djz

-

Posts

228 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by djz

-

-

Why only 260 degrees? Has the head been notched for high lift cams? You'll need thicker buckets at that lift too probably.

-

Ross Racing/Raw Brokerage have a few different oil pump mounts, including an under alternator one I just spied.

http://www.rawbrokerage.com/oil-pumprb26/?sort=featured&page=2

http://www.rawbrokerage.com/ross-tuffbond-single-stage-external-oil-pump-kit-rb20-rb25-rb26-rb30/

-

Interesting crossmember djz... Would a certifier allow that?

It's been certed here in NZ with no problems, I gusseted the two L brackets in the corners, it's bolted to the floor with 3 x 10mm bolts each side and 2 x 8mm bolts on each side of the flat piece the mount sits on. The L brackets are 50x5mm steel and there are 50x5 plates on the inside of the car too.

-

I chopped both the ears off and made a mount similar to the JTR V8 mount that bolts through the tunnel.

Like so:

-

Probably what matters more is how good your manifold is for wastegate flow.

-

Hey, your engine mounts might be a little different to mine, I've got a reasonable amount of room above the head but not a lot between the sump and the crossmember. You should post up some pictures of yours, I'd like to see it.

I'm actually keen on doing a low mount single turbo, I think that'd be pretty cool.

-

I'm not sure what you mean "piece by piece", but buy either motor, fit something like a GT3582R and possibly some bigger injectors (to the RB25) and you'll be in your power range.

-

I'm pretty sure that calculator has the wrong rod length for L20A rods, they are the same as L24 rods, apart from the odd ball late L20As that have smaller journals etc.

-

Check the rocker cover gasket and head gasket at the back too, the highest up place you can find oil is probably where it's coming from.

-

Hmm measuring crank rod journal... I/m getting 49.657mm.... Why the hell would this have +.25mm bearings when standard calls for min of 49.961mm and max size of 49.974mm. hmmmm.

49.961 + 49.974 / 2 = 49.9675

49.9675 - 49.657 = 0.3105, that's pretty close to 0.25mm

I wouldn't be relying too much on measuring a journal that rooted.

-

0.25 or 0.025? ACL make both. I'll think you'll find they are in millimetres as well, not imperial.

How long did you "cruise" for while it was knocking?

-

You know that "torque" isn't actually a unit of measurement and the abbreviation TQ as a suffix to a set of numbers means absolutely nothing?

-

If you rotate the hub so the stud is at the 6 o'clock position standard length studs should clear the control arm. I managed to get extra long studs in mine by grinding a small notch (maybe 1 - 2mm) in the control arm where they were just touching.

-

Front turbo or rear turbo?

-

That angle does look terrible, you should be able to grind the weld off then pop the lever arm off and weld it back on, just be careful because on some flapper assemblies you can knock the tube that the flapper runs through into the housing so the flapper and hole won't line up so don't go hitting it too hard. Your bracket looks a little flimsy as well, it seems to move quite a lot when you pop the rod off?

-

Can you organise shipping from New Zealand?

-

What's the throttle body off? That's an aftermarket plenum, correct?

-

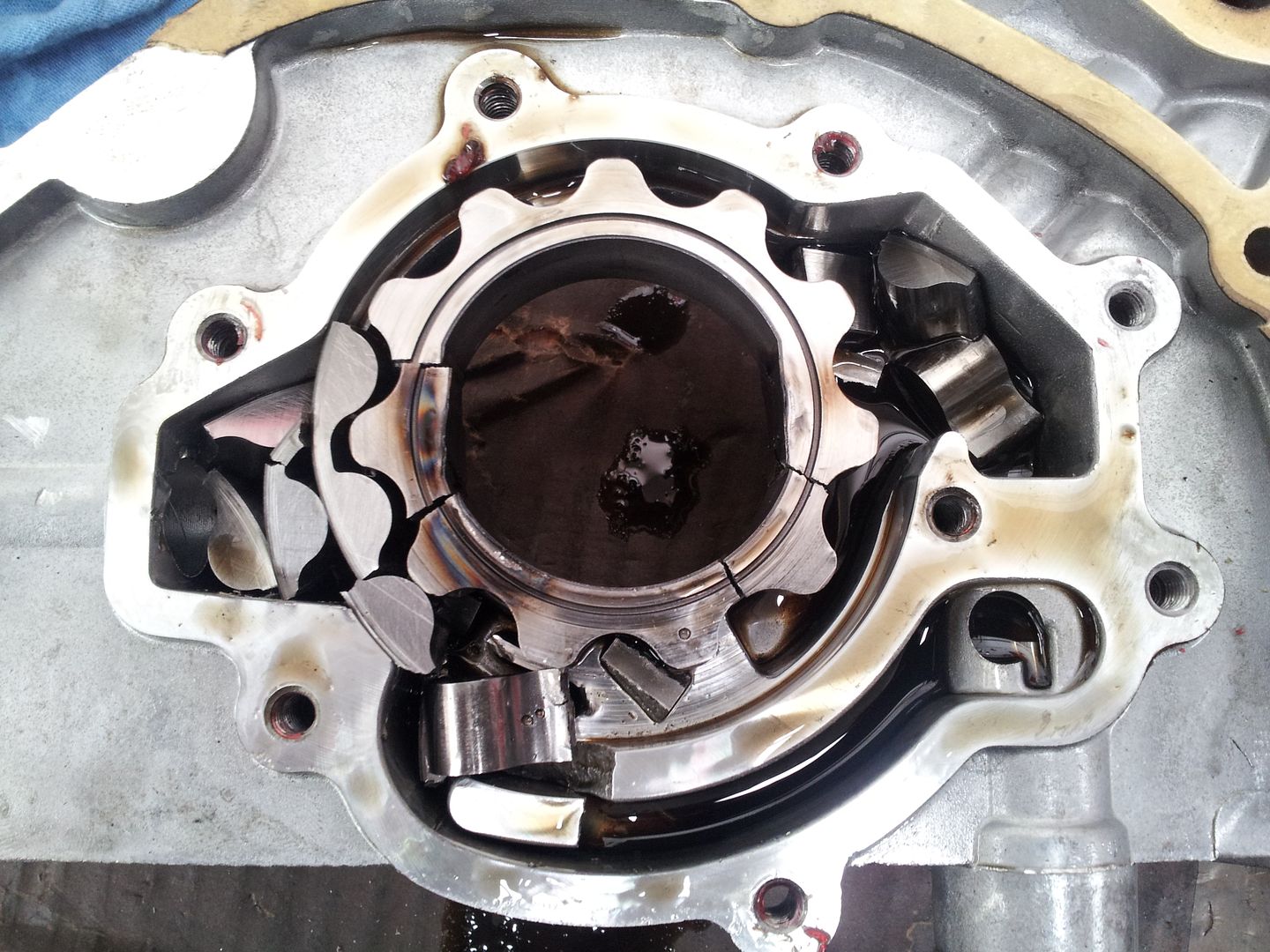

This is what my N1 pump ended up like after 2800Ks at 360rwhp. I've got a Tomei pump now.

-

The N1 pump is different to the stock pump in other ways that just the springs, I don't know who started that rumour but it needs to disappear. The housings are different, the backing plate is different, the gears are bigger in diameter.

-

I ran an RB30 flywheel on an L28 for about 5 years with no problems, that was running it with no shim around the spigot either, just located on the bolts. That was using a late S130 reduction gear starter. Neither the starter or the ring gear showed any signs of damage.

-

This may be a silly question but what ECU are you using?

-

Why would there have to be a better way? It's a completely different motor. I have a feeling the L series splined drive is bigger than the RB one, I'll have a look next time I'm in the garage, I've got an RB CAS in pieces somewhere. I have a feeling the RB CAS will spin the opposite way as well but I don't think that will matter in the chopper wheel is symmetrical.

I'm pretty sure the output signals are the same between the two (if you use a VG30 chopper wheel) so as far as I can see the only reason to use an RB one is because it's smaller? And possibly because L series optical dizzys are getting old.

-

Aren't the insides pretty much the same between the optical Z dizzys and the RB crank angle sensors?

-

The pressure line has a threaded fitting to attach to the pump, the return line has a barb fitting and a hose clamp.

Rear Subframe and Differential mounting

in S130 Series - 280ZX

Posted · Edited by djz

Did you put the rubber isolators back in place? Have a look at this diagram, part number 7.

http://www.xenons130.com/4C05.html