72turboz

Members-

Posts

21 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by 72turboz

-

New plugs were in the car, we even pulled them and inspected them during the dyno session. Everything was good, used non projected tip plugs as well as one step colder. Gapped 0.028 if I remember correctly. Will begin the process of replacing cam and having a 3 inch exhaust installed then heading back to the dyno shortly after.

-

Yes and that’s what the lower psi runs showed. He found peak torque made adjustments and tuned around it. Like I said the graphs moved up from there till it hit a wall and any increase above 13psi did not net any gains.

-

Wasn’t identical as he was adjusting each pull. But power and torque were increasing with variations on where peak was until 13psi. I strongly think the cam specs are the main culprit coupled with the 2.5 exhaust from downpipe back.

-

I don’t have access to any other dyno sheets, but I can assure you the curve was trending upwards as it should till around 13psi where it failed to make any gains. The cam was degreed correctly, I verified with a wheel, was my first thought initially as well.

-

Gaps are good, and coil is strong, new msd. No break up in the higher rpm’s afrs not going rich with unburnt fuel.

-

To be fair I destroyed the first crank in my block.

-

Thanks for the link. I’ve read that post extensively. I figure I’ll replace the cam so it’s where I’ll be doing most of my driving and get a 3 inch mandrel exhaust out the back. I’ll take care of some smaller items like adding an idle air control valve to the car for cold starts and when the electric fans kick on. Cars almost ready just is frustrating with the power figures.

-

The only reason I rebuilt/refreshed the block was because it suffered a blown head gasket, and spun a crank bearing pretty much destroying the crank surface. Since I was having to replace it anyways I spent a little extra so I was happy with it. As far as the lower boost runs I don’t have pictures of those, but I do remember that the curve was slowly moving up as we turned up boost until roughly 13psi where it stopped making any power. As far as spark the car was not breaking up at all, and we were running one step colder plugs gapped at 30 and used non projected tips. Tuner didn’t seem to think it was spark related. I have no doubt that I’m running into some kind of restriction I just don’t know where it’s happening at.

-

Thanks for the thread link, I read through it awhile ago and I’ll read through it again. Might just be the nature of the beast with this engine. As far as the engine goes it’s a built/refreshed long block. Bottom end and top end have been gone through, replaced crank, balanced, bored over etc. only weak spots left are probably the pistons and if those go I’ll replace with forged flat tops. Im hungry for the 300whp number, although the car drives great and is a blast in its current state. Next time I’m on the dyno with the new intake, exhaust and cam I’ll bump the boost to 18psi to see if I can’t get anything more out of it.

-

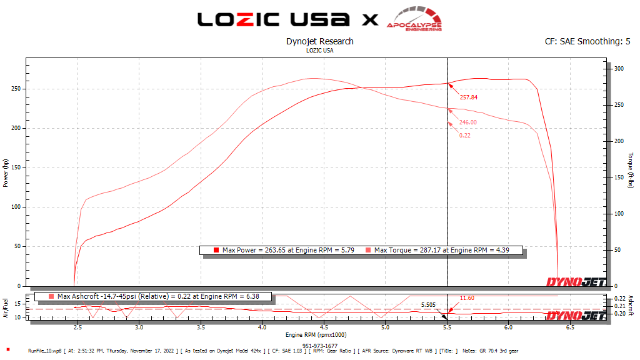

Adding boost and or adjusting timing doesn’t affect the curve in anyway. Stays relatively the same. Running out of something somewhere. This was at 12 psi if I’m not mistaken.

-

Trying to upload a picture of the dyno graph but it keeps inserting upside down.

-

The heat shields are bolted to the underside of the intake manifold and bolted to the exhaust manifold you can’t see them in the picture. The IAT sensor is on the intercooler piping right before the throttle body, you can see it standing straight up. It’s right before entering the intake. I don’t think it’s heat soak, dyno pulls we’re done with ambient temps in low 80’s here in socal.

-

I miss spoke, having the tuner send me a picture of one of the runs the torque does fall off, he’s sending me a picture of the final 12 psi run, again adding boost up to 16 psi did not yield any gains.

-

Roughly what the engine looks like, something’s have been replaced or tweaked since this picture was taken but overall what how it looks.

-

Yes he confirmed the rpm against mph and roller loads. Tires were not slipping either. IAT were high 80s to low 100s during the dyno session, averaging high 90s during wot pulls. No knock sensor MS2 doesn’t have the greatest support for that. I also have the coolant bypass mod for all cylinders on this head, coolant temps sit nicely at 180 degrees. The IAT is just prior to the throttle body. Factory heat shield is installed so heat soak doesn’t seem to be the issue. The turbo intake is kicked down and left just outside of the front wheel well to minimize heat from the radiator. I’ll try to upload a picture of the engine.

-

Both my Hp and torque numbers stay flat all the way to redline, torque does not drop off and hp does not increase. They are also the same number 270whp and 270tq. This trend stays the same no matter how much boost we put into it, 5 psi increase is all we messed with, and timing does not change the output. I will take a picture of the graph and upload it. Current muffler is a 2.5 hks fart can with the silencer removed, no resonator upstream just the muffler. I thought about removing the exhaust from doe pipe back but figured might as well have a full 3 inch made if I’m going to mess with it and put it back in the dyno. Still the exhaust being the culprit seems off me to. Boost is measured from the intake manifold, so doesn’t seem to be an issue with the intercooler or piping. The stock runners are narrow but people have been getting upwards of 350hp on essentially the same setup that I have. So my thoughts are it’s not intake related. I wouldn’t doubt that the current cam was running out of air though as the grind was for high rpm power.

-

I have since spoken to Ron at isky cams, going to drop off a core for a cam re-grind that better suits my needs. Went through the valve train and everything seems fine there so that’s out of the question. Fuel is good afrs stay consistent fuel pressure checks out. Clutch is not slipping we verified that on the dyno, it’s a comp clutch unit that was broken in correctly. Boost is increasing in the manifold, thats been verified. I will up the exhaust size to 3 inch next but I can’t imagine the current set up is causing so much back pressure that it’s hindering flow and performance, maybe I’m wrong here. on a side note I picked up a nice n42 intake manifold and throttle body setup at ZCon, so there’s some positive news.

-

Just took a look and I have Schneider springs installed in the head right now. Would it still be worth looking at a smaller cam or freeing up airflow for the current cam?

-

Hello all, First time poster, long time lurker. As the title states i am wondering if my cam grind is too big for what i want out of it. The car is mainly now going to be street driven with occasional track use, car has a L28et. The cam specs are as follows; @015 TDC, Intake opens 33, Exhaust closes 33, Overlap 66. Intake Closes 77, Exhaust opens 77. Intake Duration 290, Exhaust Duration 290. Intake lift 540, exhaust lift 540. 112 LSA. I also believe i have Isky springs installed but need to double check, small chance they could be new oem springs. Also have brown L28 valve seals installed but plan to replace them with the ford Vitron seals from Felpro. Heres the overall specs of the car; l28et block with ITM dished pistons 30 thou over, Holset He351cw turbo with wastegate welded shut, stock intake manifold and stock exhaust manifold modified to fit a F38 external wastegate. P90a head converted to solid lifters, no port work, plan to have the head CNC ported in the near future. 440cc injectors. FMIC. 2.5 inch charge pipes. 3 inch downpipe into 2.5 inch exhaust, plan to have full 3 inch in near future as maybe this is choking power. T5 transmission, long nose R200 with LSD, 300zxt axles, disc brakes all around. Car is tuned on Megasquirt ms2 and runs great when warmed up, need to install a idle control valve for cold start. This is the general setup of the car right now. So the big question, on the dyno the car made 270whp at 12psi but as we tried to add more boost and/or timing the power did not increase, dyno showed flat power from 4000 rpm to 6500 rpm. No wheel slip or clutch slip was observed. Is my cam too large? Causing valve float? Typically you see variations in power or power dropping off with valve float but the dyno was reporting a horizontal line holding till 6500. Car runs great and is healthy, just cant get anymore power out of it with timing or boost. I am just curious as to what you guys may think is going on. Is my 2.5 inch exhaust causing too much back pressure and choking the car at high rpm? Do i need head work and porting to make the current cam work? Something is happening and before i go digging into the car chasing an unknown issue i wanted to get more opinions. My general thoughts are to put a smaller isky or robello cam in, or find heavier springs for the current cam if its worth keeping it in, i will more than likely have the head CNC ported, and increase the exhaust to a full 3 inch at the same time. The car is a blast to drive, spools up at around 3400 rpm and holds till redline, but i was aiming for 300-350whp when i built the car/engine so naturally im slightly disappointed. Any thoughts or help would be greatly appreciated, thanks guys!