-

Posts

1695 -

Joined

-

Last visited

-

Days Won

8

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by SUNNY Z

-

-

Looking at RockAuto, I'm not sure which O2 sensors I need? Do I need the heated ones? or the non heated? I know I just need the upstream ones but it looks like all of them are compatible with upstream/downstream.

just buy two fronts that match the harness you have.

-

I have a Magnum T56 in my car. It does fit and shift nice.

-

This is all good info. However I think I'm going to scrap the T56 and just go with an auto.. It will cost me little to nothing to get into a built trans and my rear end is built up good enough as is that white a good auto I don't have to worry about breaking stuff.

LMK if you're serious about selling the T56.

-

Where'd you get your pumpkin? I can't find one to save my life

I bought an entire IRS out of a cobra. They pop up on ebay and craigslist pretty often.

-

I'm more curious how many times you've made a pass on it at your current WHP rating. Also Everyone is so wrapped up in spline count but I haven't heard much about diameter.. Wills kit uses F-150 CV/stub axles and not once does it mention the diameter of the shaft. I could care less if it had 100 splines. If the shaft was 1/4 thick it's useless.

Also sunny do you know how large your Z31 outer stubs are? Do you know the diameter of your inner stubs? Thanks for chiming in.

25 track passes at around 750 rwhp. Similar on the street.

Ford 8.8 Axle diameters

-28 Spline axle shafts with a 1.29" diameter

-31 Spline axle shafts with a 1.32" diameter

Not sure on the outers, cant find it right now. They're the 29 spline Z32 NA hubs, or the 240sx 4 lug. Same splines and size.

-

30-40 on the track, same on the street.

-

From the video, it sounds like it (they?) were already broken. Possibly from the previous launch? Either way, they're toast.

Somewhat surprised you got it to hook enough on those 18"? rims to do that.

8.8 Here, with porsche 930 CV's, 31 spline inners, 29 spline outers (240sx) and Its holding up great. Don't know the power the car is making, but it traps 150+, and cut a 1.400 60'.

-

m...f...r , any video of the 8.xx pass?

-

When I had a factory PCM, it was behind the glove box.

When I did my Holley system I modified the harness length to go under the passenger's seat.

If you're looking for a clean location, under the seat is pretty easy. You will have to spend a couple hours soldering though. What's it worth to YOU?

-

Is there any reason you didn't drop the door bars lower? Is this an SCCA / other rule?

Cage looks great, not nit-picking, just wondering.

-

How are you going to do a PCV setup? Not from the valve covers?

-

Finally got the car back up and running a couple weeks back. We have been oscillating between negative temps with feet of snow, to 50+ degrees, but I was able to drive it a while back. Finished "breaking in" the new engine on 20#, and it is crazy on the cold roads. It doesn't get traction, ever. I can roll into it at 70, and it will blow the tires off, lol. Really looking forward to next season and getting some more reps in.

Been MIA from the boards for a while, so I just thought I'd check in.

-

What engine harness? Assuming its a 1 wire alternator, does it have the proper resistor in the exciter wire? Verified +12V to exciter wire?

Have you had the alternator checked, or checked output voltage?

1. Load test batter

2. Check alternator output voltage (sounds like this is erratic)

3. Verify exciter wire voltage and resistor.

4. Detailed report back

Electrical stuff can be a PITA to diagnose, but that should give you a good leg up.

-

What are the cam specs?

-

I've had both dual 3" with an x and 3.5" to dual 3". Magnaflow 3" bullets right at the tips. Still pretty throaty, but not nearly as loud as if the mufflers were in the middle of the pipe.

-

Was thinking of doing the same, the idea being that the stock PCV outlets are too small. Did you weld the AN fittings or just tap for 1/2 NPT?

I had a buddy weld the bungs on, and fill the un-needed holes.

-

Very cool. Any video?

-

If you are pushing hard enough, even two catch cans (one in each line) is not enough to keep oil out of your intake. For 99% of the world probably would be great. Still not enough for me. Need to keep noodling on this some more as I would prefer not to open vent the crankcase.

Why do you still have it circulating back into the intake?

I put a -10 on each valve cover and ran them to a single catch can. Plug/ cap all other spots on valve covers and throttle body / intake. Works like a charm, and doesn't even mist the engine bay.

Why make it complicated?

-

Get that 60' down and it will really fly!

-

very tame 8 sec hit. I like it!

-

A lil tip for running an oil pressure sending unit up top in the stock location (drivers side, just behind the intake manifold). IF you have the stock electric sender, literally break or cut the plastic part off the sender and clean out the metal nut/thread part. Tap it with 1/8th inch NPT or whatever your sender is and bam. No need for adaptors. Plus its away from the headers. I personally dont like the JCI adaptor. Also you can use a stock datsun sending unit for your stock guage.

post-27908-063292100 1348914213.jpg

post-27908-063292100 1348914213.jpgYep. I've done about a half dozen this way. Works well. Only thing that sucks is the autometer mechanical sender is huge, so you might have to run a 45* elbow on it.

-

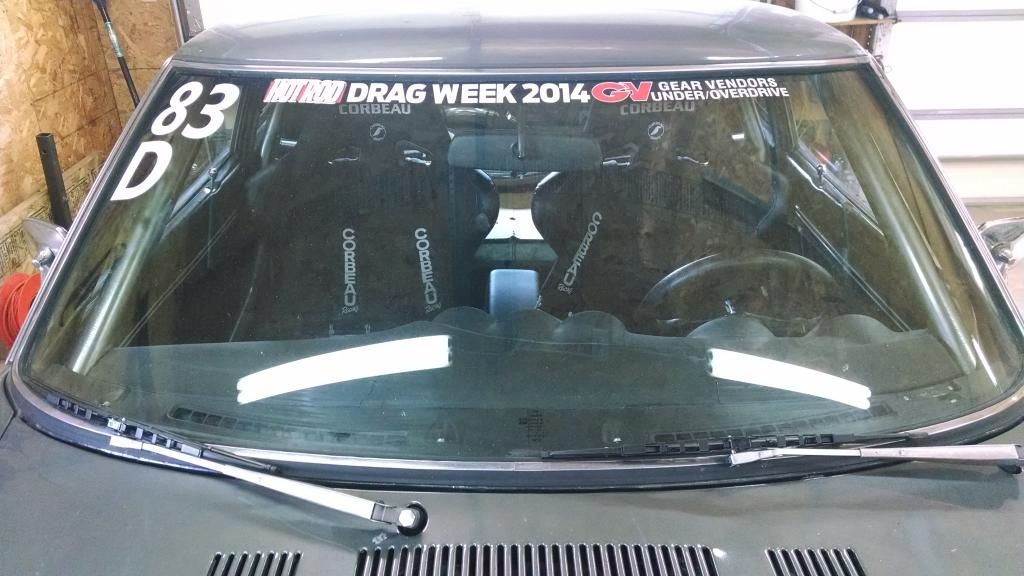

Heres a few that show the interior in.

-

Here are some pictures of the cage:

You have to look close, but the halo is in there.

You have to look close, but the halo is in there.

-

Well I stand corrected on the diff gear ratio thing.

Good! 3.55's are a much better gear for most applications.

Question about heater core lines

in Gen III & IV Chevy V8Z Tech Board

Posted

Great minds think alike! this sounds exactly like my setup.... which i cant find a picture of right now