-

Posts

1872 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by naviathan

-

-

5 second 1/4 mile and 1 second 0-60...

No really, who knows? It's all dependant on how you tune it, how you drive and how you put it to the ground. In other words, it all depends on you.

-

I had this problem when I was doing my Jeep engine swap. At least with the Jeep, the input shaft has to be PERFECTLY aligned with the block. I ended up using two jacks and a strap. One jack under the tranny, one under the backside of the block and a long wratchet strap to wrap around both. The strap gives a point of reference to see how far off your angle is and when you get the spliens lined up the strap can be helpful in pulling the two together.

-

Wouldn't it be easier to just balance the crank by removing material?

-

Even the vette swap has been done. Someone on ZCar.com has it.

-

Attaching fiberglass to any car is difficult to do without it eventually cracking. That is if you're doing a smooth blended look. If you want a bolt on application and aren't worried about lines I would look at connecting with a weather strip between the panels to keep the glas from cracking when you hit a bump or something.

-

I would find something with trailing arm style suspension. My Jag has it and the ride in that car is incredible. Taking corners is so smooth I can leave my coffee cup sitting on the console until the G-Forces grab it. Almost no body roll, great hook up, and the ride is like a cloud.

-

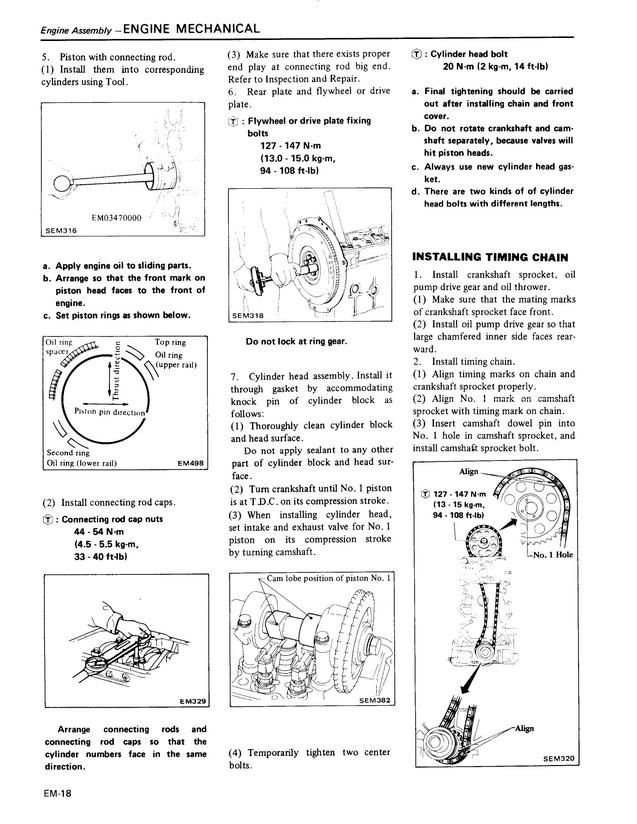

Hope this helps a little more. The image in the lower right should be what you're looking for.

-

Sorry we couldn't get you running when you wanted. I'm looking over the FSM right now. If the cam sprocket isn't lined up properly you could have several problems, the worst of which is bent valves. I wouldn't risk it.

That said, according to the images provided in the FSM there appears to be 3 alignment wholes in the sprocket. The one that should have the alignment dowel inserted in it is the top hole with the three trailing to the left side. If this is aligned and the chain is properly aligned on the crank sprocket the shiny link should be on the upper right side of the cam sprocket which aligns with the timing mark on the outter ring of the cam. Wish I had a pic of the page in the FSM for you. It's really simple to understand when you can see it.

-

The problem there is I can't find any Z's in the junkyards around here. Not to mention these guys think they have gold in their yards. Most parts are $10 shy of a new one. Not even worth pulling it. They make their money on scrap metal here.

-

Oh no, the 81ZX is my daily driver. I was planning to rebuild a 5 speed for the 77 project later using the tripple rate springs for longevity. I just don't want to tear into this thing and find I could have just picked up another tranny for the time being cheaper than the parts.

-

Sorry, guess I should have mentioned that. It's the stock tranny out of an 81ZX. I think they call it a "B" box.

-

Had some problems with my tranny not going into gear when it was moving. If I stop it would shift into whatever gear, but as soon as I started moving it wouldn't shift at all. I pulled the tranny yesterday, put it in neutral and tried to turn the input shaft and it wouldn't budge. Any ideas on whether or not it's worth rebuilding?

-

Ewwww...Bosch Platinum Four....

-

Yeah, so are the ones from TEP. Here's the page I picked mine up from. Race TEP I haven't had a chance to go through it, but I bought it all. The TEC3, throttle bodies, linkage, fuel rail, injectors, pump, intake..etc...

-

Is that the webber tripple throttle body intake? Looks just like the one I bought from Top End Performance.

-

Sounds like the alt is going out.

-

Very similar to the MSA stage III grind. It will have a rough idle, but should have a nice pull from 3k-6500. Your vacuum at idle will be less because of valve overlap.

-

If you're using a Haynes manual, you need to ditch the book. They are wrong on many aspects of the Z engine.

-

Crank up the boost, MS&S, and a mild cam should get you there.

-

Figure up the angle you need and get some of those ricer mandrel bent tubing pieces. Any local performance shop should have the mandrel bent angles and some rubber connectors used for cold air intakes. They may also have a piece to fit that will have a bung already in it. If not it can be added by drilling a hole for a proper sized pipe fitting and using a securing nut and plastic/rubber washers on the inside and outside of the fitting. I've thought about this a lot and although i haven't done it myself, I know it will work.

-

Haha...Edumacation Rulz!

-

Sounds like good numbers. Figure out where the oil is going, but with that compression I doubt it's the rings. Might be valve seals or a leaky gasket.

-

Usually what your gauge reads isn't very accurate. The sending units tend to go bad and start sending low/fluctuating signals. My 81ZX sits at50/60 at idle and jumps as high as 80/90 when moving.

-

That is really nice but I want to see something like that for us turbo Z guys. That is really a great looking piece though.

So when are you going to make the turbo manifold for us boosted guys' date=' well, hmmmm, huh, huh, huh?[/quote']Top End Performance has what you're looking for.

Douche bag part deux....

in Non Tech Board

Posted

Sounds to me like this guy needs a good lesson in what's what under the hood. I say pull the piston and rod with the bad bearing out and beat him till he's bloody with it. He'll never forget what rod bearing pieces look like again.