-

Posts

239 -

Joined

-

Last visited

-

Days Won

1

5 Star Rising last won the day on October 8 2019

5 Star Rising had the most liked content!

About 5 Star Rising

- Birthday 05/01/1978

Profile Information

-

Gender

Male

-

Location

Humboldt County Northern CA Coast

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

5 Star Rising's Achievements

Newbie (1/14)

12

Reputation

-

Engine Blow-By. Catch Can hose routing

5 Star Rising replied to 5 Star Rising's topic in S30 Series - 240z, 260z, 280z

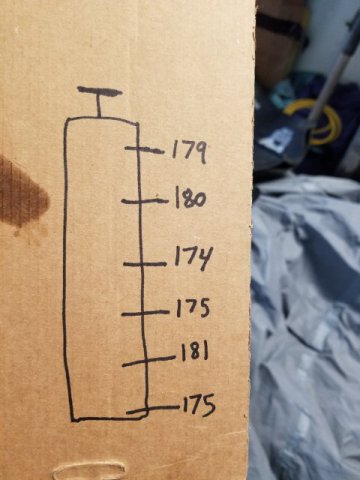

Still going to do a leak down test but compression looks good. Spark plugs from cyls 4 and 5 are pretty different.. -

Engine Blow-By. Catch Can hose routing

5 Star Rising replied to 5 Star Rising's topic in S30 Series - 240z, 260z, 280z

Yep Eureka is 15 minutes away, small world. I wrapped my headers with fiberglass wrap so the heat is not bad in the engine compartment. I have slip on foam air filters over the trumpets but no air box. -

Engine Blow-By. Catch Can hose routing

5 Star Rising replied to 5 Star Rising's topic in S30 Series - 240z, 260z, 280z

Good to know, I have seen what the oil and coolant looks like with blown head gaskets and this doesn't look like it BUT I will do a leak down test anyway because I just bought the damn tester and the car has a miss and at one point I thought I may have had sticking valves as it was fluttering pretty bad but then again I have not tuned these Weber's yet. Just want to make sure the mechanical part of the engine is working correctly before I start tuning these carbs and possibly rejetting if needed. Here on the coast the humidity is high and moisture could be under the valve cover mixing with the combustion gasses maybe creating the white sooty stuff under the oil cap. -

Engine Blow-By. Catch Can hose routing

5 Star Rising replied to 5 Star Rising's topic in S30 Series - 240z, 260z, 280z

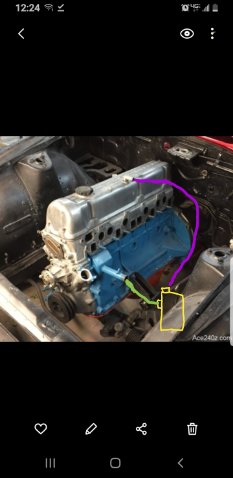

Yeah after seeing how I routed my hoses like a dummy it made since that the pressure would not escape. I hope I didnt blow my head gasket as I found alittle white residue up under the oil filler cap and also way up on the oil dip stick. The oil seems ok and clear and clean and i didnt see any oil in the coolant but you never know. I will do a leak down test on it next week. The reason for the catch can is that with these triple Weber's there really Isn't a place in the cannon manifold to connect the line unless I tap into the brake booster port or drill and tap a new inlet but I dont want to add metal shavings into the intake while it's still on the car, the other reason for adding the can is that this car has a fresh white paint job including the engine bay and I didnt want black soot from breather filters getting all over the place, I think I will plug the bottom engine block port and run the hose from the valve cover into the inlet of the catch can and then add a breather to the outlet of the catch can. This catch can has a brass baffle filter on the inlet side to help catch alot of debris. I will see how it works. Cant believe I routed the hoses like that the first time lol. I unhooked the hose going from the catch can to the block last night and the pressure was released from the block and the blowby went away. I'm going to clean it up better this week. Thanks for the advice.. -

Engine Blow-By. Catch Can hose routing

5 Star Rising posted a topic in S30 Series - 240z, 260z, 280z

Have a early 71 240Z that I have been working on off and on for years trying to get it on the road and there is always something to fix. In this episode we have blow-by blowing my oil dipstick out and spraying oil all over the engine compartment while just idling for 10 minutes.. I have not really ever got this car road worthy enough to say it did or didn't do it before. But I switched to triple Weber's and decided to remove all the PCV stuff and I added a catch can. I had done a compression test not too long ago and everything looked pretty even, but I thought maybe I had a stuck valve because the carbs dont run so well but that maybe just needs a fine tuning after rebuilding and installing them for the first time. As far as the catch can installed, this is how I routed the hoses and after looking at it I dont believe there is anyway to vent anything, it just comes off the valve cover, goes to the can on one side and the other side of the can goes to the lower crankcase pipe. Do you guys recommend a batter way to route the hoses or add a filter maybe? Not my engine in this picture but this is how I routed the can. It may not be right and not venting anywhere lol. Oops.. -

New 280zx Alternator Swap not charging 240Z.

5 Star Rising replied to 5 Star Rising's topic in Ignition and Electrical

Ok so I found the problem. I checked continuity from the main power wire from the alternator and followed it to where the in and out connection is for the Ammeter under the glove box passenger kick panel area. The 2 Spade connections for the Red/White wire and White wire were really corroded and not making a good connection, I cleaned the female and male spade connectors and now I get 13.85 volts at the battery. With just the ignition key on but motor not running you could jiggle the wire connections and here the relay kick on and off due to the bad connection..The only thing that concerns me is this is a 60 amp alternator replacing the 45amp? The spaded wires are warm to the touch when the car is running, alittle more amperage on those wires I guess. looks like they got alittle hot before though with the 45 amp alternator as one of the clear plastic connector sleeves was slightly melted and discolored. I'm going to keep an eye on it. Now to move on to another issue on this damn car. Never been able to get the carbs to run right with SUs and now with Triple Weber's also. While the car was running earlier the oil dip stick shot out and it sounded like I cut the valve stem off a bicycle tire. Haven't dug into this yet but this could be bad.. A stuck valve perhaps? Might post this in another part of the forum if I get stuck diagnosing it. Thanks for the alternator info.. -

New 280zx Alternator Swap not charging 240Z.

5 Star Rising replied to 5 Star Rising's topic in Ignition and Electrical

Yes it has its factory Ammeter in place. How would I test it? Measure resistance? -

Hood won't fit 240Z fresh paint.

5 Star Rising replied to 5 Star Rising's topic in Body Kits & Paint

I was able to carefully straighten the front clip alittle and get everything lined up and put back on. The hood is lined up and opens and shuts. Finally!! Thanks for the advice -

New 280zx Alternator Swap not charging 240Z.

5 Star Rising posted a topic in Ignition and Electrical

I have a early 71 240z that is not charging the battery I checked all the fuses behind the ash tray and they were good (PO added a aftermarket fuse box with spade type fuses).... I took the stock alternator down and it tested bad at the parts store, so I ordered a rebuilt replacement and installed it. It still didnt charge the battery, I swapped 2 other old external voltage regulators that I had on different parts cars and still no charge at battery (guess they could have all been bad). The reman alternator was putting out like 40 volts out of the back of it ,seems like a bit much. Changed plans and returned that first reman alternator and decided to go with the 280ZX alternator upgrade instead. I installed the 280ZX alternator and I also bought the little diode plug adapter from Z Car source and plugged it into my factory harness..I'm getting around 16 volts off the alternator now but it's not charging the battery only getting like 11.9 volts at the battery. Has anyone ran into this issue? What could be going wrong here? Advice would be much appreciated. -

Hood won't fit 240Z fresh paint.

5 Star Rising replied to 5 Star Rising's topic in Body Kits & Paint

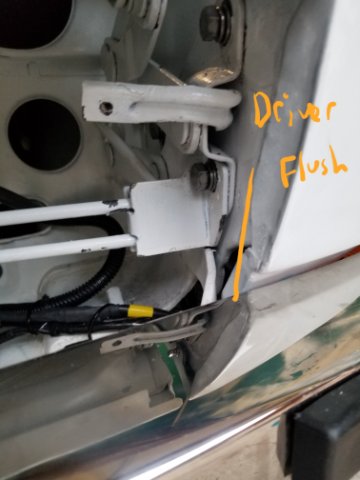

I took another close look. Looks like the front clip ledge that the fender extension goes on is bowed in alittle. It is also the area where the hood hinges bolt to. Looks as if it was hit in the downward position on the front passenger side causing the hood hinge bolts and section to sit 5/8" lower than on the drivers side. I dont believe the car was in a major collision just a light tap in that area. I think I'm going to remove the fender and hood and try to pull that area up a little until I get that bottom hinge bolt to around the same height as on the drivers side from the ground up. Sucks but it has to be even. -

Got the car started a few weeks ago. Turns out it was the wrong distributor and base for my car. The off centered slot on the bottom that fit over the oil pump shaft was completely opposite to another 240z distributor that I got, as soon as I installed the other distributor it fired right up for the first time in decades. Both distributors set to TDC but the slot on the bottom is 180 off.

-

Hood won't fit 240Z fresh paint.

5 Star Rising replied to 5 Star Rising's topic in Body Kits & Paint

I took a break from this car, but I'm back at it and still have the hood issue obviously. I took some measurements from the ground to the first hood hinge bolt on each side and the passenger side of the car sits a whopping 5/8"s lower than the drivers side. It looks like everything is like 5/8 off. The drivers side of the hood sits up high and its hood hinge is bottomed out ontop of the bumper bracket and cant go down any further and that's even after slotting the holes. I could still slot the actual hood holes and that might bring down the hood on the drivers side But I would still have a issue on the passenger side where the hood cant go any further down without it teetering up at the cowl side. It's like the passenger side of the car needs to come up 5/8".. that's around the location where the car was slightly hit. How can this be done with out screwing up the paint? This is bummer. -

Thanks for the heads up. Yeah I'm not sure what distributor this is for. It came from a 73 240z that someone had put a L28 in. It had the stock flat top carbs installed on it so I assumed they used the stock distributor too but you never know. Could be different to fit the L28 set up I'm not sure. Distributors are getting harder to find by these days and if you do they are pretty expensive.

-

I'm going to mess with it later today. I was going to squirt some oil in the cylinders but cant find my little pump oiler can, going to find it later, pull the valve cover and oil every thing up. So the #1 cam lobe being straight up 12 o'clock while it's at TDC is not correct? Thought I read that some where but could be wrong. I had pulled and stabbed the distributor a few times and rolled the motor by hand to make sure it wasn't on the exhaust stroke. Crank pointer at Zero, cyl#1 to top of chamber and rotor pointing at #1 spark plug wire on the cap. The linkage on the round top carbs was all frozen and the they had placed aftermarket throttle springs that were are rusted and broken, the throttle screw on the front carb is missing so I have the linkage clamped together with small vise grips and added a new throttle spring. I honestly spent 15 minutes doing this, definitely not how I will fix any of the problems permanently, just trying to move the car into the backyard for now. But maybe the carbs are really messed up... You would think it would run for 5 seconds atleast when lifting up the carb pistons and spraying starting fluid in the Intake. That's why I was still stuck on the spark issue.

-

So a few months ago I picked up another 240z. This 73 had been sitting in a guys garage for 20 years and I'm trying to start it for the first time. When I bought it, it was missing the distributor, the seller said he had pulled it and gave it to another guy that he had sold his other 240z to. Luckily I have a rusted 73 parts car but I dont know the history of that motor, it has a L28 in it with the 73 flat top carbs, I pulled the distributor from it, dont know if it's good but there is not much to them. I Installed a new set of points, and condensor, set the gap and put the distributor onto my new 73 that I just got. This car has been changed to round top carbs and the guy I bought it from said he drove it 2 miles and parked it in the garage/barn 20 years ago and there it sat. I'm getting spark from the coil and to the ends of the spark plug wires. I dont have fuel in the car yet as I have just been spraying starting fluid in the carbs to see if it will run for 5 seconds like I have done to a bunch of 240zs in the past. but instead I just get a backfire every now and then. It almost feels like the distributor is 180 off but it only goes in one way. I set the car to TDC physically watched #1 piston come to the top using a flash light and looking through the spark plug hole.. I lined up "0" on the crankshaft to point mark. The rotor points to the #1 plug wire on the cap like it should. I think I read somewhere that the cam lobes on #1 need to be facing up when it's in TDC when looking through the oil cap hole. The lobes are not up, they are at like 10 o'clock. Could the timing chain have skipped and it's so far off that it wont fire up? I'm trying to check all the simple stuff first before tearing into the motor. He said he drove it and parked it. I did not mess with the oil pump or oil pump shaft, just dropped in the new distributor. Wonder if these carbs could be so far out or gummed up that it wont even run for 5 seconds. At this point I just want it to run enough so i can drive it out of the driveway and into the back yard on it's own power doesn't have to run perfect. As I will restore the car another time. What can I check or try at this point to get her running?