with the bore but I went on running the engine for a few thousand miles until for some unknown reason the bottom end bearing failed.

When stripping the engine for rebuild the bore scoring was really quite bad unsure if it could be cleaned up I took it to the machine shop who said it would need a fresh rebore .

Not wanting to buy another set of larger pistons they said that if I supplied another std block they could rebore it using the original pistons with new rings

Anyway long story the fresh engine has now been totally rebuilt (bore and ring clearance are to spec.) Having now run the engine approx 150miles I decided out of curiosity to look inside the bore with an endoscope (see picture one) there are the same signs of skirt contact with the rebuild engine .

I’m obviously now wondering if skirt/ bore contact is normal with slipper pistons

-

I’m using 87mm kameari street pistons

I had cause to remove the cylinder head after approx 150miles running in and was surprised to seeevidence that the lower skirt is contacting the cylinder wall.

Anyone else witnesses simulator wear ? If anyone is running slipper pistons and has a endoscope I’d be very interested in seeing a photo of your cylinder wall .

-

Worth mentioning if you using a aftermarket ecu with wasted spark cop coils . Forget the ecu tach output

If you power your coils through the original inductive loop tach wiring (same way the original coil was feed)

you tach will work -

Quick up date .

Jenvey loaned me a set of there 45mm bodies fitted up with Bosch 350cc injectors the same as where fitted in the heritage units.

back to the tuner/ rolling road.

Car is now running great no more pinging,plugs are burning equal and ign timing advance put back in

So the heritage units have gone back and I’m running the normal itb

-

Well bit of a update

swapped out the heritage units for a set of there standard bodies and had the car back on the rolling road

Car is now running great

pinking has gone ,all plugs are burning the same colour,

looks like I’ll be sticking with standard throttle bodies

-

6 hours ago, madkaw said:

Yes- what kind of COPs?

I run 42lb injectors in my 3.2

There LS coils. DG508

-

14 minutes ago, AydinZ71 said:

48 should be fine. OER makes a 50mm carb that is significantly more expensive (almost 2X their 47). I would be surprised if you saw a big performance increase from just the increased diameter.

Curious, why did you go with ITB’s? I know they are sexy, but I’m not convinced they are worth all the trouble when most folks don’t lighten the engine internals or go with a smaller diameter clutch friction surface to really make the response pop. Is it for the “wow” factor?

Suppose I could refit the old manifold and injectors and load the old map and see how it runs it’s just a pain having to rewire the old injectors resistors plus it’s not very sexy .

The engines crank has been balanced and has alloy light weight flywheel. I’ve used maxsppeading rods ,electric water pump

cop ign

i just hoped the throttle bodies would give a sharper response and finish it off

Photo of old plenum set up

-

Here is a photo of the angle of fitment of the injector in the throttle body .

these bodies a 48mm with 350cc injector.

also can’t help thinking there probably on the large size for 230-50hp I’m thinking it might be worth seeing if I can try a set of standard itb with the injector firing straight,

my question also would be

what size would be recommended to work well

and has anyone else found that they need to pull timing out

-

4 hours ago, madkaw said:

That’s a tough one . Running a 3.2 and the n42 intake now .

Did you do anything with the head when you had it apart ?As mentioned engine was running great in another car with same set up but a single stock plenum.

until the engine through all it’s oil out.

Engine has been rebuilt now with kameari pistons .35 above deck. But now has jenvey heritage itb.

we removed the spark plugs the centre cyl plugs feed by the centre manifold where clearly running richer.

we swapped them to a different cylinders and ran the car again on removal they where showing richer.

this lead us to the conclusion that the is a mixture in balance and that only the centre cylinder are running correctly .The ideal of itb that all cylinder a receiving the same fuel.

we had the injectors out and tested them on the bench they are all good

Chatting with the tuner he’s having to pull about 10deg of timing out to stop the pinging .

so where on the old ign map it was a 20 deg it’s now at 10degs

I forgot to say the ping is at low rpm open throttle under load at higher rpm the timing has still had to be pulled by a few degs

Clearly there is wetting of the wall of the outer manifolds as the angle of the injector fires directly at it I’m guessing that higher rpm there is enough air flow to ensure it mixes and never hits the wall .

-

1 hour ago, AydinZ71 said:

@Fairlineguy Hey there. Is your cam duration a typo? Just have not seen anything as high as 480. My race cam is at 320 duration I&E (not streetable), and I don't think there is much room to go from here.

1 hour ago, AydinZ71 said:@Fairlineguy Hey there. Is your cam duration a typo? Just have not seen anything as high as 480. My race cam is at 320 duration I&E (not streetable), and I don't think there is much room to go from here.

1 hour ago, AydinZ71 said:@Fairlineguy Hey there. Is your cam duration a typo? Just have not seen anything as high as 480. My race cam is at 320 duration I&E (not streetable), and I don't think there is much room to go from here.

Opps my typo 280 duration

-

The problem

Pinging whilst setting up new jenvey heritage itb on rolling road

Brief story /Engine spec

F54 block with kameari flat top pistons (10-1)

Ported F42 head

Comp cam 480 duration / 460lift

Ms2 ecu (wasted spark /batch firing)

Last year I ran the same engine in another car but with a single plenham manifold (stock 280z)

I had the car rolling road tuned but the feeling then was that the manifold was restricting its performance.

The car mapped and ran well 230hp no pinging issues and ran with a normal amount of ign advance

The engine is now installed in my new 240z build the engine has been refreshed with a rebore (kameari 87mm street pistons )

I’ve now fitted jenvey heritage itb to a cannon intake manifold in place of the old single plenum manifold and injectors .

On the first rolling road session to set up the jenveys the tuner detected pinging / detonation with his det can sensor attached to the block.

He had to pull out up to 10degs of timing .His initial thought was that I should adjust the camshaft timing from 110 to 108.

But last week when returning for a second session the pinging /det was still there so we pulled the spark plugs on very close inspection the plugs on 3 and 4 cylinder appeared richer.

As it’s on itb you would not expect to see this . So Looking at the manifold the center cylinders intakes are fairly straight where as the outer cylinder manifold tracks are angled inwards.

Heritage itb also have there injectors at a angle 15degs i think ? where as most stock itb the injectors fire straight

What I’ve now found is that the injectors in the two outer heritage unit when injecting fire there fuel which hits the side wall of the manifold about halfway down the track but the centre unit pretty much fires it’s fuel directly down the manifold missing the side wall

Also when removing the manifold the tracks where wetter than I would

have expected and looking into the cylinders with a endoscopes the piston crown looks wet with bore wash

My tuner says that it’s near on in possible to map it if all cylinders are not equal

Come on guys give me your thoughts and experiences plenty of you must be running similar set ups

-

Got there in the end 220degs

my strobe just wasn’t playing ball ended up borrowing a cheap strobe

any managed to see the mark.

-

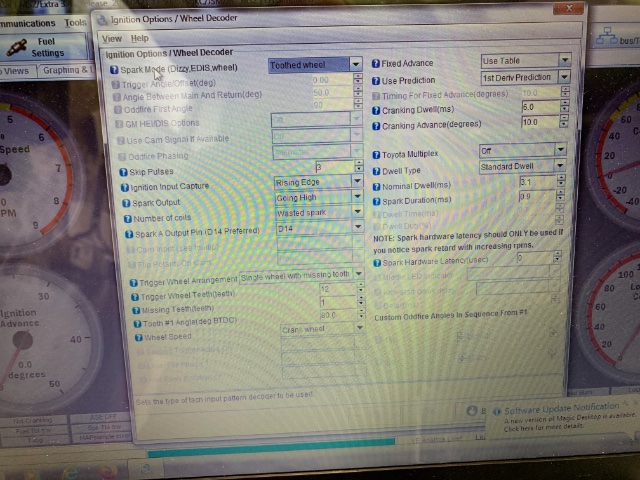

In need a bit of help guys with basic ign timing for first start up.

I’ve recently purchased a 280z as a non runner with a missing ms3 ecu.The car is running coil over plug with x2 Quad spark units and a turboDistributor fitted with a diyauto tuner 1-12 wheel.I’ve a new ms2 ecu and am having trouble setting the basic start up timing with a strobe.I simply can’t see the pulley mark at cranking speed to adjust the trigger1 settingAnyone have a similar set up and know a rough setting that might let me get it started so I can set up with strobeAny thoughts -

I’m in the uk and have just purchased a recently imported 280z and would like to contact the previous owner

who I believe was David Bettis from San Mateo CA??

The reason being is that the car has been modified and appears to have been running Megasquirt .

(the car is missing the ecu )and I’d like to find out the spec to order a replacement .

Any leads/ info please pm me or email. barberneil@ymail.com

-

Keen to keep my original instruments with the rb25det I've just installed a TachMatch TM-02-I-Drive unit.

it works a treat using the signal output from pin 7 of the ecu

-

Having messaged the guys at tach match and received the following reply have decided to go with one of there units.

Indeed you do have a current driven tachometer. The TachMatch TM-02-I-Drive unit will operate your stock tachometer.My understanding is that the RB25 has a tach output signal on pin 7, which is an open-collector output. Being open-collector, it needs a pull-up resistor to get the signal operative. I would recommend a 1.3k ohm pull-up resistor for use with the TachMatch. If you wish, I could install one inside the unit for you at no extra charge. I'm not sure about the maximum sink current on the RB25 pins, I've seen on the internet that folks use 1k resistors sometimes, so I'm presuming that this slightly higher value (1.3k) should be ok, it loads the pin less than 1k. I can't find the actual spec anywhere for your ECU. -

Any one using a tach adaptor or step up resistor to get there original Rev countre to

Work with a ecu output? (RB25det s2 )

Read numerous treads some say they have been able to get it to work others haven't

As I would prefer not to swop out the original unit.

-

Sorry guys I didn't give enough info when posting

Car is a 240z standard fuel tank.

Engine rb25det standard

Using 8mm supply and return pipes

Planning on using in line high pressure pump

Was kind of thinking that as I will only be using on the road and probably always with a 1/4 tank of fuel min

Do I really need a swirl pot set up

Mind you wrcbonk you set up look nice and compact don't think I have seen that filter/ tank here in the uk?

-

I am at the point of installing the fuel supply system.

Do I need a swirl pot set up for road use? I am only planning mild running up to 320bhp

-

Looking at fuel pump options for my rb25 install into my S30 240z

As the fuel tank is out would I be better fitting an internal pump as apossed to a swirl pot system?

Any advise or photos of an install would be a great help.

R180 Pinion preload

in Drivetrain

Posted

So my R180 diff is stripped and I’m replacing all the bearings .

Question is the item described as a crush tube actually a crush tube ?

I ask as mine had a shim under it which wouldn’t be required if it actually crushes secondly I see the tube in question is available in different sizes

Both make me think it doesn’t crush and you either fit shims or fit a different size tube to set the preload