juggernautjoee

Members-

Posts

66 -

Joined

-

Last visited

Profile Information

-

Location

Covington, KY

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

juggernautjoee's Achievements

-

Early 1974 260z build

juggernautjoee replied to juggernautjoee's topic in S30 Series - 240z, 260z, 280z

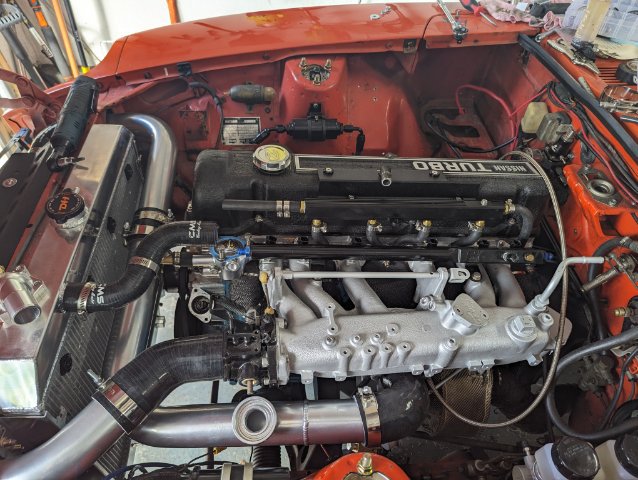

Getting very close now. Just need to run another vacuum line, hook up the crank vent to pcv in the intake, get the small braille battery hold down, and we should be able to fire it up. I've just got the turbo open to the air right now. I need to mock up some kind of filter/intake tube. I might just buy some cheap chinese universal one and cut it up to fit. I'm emailing around my area (northern KY/Cincinnati) to tuning shops to see if anyone would want to help take this on. But so far I'm not getting many favorable responses. Does anyone have any recommendations on someone who has MS tuning knowledge that can do it remotely? -

Early 1974 260z build

juggernautjoee replied to juggernautjoee's topic in S30 Series - 240z, 260z, 280z

Thanks man! Just another quick update. Got a used black hks bov for a good price. Ran a few more lines and tested the fuel system. No leaks! I wouldn't have believed all those AN lines I made actually worked lol. I let it run off a battery for a minute or two. The FPR was showing ~45psi at the return line. Now I'm debating on going with protunerz or godzilla for my ecu. I want to go with ls coils and a CAS for sure. -

Early 1974 260z build

juggernautjoee replied to juggernautjoee's topic in S30 Series - 240z, 260z, 280z

Getting a bit farther. Buying more an fittings and various other things to get it buttoned up. Got a used black hks bov on the way -

Early 1974 260z build

juggernautjoee replied to juggernautjoee's topic in S30 Series - 240z, 260z, 280z

Cooling head mod finally came in. Getting that installed over the next few days. Then it's going to be putting the manifolds back on, finishing up the few more AN lines for fuel feed & return, finding a BOV, then purchasing and installing the MS system. -

Early 1974 260z build

juggernautjoee replied to juggernautjoee's topic in S30 Series - 240z, 260z, 280z

Fuel lines and pump done. Waiting on the cooling head mod kit from godzilla raceworks, then I'll be able to put the engine bay back together. Decided to put a front air dam on. Now I feel like it really needs a bumper to help fill that area out. Not sure if I want to go chrome, raw aluminum, black fiberglass... or what. I feel like chrome or raw aluminum would look good with those konigs, but not sure. -

Early 1974 260z build

juggernautjoee replied to juggernautjoee's topic in S30 Series - 240z, 260z, 280z

This is how I think I'm going to do it. I've got it semi-mocked up/semi-installed. Some of the lines are really short, but I guess that's not necessarily a bad thing. I know these electric pumps are better at pushing than pulling, so I tried to keep it short as possible. -

Early 1974 260z build

juggernautjoee replied to juggernautjoee's topic in S30 Series - 240z, 260z, 280z

While the trans is out, decided to run some actual hardline 3/8in from front to rear. The FPR is probably in a bad spot near the heater hoses, but i don't plan on running heat right now anyways. I'll move it later if I decide to. Right now I've just got a right angle AN fitting on the bottom of the drain plug for the fuel tank. Need to figure out a layout for a pre-filter and pump back under there. Not a whole lot of room to work with. -

Early 1974 260z build

juggernautjoee replied to juggernautjoee's topic in S30 Series - 240z, 260z, 280z

Decided to swap over to some electric fans. As I was mocking up the shroud for them, I punctured a hole in the rad. So I had to get another one. And the aluminum sheet I tried to use for the shroud ended up being too thin for my liking. I just attached the fans straight to the rad for now. I'll do a shroud later. Also dropped the trans and took the 225mm clutch out. That isn't going to hold once the boost kicks in. I'm going to throw in a rb flywheel w/adapter from godzilla. I have a spare 240mm clutch from a 280zx new in a box that I bought by accident last year. I'm gonna go with that and see if it holds up. ARP bolts for flywheel and pressure plate as well. Just waiting on parts to come in. Hopefully I can get it all buttoned up soon -

Early 1974 260z build

juggernautjoee replied to juggernautjoee's topic in S30 Series - 240z, 260z, 280z

-

Early 1974 260z build

juggernautjoee replied to juggernautjoee's topic in S30 Series - 240z, 260z, 280z

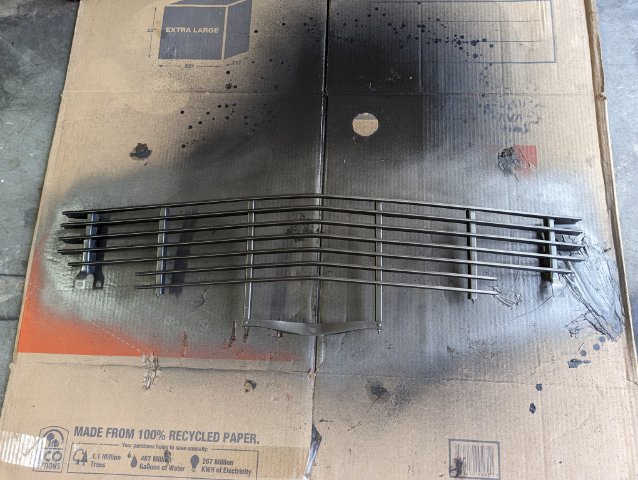

Waiting on a few parts to get the engine back together. Decided to take off the front bumper permanently. Might see what I can find to get a set of smaller bumpers installed. Took the grille off, cleaned and painted it. Used some gm silver grey metallic paint I had laying around. People say the original is more of a darker gunmetal type grey. But I think it'll turn out fine. -

Early 1974 260z build

juggernautjoee replied to juggernautjoee's topic in S30 Series - 240z, 260z, 280z

Brakes are done. Had to bend the ebrake bracket a bit to get it lined up properly, but it works. I bought a headgasket for a later model 280zx. Noticed that it blocked a lot of the coolant ports. I went down that rabbit hole of reading posts over the past 10+yrs on this site and multiple other ones. Some people saying they saw more heat in those center cylinders, others said "why would nissan do this without proper cause?". Others were saying nissan blocked the ports on purpose to make the engine run hotter to pass emissions. Some people had data to back it up, others had feelings lol. I'm making the call to use an earlier gasket with the coolant passages open. I was already planning on doing the cooling head mod as well. So now I'm waiting on that gasket to get the head on. -

Early 1974 260z build

juggernautjoee replied to juggernautjoee's topic in S30 Series - 240z, 260z, 280z

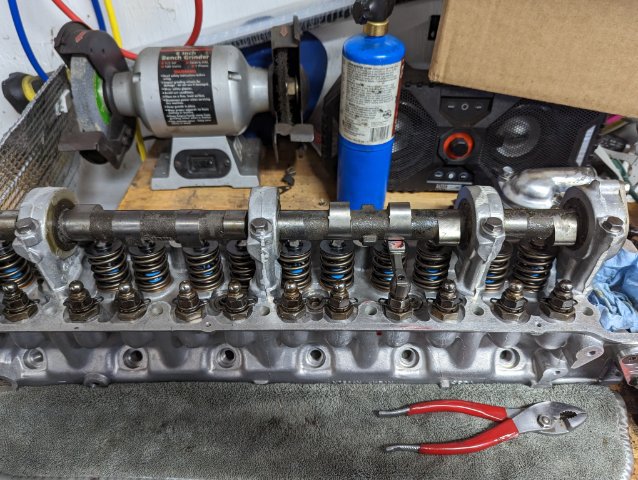

Timeserts installed. Lifters installed. Cam came back from Schneider. Slowly coming together. Got the wildwood MC on. Going to bleed those brakes and fab something up for the ebrake cable too -

Early 1974 260z build

juggernautjoee replied to juggernautjoee's topic in S30 Series - 240z, 260z, 280z

Head is done. They had to take off .007 due to warping. Valve job and cleaned. New plugs etc.. Gotta finish up brakes then I get to tackle putting these timeserts in. Schneider springs and retainers installed. Still waiting on the regrind on that cam -

Early 1974 260z build

juggernautjoee replied to juggernautjoee's topic in S30 Series - 240z, 260z, 280z

Front brakes mainly done. Had to put a 1/4in spacer to clear the caliper. Longer studs too. I probably could have just shaved the caliper down a bit with a file, but whatever. Starting on rears now. One of the calipers already has the ebrake bracket, one does not. I'll have to get one from a vendor. Got some longer studs and the same size spacer for the rears too. Also went ahead and grabbed a 1in Wilwood MC. Hopefully I can get this all squared away before the head comes back. -

Early 1974 260z build

juggernautjoee replied to juggernautjoee's topic in S30 Series - 240z, 260z, 280z

Attempted to put the brakes on the front, but the calipers were hitting the rotor. After thinking about it for a minute, I realized these came off a 240/early 260z. And my frankenstein car with the 280z sized front spindles need a different spacer. So I've got a set of those coming in soon.